Professional Documents

Culture Documents

Buchas

Buchas

Uploaded by

Rennan BrasilOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Buchas

Buchas

Uploaded by

Rennan BrasilCopyright:

Available Formats

Original instructions

SAFETY BULLETIN 1 (11)

ID B000280

READ AND UNDERSTAND FIRST, THEN ACT Rev. 1

2023-05-01

1. Topic: MAST RAISE AND BUSHING REPLACMENT

2. Exposed product(s) / Model: DR416i for Serial No 733790, 734047 and 734132

Part(s):

The Owner of machinery has a liability to inform and when necessary to train according to the content of this Bulletin all the

personnel (like operators, maintenance personnel) whom this Bulletin concerns.

3. Possible occurrence of Transport Maintenance

topic: Operation Spare parts

Tramming Other:

4. Sales area: EU Canada

Others USA

Australia

5. Supplementary safety information including new hazard(s) identified, how to avoid the hazard(s)

and the potential consequences of not avoiding the hazard:

WARNING

FALLING PARTS HAZARD!

Thoroughly inspect mast raise pins and bushings.

Inspections and repair must be performed by qualified

persons only and in accordance with the manual and

maintenance program. If any cracks are found, stop all

operation of the machine.

Sandvik Mining and Rock Technology has learned that on the DR416i mast raise pins and bushings have

incorrect tolerance and must be replaced. Long term use of old pin will create grooves or gouging of pins.

6. Actions to be taken immediately:

Copyright © Sandvik Mining and Construction USA LLC

13500 NW County Road 235

Alachua, FL 32615 USA

www.sandvik.com

This document shall be incorporated in the "information of use" documentation and kept there for the life of the product.

Unless otherwise specified, Sandvik accepts no responsibility for changes, labor or replacements incurred from this bulletin.

Original instructions

SAFETY BULLETIN 2 (11)

ID B000280

READ AND UNDERSTAND FIRST, THEN ACT Rev. 1

2023-05-01

Sandvik recommends the following:

Replace the mast raise and upper pedestal bushings.

a. Remove Original pin BJ00004594 and replace with BG01764652 pin. Before installing new pins, remove

old bushing BH00028039 and replace with new bushing BG01764594.

b. Remove Original pin BH00024046 and replace with BG01764656 pin. Before installing the new pins,

remove old bushing BH00028040 and replace with new bushing BG01764614.

7. List of Appendices:

NA

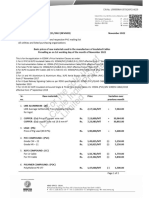

8. List of tools, parts and safety labels required for corrective measures:

Copyright © Sandvik Mining and Construction USA LLC

13500 NW County Road 235

Alachua, FL 32615 USA

www.sandvik.com

This document shall be incorporated in the "information of use" documentation and kept there for the life of the product.

Unless otherwise specified, Sandvik accepts no responsibility for changes, labor or replacements incurred from this bulletin.

Original instructions

SAFETY BULLETIN 3 (11)

ID B000280

READ AND UNDERSTAND FIRST, THEN ACT Rev. 1

2023-05-01

Complete a Job Risk Assessment (JRA) before starting this procedure:

Before beginning these procedures, take time to observe any safety hazards in the area or on the machine.

Check the condition of the required tools, parts, and personal protection equipment (PPE) that may be

required or any factors that may indicate an unsafe condition.

Report and correct any unsafe condition before starting

this procedure!

NOTICE

Table 1: Safety First!

• Always perform Job Risk Assessment (JRA)

• Always wear proper PPE

• Always Lock Out/Tag Out Machine

• Clean the area where work is to be done

• Use appropriately rated lifting slings

• Tighten all bolts, nuts, and fittings to factory

specifications

Table 2: Minimum PPE Requirements

• Steel toe boots • Gloves • Hard hat

• Safety glasses • Safety shield • Hearing protection

Copyright © Sandvik Mining and Construction USA LLC

13500 NW County Road 235

Alachua, FL 32615 USA

www.sandvik.com

This document shall be incorporated in the "information of use" documentation and kept there for the life of the product.

Unless otherwise specified, Sandvik accepts no responsibility for changes, labor or replacements incurred from this bulletin.

Original instructions

SAFETY BULLETIN 4 (11)

ID B000280

READ AND UNDERSTAND FIRST, THEN ACT Rev. 1

2023-05-01

Tools needed:

200-ton overhead crane or two 100-ton cranes.

Instructions to be followed:

Replace Mast Raising pins and bushings. You will need to remove mast. Follow the procedure below for

mast removal.

Note: Perform a risk assessment with the assembly crew and crane operator prior to lifting the mast

structure. Establish crane operators and ground guides that will communicate during the lift and

install process.

1. Attach lifting device to mast at lifting points as shown.

The lifting points are marked with a lifting hook decal

2. Attach crane or cranes to lifting devices on the mast.

3. Install sand lines or guidelines to each end of the mast.

4. Disconnect air supply hose and safety restraint from air pipe adapter. Use tape or rope to secure air hose

and pipe adapter.

Copyright © Sandvik Mining and Construction USA LLC

13500 NW County Road 235

Alachua, FL 32615 USA

www.sandvik.com

This document shall be incorporated in the "information of use" documentation and kept there for the life of the product.

Unless otherwise specified, Sandvik accepts no responsibility for changes, labor or replacements incurred from this bulletin.

Original instructions

SAFETY BULLETIN 5 (11)

ID B000280

READ AND UNDERSTAND FIRST, THEN ACT Rev. 1

2023-05-01

5. Disconnect grease lines for auto grease systems as needed.

• Engage pipe support/ pipe centralizer/ break out wrench

• Raise winch hook to the top of the mast

• Disconnect hydraulic lines and electrical harness.

6. Secure the mast cylinders with turnbuckles.

7. Remove the pin retainer plates and drive the mast cylinder pins from the mast assembly.

8. Remove the stay rods from the mast.

9. Use straps to hold the ends so they do not move from lack of balance.

Copyright © Sandvik Mining and Construction USA LLC

13500 NW County Road 235

Alachua, FL 32615 USA

www.sandvik.com

This document shall be incorporated in the "information of use" documentation and kept there for the life of the product.

Unless otherwise specified, Sandvik accepts no responsibility for changes, labor or replacements incurred from this bulletin.

Original instructions

SAFETY BULLETIN 6 (11)

ID B000280

READ AND UNDERSTAND FIRST, THEN ACT Rev. 1

2023-05-01

10. Position the mast cylinder rod ends as needed to aid pin removal.

Copyright © Sandvik Mining and Construction USA LLC

13500 NW County Road 235

Alachua, FL 32615 USA

www.sandvik.com

This document shall be incorporated in the "information of use" documentation and kept there for the life of the product.

Unless otherwise specified, Sandvik accepts no responsibility for changes, labor or replacements incurred from this bulletin.

Original instructions

SAFETY BULLETIN 7 (11)

ID B000280

READ AND UNDERSTAND FIRST, THEN ACT Rev. 1

2023-05-01

WARNING

FALLING OBJECT HAZARD!

Do not allow anyone below the mast pedestal area when

removing pins as they can cause serious injury or death

if dropped on a person.

11. Remove the retaining plate bolts and slide the retaining plates from the pedestal pins.

12. Remove the pins from the mast and pedestal. The pins are heavy. Keep personnel away from area

below.

13. Move the mast as needed to get the pins to slide out.

14. Remove lock out/tag out so machine can be started after mast is lifted.

15. With all personnel clear of the area, use the crane to lift the mast.

16. Lift mast with crane less than 1 meter (3 feet) off the machine. Check the supported mast for stability

and balanced to both front/rear and left/right. Lower mast to machine and adjust straps as needed to get

the balance correct.

17. Once the mast balance is correct, continue to raise the mast so machine may be driven from under

raised mast.

18. One operator should be in the cab. Start machine.

Copyright © Sandvik Mining and Construction USA LLC

13500 NW County Road 235

Alachua, FL 32615 USA

www.sandvik.com

This document shall be incorporated in the "information of use" documentation and kept there for the life of the product.

Unless otherwise specified, Sandvik accepts no responsibility for changes, labor or replacements incurred from this bulletin.

Original instructions

SAFETY BULLETIN 8 (11)

ID B000280

READ AND UNDERSTAND FIRST, THEN ACT Rev. 1

2023-05-01

19. On the GUI, select Menu > Maintenance > Bypass and set the Mast Lock Pins Extended bypass to ON.

Repeat that process for strut locks, Bit stow position, Mast position.

20. Tram from under the mast.

21. Lower mast down to rest on appropriate cradle or sawhourse to working level.

22. After mast is placed on appropriate sawhorse or cradle, the below outlined bushings in black need to be

removed.

Copyright © Sandvik Mining and Construction USA LLC

13500 NW County Road 235

Alachua, FL 32615 USA

www.sandvik.com

This document shall be incorporated in the "information of use" documentation and kept there for the life of the product.

Unless otherwise specified, Sandvik accepts no responsibility for changes, labor or replacements incurred from this bulletin.

Original instructions

SAFETY BULLETIN 9 (11)

ID B000280

READ AND UNDERSTAND FIRST, THEN ACT Rev. 1

2023-05-01

23. For bushing removal you will need a Saw- all Like pictured below with metal blades to be able to cut the

old bushing out (do not cut into mast).

24. With old bushing out make sure the inner surface area of the weldment is clean of all burs and clean of

any debris. This will make the installation of new bushings easier.

• To install new bushings some heating may be required to the surface area of the mast where the new

bushing is going to be received.

• This will allow for expansion of the metal some to accept the new bushing. It is suggested that a trial run

might be done first as you also might need to have the new bushing placed in Dry ice to shrink them

down making it easier to install in the weldment.

Use caution if you are using a hammer on the bushing install as that will cause the new bushing to

mushroom out and it will not accept the new mast pins. After new bushings are installed, they should look

like the below.

25. Before re-install of mast take the new pins and make sure they go through the new bushing with no

issues.

Copyright © Sandvik Mining and Construction USA LLC

13500 NW County Road 235

Alachua, FL 32615 USA

www.sandvik.com

This document shall be incorporated in the "information of use" documentation and kept there for the life of the product.

Unless otherwise specified, Sandvik accepts no responsibility for changes, labor or replacements incurred from this bulletin.

Original instructions

SAFETY BULLETIN 10 (11)

ID B000280

READ AND UNDERSTAND FIRST, THEN ACT Rev. 1

2023-05-01

WARNING

CRUSHING HAZARD!

All items of the machine are extremely heavy or can

cause serious injury or death.

Do not work under suspended loads, do not move loads

with personnel in unsafe areas, and ensure all items are

secured to prevent falling or tripping.

26. Re-install mast to drill base using the new pins provided. Use anti-seize compound on new pins before

installation (nickel or copper).

DANGER

The sudden release of a pressurized lid or hose can spray

hot oil.

Do not open hydraulic tanks or air reservoir or hydraulic

connection while machine is running or the systems are

under pressure.

WARNING

CRUSHING HAZARD!

Moving or falling parts can crush. Ensure all loads are

supported securely.

Parts are heavy, do not work under items while they are

loose. Keep all body parts away from pinch points.

9. Further details to Customers:

• No software required for this update.

• Take a picture of old Pins and bushings and please sent to Sandvik via Salesforce case.

• Please send one of the older pins and bushing back to Sandvik to be evaluated.

10. Warranty Information:

Parts will be issued F.O.C. per factory to customer.

Copyright © Sandvik Mining and Construction USA LLC

13500 NW County Road 235

Alachua, FL 32615 USA

www.sandvik.com

This document shall be incorporated in the "information of use" documentation and kept there for the life of the product.

Unless otherwise specified, Sandvik accepts no responsibility for changes, labor or replacements incurred from this bulletin.

Original instructions

SAFETY BULLETIN 11 (11)

ID B000280

READ AND UNDERSTAND FIRST, THEN ACT Rev. 1

2023-05-01

11. Contact Details

Please contact Sandvik for any further information you may require at alachua.partsupport@sandvik.com.

If you need additional support, you can contact your local Sandvik office.

Copyright © Sandvik Mining and Construction USA LLC

13500 NW County Road 235

Alachua, FL 32615 USA

www.sandvik.com

This document shall be incorporated in the "information of use" documentation and kept there for the life of the product.

Unless otherwise specified, Sandvik accepts no responsibility for changes, labor or replacements incurred from this bulletin.

You might also like

- Kioti Daedong Nd80, Nd100, Nd130, Nd8d (E), Nd10d (E), Dt8d (E), Dt10d (E) Power Tillers Service ManualDocument19 pagesKioti Daedong Nd80, Nd100, Nd130, Nd8d (E), Nd10d (E), Dt8d (E), Dt10d (E) Power Tillers Service ManualLisakolyNo ratings yet

- CAT TH48-E80 Operation and Maintenance ManualDocument56 pagesCAT TH48-E80 Operation and Maintenance ManualАлексей Федоров100% (1)

- DP15 To 100 BManualweb 2Document22 pagesDP15 To 100 BManualweb 2juantecsup0% (1)

- Gas Cutting Set ChecklistDocument1 pageGas Cutting Set ChecklistMOJIB83% (12)

- PERMASWAGE System Presentation (NXPowerLite)Document16 pagesPERMASWAGE System Presentation (NXPowerLite)Edwar ZulmiNo ratings yet

- QJ - Warning Codes (Blue) : Code 1Document6 pagesQJ - Warning Codes (Blue) : Code 1avtonika38No ratings yet

- Green Ats Egsu200ac & Egsu200nseac Instruction ManualDocument28 pagesGreen Ats Egsu200ac & Egsu200nseac Instruction ManualAriNo ratings yet

- Win713en 00Document34 pagesWin713en 00MohamedAbdelnasserNo ratings yet

- O & M Manual For The EGS Automatic Transfer Switch With RTC-50 Control and Integral LoadcenterDocument72 pagesO & M Manual For The EGS Automatic Transfer Switch With RTC-50 Control and Integral Loadcenterpedro marinNo ratings yet

- User Instructions: Valtek Shearstream HP Control Valves Segmented V-Port Ball ValvesDocument12 pagesUser Instructions: Valtek Shearstream HP Control Valves Segmented V-Port Ball ValvesKyrie AbayaNo ratings yet

- HCV5HA ManualDocument24 pagesHCV5HA ManualDiego OliveiraNo ratings yet

- O & M Manual For The EGS Automatic Transfer Switch With RTC-50 ControlDocument84 pagesO & M Manual For The EGS Automatic Transfer Switch With RTC-50 ControlOsmel SuarezNo ratings yet

- Wilo-Star RS, RSD: Pioneering For YouDocument136 pagesWilo-Star RS, RSD: Pioneering For YouKirill KNo ratings yet

- User Manual: Auto Crib-It Ac SeriesDocument21 pagesUser Manual: Auto Crib-It Ac SeriesForum PompieriiNo ratings yet

- Ajin SMT - Operating Manual-1Document38 pagesAjin SMT - Operating Manual-1henry vegaNo ratings yet

- 5 MTT30 CatDocument19 pages5 MTT30 CatMartin GomezNo ratings yet

- Progressive Cavity Pump O&M PDFDocument120 pagesProgressive Cavity Pump O&M PDFharry_chemNo ratings yet

- O&M Manual For 1200 & 1600A (480 Vac) 3-Position, Open, Service Entrance Contactor Based Transfer SwitchDocument26 pagesO&M Manual For 1200 & 1600A (480 Vac) 3-Position, Open, Service Entrance Contactor Based Transfer SwitchTarek KasemNo ratings yet

- BW11RHDocument92 pagesBW11RHhernando ramosNo ratings yet

- O & M Manual For 40-1200A (480/600 Vac) ATC-800 3-Position, Open/Closed Transition Contactor Based Transfer SwitchDocument44 pagesO & M Manual For 40-1200A (480/600 Vac) ATC-800 3-Position, Open/Closed Transition Contactor Based Transfer SwitchJorge GiménezNo ratings yet

- EatonDocument42 pagesEatonkarencNo ratings yet

- Ib 140049 enDocument26 pagesIb 140049 enalaa adelNo ratings yet

- Service Manual Contents Notice: For Use in Service Manual Form SB4031E01 SB4032E01 Nov. 2004Document1,136 pagesService Manual Contents Notice: For Use in Service Manual Form SB4031E01 SB4032E01 Nov. 2004sergio mata100% (1)

- SB 4031 eDocument442 pagesSB 4031 eHenry Huayhua100% (1)

- EPM Manual TVA2020Document206 pagesEPM Manual TVA2020Renan AguiarNo ratings yet

- User's Manual: Insulation Resistance TesterDocument60 pagesUser's Manual: Insulation Resistance TesterNui DirekNo ratings yet

- ADB - 12" F-Range Inset Lights (Treshold) - FTH-1-200-GDocument56 pagesADB - 12" F-Range Inset Lights (Treshold) - FTH-1-200-GFranciscoVicenteNo ratings yet

- Wilo-Control SC-Fire Electric: Pioneering For YouDocument32 pagesWilo-Control SC-Fire Electric: Pioneering For YouhabtamubedassaNo ratings yet

- Emergency Lube Oil PumpDocument28 pagesEmergency Lube Oil Pumpdac3524No ratings yet

- Centrifugal Liquid Chillers: Operating & MaintenanceDocument156 pagesCentrifugal Liquid Chillers: Operating & MaintenanceWillie TanyuNo ratings yet

- Esib 04 CompleteDocument782 pagesEsib 04 CompleteJorge AndradeNo ratings yet

- WM1 WM2 WM3 PM1 PM2 ManualDocument8 pagesWM1 WM2 WM3 PM1 PM2 ManualrajaanwarNo ratings yet

- Yonos PICO Installation and Operating InstructionsDocument128 pagesYonos PICO Installation and Operating InstructionsЮрій РудийNo ratings yet

- Bomag Bw11rh Pneumatic-Tired Roller Service Repair ManualDocument220 pagesBomag Bw11rh Pneumatic-Tired Roller Service Repair ManualAbraham RamirezNo ratings yet

- Magicolor 4690MF: Service ManualDocument172 pagesMagicolor 4690MF: Service ManualFrei HerrNo ratings yet

- Wilo PumpsDocument28 pagesWilo PumpsHunney KotiyaNo ratings yet

- Wilo 31895Document30 pagesWilo 31895Titi FiliNo ratings yet

- PCS-9705 X Instruction Manual en Domestic General X R1.03 (En CKZZ5305.0086.0004)Document255 pagesPCS-9705 X Instruction Manual en Domestic General X R1.03 (En CKZZ5305.0086.0004)ngocanhvy67% (3)

- Trav L Cutter - 02 MAN 01 - R4 0308Document50 pagesTrav L Cutter - 02 MAN 01 - R4 0308LuisNo ratings yet

- User's Manual: Insulation Resistance TesterDocument60 pagesUser's Manual: Insulation Resistance TesterconglxNo ratings yet

- CFC-201 User's MunualDocument214 pagesCFC-201 User's Munualmaherianto 2950% (4)

- ManualDocument106 pagesManualEmmanuel EntzanaNo ratings yet

- O & M Manual For 40-1200A (480 600 Vac) ATC-300+ 3-Position Contactor Based Transfer SwitchDocument40 pagesO & M Manual For 40-1200A (480 600 Vac) ATC-300+ 3-Position Contactor Based Transfer SwitchsabeerNo ratings yet

- Operational & Maintenance Manual GT-550E-1Document212 pagesOperational & Maintenance Manual GT-550E-1ary fauzi rahman100% (1)

- FIN Nal Operat Tion and Ma Orden D FMC Aintenanc E Compra C Technol E Manual - H336073-PM Ogies Proj - Mina Minis M031/A 45011 JECT B6042 Stro Hales 90525 S ProjectDocument44 pagesFIN Nal Operat Tion and Ma Orden D FMC Aintenanc E Compra C Technol E Manual - H336073-PM Ogies Proj - Mina Minis M031/A 45011 JECT B6042 Stro Hales 90525 S ProjectEdgarNo ratings yet

- Liebert Ita2 30kva Ups User Manual v1.2Document108 pagesLiebert Ita2 30kva Ups User Manual v1.2nelson yenner ramirez minayaNo ratings yet

- Slips Catalog PDFDocument194 pagesSlips Catalog PDFDaniel Alencar100% (1)

- EPM Manual TVA2020 PDFDocument202 pagesEPM Manual TVA2020 PDFYorkNo ratings yet

- Wilo - 2 PDFDocument28 pagesWilo - 2 PDFAlexandru BocoșNo ratings yet

- New Holland E18B TIER 4 Hydraulic Excavator Service Repair ManualDocument21 pagesNew Holland E18B TIER 4 Hydraulic Excavator Service Repair ManualggjjjjotonesNo ratings yet

- Induction Motors/ Generators: Installation Operation MaintenanceDocument38 pagesInduction Motors/ Generators: Installation Operation Maintenancepatelr123No ratings yet

- Bea 251580 en 01Document12 pagesBea 251580 en 01Edmundo MIguelNo ratings yet

- Magicolor 2490MF: Service ManualDocument150 pagesMagicolor 2490MF: Service ManualEstanislao Amadeo AvogadroNo ratings yet

- KBCH 120, 130, 140 Transformer Dirrerential Relay Service ManualDocument236 pagesKBCH 120, 130, 140 Transformer Dirrerential Relay Service ManualduonzaNo ratings yet

- Amx-Omx0018 Operation ManualDocument36 pagesAmx-Omx0018 Operation ManualpiojevskyNo ratings yet

- Instruction ManualDocument42 pagesInstruction ManualQuy HoangNo ratings yet

- Kioti Daedong PX1153PC Tractor Service ManualDocument19 pagesKioti Daedong PX1153PC Tractor Service ManualLisakolyNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Additional Safety Rules For A Drill Presses: 5) ServiceDocument7 pagesAdditional Safety Rules For A Drill Presses: 5) ServiceRoger OrtegaNo ratings yet

- 12.5 Oh GR CN ZDL SP Hdil CalDocument22 pages12.5 Oh GR CN ZDL SP Hdil CalStephanyNo ratings yet

- Manual / Handbuch Spare Parts List / ErsatzteillisteDocument59 pagesManual / Handbuch Spare Parts List / Ersatzteillisteneno111No ratings yet

- Ball Mill Standard Product Definition-Rev0Document12 pagesBall Mill Standard Product Definition-Rev0krishnabijuNo ratings yet

- Kidde Engineered Fire Suppression System: Supervisory Pressure Switch, 1-1/2", 2", and 3" ValveDocument1 pageKidde Engineered Fire Suppression System: Supervisory Pressure Switch, 1-1/2", 2", and 3" ValveJulio Andres Garcia PabolaNo ratings yet

- IEEMA Circular For Nov 2022REVDocument2 pagesIEEMA Circular For Nov 2022REVAMARENDRA SINo ratings yet

- Manual Volvo XC90 2005Document17 pagesManual Volvo XC90 2005Diego Alejandro QuinteroNo ratings yet

- KW810 Autopilot Relay Diagram Iss01 Rev00Document1 pageKW810 Autopilot Relay Diagram Iss01 Rev00Vishwas MaritronicsNo ratings yet

- GLL2-80P Manual PDFDocument302 pagesGLL2-80P Manual PDFParalis DimiNo ratings yet

- Sensoriamento Top TopDocument5 pagesSensoriamento Top TopMaykon SantosNo ratings yet

- 2022 Transtector Tower Top DC Surge ProtectionDocument4 pages2022 Transtector Tower Top DC Surge Protectionabdulkawi alasharyNo ratings yet

- Ficha Tecnica SOL GT PolyDocument2 pagesFicha Tecnica SOL GT Polylic_palominoNo ratings yet

- Electromagnetism S4 Physics NotesDocument20 pagesElectromagnetism S4 Physics NotesOKURUT MARIKONo ratings yet

- MR 10MSX 5400700 M2 GBDocument76 pagesMR 10MSX 5400700 M2 GBFarid RezigNo ratings yet

- 160 69-rp1Document12 pages160 69-rp1Nha Trang100% (1)

- Control Valve and It's Controls-25-Aug-2023Document16 pagesControl Valve and It's Controls-25-Aug-2023Vinay SharmaNo ratings yet

- Cl-9302a UniverDocument1 pageCl-9302a UniverMudasir ATNo ratings yet

- Dometic All Models W InstructionsDocument1 pageDometic All Models W InstructionsHeather Stephanie SchweitzerNo ratings yet

- For Inverter Users: When Studying How To Use Our Inverters When Wiring The Inverter When Changing The Motor SpeedDocument4 pagesFor Inverter Users: When Studying How To Use Our Inverters When Wiring The Inverter When Changing The Motor SpeedhuyvuNo ratings yet

- Cat5 Cat5e Vs Cat6Document1 pageCat5 Cat5e Vs Cat6ruletriplexNo ratings yet

- BHP 2919 02Document7 pagesBHP 2919 02ardiandawoodNo ratings yet

- 4-OMMXTS-W00134 - 2 - MaintenanceDocument32 pages4-OMMXTS-W00134 - 2 - Maintenancediego19absNo ratings yet

- Spring Loaded Power SlipsDocument3 pagesSpring Loaded Power SlipsAliNo ratings yet

- Installation Instructions: Fronius Symo 3 - 8,2 KWDocument44 pagesInstallation Instructions: Fronius Symo 3 - 8,2 KWFranck RobertNo ratings yet

- Fire Protection IndexDocument1 pageFire Protection IndexBams ArifinNo ratings yet

- Linked PDFDocument271 pagesLinked PDFroparts clujNo ratings yet

- FYEA Flexi GPS Surge Protection KitDocument8 pagesFYEA Flexi GPS Surge Protection KitSerjNo ratings yet