Professional Documents

Culture Documents

GTP 120

GTP 120

Uploaded by

er.manishnhpc0 ratings0% found this document useful (0 votes)

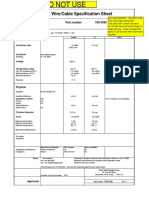

13 views2 pagesThis document provides technical specifications for an 11 kV armored power cable manufactured by Havells India Ltd. Key details include:

1) The cable has a voltage rating of 6.35/11kV and is compliant with Indian standards IS 7098-2 and IS 8130.

2) It has 3 cores with graphite coated copper conductors and extruded semiconducting and screening layers.

3) Key ratings include a current capacity of 4.17kA and maximum resistances at 200C of 0.253 ohm/km (dc) and 0.103 ohm/km (ac).

Original Description:

Under ground cable

Original Title

GTP-120

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides technical specifications for an 11 kV armored power cable manufactured by Havells India Ltd. Key details include:

1) The cable has a voltage rating of 6.35/11kV and is compliant with Indian standards IS 7098-2 and IS 8130.

2) It has 3 cores with graphite coated copper conductors and extruded semiconducting and screening layers.

3) Key ratings include a current capacity of 4.17kA and maximum resistances at 200C of 0.253 ohm/km (dc) and 0.103 ohm/km (ac).

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

13 views2 pagesGTP 120

GTP 120

Uploaded by

er.manishnhpcThis document provides technical specifications for an 11 kV armored power cable manufactured by Havells India Ltd. Key details include:

1) The cable has a voltage rating of 6.35/11kV and is compliant with Indian standards IS 7098-2 and IS 8130.

2) It has 3 cores with graphite coated copper conductors and extruded semiconducting and screening layers.

3) Key ratings include a current capacity of 4.17kA and maximum resistances at 200C of 0.253 ohm/km (dc) and 0.103 ohm/km (ac).

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

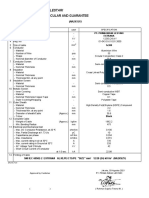

GUARANTEED TECHNICAL PARTICULARS FOR 11 kV ARMOURED POWER CABLES

Item Description Unit Particulars

HAVELLS INDIA LTD

Name and Address of Manufacturer

INDIA

Country of manufacture

Item Code / Catalogue A2XFY

IS 7098-2,IS 8130

Standard/s it complies with

Voltage Designation, U0/U (Um) kV 6.35/11(12)

Item Description

Item Description Unit

Unit Particulars

Particulars

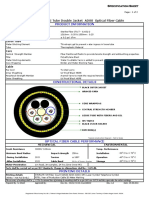

Nominal frequency Hz 50

YES

Strippable Semiconducting compound

Insulation Material

Graphite coating? Y/N 3

Number of Cores

Screen Application Extruded

H2/H4 grade Aluminium

(Semi- Material - Aluminum

Taped/ Extruded 61.5 mm

Overall Diameter of Cable mm

conducing 120

Strippablity

Nominal cross sectional area mm Cold Strippable

layer) Kg / 4465 Kg/Km

Approximate weight of/cable

Hot Cold

km mm 12.8

Diameter

Copper wire screening followed by open helix copper binder

Type 15XO.D

Minimum bending radius mm tape

Straned

Type Solid/Stranded

Plain copper

Conductor Material (Non Returnable Steel Drum) 500+5%

Cable length / drum Type m compacted

Insulation Copper wireShrinkable

screen applied

Cores applied

Compacted/Un-compacted Heat PVC over each core

end caps

Whether the cable ends

Screen are sealed?

Individual (Y/N)

/ Collective Circular

(Metallic Shape Round/Flat

In Air 400C Amb.

(atsectional A2 Shall be adequately provided

216 to meet the short circuit

layer) Cross areaTemp) mm

capacity

18 (min.)

Number of strands 188

Current In ducts 300CCapacity A 1/3 of 12.5 KA (system fault current) i.e. 4.17 KA for all 3

Short (at

Circuit ground temp) kA

Ratings Min. strand dia. shall

cores be corresponding to meet the

combined

Diameter of strands

Direct underground In ducts (at mm 256Resistance as per relevant clause

Water swellable tapes? A requirements of

Semiconducting conductor

water swellable tape applied over copper

0

30 C ground temp) of I.S.

screening over-8130/2013

each core

(Y / N)

Whether correction Material

factor tables for As semiconducting compound

per Havells Catalouge

Extrusion process for insulation andabove current Tripple extrusion

ratings provided ? (Y/N)

screens (Single / Triple)Thickness 0.3 (Approx.)

mm

Whether the maximum symmetrical short circuit

Material PVC-ST2

Shall be provided later

Conductor Method Extruded

Inner

current rating curves for 0.2 to 3ofSec.

Application

duration

0.6 (Min.)

Screen

covering

provided /? (Y/N) Thickness

Lapped/Extruded mm

Sheath Application

Ω/ YesExtruded

(0.253

Tripple extrusion)

Maximum dc resistance at 20/0Tape

Applied

Extruded Cin the same

km

operation as insulation? Hollow or Solid shall be as per manufacturing practice

Type Ω/ 0.325 (90 deg C)

Maximum ac resistance at 200C

Fillers km Non hygroscopicTRPVCXLPE

(Side+Filler)

Material

Material

Ω/ 0.103 ( 90 deg C)

Maximum reactance at 200C Flat Strip

Type (Wire / Tape) km 3.6 (Avg. or Nom.)

Thickness - min average W/kV/mm 17.23

Insulation

Dielectric losses at Material

rated (Uo/U) Galvanized Steel

/ Shape Ph

Armour 3.14

WireThickness

/ Tape - min at a point The measured value 4ofxtan

0.8d(+/-10%)

at Uo shall not exceed 0.004

Tan-delta at 0.5 Uo / Uo/ 1.5Uo and 2Uo mm- mm

(Diameter/Thickness) and the increment of tan d between 0.5 Uo and 2 Uo shall

not be more than 0.002

110 gm/m²

If Steel, mass of zing coating 0

mm

C/ 90 0C (Continuous operating condition)

Maximum allowable Load

Sec

conductor temperature at, A layer Non conducting water swellable tape applied over

Armour separation layer provided? (Y/N) 0

and duration 0C / armourn as per 250 C

mentioned in the spec

Short Circuit

Sec Extruded PVC -ST2 with FR , ATR properties

Material

ISI / Other quality Certifications provided ? Yes

(Y/N) YES

Anti- termite treatment Y/N

Whether copies of Type Test Certificates YES

Outer sheath The thickness shall not go below the min. value mentioned

furnished ? (Y/N) Thickness – Nominal mm

below.

Test Laboratory for Type Tests NABL

Thickness - Minimum mm 2.20

YES

Manufacturer experience records provided? HAVELLS 6.35/11 KV ELECTRIC CABLE XLPE (NO

Markings (Y/N)

OF CORE X SIZE IN SQMM) FR POWER DEPT.

As per the tender

SIKKIM documents

ISI MARK

Warranty (Months)

SUCCESIVE LENGTH

Signature

Name:

Date:

Company Seal:

You might also like

- Acroba SerManual FA15-30Document190 pagesAcroba SerManual FA15-30Vasile Vrabie100% (4)

- Samsung LCD Monitor 2032BW 2232BW 2232GW Plus Parts and Service ManualDocument51 pagesSamsung LCD Monitor 2032BW 2232BW 2232GW Plus Parts and Service ManualroldskiNo ratings yet

- GTP 50Document2 pagesGTP 50er.manishnhpcNo ratings yet

- GTP 95Document2 pagesGTP 95er.manishnhpcNo ratings yet

- GTP 185Document3 pagesGTP 185er.manishnhpcNo ratings yet

- GTP 240Document2 pagesGTP 240er.manishnhpcNo ratings yet

- FICHA TECNICA - 3X 35+50 SQ - MM AB CableDocument1 pageFICHA TECNICA - 3X 35+50 SQ - MM AB Cablejohana leonNo ratings yet

- Ficha Tecnica - 3X70+50 MM y 3X95+50 MMDocument1 pageFicha Tecnica - 3X70+50 MM y 3X95+50 MMjohana leonNo ratings yet

- Revised GTP Ab CableDocument1 pageRevised GTP Ab Cableer.manishnhpcNo ratings yet

- 1.93.3KV 3Cx 35 SQMM Cable GTPDocument1 page1.93.3KV 3Cx 35 SQMM Cable GTPDarshit VyasNo ratings yet

- Copper Conductor, PVC Insulated, PVC Inner Sheathed, Armoured & Overall PVC Outer Sheathed CableDocument2 pagesCopper Conductor, PVC Insulated, PVC Inner Sheathed, Armoured & Overall PVC Outer Sheathed Cableraviroj SOMVADEENo ratings yet

- Nexans 24035EXZZDB09BA3Document2 pagesNexans 24035EXZZDB09BA3test examNo ratings yet

- AC Cable 70mm 3.5-C CU-PVC-PVC SpecsDocument1 pageAC Cable 70mm 3.5-C CU-PVC-PVC Specslahore0022No ratings yet

- NFC 1kv ABC 2&4c16 Ees CableDocument5 pagesNFC 1kv ABC 2&4c16 Ees CableazzouzimedNo ratings yet

- ACCC Midal Data (Imperial Units) PDFDocument10 pagesACCC Midal Data (Imperial Units) PDFYusroni NainggolanNo ratings yet

- Spesifikasi Barang ListrikDocument2 pagesSpesifikasi Barang ListriksaypunyaNo ratings yet

- GTP HavellsDocument24 pagesGTP HavellsPradeep GoelNo ratings yet

- Indeco Welding Cable WS-105 600 V: DescriptionDocument3 pagesIndeco Welding Cable WS-105 600 V: DescriptionElmer Leodan Rojas CachayNo ratings yet

- Marineflex Yzp 0,6/1 KV: Low Voltage Power Cables 16098Document2 pagesMarineflex Yzp 0,6/1 KV: Low Voltage Power Cables 16098Javier EverestNo ratings yet

- Marineflex Yozp 0,6/1 KV: Low Voltage Power Cables 16197Document2 pagesMarineflex Yozp 0,6/1 KV: Low Voltage Power Cables 16197Javier EverestNo ratings yet

- CABT CablesDocument1 pageCABT CablesKristaNo ratings yet

- RG179B UDocument3 pagesRG179B Ujonathan.boussoir2215No ratings yet

- Datos CableDocument3 pagesDatos CablePablo Briceño NavarroNo ratings yet

- Cable MT NFC 33-226 18/30 (36) KV: DescriptionDocument2 pagesCable MT NFC 33-226 18/30 (36) KV: DescriptionIbrahim LANDOZINo ratings yet

- Ac Cable 35mm SC CU-PVC-PVC SpecsDocument1 pageAc Cable 35mm SC CU-PVC-PVC Specslahore0022No ratings yet

- ACCC Midal Data (European Sizes)Document23 pagesACCC Midal Data (European Sizes)Kapil MishraNo ratings yet

- Fire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Document1 pageFire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Cost RootsNo ratings yet

- TDS, CSD - Iec 60502-2Document4 pagesTDS, CSD - Iec 60502-2Ghiles AOUICHENo ratings yet

- L2B2AT-Canare Corp. - Two-Conductor Shielded Cables - Two-Conductor Shielded Cables (Single) Aluminum Foil Shield (L-2B2AT)Document3 pagesL2B2AT-Canare Corp. - Two-Conductor Shielded Cables - Two-Conductor Shielded Cables (Single) Aluminum Foil Shield (L-2B2AT)Antonius Patra100% (1)

- 1X240 - AL - XLPE - ATA - PVC - 18 - 30 (36) KVDocument1 page1X240 - AL - XLPE - ATA - PVC - 18 - 30 (36) KVShadi BadawyNo ratings yet

- MV Power CablesDocument2 pagesMV Power CablesQC ĐNNo ratings yet

- JEMBO Secondary CablesDocument9 pagesJEMBO Secondary CablesPrem HNo ratings yet

- Belden 8762Document1 pageBelden 8762AlerianoNo ratings yet

- Calculation - Cable Sizing 11kV-25Document1 pageCalculation - Cable Sizing 11kV-25SivanandNo ratings yet

- Cable Nac 81602Document1 pageCable Nac 81602Andres Varea RomoNo ratings yet

- Solar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Document1 pageSolar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Koushik KarmakarNo ratings yet

- Nexans - Anti Theft Power Cable PVC In...Document5 pagesNexans - Anti Theft Power Cable PVC In...abdulkawi alasharyNo ratings yet

- CABLE EXTERIOR SUPERIORES CSCAI2x18EDocument1 pageCABLE EXTERIOR SUPERIORES CSCAI2x18EJhon Mario Rendón GiraldoNo ratings yet

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDocument2 pagesNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanNo ratings yet

- Technical Offer-SWE-298-23-V1Document1 pageTechnical Offer-SWE-298-23-V1Karim RahmaniNo ratings yet

- Lvis09axsfy23 5c300sa002sDocument1 pageLvis09axsfy23 5c300sa002sVishal SharmaNo ratings yet

- TPG NA2XS2Y 1x300 mm2 20KVDocument2 pagesTPG NA2XS2Y 1x300 mm2 20KVtees220510No ratings yet

- ACCC Data Sheets (Metric Size) PDFDocument23 pagesACCC Data Sheets (Metric Size) PDFkabardey46No ratings yet

- Product Description - (V100R002C01 05)Document2 pagesProduct Description - (V100R002C01 05)Hashim ShafquatNo ratings yet

- EV CablesDocument1 pageEV CablesVijay KarthikeyanNo ratings yet

- Na2xseyby 3 X (35-300) MMDocument1 pageNa2xseyby 3 X (35-300) MMMario SitorusNo ratings yet

- TPG Xiii.2.4 - Opgw 60 MMDocument5 pagesTPG Xiii.2.4 - Opgw 60 MMALVINNo ratings yet

- Belden - Rs 485 4p20awg Nonarmor & ArmorDocument2 pagesBelden - Rs 485 4p20awg Nonarmor & ArmorBasten M H SilitongaNo ratings yet

- OHTL Materials Technical Specifications and DrawingsDocument42 pagesOHTL Materials Technical Specifications and DrawingsVictor ChirembaNo ratings yet

- Technical Data Sheet: Description Technical Particulars ValuesDocument1 pageTechnical Data Sheet: Description Technical Particulars ValuesMuhammad Ali TariqNo ratings yet

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDocument2 pagesMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- SC - Medium & High Voltage Catalogue - 2020Document6 pagesSC - Medium & High Voltage Catalogue - 2020Ḉhển KěngwểěNo ratings yet

- Wire/Cable Specification Sheet: Part Number 106-3385Document1 pageWire/Cable Specification Sheet: Part Number 106-3385Marilton SiqueiraNo ratings yet

- 2C + e Cu-Xlpe-PvcDocument3 pages2C + e Cu-Xlpe-Pvcraviroj SOMVADEENo ratings yet

- Accc/Tw Paris (800) : Data SheetDocument1 pageAccc/Tw Paris (800) : Data SheetkmiqdNo ratings yet

- GTP For 1CX300sqmmDocument4 pagesGTP For 1CX300sqmmpriyanka236No ratings yet

- Wire, 10 AWG, 5000 V, Tefzel - Focal 3393Document1 pageWire, 10 AWG, 5000 V, Tefzel - Focal 3393Marilton SiqueiraNo ratings yet

- 24F - 48F DJ ADSS Specs 600 MTRDocument2 pages24F - 48F DJ ADSS Specs 600 MTRJose GonzalesNo ratings yet

- 2c x1.5 FAS CableDocument1 page2c x1.5 FAS CableSanjay KumarNo ratings yet

- Draka - Xlpe CableDocument2 pagesDraka - Xlpe Cablewe202No ratings yet

- Accc/Tw Prague (700) : Data SheetDocument1 pageAccc/Tw Prague (700) : Data SheetkmiqdNo ratings yet

- Delta Connection in A 3 Phase SystemDocument5 pagesDelta Connection in A 3 Phase SystemnpavankNo ratings yet

- Homework #02 (Phy 112) SolutionsDocument19 pagesHomework #02 (Phy 112) SolutionsKvn4N6No ratings yet

- Microwave Technology PresentationDocument11 pagesMicrowave Technology PresentationVani ChitkaraNo ratings yet

- Aoc 712sa+Service+ManualDocument50 pagesAoc 712sa+Service+ManualGiovanny Gregorio Gonzalez SanchezNo ratings yet

- Aspl NVCL 230209 Technical QuotationDocument5 pagesAspl NVCL 230209 Technical QuotationNitesh KhamariNo ratings yet

- The Modeling and Simulation of ImprovedDocument182 pagesThe Modeling and Simulation of ImprovedNguyễn Trung HiếuNo ratings yet

- ECG ThesisDocument40 pagesECG ThesisMirza MehranNo ratings yet

- Evac-105 / Evdc-105 Energy StorageDocument2 pagesEvac-105 / Evdc-105 Energy StorageYoslin RuizNo ratings yet

- Sds 1102 CNLDocument127 pagesSds 1102 CNLccstcesarNo ratings yet

- NovaDisk P8 SpecsDocument2 pagesNovaDisk P8 SpecsbaljogiNo ratings yet

- KDL 52V4100Document114 pagesKDL 52V4100theduddNo ratings yet

- LTC 1052Document25 pagesLTC 1052roozbehxoxNo ratings yet

- 345 KV LineDocument62 pages345 KV Lineroxi50No ratings yet

- EE301 Lesson 38 Shipboard PowerDocument33 pagesEE301 Lesson 38 Shipboard PowerNoman KhanNo ratings yet

- Equipment Kks Equipment Description Nameplate DetailsDocument3 pagesEquipment Kks Equipment Description Nameplate DetailsMichael Adu-boahenNo ratings yet

- Motor BrushlessDocument5 pagesMotor BrushlessHector CarrilloNo ratings yet

- RTN 950 Commissioning Guide (U2000) - (V100R003C03 - 01)Document250 pagesRTN 950 Commissioning Guide (U2000) - (V100R003C03 - 01)andi_as_3100% (6)

- DDD - 410575 - Carret. Villa El Carmen - San Cayetano - 20170629 - V1.0Document6 pagesDDD - 410575 - Carret. Villa El Carmen - San Cayetano - 20170629 - V1.0Marielba BernottyNo ratings yet

- SCIENCE 9 2nd QUARTER MODULE 1Document39 pagesSCIENCE 9 2nd QUARTER MODULE 1Jinky AydallaNo ratings yet

- 3RT20361AG20 Datasheet enDocument10 pages3RT20361AG20 Datasheet enWladimir RomeroNo ratings yet

- CYMGRD Optimal Design of Substation Grounding GridsDocument5 pagesCYMGRD Optimal Design of Substation Grounding Gridsjaneth lozanoNo ratings yet

- TTLDocument35 pagesTTLShravan Kumar NamdeoNo ratings yet

- Hydrastep & Hydratect Water/steam Monitoring Systems: Solartron Mobrey LTD B246801Document7 pagesHydrastep & Hydratect Water/steam Monitoring Systems: Solartron Mobrey LTD B246801cytech6619No ratings yet

- Relay Board Connection InstructionDocument6 pagesRelay Board Connection Instructionkum512No ratings yet

- EEE Software Lab Report On PspiceDocument9 pagesEEE Software Lab Report On PspiceSayem Mahmud (Sym)No ratings yet

- X200 Hardware Maintenance ManualDocument260 pagesX200 Hardware Maintenance ManualAndre PennNo ratings yet

- Lsa 37 Shunt - 2 & 4 Pole: AlternatorsDocument20 pagesLsa 37 Shunt - 2 & 4 Pole: AlternatorsSubagyo Wahyu RiyadiNo ratings yet

- Data Download HAT560NC HAT560NBC V1.0 enDocument25 pagesData Download HAT560NC HAT560NBC V1.0 enArc Hie100% (1)