Professional Documents

Culture Documents

6250 Galbon S-HB

6250 Galbon S-HB

Uploaded by

ChristinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6250 Galbon S-HB

6250 Galbon S-HB

Uploaded by

ChristinaCopyright:

Available Formats

No.

6250

GALBON S-HB Dec. ‘96

(G/S-HB) CPI

GALBON S-HB is a high-build type inorganic zinc paint based on a combination of ethyl silicate and

selected zinc powder. It has the following advantages:

1. Excellent protective property against corrosion.

2. Excellent application workability (self-curing type).

3. Excellent resistance to seawater and fresh water, oil and petroleum products.

4. Excellent resistance to heating up to 400°C.

5. Fast dry.

6. Excellent compatibility with organic subsequent coats.

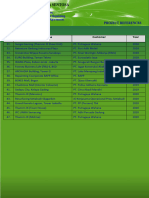

TECHNICAL DATA

Type : Inorganic zinc paint, alcohol soluble, self-curing type, high-build type

Recommended Use : As a protective coat for inside of oil tanks, petroleum product (solvent)

tanks, and ballast tanks. As a primer for plants, bridges, pipes, offshore,

steel structures

Mixing Ratio : Base : Powder = 25 : 75 (by weight)

Colour : Grey

Flash Point : Base : 14.5°C , Powder : -

Solids by Volume : 45.2 %

Coverage(Theoretical) : 0.083 – 0.125 L/m² ; 220 – 330 gr/m²

Wet Film Thickness : 3.3 – 5.0 mils ; 83 – 125 µ

Dry Film Thickness : 2.0 – 3.0 mils ; 50 – 75 µ

Drying Time : Temperature 5°C 10°C 20°C 30°C

(at D.F.T. 75 µ) Surface Dry 40 min. 30 min. 20 min. 10 min.

Hard Dry 6 hrs. 5 hrs. 4 hrs. 3 hrs.

Painting Interval : Minimum 72 hrs. 32 hrs. 24 hrs. 18 hrs.

(at D.F.T. 75 µ) Maximum - - - -

Pot Life : 14 hrs. 10 hrs. 7 hrs. 5 hrs.

Thinner : GALBON THINNER

Method of Application : Airless Spray, Brush (touching-up only)

Conditions of Application : Temperature Minimum 0 – 50°C

Humidity Maximum 50 – 95% R.H.

For Airless Spray ; (Pump ratio 1:23 or 1:28)

Tip No. GRACO 419, 519

Paint output pressure 100 kgf/cm²

Viscosity 10 - 12 sec.(Ford Cup No.4)

Thinning 0 – 5% by volume

Surface Preparation : SSPC – SP 10 or ISO Sa 2.5

Preferable Preceding Coats : GALBON S, GALBON SP, WELBOND

Preferable Subsequent Coats : Any one of our product and/or the equivalent, e.g. Chlorinated rubber paint,

Epoxy paint, Tar-epoxy paint

Packaging : Two pack product

Note:

Dry film thickness should be controlled less than 150 microns per one coat. In case of over coating with organic paint,

recommended dry film thickness of GALBON S-HB is 65 microns.

The Information given in this sheet is effective at the date shown above and subject to revision from time to time without notice

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2102 Lzi Primer NPDocument1 page2102 Lzi Primer NPChristinaNo ratings yet

- 01.PFP - 211 (Rev)Document2 pages01.PFP - 211 (Rev)ChristinaNo ratings yet

- 5871 Tfa 10Document1 page5871 Tfa 10ChristinaNo ratings yet

- 2012 Chugoku Af TDocument1 page2012 Chugoku Af TChristinaNo ratings yet

- CMP - ThermoshadanDocument1 pageCMP - ThermoshadanChristinaNo ratings yet

- Clean Mild UrethaneDocument8 pagesClean Mild UrethaneChristinaNo ratings yet

- 1046 Welbond HDocument1 page1046 Welbond HChristinaNo ratings yet

- Ceratight Si WDocument8 pagesCeratight Si WChristinaNo ratings yet

- 19092023-Map RBADocument2 pages19092023-Map RBAChristinaNo ratings yet

- 12 MJBSDocument1 page12 MJBSChristinaNo ratings yet

- 9 MJBSDocument1 page9 MJBSChristinaNo ratings yet

- 10 MJBSDocument1 page10 MJBSChristinaNo ratings yet

- 14092023-Map RBADocument2 pages14092023-Map RBAChristinaNo ratings yet

- Acristar #200Document1 pageAcristar #200ChristinaNo ratings yet

- 11 MJBSDocument1 page11 MJBSChristinaNo ratings yet

- BIOFINEDocument1 pageBIOFINEChristinaNo ratings yet

- 7 MJBSDocument1 page7 MJBSChristinaNo ratings yet

- Acristar #400Document1 pageAcristar #400ChristinaNo ratings yet

- 1 12MJBSDocument12 pages1 12MJBSChristinaNo ratings yet

- Arkifloor PUDocument2 pagesArkifloor PUChristinaNo ratings yet

- Acristar #150Document1 pageAcristar #150ChristinaNo ratings yet

- Acristar #300Document1 pageAcristar #300ChristinaNo ratings yet

- Lilicatight 1000 PrimerDocument1 pageLilicatight 1000 PrimerChristinaNo ratings yet

- Arkifloor EHGDocument2 pagesArkifloor EHGChristinaNo ratings yet

- Acristar #100Document1 pageAcristar #100ChristinaNo ratings yet

- Grani QueenDocument8 pagesGrani QueenChristinaNo ratings yet

- 02032023-Text DescriptionDocument1 page02032023-Text DescriptionChristinaNo ratings yet