Professional Documents

Culture Documents

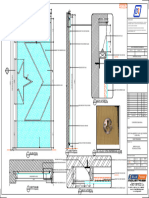

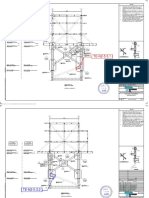

Produced by An Autodesk Educational Product: Detail of Drainage Box

Produced by An Autodesk Educational Product: Detail of Drainage Box

Uploaded by

shashi rajhansCopyright:

Available Formats

You might also like

- Typical Slab On Metal Deck Detail: Deck Parallel To Beam Deck Perpendicular To BeamDocument1 pageTypical Slab On Metal Deck Detail: Deck Parallel To Beam Deck Perpendicular To BeamAlbert GalagNo ratings yet

- Clarifier Tank Structural PDFDocument3 pagesClarifier Tank Structural PDFBenderlip CortezNo ratings yet

- Epson 3800 3880 SMDocument306 pagesEpson 3800 3880 SMIon IonutNo ratings yet

- ZxcasDocument1 pageZxcasbillNo ratings yet

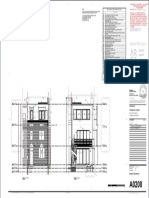

- A0200 - Exterior ElevationsDocument1 pageA0200 - Exterior ElevationsMuhammad AbuBakarNo ratings yet

- Aacm Standard DrawingsDocument7 pagesAacm Standard Drawingshussein247No ratings yet

- Bri Amcd SW FC SD 1001 00Document1 pageBri Amcd SW FC SD 1001 00mahadheer mohammedNo ratings yet

- Ci RD 07 11 001Document1 pageCi RD 07 11 001naveenNo ratings yet

- Elevation: NotesDocument1 pageElevation: NotesErika Faye GutierrezNo ratings yet

- Sample Structural DrawingDocument1 pageSample Structural DrawingCherish Taguinod Aliguyon100% (1)

- Grating Specifications.: 40 THK Grating 40 THK GratingDocument1 pageGrating Specifications.: 40 THK Grating 40 THK GratingsivagnanamNo ratings yet

- A519 - STAFF PANTRY ENLARGED PLANS & ELEVATIONSDocument1 pageA519 - STAFF PANTRY ENLARGED PLANS & ELEVATIONSkuromiislay00No ratings yet

- Spot Detail Elevation Spot Detailsection Detail of Ceiling AirventDocument1 pageSpot Detail Elevation Spot Detailsection Detail of Ceiling Airventglen raymundoNo ratings yet

- Reference Drawings: Saudi Arabian Oil CompanyDocument1 pageReference Drawings: Saudi Arabian Oil CompanyJohn Philip BuntalesNo ratings yet

- LOS1-A-2204-OPS-PH1A - Rev 11 - Plan - Builders Work - Level 02Document1 pageLOS1-A-2204-OPS-PH1A - Rev 11 - Plan - Builders Work - Level 02Tosin FamuyiwaNo ratings yet

- Grade Beam Dowel BarDocument1 pageGrade Beam Dowel BarSehna SerajNo ratings yet

- ING10374D2X741 REINF'TDETAIL - SHEET 2 OF 2-Rev - C-741Document1 pageING10374D2X741 REINF'TDETAIL - SHEET 2 OF 2-Rev - C-741mhazarath murariNo ratings yet

- See Detail 1: NotesDocument1 pageSee Detail 1: NotesYazan MohammadNo ratings yet

- Ajv DPW 10 525 CL DWG 0695 03 R03Document1 pageAjv DPW 10 525 CL DWG 0695 03 R03sivagnanamNo ratings yet

- 05-DETAILS OF SOFFIT SLAB IN SUPER STRUCTURE-ModelDocument1 page05-DETAILS OF SOFFIT SLAB IN SUPER STRUCTURE-ModelManvendra Singh RaghuwanshiNo ratings yet

- Se 014 PDFDocument1 pageSe 014 PDFAmjad AlibrahimNo ratings yet

- PID Booklet As Built Without PFD Rev - Part75Document1 pagePID Booklet As Built Without PFD Rev - Part75megarezky235No ratings yet

- Issued For Construction: Detail Detail Section SectionDocument1 pageIssued For Construction: Detail Detail Section SectionFahadNo ratings yet

- 21A. GA & Structural Details of Stilling BasinDocument1 page21A. GA & Structural Details of Stilling BasinManoranjan SethiNo ratings yet

- Section 1 - 1 Section 2 - 2 Section 3 - 3: Revision No. byDocument1 pageSection 1 - 1 Section 2 - 2 Section 3 - 3: Revision No. byPaschal MazikuNo ratings yet

- STR 200Document1 pageSTR 200nuwanNo ratings yet

- Electrical Resistance Soil Corrosion Probe Test StationDocument1 pageElectrical Resistance Soil Corrosion Probe Test StationmohsenNo ratings yet

- Column ND Footing DetailsDocument1 pageColumn ND Footing Details025Karthik ReddyNo ratings yet

- Retaning WallDocument1 pageRetaning Walldanish javedNo ratings yet

- Saudi Arabian Oil Company: NotesDocument1 pageSaudi Arabian Oil Company: NotesJohn Philip BuntalesNo ratings yet

- Saudi Arabian Oil Company: NotesDocument1 pageSaudi Arabian Oil Company: NotesJohn Philip BuntalesNo ratings yet

- Bsi STD DWG El 001 Electrical Standard Installation 2of6Document1 pageBsi STD DWG El 001 Electrical Standard Installation 2of6dharuNo ratings yet

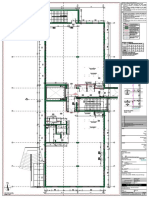

- Plumbing 01Document1 pagePlumbing 01schneidereit realtyNo ratings yet

- Detail 1: C SectionDocument1 pageDetail 1: C SectionHimal Nilanka RathnayakaNo ratings yet

- Notes:: Slope ToDocument1 pageNotes:: Slope ToThomas JohnNo ratings yet

- Piping Plan - Foam LateralDocument1 pagePiping Plan - Foam LateralGurumoorthy RajavijayanNo ratings yet

- Ramboll With Mark-Up1Document7 pagesRamboll With Mark-Up1gusyahri001No ratings yet

- Updated RCP All UntsDocument18 pagesUpdated RCP All Untsnikkoelbao96No ratings yet

- Type 1: in Various Areas of Greater Doha Phase - 8Document1 pageType 1: in Various Areas of Greater Doha Phase - 8abdul jackilNo ratings yet

- J414221002PADocument1 pageJ414221002PASehna SerajNo ratings yet

- 2+2 Jodi PlanDocument1 page2+2 Jodi Planshashank waghmareNo ratings yet

- Section-A Section-A: Saudi Arabian Oil CompanyDocument1 pageSection-A Section-A: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- Unit 5 Lighting LayoutDocument1 pageUnit 5 Lighting Layoutnikkoelbao96No ratings yet

- Capping and Sub-Base Thickness Design: Load Category 2Document1 pageCapping and Sub-Base Thickness Design: Load Category 2issam.qamhiaNo ratings yet

- Unit Weight KG 0.2 2: RevisionsDocument1 pageUnit Weight KG 0.2 2: RevisionsANIL PLAMOOTTILNo ratings yet

- Guardwall Block Perspective: Billboard SpecificationDocument1 pageGuardwall Block Perspective: Billboard SpecificationArmand Mikhail TempladoNo ratings yet

- First Floor Level Beam Details Part-2 (Sheet-1 of 2)Document1 pageFirst Floor Level Beam Details Part-2 (Sheet-1 of 2)Sumit LathwalNo ratings yet

- P203 Sie DWG 008 Arc 500002Document1 pageP203 Sie DWG 008 Arc 500002viswanathanNo ratings yet

- A-207-Residence Entrance Porch DetailsDocument1 pageA-207-Residence Entrance Porch DetailsEmmanuel InfanteNo ratings yet

- R03 C07B01 IKP 01 GF SDW AR 50003 - Comments12Document1 pageR03 C07B01 IKP 01 GF SDW AR 50003 - Comments12Eleazar SacloloNo ratings yet

- Sa-Ami-000-Hdai-370105 - 1 - Standard Details For Paving and JointsDocument1 pageSa-Ami-000-Hdai-370105 - 1 - Standard Details For Paving and Jointsmohamed esmailNo ratings yet

- Notes:: Plan View: Guard House / Toilet Section L-L: Guard House / ToiletDocument1 pageNotes:: Plan View: Guard House / Toilet Section L-L: Guard House / ToiletSolidr ArchitectsNo ratings yet

- Ati Pier 3 - SD (PDB) - Proposed Man CageDocument1 pageAti Pier 3 - SD (PDB) - Proposed Man CageMark L. AlmencionNo ratings yet

- WW Linear Veneered Planks Master SheetDocument2 pagesWW Linear Veneered Planks Master SheetChiara NaderNo ratings yet

- Ta-249813-023 - C - P&id - Caustic Injection PacakgeDocument1 pageTa-249813-023 - C - P&id - Caustic Injection Pacakgerizwan.zamanNo ratings yet

- A-518-External Ramp DetailDocument1 pageA-518-External Ramp DetailEmmanuel InfanteNo ratings yet

- OP-01 DrawingsDocument5 pagesOP-01 DrawingsifyNo ratings yet

- Produced by An Autodesk Student VersionDocument1 pageProduced by An Autodesk Student VersionRinkal ParmarNo ratings yet

- Icpl-Cp-Re-T1-002 (Sheet 2 of 2) - R0Document1 pageIcpl-Cp-Re-T1-002 (Sheet 2 of 2) - R0Engineering CivilMantraNo ratings yet

- Bearing LoadsDocument10 pagesBearing Loadsshashi rajhansNo ratings yet

- 639 x1 Final Detail of Dranage Spout, RCC Railing & Bearing-Railing 1Document1 page639 x1 Final Detail of Dranage Spout, RCC Railing & Bearing-Railing 1shashi rajhansNo ratings yet

- 641 Final Detail of Dranage Spout, RCC Railing & Bearing-Railing 1Document1 page641 Final Detail of Dranage Spout, RCC Railing & Bearing-Railing 1shashi rajhansNo ratings yet

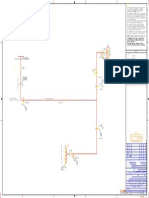

- Produced by An Autodesk Educational Product: Development of Rural Roads/Bridges in The State of Bihar Under Pmgsy SchemeDocument1 pageProduced by An Autodesk Educational Product: Development of Rural Roads/Bridges in The State of Bihar Under Pmgsy Schemeshashi rajhansNo ratings yet

- Stability Analysis of Well For PierDocument6 pagesStability Analysis of Well For Piershashi rajhansNo ratings yet

- 639 X1 ABUTMENT - SH - 01, 02 & 03-sh 3Document1 page639 X1 ABUTMENT - SH - 01, 02 & 03-sh 3shashi rajhansNo ratings yet

- 7Document6 pages7shashi rajhansNo ratings yet

- Produced by An Autodesk Educational Product: Detail - 1Document1 pageProduced by An Autodesk Educational Product: Detail - 1shashi rajhansNo ratings yet

- 4Document7 pages4shashi rajhansNo ratings yet

- 10Document1 page10shashi rajhansNo ratings yet

- 646X1 ABUTMENT - SH - 01, 02 & 03-sh2Document1 page646X1 ABUTMENT - SH - 01, 02 & 03-sh2shashi rajhansNo ratings yet

- 6Document1 page6shashi rajhansNo ratings yet

- 639 X1 ABUTMENT - SH - 01, 02 & 03-sh1Document1 page639 X1 ABUTMENT - SH - 01, 02 & 03-sh1shashi rajhansNo ratings yet

- 9Document1 page9shashi rajhansNo ratings yet

- 7Document1 page7shashi rajhansNo ratings yet

- 2Document1 page2shashi rajhansNo ratings yet

- 3Document1 page3shashi rajhansNo ratings yet

- Pier Design 2x20.84Document52 pagesPier Design 2x20.84shashi rajhansNo ratings yet

- 20.00m (3 Girder)Document16 pages20.00m (3 Girder)shashi rajhansNo ratings yet

- Abutment 2x20.84Document46 pagesAbutment 2x20.84shashi rajhansNo ratings yet

- BBS U-TROUGH Wall For 20.84m Bridge 3Document2 pagesBBS U-TROUGH Wall For 20.84m Bridge 3shashi rajhansNo ratings yet

- Reinforcement Calculation of Abutment (2) : A B A BDocument12 pagesReinforcement Calculation of Abutment (2) : A B A Bshashi rajhansNo ratings yet

- Part 13 Soil ReportDocument10 pagesPart 13 Soil Reportshashi rajhansNo ratings yet

- Bihar Rural Roads Project: Under BRICKS & Bihar Rural Road Development Agency (BRRDA), Govt. of BiharDocument21 pagesBihar Rural Roads Project: Under BRICKS & Bihar Rural Road Development Agency (BRRDA), Govt. of Biharshashi rajhansNo ratings yet

- For T-Beam Bridge Enter Foundation and Sub-Structure Data in The 1st Table and Super Structure Data in The 2nd TableDocument27 pagesFor T-Beam Bridge Enter Foundation and Sub-Structure Data in The 1st Table and Super Structure Data in The 2nd Tableshashi rajhansNo ratings yet

- Bridge No. 3 Vertical Pile Capacity Calculation of Pile For A-1Document5 pagesBridge No. 3 Vertical Pile Capacity Calculation of Pile For A-1shashi rajhansNo ratings yet

- A Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeDocument4 pagesA Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeGina CastilloNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Bael-Tree Details and Medicinal UsesDocument4 pagesBael-Tree Details and Medicinal UsesSanjay PatilNo ratings yet

- Mouser TestsectionDocument33 pagesMouser TestsectionalltheloveintheworldNo ratings yet

- Relative Color Pickup of Three Different Knits and Predictive Dyeing Recipe FormulationDocument17 pagesRelative Color Pickup of Three Different Knits and Predictive Dyeing Recipe FormulationNguyễn Huy CườngNo ratings yet

- ISA - Study Guide Table of ContentsDocument3 pagesISA - Study Guide Table of Contentsasdf123asdfasdfNo ratings yet

- TSB-1139 8SC Wiring DiagramDocument2 pagesTSB-1139 8SC Wiring Diagramxavier marsNo ratings yet

- Anthropological Thought Session by DR G. VivekanandaDocument277 pagesAnthropological Thought Session by DR G. Vivekanandahamtum7861No ratings yet

- Earth Quake DesignDocument13 pagesEarth Quake DesignRanie boy CabanillaNo ratings yet

- Kerr EffectDocument5 pagesKerr EffectJose GalvanNo ratings yet

- CR Unit 1 &11 (Part A &B)Document12 pagesCR Unit 1 &11 (Part A &B)durai muruganNo ratings yet

- Lecture 7 - Synchronous Generators 7 PDFDocument28 pagesLecture 7 - Synchronous Generators 7 PDFDorwinNeroNo ratings yet

- Jayvee Dime,,,,project in Physics Light and SoundDocument25 pagesJayvee Dime,,,,project in Physics Light and SoundJayvee DimeNo ratings yet

- Visual Storytelling The Digital Video Documentary - Original PDFDocument44 pagesVisual Storytelling The Digital Video Documentary - Original PDFjparanoti100% (1)

- UntitledDocument14 pagesUntitlednaresh kumarNo ratings yet

- Absolute Priority Based Cell ReselectionDocument11 pagesAbsolute Priority Based Cell ReselectionNeoRa Ndivo RamsNo ratings yet

- TDS 0033 FlexoTop 202003Document3 pagesTDS 0033 FlexoTop 202003Mearg NgusseNo ratings yet

- Hybrid Vehicle A Study On Technology IJERTV3IS120917 PDFDocument8 pagesHybrid Vehicle A Study On Technology IJERTV3IS120917 PDFAshish MathurNo ratings yet

- South Africa Hard Copy Lit 2Document20 pagesSouth Africa Hard Copy Lit 2Jennifer Española BernalNo ratings yet

- 4.phases in Agricultural DevelopmentDocument16 pages4.phases in Agricultural Developmentakuril100% (3)

- Cobra XRS9690Document45 pagesCobra XRS9690marwan71No ratings yet

- En Mongolia 06Document39 pagesEn Mongolia 06Sandeep DasNo ratings yet

- Snag SummmariesDocument171 pagesSnag Summmarieslaltu adgiriNo ratings yet

- WiringDocument147 pagesWiringYovani Cortes50% (2)

- Kohima Nagaland LBDocument1 pageKohima Nagaland LBIndia TreadingNo ratings yet

- Structural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormDocument30 pagesStructural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormCesar Paul Purihuaman MoraNo ratings yet

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- EuropeDocument5 pagesEuropeAmicus CuriaeNo ratings yet

- BEL PE Question Papers For ECE With Answers - 6 Knowledge AddaDocument14 pagesBEL PE Question Papers For ECE With Answers - 6 Knowledge AddaVishwanand ThombareNo ratings yet

Produced by An Autodesk Educational Product: Detail of Drainage Box

Produced by An Autodesk Educational Product: Detail of Drainage Box

Uploaded by

shashi rajhansOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Produced by An Autodesk Educational Product: Detail of Drainage Box

Produced by An Autodesk Educational Product: Detail of Drainage Box

Uploaded by

shashi rajhansCopyright:

Available Formats

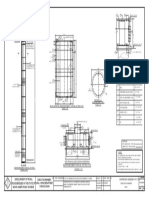

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

50 100 50

SPECIAL NOTES FOR ELASTOMERIC

INSTALLATION INSTRUCTIONS :

300 260 3 50 1. CARE SHALL BE TAKEN IN PACKING ,TRANSPOTATION,STORAGE AND HANDLING TO AVOID ANY MECHANICAL

KERB 6 THK. WELD 6 DAMAGE, CONTAMINATION WITH OIL,GREASE AND DIRT,UNDUE EXPOSURE TO SUNLIGHT AND WEATHER.

25

4 2. THE BEARINGS SHALL BE PLACED IN A RECESS

WEARING COAT M.S. FLATS

12 X 25 3. THE POSITION OF THE BEARINGS SHALL BE ACCURATELY MARKED ON THE PEDESTALS AND AREA WHERA THE

2 PL 198X100X6 THK. BEARINGS SHALL BE SEATED ACCURATELY LEVELLED.

210

SLOPE

1:9.4 A 6 THK. WELD 4. THE CONCRETE SURFACE SHALL BE FREE FROM ANY LOOSE MATERIAL AND CLEANED OF ANY GREASE,OIL PAINT

33

ETC.THE SURFACE SHALL BE SAND BLASTED,CLEAN OF ALL LAITANCE AND LEVELLED TRUE.

32 35

12(TYP.) 100 5. BEARINGS MUST BE PLACD BETWEEN TRUE HORIZONTAL SURFACES (MAXIMUM TOLERANCE 0.2 PER CENT

SLOPE 1:40 100 6 23 6 PERPENDICULAR TO LOAD) AND AT TRUE PLAN POSITION OF THEIR CONTROL LINES MARKED ON RECELVING

26

(TYP.) 6

100 SURFACES(MAXIMUM TOLERANCE + 3mm).CONCRETE SURFACES SHALL BE FREE LOCAL IRREGULARITIES(MAXIMUM

6 20

198 TOLERANCE+ 1mm IN HEIGHT).

FILLET WELD 1 PL 210X210X6 THK.

FILLET WELD 6.THE FROMS AROUND THE BEARINGS SHALL BE SOFT ENOUGH FOR EASY REMOVAL . FROMS SHALL ALSO FIT THE

BEARINGS SNUGLY AND PREVENT ANY LEAKAGE OF MORTAR GROUT . ANY MORTAR CONTAMINATING THE BEARING

DURING CONCRETING SHALL BE COMPLETELY REMOVED BEFORE SETTING.

6 7. THE TEMPORARY FORMS SHALL BE REMOVED AFTER THE SUPERSTRUCTURE CONCRETE HAS SET. THE SIDES OF

CUT OUT FOR MS PIPE 6 THK. WELD THE BEARINGS SHALL BE CLEANED OF ANY DEPOSIT OF CEMENT SLURRY/CONCRETE.

3 PL 210X100X6 THK. 8. SURFACE OF REACTION BLOCK, USED FOR BEARING INSTALLATION SHOULD BE FAIR FACED.

600

2

6 VIEW: B-B MAINTENANCE :

SECTION 1-1 DRAIN PIPE 1. THE BEARINGS SHALL BE SUBJECTED TO PLANNED MAINTENANCE CARE.

SCALE- 1:15 2.THE EXPOSED BEARING SURFACE SHALL BE MAINTANED CLEAN AND FREE FROM CONTAMINATION WITH GREASE OR

OIL,ETC.

3. ANNUAL ROUTINE MAINTENANCE INSPECTION OR SPECIAL MAINTENANCE INSPECTION OF ALL BEARINGS SHALL BE

3 PL 210X100X6 THK.

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

MADE TO CHECK FOR ANY SURFACE CRACKING OR SIGNS OF DAMAGE, DETERIORATION OR DISTRESS.

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

210

4. DAMAGED BEARINGS SHALL BE REPLACED IMMEDIATELY. TO AVOID DIFFERENCES IN STIFFNESS, ALL ADJACENT

B B BEARINGS ON THE SAME LINE OF SUPPORT SHALL ALSO BE REPLACED AND UNIFORM SEATING OF THE MAIN GIRDERS

OVER ALL THE NEW BEARINGS SHALL BE ENSURED.

300 236 DETAIL OF DRAINAGE BOX

SCALE 1:5 NOTES OF DRAINAGE SPOUT

1. ALL STEEL WORK SHALL BE AS PER IS - 2062.

D SEISMIC REACTION BLOCK 2. DRAINAGE SPOUT & COLLECTION PIT ASSEMBLY SHALL BE FABRICATED FROM MILD STEEL & AFTER FABRICATION,

185/135 185/135 THE COMPLETE ASSEMBLY EXCEPT GRATING SHALL BE GIVEN A HOT DIPPED GALVANISED COATING.

SLOPE

1:12.5

145/95 145/95 6 4. THE REINFORCEMENT OF TOP SLAB OF BOX SHALL BE SUITABLY MODIFIED TO ACCOMMODATE THE DRAINAGE

6 SPOUT.

125/75 125/75

300 5. THE DRAINAGE SPOUT SHALL BE GALVANIZED AFTER WELDING THE PLATES & FLATS.

4

32 32 6 THIK GALVANIZED PLATE 6

30

198 4 (CONFORMING TO I.S 226) 4 NOTES :

30 30 30 4

25 THK. MS PLATE 1. ALL DIMENSIONS ARE IN mm. UNLESS OTHERWISE NOTED.

32 50 2. BEARING TYPE B1,B1a B2 & B3 SHOULD BE PLACED ON PIER AND ABUTMENT AS PER THEIR POSITIONS MARKED IN

30 G.I. GULLY GRATING DRAWINGS.

1 1 5 THK.STEEL PLATE

SLOPE 545 3. SPECIFICATIONS INCLUDING PERMISSIBLE TOLERANCES FOR THE ELASTOMERIC BEARINGS SHALL BE IN

425 FOR B2/300 FOR B3

545 FOR B2/420 FOR B3

1:9.4 ACCORDANCE WITH IRC:83(PART ll)1987 STANDARD SPECIFICATIONS AND CODE OF PRACTICE FOR ROAD BRIDGES

262 425 SECTION lX PART ll-ELASTOMERIC BEARINGS.

M S FLATS 20 THK. MS PLATE

30 12 X 25 @ 29mm C/C 4. RAW MATERIAL CHLOROPRENE (CR) SHALL ONLY BE USED IN MANUFCATURE OF BEARINGS.

32

5. GRADES OF RAW ELASTOMER OF PROVEN USE IN ELASTOMERIC BEARINGS, WITH LOW CRYSTALLISATION RATES

12 AND ADEQUATE SHELF LIFE (E.G.NEOPRENE WRT. BAYPRENE 110 OR EQUIVALENT) SHALL BE USED. NO RECLAIMED

12 RUBBER OR VULCANISED WASTES SHALL BE USED. THE RAW ELASTOMER CONTENT OF THE COMPOUND SHALL NOT BE

1:12.5

SLOPE

6 LOWER THAN 60 PER CENT. THE ASH CONTANT SHALL NOT EXCEED 5 PER CENT.(AS PER TESTS CONDUCTED IN

300 ACCORDANCE WITH ASTM D-297).EPDM AND OTHER SIMILAR CANDIDATE ELASTOMERS FOR BRIDGS BEARING USE

KERB LINE

"X" SHALL NOT BE PERMITTED.

48 6. FABRICATION, TESTING AND ACCEPTANCE OF BEARINGS SHALL BE IN ACCORDANCE WITH IRC:83(PART ll) 1987.

50 98 7. BEARINGS SHALL BE HANDLED CAREFULLY. THESE SHALL BE PROCTED FROM BRIGHT SUN LIGHT AND EXTREME

105 COLD. THESE SHALL BE STORED NEATLY UNDER COVER TILL INSTALLATION.

30 8. BEARINGS & EXPANSION JOINTS SHALL BE PROCURED ONLY FROM PREQUALIFIED MANUFACTURERS.

30

PLAN CL OF DRAIN PIPE

SECTION D-D

DETAIL OF DRAINAGE D (FOR B2)

SPOUT AND COLLECTION PIT 350 FOR B2/250 FOR B3 SCALE 1:10

SCALE- 1:15

CL OF BEARING

DETAIL OF ELASTOMERIC BEARING

WITH FIXTURES SEISMIC REACTION BLOCK

570

(TYPE B2 & TYPE B3) 4

6

26 6 SCALE 1:10

GIRDER/BEARING

13 4

CL OF END CROSS

26 6

2 2 570

C

DIRECTION OF TRAFFIC

10 5 C

3

25 THK. MS PLATE 141 FOR POT BEARING

3

167 FOR PTFE BEARING

22 12 M.S. ROD WELDED

300 570

WITH ANCHOR 5 THK.STEEL PLATE

120 SLEEVE 10 R.C.C. PEDESTAL

SEISMIC REACTION 420

6 TOP PLATE 20 THK. MS PLATE

BLOCK 10

WELD 8 THK. CONSTRUCTION JOINT

WELD 6

WASHER "X" R.C.C.

PLAN AT 2-2 PEDESTAL

3 40

10 10

SCALE- 1:2 39

26 6 89 ELEVATION SHOWING BEARING

HEXAGON BOLT BEARING TYPE - B1a,B1 OVER R.C. PEDESTAL

DETAIL - A (M-20) 25 PEDESTAL 40 40

SECTION D-D SCALE 1:15

SCALE- 1:2 ANCHOR SLEEVE DETAIL OF "X" (FOR B3)

(INSIDE PLAN C-C

THREADED) SCALE 1:5 SCALE 1:10 SCALE 1:15

DIST: EAST CHAMPARAN

TITLE : MISC DRAWING 2 DRAWN BY: MunnaDATE :APR.., 2022 SUPERSTAR DESIGNER PVT. LTD.

DEVELOPMENT OF RURAL EXECUTIVE ENGINEER,

BRIDGE : RCC BRIDGE AT REO ROAD TO KALUPAKAD ROAD AS SHOWN

ROADS/BRIDGES IN THE STATE OF RURAL WORKS DEPARTMENT, VIA BELAHEERAM IN EAST CHAMPARAN DIST.

DESIGNED BY: S.R. CONSULTANT & ENGINEERS

BIHAR UNDER PMGSY SCHEME WORKS DIVISION DRG NO : SDPL -2022-23/NABARD/KALUPAKAD/GAD/MISC/05 CHECKED BY: H.K. PATNA

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

You might also like

- Typical Slab On Metal Deck Detail: Deck Parallel To Beam Deck Perpendicular To BeamDocument1 pageTypical Slab On Metal Deck Detail: Deck Parallel To Beam Deck Perpendicular To BeamAlbert GalagNo ratings yet

- Clarifier Tank Structural PDFDocument3 pagesClarifier Tank Structural PDFBenderlip CortezNo ratings yet

- Epson 3800 3880 SMDocument306 pagesEpson 3800 3880 SMIon IonutNo ratings yet

- ZxcasDocument1 pageZxcasbillNo ratings yet

- A0200 - Exterior ElevationsDocument1 pageA0200 - Exterior ElevationsMuhammad AbuBakarNo ratings yet

- Aacm Standard DrawingsDocument7 pagesAacm Standard Drawingshussein247No ratings yet

- Bri Amcd SW FC SD 1001 00Document1 pageBri Amcd SW FC SD 1001 00mahadheer mohammedNo ratings yet

- Ci RD 07 11 001Document1 pageCi RD 07 11 001naveenNo ratings yet

- Elevation: NotesDocument1 pageElevation: NotesErika Faye GutierrezNo ratings yet

- Sample Structural DrawingDocument1 pageSample Structural DrawingCherish Taguinod Aliguyon100% (1)

- Grating Specifications.: 40 THK Grating 40 THK GratingDocument1 pageGrating Specifications.: 40 THK Grating 40 THK GratingsivagnanamNo ratings yet

- A519 - STAFF PANTRY ENLARGED PLANS & ELEVATIONSDocument1 pageA519 - STAFF PANTRY ENLARGED PLANS & ELEVATIONSkuromiislay00No ratings yet

- Spot Detail Elevation Spot Detailsection Detail of Ceiling AirventDocument1 pageSpot Detail Elevation Spot Detailsection Detail of Ceiling Airventglen raymundoNo ratings yet

- Reference Drawings: Saudi Arabian Oil CompanyDocument1 pageReference Drawings: Saudi Arabian Oil CompanyJohn Philip BuntalesNo ratings yet

- LOS1-A-2204-OPS-PH1A - Rev 11 - Plan - Builders Work - Level 02Document1 pageLOS1-A-2204-OPS-PH1A - Rev 11 - Plan - Builders Work - Level 02Tosin FamuyiwaNo ratings yet

- Grade Beam Dowel BarDocument1 pageGrade Beam Dowel BarSehna SerajNo ratings yet

- ING10374D2X741 REINF'TDETAIL - SHEET 2 OF 2-Rev - C-741Document1 pageING10374D2X741 REINF'TDETAIL - SHEET 2 OF 2-Rev - C-741mhazarath murariNo ratings yet

- See Detail 1: NotesDocument1 pageSee Detail 1: NotesYazan MohammadNo ratings yet

- Ajv DPW 10 525 CL DWG 0695 03 R03Document1 pageAjv DPW 10 525 CL DWG 0695 03 R03sivagnanamNo ratings yet

- 05-DETAILS OF SOFFIT SLAB IN SUPER STRUCTURE-ModelDocument1 page05-DETAILS OF SOFFIT SLAB IN SUPER STRUCTURE-ModelManvendra Singh RaghuwanshiNo ratings yet

- Se 014 PDFDocument1 pageSe 014 PDFAmjad AlibrahimNo ratings yet

- PID Booklet As Built Without PFD Rev - Part75Document1 pagePID Booklet As Built Without PFD Rev - Part75megarezky235No ratings yet

- Issued For Construction: Detail Detail Section SectionDocument1 pageIssued For Construction: Detail Detail Section SectionFahadNo ratings yet

- 21A. GA & Structural Details of Stilling BasinDocument1 page21A. GA & Structural Details of Stilling BasinManoranjan SethiNo ratings yet

- Section 1 - 1 Section 2 - 2 Section 3 - 3: Revision No. byDocument1 pageSection 1 - 1 Section 2 - 2 Section 3 - 3: Revision No. byPaschal MazikuNo ratings yet

- STR 200Document1 pageSTR 200nuwanNo ratings yet

- Electrical Resistance Soil Corrosion Probe Test StationDocument1 pageElectrical Resistance Soil Corrosion Probe Test StationmohsenNo ratings yet

- Column ND Footing DetailsDocument1 pageColumn ND Footing Details025Karthik ReddyNo ratings yet

- Retaning WallDocument1 pageRetaning Walldanish javedNo ratings yet

- Saudi Arabian Oil Company: NotesDocument1 pageSaudi Arabian Oil Company: NotesJohn Philip BuntalesNo ratings yet

- Saudi Arabian Oil Company: NotesDocument1 pageSaudi Arabian Oil Company: NotesJohn Philip BuntalesNo ratings yet

- Bsi STD DWG El 001 Electrical Standard Installation 2of6Document1 pageBsi STD DWG El 001 Electrical Standard Installation 2of6dharuNo ratings yet

- Plumbing 01Document1 pagePlumbing 01schneidereit realtyNo ratings yet

- Detail 1: C SectionDocument1 pageDetail 1: C SectionHimal Nilanka RathnayakaNo ratings yet

- Notes:: Slope ToDocument1 pageNotes:: Slope ToThomas JohnNo ratings yet

- Piping Plan - Foam LateralDocument1 pagePiping Plan - Foam LateralGurumoorthy RajavijayanNo ratings yet

- Ramboll With Mark-Up1Document7 pagesRamboll With Mark-Up1gusyahri001No ratings yet

- Updated RCP All UntsDocument18 pagesUpdated RCP All Untsnikkoelbao96No ratings yet

- Type 1: in Various Areas of Greater Doha Phase - 8Document1 pageType 1: in Various Areas of Greater Doha Phase - 8abdul jackilNo ratings yet

- J414221002PADocument1 pageJ414221002PASehna SerajNo ratings yet

- 2+2 Jodi PlanDocument1 page2+2 Jodi Planshashank waghmareNo ratings yet

- Section-A Section-A: Saudi Arabian Oil CompanyDocument1 pageSection-A Section-A: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- Unit 5 Lighting LayoutDocument1 pageUnit 5 Lighting Layoutnikkoelbao96No ratings yet

- Capping and Sub-Base Thickness Design: Load Category 2Document1 pageCapping and Sub-Base Thickness Design: Load Category 2issam.qamhiaNo ratings yet

- Unit Weight KG 0.2 2: RevisionsDocument1 pageUnit Weight KG 0.2 2: RevisionsANIL PLAMOOTTILNo ratings yet

- Guardwall Block Perspective: Billboard SpecificationDocument1 pageGuardwall Block Perspective: Billboard SpecificationArmand Mikhail TempladoNo ratings yet

- First Floor Level Beam Details Part-2 (Sheet-1 of 2)Document1 pageFirst Floor Level Beam Details Part-2 (Sheet-1 of 2)Sumit LathwalNo ratings yet

- P203 Sie DWG 008 Arc 500002Document1 pageP203 Sie DWG 008 Arc 500002viswanathanNo ratings yet

- A-207-Residence Entrance Porch DetailsDocument1 pageA-207-Residence Entrance Porch DetailsEmmanuel InfanteNo ratings yet

- R03 C07B01 IKP 01 GF SDW AR 50003 - Comments12Document1 pageR03 C07B01 IKP 01 GF SDW AR 50003 - Comments12Eleazar SacloloNo ratings yet

- Sa-Ami-000-Hdai-370105 - 1 - Standard Details For Paving and JointsDocument1 pageSa-Ami-000-Hdai-370105 - 1 - Standard Details For Paving and Jointsmohamed esmailNo ratings yet

- Notes:: Plan View: Guard House / Toilet Section L-L: Guard House / ToiletDocument1 pageNotes:: Plan View: Guard House / Toilet Section L-L: Guard House / ToiletSolidr ArchitectsNo ratings yet

- Ati Pier 3 - SD (PDB) - Proposed Man CageDocument1 pageAti Pier 3 - SD (PDB) - Proposed Man CageMark L. AlmencionNo ratings yet

- WW Linear Veneered Planks Master SheetDocument2 pagesWW Linear Veneered Planks Master SheetChiara NaderNo ratings yet

- Ta-249813-023 - C - P&id - Caustic Injection PacakgeDocument1 pageTa-249813-023 - C - P&id - Caustic Injection Pacakgerizwan.zamanNo ratings yet

- A-518-External Ramp DetailDocument1 pageA-518-External Ramp DetailEmmanuel InfanteNo ratings yet

- OP-01 DrawingsDocument5 pagesOP-01 DrawingsifyNo ratings yet

- Produced by An Autodesk Student VersionDocument1 pageProduced by An Autodesk Student VersionRinkal ParmarNo ratings yet

- Icpl-Cp-Re-T1-002 (Sheet 2 of 2) - R0Document1 pageIcpl-Cp-Re-T1-002 (Sheet 2 of 2) - R0Engineering CivilMantraNo ratings yet

- Bearing LoadsDocument10 pagesBearing Loadsshashi rajhansNo ratings yet

- 639 x1 Final Detail of Dranage Spout, RCC Railing & Bearing-Railing 1Document1 page639 x1 Final Detail of Dranage Spout, RCC Railing & Bearing-Railing 1shashi rajhansNo ratings yet

- 641 Final Detail of Dranage Spout, RCC Railing & Bearing-Railing 1Document1 page641 Final Detail of Dranage Spout, RCC Railing & Bearing-Railing 1shashi rajhansNo ratings yet

- Produced by An Autodesk Educational Product: Development of Rural Roads/Bridges in The State of Bihar Under Pmgsy SchemeDocument1 pageProduced by An Autodesk Educational Product: Development of Rural Roads/Bridges in The State of Bihar Under Pmgsy Schemeshashi rajhansNo ratings yet

- Stability Analysis of Well For PierDocument6 pagesStability Analysis of Well For Piershashi rajhansNo ratings yet

- 639 X1 ABUTMENT - SH - 01, 02 & 03-sh 3Document1 page639 X1 ABUTMENT - SH - 01, 02 & 03-sh 3shashi rajhansNo ratings yet

- 7Document6 pages7shashi rajhansNo ratings yet

- Produced by An Autodesk Educational Product: Detail - 1Document1 pageProduced by An Autodesk Educational Product: Detail - 1shashi rajhansNo ratings yet

- 4Document7 pages4shashi rajhansNo ratings yet

- 10Document1 page10shashi rajhansNo ratings yet

- 646X1 ABUTMENT - SH - 01, 02 & 03-sh2Document1 page646X1 ABUTMENT - SH - 01, 02 & 03-sh2shashi rajhansNo ratings yet

- 6Document1 page6shashi rajhansNo ratings yet

- 639 X1 ABUTMENT - SH - 01, 02 & 03-sh1Document1 page639 X1 ABUTMENT - SH - 01, 02 & 03-sh1shashi rajhansNo ratings yet

- 9Document1 page9shashi rajhansNo ratings yet

- 7Document1 page7shashi rajhansNo ratings yet

- 2Document1 page2shashi rajhansNo ratings yet

- 3Document1 page3shashi rajhansNo ratings yet

- Pier Design 2x20.84Document52 pagesPier Design 2x20.84shashi rajhansNo ratings yet

- 20.00m (3 Girder)Document16 pages20.00m (3 Girder)shashi rajhansNo ratings yet

- Abutment 2x20.84Document46 pagesAbutment 2x20.84shashi rajhansNo ratings yet

- BBS U-TROUGH Wall For 20.84m Bridge 3Document2 pagesBBS U-TROUGH Wall For 20.84m Bridge 3shashi rajhansNo ratings yet

- Reinforcement Calculation of Abutment (2) : A B A BDocument12 pagesReinforcement Calculation of Abutment (2) : A B A Bshashi rajhansNo ratings yet

- Part 13 Soil ReportDocument10 pagesPart 13 Soil Reportshashi rajhansNo ratings yet

- Bihar Rural Roads Project: Under BRICKS & Bihar Rural Road Development Agency (BRRDA), Govt. of BiharDocument21 pagesBihar Rural Roads Project: Under BRICKS & Bihar Rural Road Development Agency (BRRDA), Govt. of Biharshashi rajhansNo ratings yet

- For T-Beam Bridge Enter Foundation and Sub-Structure Data in The 1st Table and Super Structure Data in The 2nd TableDocument27 pagesFor T-Beam Bridge Enter Foundation and Sub-Structure Data in The 1st Table and Super Structure Data in The 2nd Tableshashi rajhansNo ratings yet

- Bridge No. 3 Vertical Pile Capacity Calculation of Pile For A-1Document5 pagesBridge No. 3 Vertical Pile Capacity Calculation of Pile For A-1shashi rajhansNo ratings yet

- A Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeDocument4 pagesA Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeGina CastilloNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Bael-Tree Details and Medicinal UsesDocument4 pagesBael-Tree Details and Medicinal UsesSanjay PatilNo ratings yet

- Mouser TestsectionDocument33 pagesMouser TestsectionalltheloveintheworldNo ratings yet

- Relative Color Pickup of Three Different Knits and Predictive Dyeing Recipe FormulationDocument17 pagesRelative Color Pickup of Three Different Knits and Predictive Dyeing Recipe FormulationNguyễn Huy CườngNo ratings yet

- ISA - Study Guide Table of ContentsDocument3 pagesISA - Study Guide Table of Contentsasdf123asdfasdfNo ratings yet

- TSB-1139 8SC Wiring DiagramDocument2 pagesTSB-1139 8SC Wiring Diagramxavier marsNo ratings yet

- Anthropological Thought Session by DR G. VivekanandaDocument277 pagesAnthropological Thought Session by DR G. Vivekanandahamtum7861No ratings yet

- Earth Quake DesignDocument13 pagesEarth Quake DesignRanie boy CabanillaNo ratings yet

- Kerr EffectDocument5 pagesKerr EffectJose GalvanNo ratings yet

- CR Unit 1 &11 (Part A &B)Document12 pagesCR Unit 1 &11 (Part A &B)durai muruganNo ratings yet

- Lecture 7 - Synchronous Generators 7 PDFDocument28 pagesLecture 7 - Synchronous Generators 7 PDFDorwinNeroNo ratings yet

- Jayvee Dime,,,,project in Physics Light and SoundDocument25 pagesJayvee Dime,,,,project in Physics Light and SoundJayvee DimeNo ratings yet

- Visual Storytelling The Digital Video Documentary - Original PDFDocument44 pagesVisual Storytelling The Digital Video Documentary - Original PDFjparanoti100% (1)

- UntitledDocument14 pagesUntitlednaresh kumarNo ratings yet

- Absolute Priority Based Cell ReselectionDocument11 pagesAbsolute Priority Based Cell ReselectionNeoRa Ndivo RamsNo ratings yet

- TDS 0033 FlexoTop 202003Document3 pagesTDS 0033 FlexoTop 202003Mearg NgusseNo ratings yet

- Hybrid Vehicle A Study On Technology IJERTV3IS120917 PDFDocument8 pagesHybrid Vehicle A Study On Technology IJERTV3IS120917 PDFAshish MathurNo ratings yet

- South Africa Hard Copy Lit 2Document20 pagesSouth Africa Hard Copy Lit 2Jennifer Española BernalNo ratings yet

- 4.phases in Agricultural DevelopmentDocument16 pages4.phases in Agricultural Developmentakuril100% (3)

- Cobra XRS9690Document45 pagesCobra XRS9690marwan71No ratings yet

- En Mongolia 06Document39 pagesEn Mongolia 06Sandeep DasNo ratings yet

- Snag SummmariesDocument171 pagesSnag Summmarieslaltu adgiriNo ratings yet

- WiringDocument147 pagesWiringYovani Cortes50% (2)

- Kohima Nagaland LBDocument1 pageKohima Nagaland LBIndia TreadingNo ratings yet

- Structural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormDocument30 pagesStructural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormCesar Paul Purihuaman MoraNo ratings yet

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- EuropeDocument5 pagesEuropeAmicus CuriaeNo ratings yet

- BEL PE Question Papers For ECE With Answers - 6 Knowledge AddaDocument14 pagesBEL PE Question Papers For ECE With Answers - 6 Knowledge AddaVishwanand ThombareNo ratings yet