Professional Documents

Culture Documents

Calc. N2 Req

Calc. N2 Req

Uploaded by

umeshdeshpandeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calc. N2 Req

Calc. N2 Req

Uploaded by

umeshdeshpandeCopyright:

Available Formats

14:06:34 01/10/2024

Calculation Cover Sheet

Ranhill Worley KeywordPerundingRanhillWorleyCover cover

Electronic File location: 'file:///conversion/tmp/activity_task_scratch/718510862.xls'#$Calc Cover

Calculation Title: Design Calc. Report for Estimation of N2 Requirement Calc Number: PR-EC-0010X

Project Title: Detailed Design for E11 & Pipelines Rejuv. Work Proj No: 4211047

Client: Sarawak Shell Berhad Phase/CTR: PR009

Cover Sheet 10-Jan-24 Total Pages: 2 Plus Cover and TOC

(a) Calculation Objective

Rev

1. To determine the total pruge gas (nitrogen) requirement to HP, LP and two atmospheric vents.

(b) Methodology/Assumptions

1 The minimum N2 gas rate to purge the four vent stacks (LP, HP and two atmospheric vents) is calculated base on graph shown in Appendix 9 of

DEP 80.45.10.10

(c) References

1. DEP 80.40.10.10 - Pressure Relief, Emergency Depressuring, Flare and Vent Systems

2. N2 Gas Purge of E11 Vent Stacks (Conceptual Design)

(d) Conclusions

The minimum N2 gas purge rate for four vent stacks is 3Sm3/h. The N2(nitrogen) gas generator package shall efficient to produce xxSm3/h of 95-99%

nitrogen by weight.

0 29/04/03 Preliminary Calculation JMK/NAS Checker 13/02/03

REVISION REV DATE DESCRIPTION BY CHECKED CHECK DATE

Perunding Ranhill Worley Calculation Pad 1 of 6 718510862.xls - Calc Cover

14:06:34 01/10/2024

Calculation Cover Sheet

Ranhill Worley table of contents

Electronic File location: 'file:///conversion/tmp/activity_task_scratch/718510862.xls'#$Calc Cover

Calculation Title: Design Calc. Report for Estimation of N2 Requirement Calc Number: PR-EC-0010X

Project Title: Detailed Design for E11 & Pipelines Rejuv. Work Proj No:

Client: Sarawak Shell Berhad Phase/CTR: PR009

Table of Contents Page: 2 Plus Cover and TOC

(e) Table of Contents

Rev

Heading: Page No: Worksheet Name: Row Number

Cover & TOC 0 Calc Cover 2

1.0 Objectives 1 Portrait

2.0 Background 1 Portrait

3.0 Basis 1 Portrait

4.0 Calculation & Discussion 1 Portrait

5.0 Conclusion 1 Portrait

(f) Attachments

Appedix 9, DEP80.45.10.10 - Figure purge rates required for pipe flares

(g) Revision History

(g) Hold List

0

0 0 0 0 0 0

0 29/04/03 Preliminary Calculation JMK/NAS Checker 13/02/03

REVISION REV DATE DESCRIPTION BY CHECKED CHECK DATE

Perunding Ranhill Worley Calculation Pad 2 of 6 718510862.xls - Calc Cover

14:06:34 01/10/2024

Ranhill Worley

Calculation Sheet 1

portrait

Electronic File location: 'file:///conversion/tmp/activity_task_scratch/718510862.xls'#$Portrait

Calculation Title: Design Calc. Report for Estimation of N2 Requirement Calc Number: PR-EC-0010X

Project Title: Detailed Design for E11 & Pipelines Rejuv. Work

KeywordPeru 1 Proj No:

Client: Sarawak Shell Berhad Phase/CTR: PR009

Include sheet in TOC: X 10-Jan-24 Page: 1 of 2

1.0 Objective

Rev

1. To determine the total pruge gas (nitrogen) requirement to HP, LP and two atmospheric vents.

2.0 Background

The vent system on E11 complex comprises a HP, LP and two atmospheric vents (at E11P-A). Recently, these four vent stacks are purged continuosly

with hydrocarbon gas to maintain positive pressures and prevent air ingress to the system as the oxygen ingress can lead to the formation of flammable or

even explosive mixtures. As a part to reduce Global Warming Potential, the vent stact headers will be purge with Nitrogen (N2) instead of hydrocarbon

which is hazardous.

To provide contingency, the N2 gas package will be designed to produce nitrogen which is 95-99% by weight. This N2 gas will be used for purge

gas for all the vent stacks and other utilities such as blanket gas.

3.0 Basis

1. Molecular weight of nitrogen is taken as 28.

2. Actual temperature of purging is assumed as 90°C (195°F)

4.0 Calculation & discussion

Description Vent stack T-375 HP vent VS-440 LP Vent VS-425 ATM Vent

Flare stack ID (in) 14 18 6 16

*Purge rate (cm/s) 0.20 0.30 0.15 0.26

Surface area(m2 ) 0.10 0.16 0.02 0.13

Actual flowrate (Am3/hr) 0.693 1.718 0.095 1.176

Standard flowrate (Sm3/hr) 0.550 1.363 0.076 0.933

Standard flowrate (MMscfd) 0.0005 0.0012 0.0001 0.0008

**Min N2 flow (Sm3/hr) 2.5 6.0 0.5 4.0 2.92

**Design Flow (SM3/hr) 4.0 9.0 1.0 6.0

Note : * figure from Appendix 9, DEP80.45.10.10

** figure from Conceptual design report

From the calculation, the minimum N2 purge rate for four (4) vent stacks is 2.92Sm3/hr (0.0025MMscfd). However, the conceptual design report shown

the minimum N2 purge rate is to be 13SM3/hr and the N2 gas generator package is designed to produce 25Sm 3/hr og 95-99% nitrogen by weight.

In this matter, SSB to advise PRW on the design purge rate for new N2 gas generator package as the minimum N 2 purge rate calculated by PRW is only

25% of the figure written in conceptual report.

5.0 Conclusion

The minimum N2 gas purge rate for four vent stacks is 3Sm3/h. The N2(nitrogen) gas generator package shall efficient to produce xxSm3/h of 95-99%

nitrogen by weight.

Perunding Ranhill Worley Calculation Pad 3 of 6 718510862.xls - Portrait

14:06:34 01/10/2024

Rev: 0 Page: 1 of 2

Perunding Ranhill Worley Calculation Pad 4 of 6 718510862.xls - Portrait

14:06:34 01/10/2024

Ranhill Worley Calculation Sheet 1

portrait

Electronic File location: 'file:///conversion/tmp/activity_task_scratch/718510862.xls'#$Landscape

Calculation Title: Design Calc. Report for Estimation of N2 Requirement Calc Number: PR-EC-0010X

Project Title: KeywordPerunDetailed Design for E11 & Pipelines Rejuv. Work 1 Proj No:

Client: Sarawak Shell Berhad Phase/CTR: PR009

Include sheet in TOC: 10-Jan-24 Page: 2 of 2

Perunding Ranhill Worley Calculation Pad 5 of 6 718510862.xls - Landscape

14:06:34 01/10/2024 6 of 6

Ranhill Worley Attachment F 6

portrait

Electronic File location: 'file:///conversion/tmp/activity_task_scratch/718510862.xls'#$Attachment

Attachment Identifier: F Calc Number: PR-EC-0010X

Attachment Title: 1 Proj No:

Phase/CTR: PR009

Include sheet in TOC: 10-Jan-24 Page: # of #

Rev

Rev: 0 Page: # of #

Ranhill Worley Calculation Pad Portrait

Rev 1 718510862.xls - Attachment

You might also like

- ISO-14726 (Color Marking On Pipes)Document1 pageISO-14726 (Color Marking On Pipes)Johan Supriyanto90% (31)

- Relief Valve Version 1Document37 pagesRelief Valve Version 1ChakerZagrouba100% (2)

- Calculation Cover Sheet Anchor Flange ForceDocument7 pagesCalculation Cover Sheet Anchor Flange ForcebabuNo ratings yet

- N2 Purging Demand Calculation Shutdown - Flare SystemDocument54 pagesN2 Purging Demand Calculation Shutdown - Flare SystemMoch FaridNo ratings yet

- Design Calculations For Grade Beams and Columns For Auxiliary Piperack CU 1308Document101 pagesDesign Calculations For Grade Beams and Columns For Auxiliary Piperack CU 1308MSW Engineering ConsultantsNo ratings yet

- Grupel - G545 - Single PhaseDocument16 pagesGrupel - G545 - Single PhasekhaledNo ratings yet

- 7.) Cost Estimate GuidelinesDocument20 pages7.) Cost Estimate GuidelinesVPN NetworkNo ratings yet

- Cost For Pipeline DesignDocument5 pagesCost For Pipeline DesignAtty Atty100% (1)

- RPT-1000483-PL-000-00-00-010 - Rev 1Document65 pagesRPT-1000483-PL-000-00-00-010 - Rev 1process1plecoNo ratings yet

- Boiler Foundation (Unit#1 & Unit#2) - Analysis and Design of Pile Cap, Tie-Beam and PedestalDocument15 pagesBoiler Foundation (Unit#1 & Unit#2) - Analysis and Design of Pile Cap, Tie-Beam and PedestalMRITYUNJOY DUTTANo ratings yet

- Layout Development Report - REFERENCE ONLYDocument105 pagesLayout Development Report - REFERENCE ONLYmb.pipingNo ratings yet

- Standard Pile Drawing and CalulationsDocument5 pagesStandard Pile Drawing and CalulationsNitaiGauranga108No ratings yet

- ETHANOL (6.0D X 8.825 H), Rev. 0Document26 pagesETHANOL (6.0D X 8.825 H), Rev. 0Sangramkeshari BejaNo ratings yet

- BCC VFD Panel Drawing R0Document29 pagesBCC VFD Panel Drawing R0gonzaraggiNo ratings yet

- 1231 de 00 DC PCJ 001 01Document33 pages1231 de 00 DC PCJ 001 01Hamid MansouriNo ratings yet

- Document Index Date of Issue Document No. Title REV-0 REV-1 REV-2 REV-3 REV-4 REV-5 Remark SR. NO Doc. SizeDocument9 pagesDocument Index Date of Issue Document No. Title REV-0 REV-1 REV-2 REV-3 REV-4 REV-5 Remark SR. NO Doc. SizeNikhil ShahNo ratings yet

- 09223-0-DB-GQ-00001.00 0 07-2-LA-7180-0005 1 18 Quest CCS Project Design Basis Engineering PackageDocument18 pages09223-0-DB-GQ-00001.00 0 07-2-LA-7180-0005 1 18 Quest CCS Project Design Basis Engineering PackagePradeepta MohantyNo ratings yet

- 602 MC 40 09 PDFDocument463 pages602 MC 40 09 PDFthongchai_007No ratings yet

- QGDL FSP 01Rv0Document16 pagesQGDL FSP 01Rv0rupeshNo ratings yet

- Subsea Pipelines Pre Commissioning 1687771720Document19 pagesSubsea Pipelines Pre Commissioning 1687771720Doğuhan DenizgezNo ratings yet

- I-Rl-3010.00-1350-000-Wc1-001 Idc-NufDocument12 pagesI-Rl-3010.00-1350-000-Wc1-001 Idc-NufFabio Henrique Oliveira RochaNo ratings yet

- Spreader Beam Calculation ReportDocument15 pagesSpreader Beam Calculation ReportGurhan Atalay100% (1)

- APQP Responsibility MatrixDocument3 pagesAPQP Responsibility MatrixSuraj RawatNo ratings yet

- Mlng-Final Documentation Progress CompilationDocument104 pagesMlng-Final Documentation Progress Compilationcheehoong82100% (1)

- PTS-20WM319 - Appendix XVIII 115KV, 13.8KV Cable Installation (Interconnection)Document18 pagesPTS-20WM319 - Appendix XVIII 115KV, 13.8KV Cable Installation (Interconnection)Durgaprasad RyaliNo ratings yet

- Title: Docid: Revision: Sheets: Draft By: Project: Description: - General Type: Doc. ClassificationDocument2 pagesTitle: Docid: Revision: Sheets: Draft By: Project: Description: - General Type: Doc. ClassificationMaria MarcanoNo ratings yet

- Cmed-12htbt-M-Cal-00-R02-20220114Document85 pagesCmed-12htbt-M-Cal-00-R02-20220114khenpin977No ratings yet

- Fatigue Design CalculationDocument3 pagesFatigue Design CalculationinnovativekarthiNo ratings yet

- Instrument 2Document5 pagesInstrument 2Elias EliasNo ratings yet

- Bc-Sua-Chp-Ele-Reg-Doc-01 (Document Register) 2Document2 pagesBc-Sua-Chp-Ele-Reg-Doc-01 (Document Register) 2gegebenercoy1No ratings yet

- Meenakshi College of Engineering Chennai - 78: Lesson Plan Grid and Cloud ComputingDocument6 pagesMeenakshi College of Engineering Chennai - 78: Lesson Plan Grid and Cloud ComputingPurushothaman MannanNo ratings yet

- PDF Capacitor Sizing Calculation 5015 LT 00 El 03 CA 0003 Rev 00 CompressDocument4 pagesPDF Capacitor Sizing Calculation 5015 LT 00 El 03 CA 0003 Rev 00 CompressrsdgdhNo ratings yet

- Design Code - Asme Sec Viii Div 1 Edition 2015 2. Software - P V Elite Version - 2016Document2 pagesDesign Code - Asme Sec Viii Div 1 Edition 2015 2. Software - P V Elite Version - 2016deepakNo ratings yet

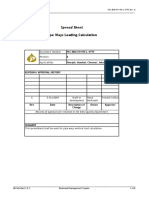

- Pipe Ways Loading Calculation: Spread SheetDocument6 pagesPipe Ways Loading Calculation: Spread Sheetvino2winNo ratings yet

- DBC - MRR - CR - 6P - 0037 v04.0.b PDFDocument336 pagesDBC - MRR - CR - 6P - 0037 v04.0.b PDFPrincess ToumaNo ratings yet

- Compal La-6901p - P5weo PDFDocument59 pagesCompal La-6901p - P5weo PDFAlexandre PatrocinioNo ratings yet

- Mechanical Design Calculation (Static) For HSD Storage Tanks (Tank Size: 24.0 M Dia X 13.50 M HT)Document20 pagesMechanical Design Calculation (Static) For HSD Storage Tanks (Tank Size: 24.0 M Dia X 13.50 M HT)Sangramkeshari Beja100% (1)

- Bachtera-Cqv-Msra - Dh3 Steam Rams Start-Up Draft U081 U081 U091 RGC 08sep2023Document25 pagesBachtera-Cqv-Msra - Dh3 Steam Rams Start-Up Draft U081 U081 U091 RGC 08sep2023Borislav VulicNo ratings yet

- Total Manpower Costs: 1,000.00 2,000.00Document3 pagesTotal Manpower Costs: 1,000.00 2,000.00reninbabaskiNo ratings yet

- Acer Chromebook C730 Quanta ZHQ v1.0 PDFDocument48 pagesAcer Chromebook C730 Quanta ZHQ v1.0 PDFdavid pintoNo ratings yet

- PCTL - NDE - RT-1 Rev.6Document19 pagesPCTL - NDE - RT-1 Rev.6Goutam Kumar Deb100% (1)

- EBMS Storage Tank - Rev.0Document20 pagesEBMS Storage Tank - Rev.0pavan100% (1)

- Compal Confidential: P5WE0 M/B Schematics DocumentDocument59 pagesCompal Confidential: P5WE0 M/B Schematics DocumentMihohohoNo ratings yet

- PRI-21 Rev B-SERVICE ENGAGEMENT PROCEDUREDocument13 pagesPRI-21 Rev B-SERVICE ENGAGEMENT PROCEDUREFernando Da RosNo ratings yet

- Compal La-6801p r1.0 SchematicsDocument62 pagesCompal La-6801p r1.0 Schematicssetiawan fendiNo ratings yet

- SVDN-CPP-M-0006-M12-0002-Rev.07-PSV CalculationDocument38 pagesSVDN-CPP-M-0006-M12-0002-Rev.07-PSV CalculationVu TranNo ratings yet

- 4124 Aa CS 21710V020S01Document24 pages4124 Aa CS 21710V020S01amitNo ratings yet

- Set-Up Observation Analysis SheetDocument23 pagesSet-Up Observation Analysis SheetUsman TowoliuNo ratings yet

- WP2 020.045.010 TD 002 E - Dishb OgchinaDocument57 pagesWP2 020.045.010 TD 002 E - Dishb Ogchinamuni1No ratings yet

- Lighting CalcDocument28 pagesLighting CalcNagoor MeeranNo ratings yet

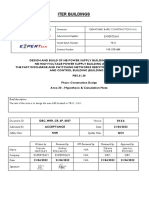

- Estimate ReportDocument4 pagesEstimate ReportJE NAGOD TOWNNo ratings yet

- 005 - Quality Management Plan - Rev03Document75 pages005 - Quality Management Plan - Rev03Kiran TejaNo ratings yet

- Demineralized Water Unit Foundation DesignDocument31 pagesDemineralized Water Unit Foundation Designisaacjoe77No ratings yet

- Filling Shed Principle DesignDocument83 pagesFilling Shed Principle Designcharleshutabara951No ratings yet

- CH BB SLD El 04 04Document2 pagesCH BB SLD El 04 04Ahmed MarzokNo ratings yet

- Manual 0583-PP-7130 A 7132Document261 pagesManual 0583-PP-7130 A 7132gabrielgonzaloverga2No ratings yet

- Wiring Diagram of VFD Panel - Jo.23-233 - FgenDocument6 pagesWiring Diagram of VFD Panel - Jo.23-233 - FgenMichael Dela CruzNo ratings yet

- Cambio 1Document1 pageCambio 1JESUS CRISTOBAL RIVERANo ratings yet

- Isogeometric Analysis: Toward Integration of CAD and FEAFrom EverandIsogeometric Analysis: Toward Integration of CAD and FEANo ratings yet

- Regulador EQA-722Document4 pagesRegulador EQA-722Ronan CristhiamNo ratings yet

- Chapter8-Campuran Pada Tingkat Molekuler - Part 1Document58 pagesChapter8-Campuran Pada Tingkat Molekuler - Part 1Uswatun KhasanahNo ratings yet

- K87170 Technical Datasheet PDFDocument1 pageK87170 Technical Datasheet PDFmoh_ichwanuddinNo ratings yet

- Methane Vs Propane C11!2!09Document11 pagesMethane Vs Propane C11!2!09jubatus.libroNo ratings yet

- GC Feature-4Document11 pagesGC Feature-4Lysa GINo ratings yet

- Iraq Refinery 2Document19 pagesIraq Refinery 2Anonymous SEt10M8sNo ratings yet

- Crude Oil TerminalDocument7 pagesCrude Oil TerminalFitri0% (1)

- Design of Sour Water Stripping System: February 2009Document23 pagesDesign of Sour Water Stripping System: February 2009kishna009100% (2)

- Petrochemical Engineering Petrochemical Engineering: 3 Years Diploma/6 Years Dual Degree inDocument2 pagesPetrochemical Engineering Petrochemical Engineering: 3 Years Diploma/6 Years Dual Degree inpavan_1988No ratings yet

- 2013 Capline Crude Oil Assay ReportDocument4 pages2013 Capline Crude Oil Assay Reportkwing175No ratings yet

- Disttilation FINAL1Document68 pagesDisttilation FINAL1sachin kumarNo ratings yet

- A Novel and Green Route For Synthesis of Pyrazoline Derivatives in An Aqueous Media by Using Ionic Liquid at Reflux ConditionDocument4 pagesA Novel and Green Route For Synthesis of Pyrazoline Derivatives in An Aqueous Media by Using Ionic Liquid at Reflux ConditioniaetsdiaetsdNo ratings yet

- XIGA™ Dead-End Ultrafiltration in Water TreatmentDocument32 pagesXIGA™ Dead-End Ultrafiltration in Water TreatmentcysautsNo ratings yet

- History of Feedwater TreatmentDocument8 pagesHistory of Feedwater TreatmentJohnnyNo ratings yet

- Everything You Want To Know About RecrystallizationDocument3 pagesEverything You Want To Know About Recrystallizationrana_mohamed558100% (2)

- UhdeDocument16 pagesUhdeCami CorderoNo ratings yet

- Oisd STD 109Document38 pagesOisd STD 109Swaraj PandaNo ratings yet

- Activity Sheet-25 (Separation of Mixtures)Document4 pagesActivity Sheet-25 (Separation of Mixtures)Nkemzi NzetengenleNo ratings yet

- Lava Heat Italia - Illume Outdoor Light Post - Owners ManualDocument13 pagesLava Heat Italia - Illume Outdoor Light Post - Owners ManuallavaheatitaliaNo ratings yet

- Solaf Chemistry SPM 2014: Chapter 1 Form 5: Rate of Reaction Faktor Kesan Suhu 1Document2 pagesSolaf Chemistry SPM 2014: Chapter 1 Form 5: Rate of Reaction Faktor Kesan Suhu 1Mohd Azman Bin Mohd NorNo ratings yet

- Chapter 9 and 10Document22 pagesChapter 9 and 10Paolo GochingcoNo ratings yet

- 01 H Oil Technology Description - VCMStudy PDFDocument27 pages01 H Oil Technology Description - VCMStudy PDFpietroNo ratings yet

- Assignment: A A A A A ADocument2 pagesAssignment: A A A A A ADev rajNo ratings yet

- An Aspen Plus® Tool For Simulation of PDFDocument16 pagesAn Aspen Plus® Tool For Simulation of PDFMahmud Arman KibriaNo ratings yet

- Sulfur Removal Methods: A. Hidalgo-Vivas and B. H. CooperDocument13 pagesSulfur Removal Methods: A. Hidalgo-Vivas and B. H. Coopergharibi.ali98486No ratings yet

- 1 s2.0 S2214157X1830090X MainDocument7 pages1 s2.0 S2214157X1830090X MainNatalino TavaresNo ratings yet

- RecrystallizationDocument5 pagesRecrystallizationHannako NgohayonNo ratings yet

- CHPR5501 Adv. Reaction Eng. Part 1Document40 pagesCHPR5501 Adv. Reaction Eng. Part 1Elena TodorovskaNo ratings yet

- PFD - Nitrogen Plant UTL Plaju (Cold Box)Document1 pagePFD - Nitrogen Plant UTL Plaju (Cold Box)Julia Dwi LestariNo ratings yet