Professional Documents

Culture Documents

PH-85 Set Up - TDS 6S

PH-85 Set Up - TDS 6S

Uploaded by

Jim SharpOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PH-85 Set Up - TDS 6S

PH-85 Set Up - TDS 6S

Uploaded by

Jim SharpCopyright:

Available Formats

Chapter 3

Maintenance

Adjustment procedures

Adjusting the torque wrench

Use the following procedure to adjust the pipehandler torque

wrench:

e The pipehandler torque wrench is properly adjusted and tested in the

factory before it is shipped. Perform the adjustment procedure after

performing maintenance on the torque wrench or if the torque

wrench does not function correctly.

1. Connect a pup joint or joint of drill pipe to the saver sub and

makeup hand tight. Be sure to use the correct thread

compound when making up.

z When adjusting torque wrench manifold needle valves, loosen the

locknut around the valve stem and use a 5/32 in. hex wrench to

adjust the valve. After obtaining desired setting tighten locknut

around valve stem.

TDS-6S Maintenance and Troubleshooting 4-39

June 23, 1999

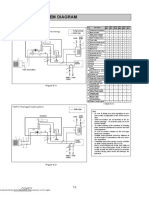

2. With the HPU off, screw the RECYCLE, CLAMP, and

TORQUE sequence valves on the torque wrench manifold

fully in (Figure 4-14).

3. Fully back out the Pressure Reducing Valve (PRV), then screw

in one turn.

4. Turn the LIFT/LOWER flow control valve fully in, and then

back it out three turns.

5. Turn on the HPU.

6. If the torque cylinders are in their full clockwise position, set

the Make/Break valve to MAKE. If they are in their full

counterclockwise position, set Make/Break valve to BREAK.

Note that torque cylinders should not move if the recycle

sequence valve is fully in.

7. Slowly back out the RECYCLE sequence valve until torque

cylinders just start to move, then screw out an additional

full turn.

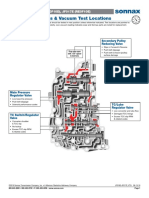

Make/Break

Valve

Recycle Clamp Torque

Sequence Sequence Sequence

Valve Valve Valve

Torque Wrench

Manifold

BREAK MAKE

Hydraulic

Pressure

Return

RECYCLE CLAMP TORQUE

PRV 50 60

40

70

1000 1500

30

Hydraulic

80

Pressure

LIFT LOWER

20

500 2000

Inlet

90

Lift/Lower

10

0 2500

10

Flow Control PSI

0

0

Valve

Ft.Lbs. x1000

Torque Gauge

0 - 2500 PSI

Figure 4-14. Torque wrench control manifold

4-40 TDS-6S Maintenance and Troubleshooting

8. Move the Make/Break valve to BREAK. Set the PRV

to 750 psi.

9. Switch the lever between MAKE and BREAK to adjust the

RECYCLE sequence valve until full rotation in each direction

takes six to eight seconds. Tighten the locknut around the

RECYCLE sequence valve adjustment screw.

10. Set the Make/Break valve to MAKE.

11. Depress and hold the torque wrench operating button on the

VDC. The torque wrench should lift and the clamp jaws

should remain retracted.

12. Slowly back out the CLAMP sequence valve until the clamp

jaws just begin to clamp onto the tool joint. Screw out an

additional half turn. Lock the CLAMP sequence valve

adjustment screw in position by tightening the locknut.

13. Back out the TORQUE sequence valve until the torque

cylinders just begin to stroke, then back out an additional half

turn. Tighten the locknut around the TORQUE sequence

valve adjustment screw.

14. Release the torque wrench operating button on the VDC.

The torque wrench should start to unclamp and drop, then

the torque cylinders should recycle.

15. If the torque cylinders recycle before the clamp cylinders

retract, screw in the RECYCLE sequence valve until the

torque cylinders do not move before clamp cylinders have

fully retracted. Tighten the RECYCLE sequence valve

adjustment screw locknut.

16. Cycle the torque wrench as many times as required to makeup

the connection.

17. Set the Make/Break valve to BREAK.

18. Verify that the torque wrench correctly breaks out the drill

pipe from the saver sub, without breaking out the saver sub or

lower IBOP.

19. The torque wrench is ready for operation.

TDS-6S Maintenance and Troubleshooting 4-41

You might also like

- Jf016e Jf017e PDFDocument4 pagesJf016e Jf017e PDFanzor86% (7)

- Jf016e Jf017e PDFDocument4 pagesJf016e Jf017e PDFSAMAD89% (9)

- Project Report Circular SawDocument31 pagesProject Report Circular SawPrince Kumar54% (28)

- HVAC Design CheckList (MEP Group Rev.0)Document16 pagesHVAC Design CheckList (MEP Group Rev.0)said amin100% (1)

- Suzuki APV Service ManualDocument7 pagesSuzuki APV Service ManualdhgdfgNo ratings yet

- JF016E-JF017E Vacuum Manual Valve BodyDocument4 pagesJF016E-JF017E Vacuum Manual Valve Bodyak_adam100% (2)

- Allis-Chalmers Model D-10 D-10series3 D-12 D-12series3 Shop SecDocument37 pagesAllis-Chalmers Model D-10 D-10series3 D-12 D-12series3 Shop SecDmitry100% (1)

- Cat Cb434c 534c 634c ST MatDocument43 pagesCat Cb434c 534c 634c ST MatMahmmod Al-Qawasmeh100% (2)

- Allison 1000-2000-3000 VTG PDFDocument4 pagesAllison 1000-2000-3000 VTG PDFDaniel villalobos garcia100% (1)

- Wood Magazine 222Document80 pagesWood Magazine 222aromero888100% (3)

- Valves: 19 L / Min Max Flow RateDocument1 pageValves: 19 L / Min Max Flow RateEdukondalu PentapatiNo ratings yet

- Chapt 6 RotationDocument8 pagesChapt 6 RotationManuelNo ratings yet

- 464192534 вакуум тест для JF016 017 PDFDocument4 pages464192534 вакуум тест для JF016 017 PDF89539306889No ratings yet

- как жить и не работать джэф016 PDFDocument4 pagesкак жить и не работать джэф016 PDFМихаил БолотинNo ratings yet

- вакуум тест для JF016-017 PDFDocument4 pagesвакуум тест для JF016-017 PDFМихаил Болотин100% (1)

- Critical Wear Areas & Vacuum Test Locations: JF016E Lower Valve BodyDocument4 pagesCritical Wear Areas & Vacuum Test Locations: JF016E Lower Valve BodySAMADNo ratings yet

- Chapter 10 Rev 3 Rod ChangingDocument13 pagesChapter 10 Rev 3 Rod ChangingAnonymous 340A7vnwV1No ratings yet

- F10 & F50 Flow SwitchesDocument12 pagesF10 & F50 Flow SwitchesarmadityaNo ratings yet

- Pressure Regulator Boost Sleeve: Jatco/Nissan RE4F02A, RL4F02ADocument1 pagePressure Regulator Boost Sleeve: Jatco/Nissan RE4F02A, RL4F02Aflash_24014910No ratings yet

- Hydraulic Force Control: Ser ManualDocument18 pagesHydraulic Force Control: Ser ManualDinh SangNo ratings yet

- Catalogue Models F10 and F50 Flow SwitchesDocument12 pagesCatalogue Models F10 and F50 Flow SwitchesNUR AFIFAHNo ratings yet

- Technical Training ManualDocument8 pagesTechnical Training ManualGabo Luna MorenoNo ratings yet

- SERIES 3000: Angle Surge Relief ValveDocument6 pagesSERIES 3000: Angle Surge Relief ValveMd Aamir AnsariNo ratings yet

- Présentation Vérin SC2Document55 pagesPrésentation Vérin SC2Vladimir SimeunovicNo ratings yet

- Symbol ListDocument4 pagesSymbol ListMa JunNo ratings yet

- Présentation Vérin SC2Document55 pagesPrésentation Vérin SC2Chinax N. AlmainNo ratings yet

- Hydraulic Pumps: Service Training Manual ECM 720Document10 pagesHydraulic Pumps: Service Training Manual ECM 720victor laraNo ratings yet

- Oversized Lockup Control Valve Kit: Jatco/Nissan JF011E (RE0F10A)Document1 pageOversized Lockup Control Valve Kit: Jatco/Nissan JF011E (RE0F10A)SAMADNo ratings yet

- Oil Pump Type T GEAR SIZES 2-3-4-5Document2 pagesOil Pump Type T GEAR SIZES 2-3-4-5Eden Ben100% (1)

- Carregadeira Hyundai 740 - 756Document115 pagesCarregadeira Hyundai 740 - 756Lucas Vieira100% (6)

- REG01 - Principles-24Document15 pagesREG01 - Principles-24Aatish ChandrawarNo ratings yet

- Ch9Rotation CircuitDocument8 pagesCh9Rotation CircuitManuelNo ratings yet

- Oversized Lockup Control Valve Kit: JF015E (REOF11A)Document1 pageOversized Lockup Control Valve Kit: JF015E (REOF11A)เฮีย โหงวNo ratings yet

- 2004 SR Johnson 2 Stroke 9.9, 15, 25, 30 HPDocument17 pages2004 SR Johnson 2 Stroke 9.9, 15, 25, 30 HPPaco Caballero SaorinNo ratings yet

- R-6 Relay ValveDocument6 pagesR-6 Relay ValveNelsonParedesNo ratings yet

- 740 Artiiculated Truck Power TrainDocument37 pages740 Artiiculated Truck Power TrainFabrizio Jesús100% (1)

- Telescopic Handlers: Service Training MalagaDocument23 pagesTelescopic Handlers: Service Training Malagaarturo laosNo ratings yet

- Suntec TA3 Pump SpecificationDocument2 pagesSuntec TA3 Pump Specificationsayda MaowiaNo ratings yet

- Model 25: Installation Instructions Parts List Service InstructionsDocument4 pagesModel 25: Installation Instructions Parts List Service InstructionsDavid BaylissNo ratings yet

- DSC Part 2Document15 pagesDSC Part 2Nguyễn Hoàng LongNo ratings yet

- Bendix - Master-Vac - Power Brake Service Manual - OCR - 8 PagesDocument8 pagesBendix - Master-Vac - Power Brake Service Manual - OCR - 8 Pagesgreg titanNo ratings yet

- Timed DrainDocument1 pageTimed Drainherysyam19800% (1)

- Spreader Training Eh5u Amp Eh170u PDF FreeDocument43 pagesSpreader Training Eh5u Amp Eh170u PDF FreeMoez KarouiNo ratings yet

- Centralised-Lubrication-Systems Catalogue PDFDocument5 pagesCentralised-Lubrication-Systems Catalogue PDFPRECITECNo ratings yet

- Super HydraulicDocument17 pagesSuper HydraulicDaniel Castillo Peña100% (2)

- Operation Slew A.R.V. and Anti-Cavitation Operation: Section E - HydraulicsDocument20 pagesOperation Slew A.R.V. and Anti-Cavitation Operation: Section E - HydraulicsMarcelo Elói De Amorim SilvaNo ratings yet

- Cylinder Head Assy (1Gr Fe) : ComponentsDocument1 pageCylinder Head Assy (1Gr Fe) : ComponentsIslam AttiaNo ratings yet

- General Service. Bulletin RTAA-SB - 4. Lit TRANE - SL Ide Valve Operat Ion and Troubleshoot I Ng. SuDocument6 pagesGeneral Service. Bulletin RTAA-SB - 4. Lit TRANE - SL Ide Valve Operat Ion and Troubleshoot I Ng. Suahmed gamalNo ratings yet

- Chapt 6 AntijamDocument6 pagesChapt 6 AntijamManuelNo ratings yet

- 6L45 6L90 VacTestDocument4 pages6L45 6L90 VacTestJehovana100% (1)

- Boost Valve Kit: Hyundai/Kia A4CF1, A4CF2Document1 pageBoost Valve Kit: Hyundai/Kia A4CF1, A4CF2ossoski100% (1)

- 20K inDocument1 page20K inossoskiNo ratings yet

- S250 Repair Kit Layout 5607146Document1 pageS250 Repair Kit Layout 5607146Cecil Eduardo Angulo MarquezNo ratings yet

- CT Hydraulic Syetem Schematics For PP and CCDocument12 pagesCT Hydraulic Syetem Schematics For PP and CCRolly Hillz SochimNo ratings yet

- Engine Assy LBCDocument53 pagesEngine Assy LBCSandeep ChoudharyNo ratings yet

- Tekton ManualDocument4 pagesTekton ManualJosueNo ratings yet

- Kpto 176 - GB - LQDocument4 pagesKpto 176 - GB - LQBenjamin MurphyNo ratings yet

- SSXXXXDocument20 pagesSSXXXXAnıl YavuzNo ratings yet

- Valvula DireccionDocument8 pagesValvula DireccionVictor Manuel Lozada ObessoNo ratings yet

- Boom & BucketDocument43 pagesBoom & BucketjackNo ratings yet

- Áp TH y L C Trên Main Ngáng DRF450Document1 pageÁp TH y L C Trên Main Ngáng DRF450Nguyễn Văn HùngNo ratings yet

- TF-80/81SC, TF-60SN: OmplaintDocument1 pageTF-80/81SC, TF-60SN: Omplaintramon baronaNo ratings yet

- TB-201Brake Perf TestingDocument4 pagesTB-201Brake Perf TestingJim SharpNo ratings yet

- BX Troubleshooting Flow ChartDocument6 pagesBX Troubleshooting Flow ChartJim SharpNo ratings yet

- NOV TrainingDocument1 pageNOV TrainingJim SharpNo ratings yet

- BX Test Spec TSEL0066Document12 pagesBX Test Spec TSEL0066Jim SharpNo ratings yet

- Enhanced Fire Protection ArrangementsDocument115 pagesEnhanced Fire Protection ArrangementsJim Sharp100% (1)

- Safety Case TrainingDocument2 pagesSafety Case TrainingJim SharpNo ratings yet

- Oilwell E3000 CoDocument125 pagesOilwell E3000 CoJim SharpNo ratings yet

- ISAGCA Quick Start Guide FINALDocument16 pagesISAGCA Quick Start Guide FINALJim SharpNo ratings yet

- Draft ORA Guideline - Sept 23Document21 pagesDraft ORA Guideline - Sept 23Jim Sharp100% (1)

- PB DSC 008Document4 pagesPB DSC 008Jim SharpNo ratings yet

- PB-DDM-032 Thrust Bearing Clearence.Document8 pagesPB-DDM-032 Thrust Bearing Clearence.Jim SharpNo ratings yet

- UAE FIRE CODE - ENG - SEPTEMBER - 2018-SprinklersDocument1 pageUAE FIRE CODE - ENG - SEPTEMBER - 2018-SprinklersmhmdjdgmailcomNo ratings yet

- Hartner Reiben 2015 enDocument60 pagesHartner Reiben 2015 enpashaNo ratings yet

- Torque Converter - Transmission PDFDocument80 pagesTorque Converter - Transmission PDFMax K.100% (1)

- United States Patent (10) Patent No.: US 7.562,614 B2: Polston (45) Date of Patent: Jul. 21, 2009Document22 pagesUnited States Patent (10) Patent No.: US 7.562,614 B2: Polston (45) Date of Patent: Jul. 21, 2009Слэйтер Строительная компанияNo ratings yet

- 2016-Catalog-Cover-Fire Arms-Small-FileDocument32 pages2016-Catalog-Cover-Fire Arms-Small-FileCipriano M RogerioNo ratings yet

- Water System Diagram 8: (Split Model System) (Split Model System For Heating and Cooling)Document1 pageWater System Diagram 8: (Split Model System) (Split Model System For Heating and Cooling)DarioDHNo ratings yet

- Technical Data Sheet Unsafe Firearm-Ammunition CombinationsDocument13 pagesTechnical Data Sheet Unsafe Firearm-Ammunition CombinationsjacobbohlandNo ratings yet

- Cursore PipingDocument3 pagesCursore PipinggerenciaNo ratings yet

- All Piping Drawings Spec SheetsDocument18 pagesAll Piping Drawings Spec Sheetsc.reid100% (1)

- Machining Process Used To Produce Various ShapesDocument33 pagesMachining Process Used To Produce Various ShapesMuhammad ArifNo ratings yet

- List of Machineries With ValueDocument8 pagesList of Machineries With ValueumeshNo ratings yet

- Titus Push Latch Catalogue Pages ENDocument2 pagesTitus Push Latch Catalogue Pages ENMATIAS FERNANDO GARABELLONo ratings yet

- Thread Data ChartsDocument4 pagesThread Data Chartsசுஜித் குமார்No ratings yet

- The Age of Flintlock - Firearms For D&D 5e - GM BinderDocument20 pagesThe Age of Flintlock - Firearms For D&D 5e - GM BinderChritoadTheToad 12No ratings yet

- On Single Point Tool Geometry: Indian Institute of Technology DelhiDocument16 pagesOn Single Point Tool Geometry: Indian Institute of Technology DelhiDhananjay PatwariNo ratings yet

- DESIGN OF MANHOLE COVER-Layout Trial 2Document1 pageDESIGN OF MANHOLE COVER-Layout Trial 2ecyandocNo ratings yet

- Blades BrochureDocument6 pagesBlades BrochureyashraoNo ratings yet

- The Thermostatic Expansion ValveDocument2 pagesThe Thermostatic Expansion ValveMark Anthony Sibayan100% (1)

- UVPX 507AGT-14 - Parts - 2003Document60 pagesUVPX 507AGT-14 - Parts - 2003Centrifugal SeparatorNo ratings yet

- Electronics Products Assembly (EPAS) : Presented By: Alex D. Bedaña TLE TeacherDocument24 pagesElectronics Products Assembly (EPAS) : Presented By: Alex D. Bedaña TLE TeacherAxelJohnBedanaNo ratings yet

- Hi EveryoneDocument5 pagesHi EveryoneHeet ShahNo ratings yet

- Eclipse Phase 2 - Actions and CombatDocument39 pagesEclipse Phase 2 - Actions and CombatJaviergvNo ratings yet

- Price List OventropDocument3 pagesPrice List OventropPattamon KhempilaNo ratings yet

- Maj IA202 MODULE MidtermDocument54 pagesMaj IA202 MODULE Midtermbalanemaryjoy4No ratings yet

- Fdadbyyoung BDocument187 pagesFdadbyyoung Baasdsfg asdsadasNo ratings yet

- Hydraulic Hidraulica HidrauliqueDocument44 pagesHydraulic Hidraulica HidrauliqueAlex ValleNo ratings yet