Professional Documents

Culture Documents

Technical Sheet Trolley TP TG 202302

Technical Sheet Trolley TP TG 202302

Uploaded by

VVCopyright:

Available Formats

You might also like

- MBA Project On CRMDocument40 pagesMBA Project On CRMsrikanthmogilla1250% (2)

- Audits of Core Banking SolutionsDocument15 pagesAudits of Core Banking SolutionskaustubhupmanyuNo ratings yet

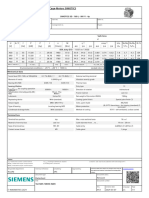

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1501-3AA23-4AB4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1501-3AA23-4AB4-ZAtiqah Putri Sari100% (1)

- Architectural SpecificationsDocument55 pagesArchitectural SpecificationsGiovani Carl Dauz Pascua100% (5)

- Live Project Test Plan SoftwareTestingHelpDocument6 pagesLive Project Test Plan SoftwareTestingHelpDat Tran ThanhNo ratings yet

- Combi Hoists - TigerDocument4 pagesCombi Hoists - TigerYADAGIRI REDDYNo ratings yet

- 36 Catenary Tools 03 2006 GeismarDocument104 pages36 Catenary Tools 03 2006 Geismaringjasilva T100% (1)

- Breaker Bretec BrochureDocument8 pagesBreaker Bretec BrochureSonny SaputraNo ratings yet

- Specifications: Standard & Heavy-DutyDocument2 pagesSpecifications: Standard & Heavy-DutyabcNo ratings yet

- 1LE1503 3AB53 4AB4 Datasheet enDocument1 page1LE1503 3AB53 4AB4 Datasheet enilker subaşıNo ratings yet

- B 11285 PHSS 00Document39 pagesB 11285 PHSS 00souhaibnguidi2No ratings yet

- XHD Durt Tracker - BastidorDocument4 pagesXHD Durt Tracker - BastidorCarlos BolvaranNo ratings yet

- Stepping Motors 3 PhasesDocument12 pagesStepping Motors 3 PhasesTamas RaduNo ratings yet

- Trak-It C3Document8 pagesTrak-It C3SerxioNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaSamir SabicNo ratings yet

- MDS For Filler Weigher Feeder (81-WQ-317)Document2 pagesMDS For Filler Weigher Feeder (81-WQ-317)WawanNo ratings yet

- DryLin T TS-01Document1 pageDryLin T TS-01Fábio LeiteNo ratings yet

- Drift Eliminators: Product ProfileDocument2 pagesDrift Eliminators: Product ProfileYohanes Joko TriyantoNo ratings yet

- MDS For ZA Weigher Feeder (81-WQ-316)Document2 pagesMDS For ZA Weigher Feeder (81-WQ-316)WawanNo ratings yet

- Montabert Silver Clip RangeDocument6 pagesMontabert Silver Clip RangeGeorge Kwamina AnamanNo ratings yet

- Trolley User Manual: Williamhackett - Co.ukDocument16 pagesTrolley User Manual: Williamhackett - Co.ukSamrat KumarNo ratings yet

- DENSO Robotics Datasheet HM-G SeriesDocument2 pagesDENSO Robotics Datasheet HM-G SeriesMarius Constantin100% (1)

- CS-510 Service DataDocument5 pagesCS-510 Service DatarexNo ratings yet

- Ero Tv-Guides UkDocument4 pagesEro Tv-Guides UkrcaletaNo ratings yet

- Atlas 2:1-Rph: Planning DataDocument12 pagesAtlas 2:1-Rph: Planning DataAdarsh ManoharanNo ratings yet

- XTEInterface ServletDocument2 pagesXTEInterface ServletRodni EmslieNo ratings yet

- 1LE1003 0DA21 7AB4 Datasheet enDocument1 page1LE1003 0DA21 7AB4 Datasheet enkamal_arbabNo ratings yet

- Tiavs UdDocument2 pagesTiavs UdgeigerNo ratings yet

- Woo Chang Coupling - 112438 - Paqndr oYtYHS8Document14 pagesWoo Chang Coupling - 112438 - Paqndr oYtYHS8Eng-anwer kadhimNo ratings yet

- Manual Hoists & Winches: WWW - Morriscranes.co - UkDocument12 pagesManual Hoists & Winches: WWW - Morriscranes.co - UkCedric Chaton100% (1)

- Latest Toshiba ScaraDocument20 pagesLatest Toshiba ScarareflextechNo ratings yet

- Rosroca Ol Mini En.Document2 pagesRosroca Ol Mini En.Branislav MandicNo ratings yet

- 1LE1003 1DA43 4AB4 Datasheet enDocument1 page1LE1003 1DA43 4AB4 Datasheet enElio TavaresNo ratings yet

- Gearless Machines For Elevators: Lift Range 2014Document8 pagesGearless Machines For Elevators: Lift Range 2014Khaled ZakariaNo ratings yet

- Technical Data Titan 525: Engine (Diesel)Document2 pagesTechnical Data Titan 525: Engine (Diesel)dmh cargoNo ratings yet

- Cable Carrier CatalougeDocument146 pagesCable Carrier Catalougebachir diengNo ratings yet

- TwinTrak 4pp Jan17 WebDocument4 pagesTwinTrak 4pp Jan17 WebEldar AtakishyyevNo ratings yet

- 0361TQ BS EN 60332-1-2 BS 638: Orange Welding CableDocument3 pages0361TQ BS EN 60332-1-2 BS 638: Orange Welding CableFacundo ArlistanNo ratings yet

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocument2 pages1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNo ratings yet

- CSRA Series PDFDocument15 pagesCSRA Series PDFDamian Huitzil CedilloNo ratings yet

- Hitachi Sumitomo Hydraulic Crawler Crane SCX900Document6 pagesHitachi Sumitomo Hydraulic Crawler Crane SCX900Nina JuliatiNo ratings yet

- Control and Signal CableDocument3 pagesControl and Signal CableLuis Carlos ValdezNo ratings yet

- KGH Series Bellows CouplingDocument1 pageKGH Series Bellows CouplingServo2GoNo ratings yet

- ATLAS Mini PD ENG v1 3Document9 pagesATLAS Mini PD ENG v1 3alper sungurNo ratings yet

- ThamesSideIndia T34Document4 pagesThamesSideIndia T34Bulk WeighingNo ratings yet

- Ats 639036700 001Document5 pagesAts 639036700 001yonigoNo ratings yet

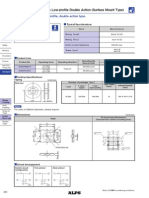

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZFredericks ACNo ratings yet

- 1le5584 3aa03 4ab4Document2 pages1le5584 3aa03 4ab4Dharmesh ChanawalaNo ratings yet

- Rotary Type Torque Sensor Model Operating InstructionDocument8 pagesRotary Type Torque Sensor Model Operating InstructionEster MujicaNo ratings yet

- 1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enDocument2 pages1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enranjithNo ratings yet

- 1LE1604 1DB43 4GB4 Datasheet enDocument1 page1LE1604 1DB43 4GB4 Datasheet ennarminaNo ratings yet

- v-sd100d-sd10 Manual BookDocument4 pagesv-sd100d-sd10 Manual BookRusmiyanto YantoNo ratings yet

- 0.6mm Low-Profile, Double Action TypeDocument3 pages0.6mm Low-Profile, Double Action TypeshyhuNo ratings yet

- Liquid - Datasheet MTB en 0707Document4 pagesLiquid - Datasheet MTB en 0707Surya TanjayaNo ratings yet

- Fy 19Document11 pagesFy 19angattiNo ratings yet

- Spech PDFDocument3 pagesSpech PDFmahmudiNo ratings yet

- TMCX Connectors For Jacketed Metal Clad Cable: Explosionproof, Dust-IgnitionproofDocument2 pagesTMCX Connectors For Jacketed Metal Clad Cable: Explosionproof, Dust-IgnitionproofFernando TovarNo ratings yet

- Basics About Rails: by (N.R. Kale) Axen/IricenDocument45 pagesBasics About Rails: by (N.R. Kale) Axen/IricenshujaNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1SDLE9YPQ3ET6FYDocument1 pageETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1SDLE9YPQ3ET6FYJorgeMendezNo ratings yet

- Quick Start Guide: Compact ExcavatorsDocument28 pagesQuick Start Guide: Compact ExcavatorsJeff SifNo ratings yet

- Breakers: Make An ImpactDocument10 pagesBreakers: Make An ImpactVICTOR BEMENGUENo ratings yet

- Pulse Transformers/SMD Type: Features Shapes and DimensionsDocument3 pagesPulse Transformers/SMD Type: Features Shapes and DimensionsRajan RajpootNo ratings yet

- VL16-VL20-VL25-XC3 - Spare PartsDocument21 pagesVL16-VL20-VL25-XC3 - Spare PartsVVNo ratings yet

- ST - Operating InstructionsDocument56 pagesST - Operating InstructionsVVNo ratings yet

- Bridgeport Series I - BrochureDocument2 pagesBridgeport Series I - BrochureVVNo ratings yet

- Bridgeport Mobile BaseDocument6 pagesBridgeport Mobile BaseVVNo ratings yet

- IBM System x3400 M3 - Tips0808Document45 pagesIBM System x3400 M3 - Tips0808Ivan LemosNo ratings yet

- Applied - Research On MRFDocument23 pagesApplied - Research On MRFJankiNo ratings yet

- BSIA - Access ControlDocument16 pagesBSIA - Access ControlSayed HashemNo ratings yet

- Methacrylic AcidDocument19 pagesMethacrylic AcidEr Bali PandhareNo ratings yet

- Fundamentals of Information Systems Chapter 1Document66 pagesFundamentals of Information Systems Chapter 1Grant Net Carlo PunzalanNo ratings yet

- DFC3043 Pbe2 Dec17Document1 pageDFC3043 Pbe2 Dec17legasi clothingNo ratings yet

- Ajs 1951 AJS Instuction and Maintenace 16M 16MS 16MC 16MCS 18 18S 18C 18CSDocument100 pagesAjs 1951 AJS Instuction and Maintenace 16M 16MS 16MC 16MCS 18 18S 18C 18CSRoyal ENo ratings yet

- Ey0411 Kul 30jun15 19752Document11 pagesEy0411 Kul 30jun15 19752Spencer RobeniolNo ratings yet

- Air TransportsDocument16 pagesAir TransportsNataliaNo ratings yet

- Chapter 14mDocument24 pagesChapter 14mamirNo ratings yet

- Naoman Sheikh's CVDocument2 pagesNaoman Sheikh's CVNaoman SheikhNo ratings yet

- Quick Start VM Download With CDH 5.3 PDFDocument2 pagesQuick Start VM Download With CDH 5.3 PDFphungocvoNo ratings yet

- Extrusion Machine and LineDocument12 pagesExtrusion Machine and Linesamurai7_77No ratings yet

- Ge Industrial Aeroderivative Gas TurbinesDocument2 pagesGe Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZ0% (1)

- Shop DrawingsDocument3 pagesShop DrawingsTommie FanNo ratings yet

- SI and MFTDocument354 pagesSI and MFTAbhishek DhawanNo ratings yet

- Rockfall BarrierDocument12 pagesRockfall BarrierĐorđe RadisavljevićNo ratings yet

- Graphical Solution of Linear Programming ModelsDocument44 pagesGraphical Solution of Linear Programming ModelsNoor AsikinNo ratings yet

- LoftingDocument206 pagesLoftingeventnowNo ratings yet

- Distributed Electronic WarfareDocument2 pagesDistributed Electronic Warfarebring it onNo ratings yet

- Pages From API ST 617, Axial and Centrifugal Compressors and Expander-CompressorsDocument9 pagesPages From API ST 617, Axial and Centrifugal Compressors and Expander-CompressorsAhmed HassanNo ratings yet

- MIG 41 - World's Fastest FighterDocument13 pagesMIG 41 - World's Fastest FighterhindujudaicNo ratings yet

- Resysta Wood Decking Noa 17111416Document9 pagesResysta Wood Decking Noa 17111416Alaym AguilarNo ratings yet

- Hurst Air ShoreDocument40 pagesHurst Air ShoreFernando GonzálezNo ratings yet

- 2012 ITS ITSM Maturity AssessmentDocument25 pages2012 ITS ITSM Maturity AssessmentWarnher100% (4)

- This Study Resource Was: Process Technology Should Reflect Volume and VarietyDocument2 pagesThis Study Resource Was: Process Technology Should Reflect Volume and VarietyPauline LagtoNo ratings yet

Technical Sheet Trolley TP TG 202302

Technical Sheet Trolley TP TG 202302

Uploaded by

VVOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Sheet Trolley TP TG 202302

Technical Sheet Trolley TP TG 202302

Uploaded by

VVCopyright:

Available Formats

HOISTING

www.tigerlifting.com

Home of the Tiger hoisting, clamping, winching and height safety ranges

Tiger Trolley

Model No. TG/TP

Main Features 20t Geared Trolley

• Plain Trolley Range from 0.5t to 10.0t 1t Geared Trolley with optional

beam locking device

• Geared Trolley Range from 0.5t to 35.0t

• The anti-drop plates design ensures extra safety, and prevents damage to the wheels when contacting

end rail stoppers

• Tiger trolley wheels are specially designed with a convex profile eliminating potential point loading

• The wheels run on sealed bearings for smoother rolling with less effort and maintenance

• Twin bar or single bar trolleys available

• Geared type available (with hand chain length to suit your requirements)

• Extended beam width available

• Corrosion or Spark Resistant versions available If you need a wider beam range

• Operating temperature of -40°C to +80°C (temperature range of -60°C or have specific headroom

to +80°C available as an option) requirements please contact us

• Optional beam locking device for bespoke solutions

• The 5:1 factor of safety allows for use with manual or powered hoists

These units meet and exceed all the requirements within BS EN 13157: 2004+A1:2009 and AS1418.2.

Certification:

Each unit comes fully certified with a test certificate or an EC Declaration of Conformity stating compliance with

the essential health and safety requirements of the Machinery Directive 2006/42/EC.

Corrosion Resistant Trolleys

Critical components, including the hand chain and the pinion gear for geared trolleys, are protected by our unique

corrosion protection finish giving unprecedented long-term reliability. Stainless steel fittings are used throughout

the trolley. These ensure the initial capital outlay of purchasing a Tiger corrosion resistant trolley is protected by

allowing the statutory inspections and re-certifications to be easier and also help with the overall aesthetics of the

trolley being maintained in an “as new” condition. Our corrosion resistant trolleys are finished in our high quality

powder coat paint offering excellent additional corrosion protection and a high degree of impact protection.

Spark Resistant Trolleys

In many areas of industry, plants are operated with potentially explosive

atmospheres. Due to the very high risk to personal and other assets, extremely strict

guidelines and technical requirements are in place in explosive zones. Tiger Spark

Resistant products are manufactured in accordance with ATEX Directive 2014/34/EU

and the Machinery Directive 2006/42/EC. Our products are lightweight and durable

with a proven track record.

Smaller minimum curve ratios may

be available – contact us for details

Our innovation, your safety

02 February 2023 Page 1 of 4

HOISTING

www.tigerlifting.com

Home of the Tiger hoisting, clamping, winching and height safety ranges

Atex marking: Ex II 2 GD c IIC T4 IIIC T135°C. Suitable for gas and dust hazardous areas: Zone 1 & 2 (gas) and

Zone 21 & 22 (dust).

• Plain or geared trolleys available

• Solid bronze trolley wheels

• Rubber buffers for trolleys

• Copper plated hand wheel (geared trolley) and hanging plate

• Special corrosion protected body

• Combination block and trolley units available

Optional

• Beam locking device

Technical Data - Plain Trolleys

D - Track width # Dimensions (mm) Min.

Net

Product Capacity curve

Weight

Code (tonne) Range 1 Range 2 radius

A A+ B C E F G H J K (kg)

(mm) (mm) (m)

TPS-0050 0.5 62-128 62-203 195 235 106 106 98 20 64 10 24 30 0.8 5.0

TPS-0100 1.0 62-128 62-203 213 253 113 113 106 20 71 10 27 34 1.0 7.5

Single Bar TPS-010W 1.0 106-305 N/A 236 284 210 210 132 25 80 13 38 45 1.3 TBA

Trolleys TPS-0200 2.0 88-154 88-230 236 284 136 136 132 25 80 13 38 45 1.3 12.0

TPS-0300 3.0 87-153 87-230 275 323 146 146 150 25 97 13 42 53 1.5 19.5

TPS-0500 5.0 106-194 106-305 323 371 169 169 174 30 117 16 46 59 1.5 30.5

TPT-0300 3.0 87-153 87-230 320 368 142 142 82 16 110 1.5 22.0

Twin Bar TPT-0500 5.0 106-194 106-305 352 400 167 166 91 24 131 1.5 35.5

Trolleys* TPT-1000† 10.0 125-320 N/A 346 394 237 236 210 40 117 1.5 68.0

TPT-1500† 15.0 150-320 N/A 461 509 271 271 248 42ǂ 182 2.7 144.0

Technical Data - with optional locking device

D - Track width # Dimensions (mm) Min.

Net

Product Capacity curve

Weight

Code (tonne) Range 1 Range 2 radius

A A+ B C E F G H J K (kg)

(mm) (mm) (m)

TPS-0050 0.5 95-128 95-203 195 235 106 106 98 20 64 10 24 30 0.8 5.0

TPS-0100 1.0 100-128 100-203 213 253 113 113 106 20 71 10 27 34 1.0 7.5

Single Bar TPS-010W 1.0 106-305 N/A 236 284 210 210 132 25 80 13 38 45 1.3 TBA

Trolleys TPS-0200 2.0 110-154 110-230 236 284 136 136 132 25 80 13 38 45 1.3 12.0

TPS-0300 3.0 90-153 90-230 275 323 146 146 150 25 97 13 42 53 1.5 19.5

TPS-0500 5.0 106-194 106-305 323 371 169 169 174 30 117 16 46 59 1.5 30.5

Twin Bar TPT-1000† 10.0 180-320 N/A 346 394 237 236 210 40 117 1.5 68.0

Trolleys* TPT-1500† 15.0 150-320 N/A 461 509 271 271 248 42ǂ 182 2.7 144.0

Notes:

3t twin bar and 5t twin bar options are not available with optional locking device

A+ is the width with optional bumpers

B and C are minimum widths for range 1

Trolleys with locking devices will have different beam width ranges – please contact us for details.

H is the thickness of the anchor point, J is the width of the anchor point opening and K is the height of the anchor point opening.

* 0.5t-2t twin bar available as special orders – minimum order 100 each size – please contact us for details.

† We are currently changing the design of our 10t and 15t trolleys. The dimensions shown are for the new type. Please contact us for

details of which types are available.

ǂ A beam flange thickness up to 50mm can be accommodated if required – please ask for more information.

# Please contact us for track widths outside of these ranges

Our innovation, your safety

02 February 2023 Page 2 of 4

HOISTING

www.tigerlifting.com

Home of the Tiger hoisting, clamping, winching and height safety ranges

Single Bar Twin Bar

Technical Data - Geared Trolleys

D - Track width # Dimensions (mm) Min.

Net

Product Capacity curve

Weight

Code (tonne) Range 1 Range 2 radius

A A+ B C E F G H J K (kg)

(mm) (mm) (m)

TGS-0050 0.5 62-128 62-203 195 235 180 106 98 20 64 10 24 30 0.8 9.0

TGS-0100 1.0 62-128 62-203 213 253 180 113 106 20 71 10 28 34 1.0 11.0

Single Bar TGS-010W 1.0 106-305 N/A 236 284 269 210 132 25 80 12 38 45 1.3 TBA

Trolleys TGS-0200 2.0 88-154 88-230 236 284 193 136 132 25 80 12 38 45 1.3 16.5

TGS-0300 3.0 87-153 87-230 275 323 198 146 150 25 97 13 42 52 1.5 24.5

TGS-0500 5.0 106-194 106-305 323 371 216 169 174 30 117 16 46 60 1.5 35.5

TGT-0300 3.0 87-153 87-230 320 368 194 142 82 16 110 1.5 23.5

TGT-0500 5.0 106-194 106-305 352 400 216 166 91 24 131 1.5 40.0

TGT-1000† 10.0 125-320 N/A 346 394 282 243 210 40 117 1.5 78.0

TGT-1500† 15.0 150-320 N/A 461 509 338 271 248 42ǂ 182 2.7 161.0

Twin Bar

Trolleys* TGT-2000† 20.0 125-320 N/A 706 754 282 263 243 40ǂ 117 30 85 95 6.0 160.0

TGT-2500† 25.0 125-320 N/A 706 754 282 263 243 40ǂ 117 35 100 115 6.0 170.0

TGT-3000† 30.0 150-320 N/A 961 1009 335 263 274 42ǂ 182 35 100 115 6.0 337.0

TGT-3500† 35.0 150-320 N/A 961 1009 335 280 274 42ǂ 182 38 100 115 6.0 341.0

Technical Data – with optional locking device

D - Track width # Dimensions (mm) Min.

Net

Product Capacity curve

Weight

Code (tonne) Range 1 Range 2 radius

A A+ B C E F G H J K (kg)

(mm) (mm) (m)

TGS-0050 0.5 95-128 95-203 195 235 180 106 98 20 64 10 24 30 0.8 9.0

TGS-0100 1.0 100-128 100-203 213 253 180 113 106 20 71 10 28 34 1.0 11.0

Single Bar TGS-010W 1.0 106-305 N/A 236 284 269 210 132 25 80 12 38 45 1.3 TBA

Trolleys TGS-0200 2.0 110-154 110-230 236 284 193 136 132 25 80 12 38 45 1.3 16.5

TGS-0300 3.0 90-153 90-230 275 323 198 146 150 25 97 13 42 52 1.5 24.5

TGS-0500 5.0 106-194 106-305 323 371 216 169 174 30 117 16 46 60 1.5 35.5

TGT-1000† 10.0 180-320 N/A 346 394 282 243 210 40 117 1.5 78.0

Twin Bar TGT-1500† 15.0 150-320 N/A 461 509 338 271 248 42ǂ 182 2.7 161.0

Trolleys* TGT-2000† 20.0 190-320 N/A 706 754 282 263 243 40ǂ 117 30 85 95 6.0 160.0

TGT-3000† 30.0 155-320 N/A 961 1009 335 263 274 42ǂ 182 35 100 115 6.0 337.0

Notes:

3t twin bar and 5t twin bar options are not available with optional locking device

Standard geared trolley hand chain length – 2.5m. We can change the length to suit your requirements.

A+ is the width with optional bumpers

Our innovation, your safety

02 February 2023 Page 3 of 4

HOISTING

www.tigerlifting.com

Home of the Tiger hoisting, clamping, winching and height safety ranges

B and C are minimum widths for range 1

Trolleys with locking devices will have different beam width ranges – please contact us for details.

H is the thickness of the anchor point, J is the width of the anchor point opening and K is the height of the anchor point opening.

* 0.5t-2t twin bar available as special orders – minimum order 100 each size – please contact us for details.

† We are currently changing the design of our 10t plus trolleys. The dimensions shown are for the new type. Please contact us for

details of which types are available.

ǂ A beam flange thickness up to 50mm can be accommodated if required – please ask for more information.

# Please contact us for track widths outside of these ranges

Single Bar Twin Bar 3.0t & 15.0t

Twin Bar Trolley 20.0t – 35.0t

Due to our policy of continual product development, dimensions, weights and specifications may change without prior notice.

Please check with your Tiger sales team when ordering.

Bespoke designs available on request – contact info@tigerlifting.com for more information.

Our innovation, your safety

02 February 2023 Page 4 of 4

You might also like

- MBA Project On CRMDocument40 pagesMBA Project On CRMsrikanthmogilla1250% (2)

- Audits of Core Banking SolutionsDocument15 pagesAudits of Core Banking SolutionskaustubhupmanyuNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1501-3AA23-4AB4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1501-3AA23-4AB4-ZAtiqah Putri Sari100% (1)

- Architectural SpecificationsDocument55 pagesArchitectural SpecificationsGiovani Carl Dauz Pascua100% (5)

- Live Project Test Plan SoftwareTestingHelpDocument6 pagesLive Project Test Plan SoftwareTestingHelpDat Tran ThanhNo ratings yet

- Combi Hoists - TigerDocument4 pagesCombi Hoists - TigerYADAGIRI REDDYNo ratings yet

- 36 Catenary Tools 03 2006 GeismarDocument104 pages36 Catenary Tools 03 2006 Geismaringjasilva T100% (1)

- Breaker Bretec BrochureDocument8 pagesBreaker Bretec BrochureSonny SaputraNo ratings yet

- Specifications: Standard & Heavy-DutyDocument2 pagesSpecifications: Standard & Heavy-DutyabcNo ratings yet

- 1LE1503 3AB53 4AB4 Datasheet enDocument1 page1LE1503 3AB53 4AB4 Datasheet enilker subaşıNo ratings yet

- B 11285 PHSS 00Document39 pagesB 11285 PHSS 00souhaibnguidi2No ratings yet

- XHD Durt Tracker - BastidorDocument4 pagesXHD Durt Tracker - BastidorCarlos BolvaranNo ratings yet

- Stepping Motors 3 PhasesDocument12 pagesStepping Motors 3 PhasesTamas RaduNo ratings yet

- Trak-It C3Document8 pagesTrak-It C3SerxioNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaSamir SabicNo ratings yet

- MDS For Filler Weigher Feeder (81-WQ-317)Document2 pagesMDS For Filler Weigher Feeder (81-WQ-317)WawanNo ratings yet

- DryLin T TS-01Document1 pageDryLin T TS-01Fábio LeiteNo ratings yet

- Drift Eliminators: Product ProfileDocument2 pagesDrift Eliminators: Product ProfileYohanes Joko TriyantoNo ratings yet

- MDS For ZA Weigher Feeder (81-WQ-316)Document2 pagesMDS For ZA Weigher Feeder (81-WQ-316)WawanNo ratings yet

- Montabert Silver Clip RangeDocument6 pagesMontabert Silver Clip RangeGeorge Kwamina AnamanNo ratings yet

- Trolley User Manual: Williamhackett - Co.ukDocument16 pagesTrolley User Manual: Williamhackett - Co.ukSamrat KumarNo ratings yet

- DENSO Robotics Datasheet HM-G SeriesDocument2 pagesDENSO Robotics Datasheet HM-G SeriesMarius Constantin100% (1)

- CS-510 Service DataDocument5 pagesCS-510 Service DatarexNo ratings yet

- Ero Tv-Guides UkDocument4 pagesEro Tv-Guides UkrcaletaNo ratings yet

- Atlas 2:1-Rph: Planning DataDocument12 pagesAtlas 2:1-Rph: Planning DataAdarsh ManoharanNo ratings yet

- XTEInterface ServletDocument2 pagesXTEInterface ServletRodni EmslieNo ratings yet

- 1LE1003 0DA21 7AB4 Datasheet enDocument1 page1LE1003 0DA21 7AB4 Datasheet enkamal_arbabNo ratings yet

- Tiavs UdDocument2 pagesTiavs UdgeigerNo ratings yet

- Woo Chang Coupling - 112438 - Paqndr oYtYHS8Document14 pagesWoo Chang Coupling - 112438 - Paqndr oYtYHS8Eng-anwer kadhimNo ratings yet

- Manual Hoists & Winches: WWW - Morriscranes.co - UkDocument12 pagesManual Hoists & Winches: WWW - Morriscranes.co - UkCedric Chaton100% (1)

- Latest Toshiba ScaraDocument20 pagesLatest Toshiba ScarareflextechNo ratings yet

- Rosroca Ol Mini En.Document2 pagesRosroca Ol Mini En.Branislav MandicNo ratings yet

- 1LE1003 1DA43 4AB4 Datasheet enDocument1 page1LE1003 1DA43 4AB4 Datasheet enElio TavaresNo ratings yet

- Gearless Machines For Elevators: Lift Range 2014Document8 pagesGearless Machines For Elevators: Lift Range 2014Khaled ZakariaNo ratings yet

- Technical Data Titan 525: Engine (Diesel)Document2 pagesTechnical Data Titan 525: Engine (Diesel)dmh cargoNo ratings yet

- Cable Carrier CatalougeDocument146 pagesCable Carrier Catalougebachir diengNo ratings yet

- TwinTrak 4pp Jan17 WebDocument4 pagesTwinTrak 4pp Jan17 WebEldar AtakishyyevNo ratings yet

- 0361TQ BS EN 60332-1-2 BS 638: Orange Welding CableDocument3 pages0361TQ BS EN 60332-1-2 BS 638: Orange Welding CableFacundo ArlistanNo ratings yet

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocument2 pages1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNo ratings yet

- CSRA Series PDFDocument15 pagesCSRA Series PDFDamian Huitzil CedilloNo ratings yet

- Hitachi Sumitomo Hydraulic Crawler Crane SCX900Document6 pagesHitachi Sumitomo Hydraulic Crawler Crane SCX900Nina JuliatiNo ratings yet

- Control and Signal CableDocument3 pagesControl and Signal CableLuis Carlos ValdezNo ratings yet

- KGH Series Bellows CouplingDocument1 pageKGH Series Bellows CouplingServo2GoNo ratings yet

- ATLAS Mini PD ENG v1 3Document9 pagesATLAS Mini PD ENG v1 3alper sungurNo ratings yet

- ThamesSideIndia T34Document4 pagesThamesSideIndia T34Bulk WeighingNo ratings yet

- Ats 639036700 001Document5 pagesAts 639036700 001yonigoNo ratings yet

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZFredericks ACNo ratings yet

- 1le5584 3aa03 4ab4Document2 pages1le5584 3aa03 4ab4Dharmesh ChanawalaNo ratings yet

- Rotary Type Torque Sensor Model Operating InstructionDocument8 pagesRotary Type Torque Sensor Model Operating InstructionEster MujicaNo ratings yet

- 1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enDocument2 pages1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enranjithNo ratings yet

- 1LE1604 1DB43 4GB4 Datasheet enDocument1 page1LE1604 1DB43 4GB4 Datasheet ennarminaNo ratings yet

- v-sd100d-sd10 Manual BookDocument4 pagesv-sd100d-sd10 Manual BookRusmiyanto YantoNo ratings yet

- 0.6mm Low-Profile, Double Action TypeDocument3 pages0.6mm Low-Profile, Double Action TypeshyhuNo ratings yet

- Liquid - Datasheet MTB en 0707Document4 pagesLiquid - Datasheet MTB en 0707Surya TanjayaNo ratings yet

- Fy 19Document11 pagesFy 19angattiNo ratings yet

- Spech PDFDocument3 pagesSpech PDFmahmudiNo ratings yet

- TMCX Connectors For Jacketed Metal Clad Cable: Explosionproof, Dust-IgnitionproofDocument2 pagesTMCX Connectors For Jacketed Metal Clad Cable: Explosionproof, Dust-IgnitionproofFernando TovarNo ratings yet

- Basics About Rails: by (N.R. Kale) Axen/IricenDocument45 pagesBasics About Rails: by (N.R. Kale) Axen/IricenshujaNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1SDLE9YPQ3ET6FYDocument1 pageETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1SDLE9YPQ3ET6FYJorgeMendezNo ratings yet

- Quick Start Guide: Compact ExcavatorsDocument28 pagesQuick Start Guide: Compact ExcavatorsJeff SifNo ratings yet

- Breakers: Make An ImpactDocument10 pagesBreakers: Make An ImpactVICTOR BEMENGUENo ratings yet

- Pulse Transformers/SMD Type: Features Shapes and DimensionsDocument3 pagesPulse Transformers/SMD Type: Features Shapes and DimensionsRajan RajpootNo ratings yet

- VL16-VL20-VL25-XC3 - Spare PartsDocument21 pagesVL16-VL20-VL25-XC3 - Spare PartsVVNo ratings yet

- ST - Operating InstructionsDocument56 pagesST - Operating InstructionsVVNo ratings yet

- Bridgeport Series I - BrochureDocument2 pagesBridgeport Series I - BrochureVVNo ratings yet

- Bridgeport Mobile BaseDocument6 pagesBridgeport Mobile BaseVVNo ratings yet

- IBM System x3400 M3 - Tips0808Document45 pagesIBM System x3400 M3 - Tips0808Ivan LemosNo ratings yet

- Applied - Research On MRFDocument23 pagesApplied - Research On MRFJankiNo ratings yet

- BSIA - Access ControlDocument16 pagesBSIA - Access ControlSayed HashemNo ratings yet

- Methacrylic AcidDocument19 pagesMethacrylic AcidEr Bali PandhareNo ratings yet

- Fundamentals of Information Systems Chapter 1Document66 pagesFundamentals of Information Systems Chapter 1Grant Net Carlo PunzalanNo ratings yet

- DFC3043 Pbe2 Dec17Document1 pageDFC3043 Pbe2 Dec17legasi clothingNo ratings yet

- Ajs 1951 AJS Instuction and Maintenace 16M 16MS 16MC 16MCS 18 18S 18C 18CSDocument100 pagesAjs 1951 AJS Instuction and Maintenace 16M 16MS 16MC 16MCS 18 18S 18C 18CSRoyal ENo ratings yet

- Ey0411 Kul 30jun15 19752Document11 pagesEy0411 Kul 30jun15 19752Spencer RobeniolNo ratings yet

- Air TransportsDocument16 pagesAir TransportsNataliaNo ratings yet

- Chapter 14mDocument24 pagesChapter 14mamirNo ratings yet

- Naoman Sheikh's CVDocument2 pagesNaoman Sheikh's CVNaoman SheikhNo ratings yet

- Quick Start VM Download With CDH 5.3 PDFDocument2 pagesQuick Start VM Download With CDH 5.3 PDFphungocvoNo ratings yet

- Extrusion Machine and LineDocument12 pagesExtrusion Machine and Linesamurai7_77No ratings yet

- Ge Industrial Aeroderivative Gas TurbinesDocument2 pagesGe Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZ0% (1)

- Shop DrawingsDocument3 pagesShop DrawingsTommie FanNo ratings yet

- SI and MFTDocument354 pagesSI and MFTAbhishek DhawanNo ratings yet

- Rockfall BarrierDocument12 pagesRockfall BarrierĐorđe RadisavljevićNo ratings yet

- Graphical Solution of Linear Programming ModelsDocument44 pagesGraphical Solution of Linear Programming ModelsNoor AsikinNo ratings yet

- LoftingDocument206 pagesLoftingeventnowNo ratings yet

- Distributed Electronic WarfareDocument2 pagesDistributed Electronic Warfarebring it onNo ratings yet

- Pages From API ST 617, Axial and Centrifugal Compressors and Expander-CompressorsDocument9 pagesPages From API ST 617, Axial and Centrifugal Compressors and Expander-CompressorsAhmed HassanNo ratings yet

- MIG 41 - World's Fastest FighterDocument13 pagesMIG 41 - World's Fastest FighterhindujudaicNo ratings yet

- Resysta Wood Decking Noa 17111416Document9 pagesResysta Wood Decking Noa 17111416Alaym AguilarNo ratings yet

- Hurst Air ShoreDocument40 pagesHurst Air ShoreFernando GonzálezNo ratings yet

- 2012 ITS ITSM Maturity AssessmentDocument25 pages2012 ITS ITSM Maturity AssessmentWarnher100% (4)

- This Study Resource Was: Process Technology Should Reflect Volume and VarietyDocument2 pagesThis Study Resource Was: Process Technology Should Reflect Volume and VarietyPauline LagtoNo ratings yet