Professional Documents

Culture Documents

RTR Ms Editable - Excavate Lamination

RTR Ms Editable - Excavate Lamination

Uploaded by

moin06314Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RTR Ms Editable - Excavate Lamination

RTR Ms Editable - Excavate Lamination

Uploaded by

moin06314Copyright:

Available Formats

DOCUMENT NO.

: BE/Q-SSA-MS-RTR0000

REVISION NO. : 00

METHOD STATEMENT SATORP W.O NO. : NA

SATORP IREP. NO. : NA

Repair For 14"-FWA-6910050003 Underground Line Unit-651

1.1.1

Revision History and Highlights

Revision Description of Change Date Article No.

00 Initial Release 21-Nov-23 NA

Prepared by: Reviewed by: Concurred by: Approved by:

Jehu Philip / MD Cruz HC. Ramiro / MDA Batacan Mohamed Hafez

MS Page 1 of 8 SANKYU SAUDI ARABIA CO.

DOCUMENT NO. : BE/Q-SSA-MS-RTR0000

REVISION NO. : 00

METHOD STATEMENT SATORP W.O NO. : NA

SATORP IREP. NO. : NA

Repair For 14"-FWA-6910050003 Underground Line Unit-651

Inspection Engineer QAQC Engineer/ Static Lead QAQC/Reliability Head SATORP

MS Page 2 of 8 SANKYU SAUDI ARABIA CO.

DOCUMENT NO. : BE/Q-SSA-MS-RTR0000

REVISION NO. : 00

METHOD STATEMENT SATORP W.O NO. : NA

SATORP IREP. NO. : NA

Repair For 14"-FWA-6910050003 Underground Line Unit-651

TABLE OF CONTENTS

Section No. Description Page(s)

1.0 Purpose and Scope 3

2.0 Applicable Documents 3

3.0 General Requirements 3-5

4.0 Attachment(s) 6

MS Page 3 of 8 SANKYU SAUDI ARABIA CO.

DOCUMENT NO. : BE/Q-SSA-MS-RTR0000

REVISION NO. : 00

METHOD STATEMENT SATORP W.O NO. : NA

SATORP IREP. NO. : NA

Repair For 14"-FWA-6910050003 Underground Line Unit-651

1. PURPOSE AND SCOPE

The purpose of these procedures is to ensure that repair for 14"-RTR Joint leak. Is carried out safely and

Quality, in compliance with SATORP minimum requirements.

This procedure covers Joint leak repair, RTR Line inspection, and testing. Restoration and forwarding to

operations department. All tests are performed to ensure the safety, reliability, and leak tightness of each

system.

2. APPLICABLE DOCUMENTS

MS Page 4 of 8 SANKYU SAUDI ARABIA CO.

DOCUMENT NO. : BE/Q-SSA-MS-RTR0000

REVISION NO. : 00

METHOD STATEMENT SATORP W.O NO. : NA

SATORP IREP. NO. : NA

Repair For 14"-FWA-6910050003 Underground Line Unit-651

2.1. PROJECT SPECIFICATIONS (CURRENT VERSION)

JERES-A-004 General Requirements for Pressure Testing

JERES-L-105 Piping Material Specification

JERES-L-610 Non Metallic Piping and Equipment

JERMS-S-070 Installation of Utility Piping System

JERMS-L-1034 RTR (Fiberglass) Pressure Pipe and Fittings

3-MMEC-012 Repairing Procedure-Reinforced Thermosetting Resin (Fiber)

MSS Manufacturers Specification and Standards (including Recipe)

JSA Job Safety Analysis for General Repair

2-SAFE-024 Work Permit Procedure

3. GENERAL REQUIREMENTS

3.1. DOCUMENTATION REQUIREMENTS

3.1.1 SATORP Maintenance Group shall prepare the relevant drawing, PID, notification, and

work order number before proceeding with the CM works.

3.1.2 Ensures Work Permit system and applicable Job Safety Analysis (JSA) had been

implemented.

3.1.3 GMS2 Inspection team shall prepare the corresponding Method Statement and shall be

submitted to M and R for review and approval.

Note 1: If a GMS2 subcontractor(s) performs the activity, they shall provide their

methodology (ies), staff qualifications, and equipment calibration certifications for

evaluation and approval.

3.1.4 Corrective maintenance activities and testing shall commence after the Method Statement

(MS) is approved.

Note1: The approved MS shall be distributed as repair recommendations to the GMS2 Area

In-charge and Support groups.

3.1.5 Once the Method Statement (MS) is approved, the corrective maintenance activities and

testing shall commence.

3.2. PREPARATION ON MAINTENANCE

3.1.6 Check the real condition for additional evaluation prior to CM work and shall follow the

safety rules to avoid mishaps.

3.1.7 Proper measures (specific clothes, tools, equipment, etc.) shall be taken to safeguard

personnel from injury before, during, and after the repair.

3.1.8 Ensure that the maintenance staff shall be completely informed of all potential hazards

throughout the whole activity, with a matching action plan in place in the event of an

unexpected incident.

3.1.9 Ensure that the executor fully understands the repair approach under the supervision of

their foreman or supervisor.

MS Page 5 of 8 SANKYU SAUDI ARABIA CO.

DOCUMENT NO. : BE/Q-SSA-MS-RTR0000

REVISION NO. : 00

METHOD STATEMENT SATORP W.O NO. : NA

SATORP IREP. NO. : NA

Repair For 14"-FWA-6910050003 Underground Line Unit-651

3.1.10 Provide a safe and functional scaffold with sufficient or adequate access.

3.1.11 Ensure that the systems shall be separated, blinded, and marked appropriately. Follow

the authorized isolation plan/test limit supplied by SATORP Operations and Maintenance,

which shows the pressure testing test limit.

3.1.12 Before beginning repair work, Operations shall properly isolate the line.

3.1.13 Continuous monitoring and inspection are required while executing job operations.

3.3. SEQUENCE OF THE REPAIR ACTIVITY

3.1.14 Ensures that the Sec. 3.1 and 3.2 of this procedure was implemented.

3.1.15 The repair activity will be carried out by competent personnel.

3.1.16 Ensures that the excavated area is safe for working, convenient, workable for adhesive

bonding activity and cannot be affected the quality after the repair.

3.1.17 QAQC shall inspects the damage existing line.

3.1.18 QAQC shall inspect the leak portion of existing line. When the defects were located;

measure the repair section to be marked (Refer to figure-1)

3.1.19 Cut and remove carefully the damage RTR pipe with the existing adhesive inside the

Elbow.

3.1.20 After grinding, clean and remove Dirt and chips with clean rags and made free of

dust and coated with adhesive.

3.1.21 Assemble the pipe, tee and flange to be inserted in the damage line.

3.1.22 Before applying for the adhesive & lamination, make sure that the pipe line is completely

dry and leakage cannot make contact with the part to be laminated.

3.1.23 Mixed Easy-Fit adhesive and applied the prepared surface preparation of leak portion &

use only the required Recipe.

3.1.24 Once adhesive is cured, apply bonding lamination & use only the required Recipe.

3.1.25 Including the existing joint for additional reinforced lamination.

3.1.26 Make sure curing was properly done at ambient temperature.

3.1.27 During the curing, the joint shall not be moved, vibrated or otherwise disturbed.

3.1.28 Once repair on the line is completed, to proceed for service test.

3.1.29 Conduct a 24 hours Service Test into repaired system when it was fully cured & has

cooled down.

3.1.30 During backfilling, ensure that the backfill materials Well be free from foreign debris

(e.g. stone/pebbles) that could damage the RTR pipe.

Note: For backfill materials: clean sand up to 1m height above top of the pipe and then

select filling materials as per JERES-A-114. (Scope of civil contractor)

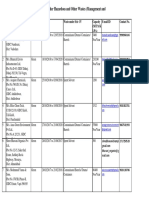

FIGURE-2 RTR Material Requirements for Repair:

1. Easy-Fit Adhesive kits A/B.

2. GRE Epoxy Resin with IPD Hardener

MS Page 6 of 8 SANKYU SAUDI ARABIA CO.

DOCUMENT NO. : BE/Q-SSA-MS-RTR0000

REVISION NO. : 00

METHOD STATEMENT SATORP W.O NO. : NA

SATORP IREP. NO. : NA

Repair For 14"-FWA-6910050003 Underground Line Unit-651

3. GRE Fiberglass Woven Roving (270/5) (360/10)

4. ATTACHMENT(S)

4.1. Attachment-A – RTR Recipe

MS Page 7 of 8 SANKYU SAUDI ARABIA CO.

DOCUMENT NO. : BE/Q-SSA-MS-RTR0000

REVISION NO. : 00

METHOD STATEMENT SATORP W.O NO. : NA

SATORP IREP. NO. : NA

Repair For 14"-FWA-6910050003 Underground Line Unit-651

ATTACHMENT – A

MS Page 8 of 8 SANKYU SAUDI ARABIA CO.

You might also like

- Inspection and Test Plan: DESCRIPTION: Manhole ConstructionDocument4 pagesInspection and Test Plan: DESCRIPTION: Manhole ConstructionDelta akathehusky50% (2)

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- Method Statement For Establishment of Site FacilitiesDocument9 pagesMethod Statement For Establishment of Site FacilitiesNaveen GladsonNo ratings yet

- 00 Saip 11Document21 pages00 Saip 11munnaNo ratings yet

- Afton PolartechDocument14 pagesAfton PolartechSuresh KumarNo ratings yet

- Method of Statement RT R Pipe 450 MM Dia PW Installation Saudi BinladinDocument19 pagesMethod of Statement RT R Pipe 450 MM Dia PW Installation Saudi BinladinShyju MelepurathNo ratings yet

- ZULUF PROJECT (0-8887) : 10-08643-0005 Saudi Aramco 0-8887-2-P-3130-MC2-A GAS-JGC-MOS-MECH-006 FA NMR Ref NODocument52 pagesZULUF PROJECT (0-8887) : 10-08643-0005 Saudi Aramco 0-8887-2-P-3130-MC2-A GAS-JGC-MOS-MECH-006 FA NMR Ref NORiaz Ali Khan BangashNo ratings yet

- Procedure For Bolt Tightening of Thermoplastic and RTR Flange JointDocument9 pagesProcedure For Bolt Tightening of Thermoplastic and RTR Flange JointDILSHAD AHEMADNo ratings yet

- A07-Za-E-7007408 Baa A 00Document9 pagesA07-Za-E-7007408 Baa A 00RAMIL0% (1)

- SAT - Rabigh - FinalDocument269 pagesSAT - Rabigh - Finalarsathmd08No ratings yet

- Procedure For Flushing and Internal Cleaning - FinalDocument7 pagesProcedure For Flushing and Internal Cleaning - FinalDILSHAD AHEMADNo ratings yet

- ITP For Instrumentation ControlDocument9 pagesITP For Instrumentation Controlsugeng wahyudiNo ratings yet

- Rev02-Work Method Statement For LV and MV Motor InstallationDocument14 pagesRev02-Work Method Statement For LV and MV Motor InstallationMahaboob PashaNo ratings yet

- SG6427-SY-CK0P-MTD-736-006 - Method Statement of Local Instrument Installattion - Rev. ADocument15 pagesSG6427-SY-CK0P-MTD-736-006 - Method Statement of Local Instrument Installattion - Rev. Abrian sanchezNo ratings yet

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNo ratings yet

- Sac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API TanksDocument14 pagesSac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API Tankshusnain aliNo ratings yet

- RWTP GB CNS MST 000030 00Document45 pagesRWTP GB CNS MST 000030 00slayerzzz22No ratings yet

- Sac Inspection ChecklistDocument21 pagesSac Inspection Checklisthusnain aliNo ratings yet

- Method Statement For Data & Communication Equipments & FOC InstallationDocument13 pagesMethod Statement For Data & Communication Equipments & FOC InstallationziaurrehmanNo ratings yet

- VD V013 ZPM Pro 1507Document105 pagesVD V013 ZPM Pro 1507abdulNo ratings yet

- 175-026400 TIP AramcoDocument2 pages175-026400 TIP Aramcoengineersalam786No ratings yet

- Itp Forabove Grade and Embedded Conduits Rev. 0Document6 pagesItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- MD 04 MT Rssta PD 509Document13 pagesMD 04 MT Rssta PD 509Nguyễn Đặng LâmNo ratings yet

- SAIC-A-2025 Rev 6 Pre Test Pressure VesselDocument4 pagesSAIC-A-2025 Rev 6 Pre Test Pressure Vesselpookkoya thangal100% (1)

- Saudi Aramco Consulting Services Department Me&Ccd/Meu Procedure Review SheetDocument3 pagesSaudi Aramco Consulting Services Department Me&Ccd/Meu Procedure Review SheetabdullaNo ratings yet

- TP-01Hydrostatic Test Cover SheetDocument4 pagesTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- Procedure For Radiography TestingDocument18 pagesProcedure For Radiography TestingRanjan KumarNo ratings yet

- Method Statement: Consolidated Contractors Company & Teyseer Contracting Company J.VDocument10 pagesMethod Statement: Consolidated Contractors Company & Teyseer Contracting Company J.Vrvsreddy1972No ratings yet

- Procedure For Bolt Torquing of Thermoplastic and RTR Flange Joint of Force Main PipingDocument8 pagesProcedure For Bolt Torquing of Thermoplastic and RTR Flange Joint of Force Main PipingDILSHAD AHEMADNo ratings yet

- Satr-P-3912 Transformer InsulationDocument8 pagesSatr-P-3912 Transformer InsulationSurendren R100% (1)

- NSH SAOMPP CMS PI 007 ReinstatementDocument13 pagesNSH SAOMPP CMS PI 007 ReinstatementNeil JavierNo ratings yet

- 1991 Agt 1500 Powerpack Improvement ProjectDocument170 pages1991 Agt 1500 Powerpack Improvement ProjectmohmehrNo ratings yet

- Attachment 3B YKTN Government Furnished InformationDocument8 pagesAttachment 3B YKTN Government Furnished InformationRebecca JohnsonNo ratings yet

- 6143 MS CU 061 - RA (1) ApprovedDocument22 pages6143 MS CU 061 - RA (1) ApprovedMubashar Ahmad KhanNo ratings yet

- Circulation PumpDocument134 pagesCirculation Pumpsushant moreyNo ratings yet

- Inspection & Test Plan For Boxes, (Pull, Junction, Terminal) & EnclosuresDocument2 pagesInspection & Test Plan For Boxes, (Pull, Junction, Terminal) & EnclosuressartajNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of Pipelines SATIP-W-012-01 31-Dec-14 MechanicalDocument10 pagesSaudi Aramco Typical Inspection Plan: Welding of Pipelines SATIP-W-012-01 31-Dec-14 Mechanicalpravin0% (1)

- Front PageDocument2 pagesFront PageEr Md AamirNo ratings yet

- Method Statement: Plumbing & Ug Piping WorksDocument17 pagesMethod Statement: Plumbing & Ug Piping WorksMuhammad Sami ParvezNo ratings yet

- TCC 524 Pmi F 001Document8 pagesTCC 524 Pmi F 001caovanthien10121992No ratings yet

- Port Arthur Liquefaction Project: Port Arthur, TX Document Title: Radiographic Examination ProcedureDocument19 pagesPort Arthur Liquefaction Project: Port Arthur, TX Document Title: Radiographic Examination Procedurebaris121919No ratings yet

- Control Valve Study ReportDocument53 pagesControl Valve Study Reportahmad santoso100% (1)

- Functional Test of The VOR - MKRDocument9 pagesFunctional Test of The VOR - MKRIvan David Silva RodriguezNo ratings yet

- 26071-100-V20A-000-00007 - 004 - Piling Test (PDA, PIT, Static Load Test Dan VMT) Procedure by Third PartyDocument118 pages26071-100-V20A-000-00007 - 004 - Piling Test (PDA, PIT, Static Load Test Dan VMT) Procedure by Third Partycrystian NapitupuluNo ratings yet

- NSH-SAOMPP-QCP-EL-004 - 02 Grounding System Installation and TestingDocument18 pagesNSH-SAOMPP-QCP-EL-004 - 02 Grounding System Installation and TestingNeil JavierNo ratings yet

- GVK Power (Goindwal Sahib) Limited, GVK Power (Goindwal Sahib) Limited Thermal Power PlantDocument15 pagesGVK Power (Goindwal Sahib) Limited, GVK Power (Goindwal Sahib) Limited Thermal Power PlantRohit100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- 600 Hour InspectionDocument1 page600 Hour InspectionAdielNo ratings yet

- Procedure For Ultrasonic Testing For Welds: Sievert Technical Inspection LLC Po Box: 851, PC 130, Azaiba, OmanDocument27 pagesProcedure For Ultrasonic Testing For Welds: Sievert Technical Inspection LLC Po Box: 851, PC 130, Azaiba, OmanSooraj RajanNo ratings yet

- T9630 Ab MMD 010 - Rev 3 PDFDocument176 pagesT9630 Ab MMD 010 - Rev 3 PDFDustin SmithNo ratings yet

- S 0 PDocument39 pagesS 0 PAnonymous Gg6z0u9IBz100% (1)

- DRT Report of 2-0700-CL-21 2019Document49 pagesDRT Report of 2-0700-CL-21 2019srinivasNo ratings yet

- SW TSP C 001 Rev - 02 Topo PDFDocument10 pagesSW TSP C 001 Rev - 02 Topo PDFramesNo ratings yet

- Adw TR RTCF QP Me 002, Rev.1Document38 pagesAdw TR RTCF QP Me 002, Rev.1Rijwan MohammadNo ratings yet

- Satr A 2001Document7 pagesSatr A 2001Naveed ShahNo ratings yet

- Chip Detector Task CardDocument13 pagesChip Detector Task CardPablo BalderramaNo ratings yet

- SATIP-W-011-01 Note5Document14 pagesSATIP-W-011-01 Note5Deo MNo ratings yet

- Inspection Request (Ir) Riyadh Metro Package-2 (Line # 3) : Cable Installation IR For ACID - JB: (QTY 2)Document2 pagesInspection Request (Ir) Riyadh Metro Package-2 (Line # 3) : Cable Installation IR For ACID - JB: (QTY 2)Kajini MohamedNo ratings yet

- 000 SA E 50308 - RevBDocument94 pages000 SA E 50308 - RevBDurga Jagan Puppala100% (1)

- Irep 18 00671Document18 pagesIrep 18 00671moin06314No ratings yet

- 021 - Blind ListDocument297 pages021 - Blind Listmoin06314No ratings yet

- RCA For 581XV2031 and 581XV2032 RCA - Area 7 R1Document7 pagesRCA For 581XV2031 and 581XV2032 RCA - Area 7 R1moin06314No ratings yet

- Methods Statement (Hydro-Jet Cleaning)Document11 pagesMethods Statement (Hydro-Jet Cleaning)moin06314No ratings yet

- HydrocarbonDocument94 pagesHydrocarbonArshNo ratings yet

- Meter Quotation-2Document2 pagesMeter Quotation-2umanathmech_75899977No ratings yet

- Plastic Materials PropertiesDocument2 pagesPlastic Materials PropertiesjohnbonjohnNo ratings yet

- Mill Lines by FlSmidthDocument4 pagesMill Lines by FlSmidthIrving Dirzo CarrilloNo ratings yet

- AtomsDocument5 pagesAtomskrisha mandriqueNo ratings yet

- Bab v. Ionic Bonding Born Haber S2Document173 pagesBab v. Ionic Bonding Born Haber S2Risna AmaliaNo ratings yet

- Plastics 2Document121 pagesPlastics 2AMIT PRAJAPATINo ratings yet

- High-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingDocument3 pagesHigh-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingAriel FernandezNo ratings yet

- DLL Tle Ia 6 - Q3 - W2Document5 pagesDLL Tle Ia 6 - Q3 - W2Jeffril Dela CruzNo ratings yet

- Quarter 1 Module 7 - Concentration of SolutionsDocument16 pagesQuarter 1 Module 7 - Concentration of SolutionsJeline MacallaNo ratings yet

- 1 - MOM Lab Manual RevisedDocument15 pages1 - MOM Lab Manual RevisedRahman SiddiqueNo ratings yet

- Wickes PlasterDocument4 pagesWickes Plasterstewuk65No ratings yet

- Thesis Literature ReviewDocument36 pagesThesis Literature ReviewAmrit AcharyaNo ratings yet

- Fdocuments - in Insert Plate Design LugsDocument8 pagesFdocuments - in Insert Plate Design Lugsarchetype designNo ratings yet

- Astm A694 F65Document1 pageAstm A694 F65Anonymous oVRvsdWzfB100% (2)

- Cabina de Ducha CurvaDocument52 pagesCabina de Ducha CurvaEdSoloNo ratings yet

- Chapt 02Document17 pagesChapt 02Jesse McClureNo ratings yet

- sl2019 685Document3 pagessl2019 685avm4343No ratings yet

- TLE - Shielded Metal Arc Welding 10 ThirdDocument4 pagesTLE - Shielded Metal Arc Welding 10 ThirdFlorinda GagasaNo ratings yet

- Kyla Isabel E. Dioneda Bsce - 3B: Discussion QuestionsDocument4 pagesKyla Isabel E. Dioneda Bsce - 3B: Discussion QuestionsKyla IsabelNo ratings yet

- Analysis of Functionally Graded Rotating Disks With Variable ThicknessDocument27 pagesAnalysis of Functionally Graded Rotating Disks With Variable Thicknessrezza ruzuqiNo ratings yet

- KR102193034B1Document10 pagesKR102193034B1SiddharthBhasneyNo ratings yet

- Kesterite, Cu2 (ZN, Fe) SNS+, and Stannite, Cuz (Fezn) $nsa, Structurally Similar But Distinct MineralsDocument7 pagesKesterite, Cu2 (ZN, Fe) SNS+, and Stannite, Cuz (Fezn) $nsa, Structurally Similar But Distinct MineralsrohitmahaliNo ratings yet

- Astm Committee E20 On Temperature Measur-Manual On The Use of Thermocouples in Temperature Measurement PCN - 28-012093-40 (Astm Manual Series) (2003) PDFDocument312 pagesAstm Committee E20 On Temperature Measur-Manual On The Use of Thermocouples in Temperature Measurement PCN - 28-012093-40 (Astm Manual Series) (2003) PDFOscar HoyosNo ratings yet

- The Chemistry of Engineering Materials: Prepared By: Engr. N. L. EscalanteDocument25 pagesThe Chemistry of Engineering Materials: Prepared By: Engr. N. L. EscalanteStephen John A. ValenzuelaNo ratings yet

- SLMR 1918 Jan 15Document3 pagesSLMR 1918 Jan 15Russell HartillNo ratings yet

- Green Passbook Spent Solvent PDFDocument2 pagesGreen Passbook Spent Solvent PDFnikhilbhorNo ratings yet

- Gagandeep Singh Department of Mechanical Engineering Jaipur Engineering College JaipurDocument23 pagesGagandeep Singh Department of Mechanical Engineering Jaipur Engineering College Jaipurcooldudevj07No ratings yet

- Z-PCABS Material Safety Data Sheet-3Document7 pagesZ-PCABS Material Safety Data Sheet-3MosinoiuNo ratings yet