Professional Documents

Culture Documents

PCA Method in

PCA Method in

Uploaded by

ravi kumar0 ratings0% found this document useful (0 votes)

12 views48 pagesOriginal Title

PCA Method In

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

12 views48 pagesPCA Method in

PCA Method in

Uploaded by

ravi kumarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 48

pee

PORTLAND CEMUEAd

ASSOCIATION

ThAcknors Design for Corrects yaa

ancl Staast Fremont

~ (184

Authded by Rolect a. Packard ,

Grtniipat paring enginiy ,

Cwif awh TaowsfeVtokion Defarbrwut 5

Portland Cewvrend Agsoctition .

Thickness+

Concrete Highway-and:

Street Pavements:

CONTENTS

Chapter I, Introduction ......

‘Applications of Design Procedures.

Computer Programs Available .

Basis for Design......

Metric Version.

Chapter 2. Design Factors ..

Flexural Strength of Conerete .

Subgrade and Subbase Support

Design Period

Traffic

Projection

Capacity

ADTT

‘Truck Directional Distribution .

Axle-Load Distribution «

Load Safety Factors

Chapter 3. Design Procedure

(Axle-Load Data Available),

Fatigue Analysis ...

Erosion Analysis .

‘Sample Problems .....-

Chapter 4, Simplified Design Procedure

(Axle-Load Data Not Available).

Sample Problems ......

Comments cn Simplified Procedure

Modulus of Rupture .

Design Period ...-

esignifor!

Aggregate Interlock or Doweled Joints

User-Developed Design Tables ...-

Appendix A. Development of Design

Procedure.

‘Analysis of Concrete Pavernents

Jointed Pavements ..

Continuously Reinforced Pavements

Truck-Load Placement. .

Variation in Concrete Strength .

Concrete Strength Gain with Age

Warpingand Curling of Conerete.

Fatigue «

Erosion

Appendix B. Design of Conerete Pavements

with Lean Concrete Lower Course «++ +36

Lean Concrete Subbase +36

Monolithic Pavement .... 36

239.

‘Appendix C. Analysis of Tridem Axle Loads =.

Appendix D. Estimating Trafic Volume

by Capacity z

Appendix E. References.

Design Worksheet for Reproduction

Figures

ural strength, age, and design rel

: poeta interrelationships of soilclassifications

ships

ng, values

s, Proportion of trucks in ight lane of a mulitane

divided highway.

4, Design 1A.

5. Fatigue analysis—allowable load repetitions based

fon stress ratio factor (with and without concrete

shoulders).

62. Erosion analysis—allowable load repetitions based

on erosion factor (without concrete shoulder)

6b, Erosion analysis—allowable load repetitions based

on erosion factor (with concrete shoulder)

7. Design 1D.

8. Design 24,

AL. Critical axle-load positions

A2, Equivalent edge stress factor depends on percent of

trucks at edge

A3, Fatigue relationships,

BI. Design chart for composite concrete pavement (lean

concrete subbase),

B2. Design chart for composite concrete pavement

(monolithic with lean concrete lower layer).

83, Modulus of rupture versus compressive strength,

“I. Analysis of tridems,

ables

1. Effect of Untreated Subbase on & Values

2. Design & Values for Cement-Treated Subbase

3 Yearly isaies of Vratlic Growth and Corresponding

Projection Factors

4 Percentages of Four-Tire Single Units and Trucks

(ADTT) on Various Highway Systems

Axle-Load Data

Equivalent Stress—No Concrete Shoulder

Equivalent Stress—Conerete Shoulder

Erosion Factors—Doweled Joints, No Concrete

Shoulder

>. Erosion Factors—Aggregate-Interlock Joints, No

Concrete Shoulder

Erosion Factors—Doweled Joints, Concrete

Shoulder

Erosion Factors—Aggregate-Interlock Joints,

Conerete Shoulder”

Axle-Load Categories

‘Subgrade Soil Types and Approximate & Values

Allowable ADTT, Axle-Load Category 1—Pavee

ments with Aggregate-Interlock Joints

Allowable ADTT, Axle-Load Category 2—Paves

ments with Doweled Joints

Allowable ADTT, Axle-Load Category 2—Pave-

ments with Aggregate-Interlock Joints

Allowable ADTT, Axle-Load Category 3—Pave.

nnents with Doweled Joints

3b, Allowable ADTT, Axle-Load Category 3—Pave-

‘ments with Aggregate-Interlock Joints

4a, Allowable ADTT, Axle-Load. Category 4—Pave~

‘ments with Doweled Joints

Ib, Allowable ADTT, Axle-Load Category 4

‘ments with Aggregate-Interlock Joints

15. Axle-Load Distribution Used for Preparing Design

Tables 11 Through 14

Cl. Equivatent Stress — Tridems

2. Erosion Factors — Tridems — Doweled Joints

(C3. Erosion Factors — Tridems — Aggregate-Interlock

Joints

DI. Design Capacities for Multilane Highways

D2. Design Capacities for Uninterrupted Flow on Two

Lane Highways

us.

customary Metric } Conversion

‘unit unit eeffecient

in mm 35.40

m 0.30

ke 0.45

N 445

kN 445

kPa 6.9

(valuey | MPajm | 0271

@ &

;

desi

The

get

Toc

fo:

/3—Pave-

4—Pave-

Arne FE

ng Design

oints

Interlock

on Two-

CHAPTER 1

Introduction

‘This bulletin deals with methods of determining slab

thicknesses adequate to carry traffic loads on concrete

streets, roads, and highways,

“The design purpose is the same as for other engineered

structures —t0 find the minimum thickness that will re-

Sult in the lowest annual cost as shown by both first cost

find maintenance costs. If the thickness is greater than

needed, the pavement will give good service with low

maintenance costs, BUI first cost will be high. [the thick

hess is not adequate, premature and costly maintenance

‘tnd interruptions ia traffic will more than offset the lower

first eost. Sound engineering requires thickness designs

that properly balance first cost and maintenance costs,

‘While this bulletin is confined to the topic of thickness

design, other design aspects are equally important t0 en-

Sure the performance and longllife of concrete pavements,

These include—

© Provision for reasonably uniform support. (See Sub-

grades and Subbases for Concrete Pavements.*)

«* Prevention of mud-pumping with a relatively thin

untreated or cement-treated subbase on projects

where the expected truck traffic will be great enough

to eause pumping, (The need forand requirements of

Subbase are also given in the booklet cited above.)

+ Use of a joint design that will afford adequate load

transfer; enable joint sealants, ifrequired, to beeffec~

tive: and prevent joint distress due to infiltration.

(See Joint Design for Concrete Highway and Street

Pavements.**)

«© Use of a concrete mix design and aggregates that will

provide quality concrete with the strength and dura~

Bility needed for long life under the actual exposure

conditions. (See Design and Coritrol of Concrete

Mixtures.t)

The thickness design criteria suggested are based on

‘general pavement performance experience. If regional or

local specifie performance experience becomes available

for more favorable or adverse conditions, the design cri

teria can be appropriately modified. This could be the

‘case for particular climate, soil, or drainage conditions

and future design innovations.

Applications of Design Procedures

“The design procedures given in this text apply te the fol-

lowing types of concrete pavements: plain, piaindowsied.

reinforced, and continuously reinforced.

Plain pavements are constructed without ré.aforsing

steel or doweled joints. Load transfer at the joints ws ob-

tained by aggregate interlock between the cracked Zace:

below the joint saw cut or groove. For load transfer 10 be

effective, itis necessary that short joint spacings be wsed

Plain-doweled pavements are built without ranfoccing

steel however, smooth steel dowel bars are instalied a1

Toad transfer devices at each contraction joint and rela-

tively short joint spacings are used to control cracking

Reinforced pavements contain’ reinforcing stec2 anc

“dowel bars for load transferat the contraction joints. The

pavements are constructed with longer joint spacing:

than used for unreinforced pavements. Betweenthe joints

fone of more transverse cracks will usually deveiop: thes:

fare held tightly together by the reinforcing steeland goo:

Toad transfer is provided.

‘Commonly used joint spacings that perform well ate t

ft for plain pavements,t not more than 20 fe for plaic

doweled pavements, and not more than abou: 40 ft fe

reinforced pavements. Joint spacings greater thar. shes

have ‘been used but sometimes greater spacing cause

pavement distress at joints and intermediate cracies be

‘owen joints.

‘Continuously reinforced pavements are buitt warhow

contraction joints. Due to the relatively heavy. comtine

Ous-steel reinforcement in the longitudinal dire=tiot

these pavements develop transverse cracks at close ante

vals. A high degree of load transfer is developed a= thet

track faces held tightly together by steel reinfoccersxtnt

“The design procedures given here cover design one

wns that have not been directly addressed bef-re

“Porand Cement Arsociaticn publication 1$0297-

Porta Cent Assocation pobliation 18059:

‘sPortland Cement Atroiation publication EBOO T-.

‘tor very thin pavements, a 154jint spacing ay Becta

ti aforementioned PCA publeaton on join eH = cats

other procedures. These include recognition of:

|The degree of load transfer at transverse joints pro-

Vided by the different pavement types described.

2. The effect of using a conerete shoulder adjacent to

the pavement, concrete shoulders reduce the flex-

ine Pisces and deflections caused by vehicle loads,

‘The effect of using a lean conerete (econocrete)sub-

base, which reduces pavement stresses and deflec-

Gong, provides considerable support when trucks

pass over joints, and provides resistance to subbase

Erosion caused by repeated pavement deflections

4. Two design criteria: (a) fatigue, to keep pavement

stresses due to repeated loads within safe limits and

thus prevent fatigue cracking: and (b) erosion, to

limit the effects of pavement deflectionsatslabedges,

joints, and corners and thus control the erosion of

Toundation and shoulder materials. The criterion for

erosion is needed since some modes of pavement

distress such as pumping, faulting, and. shoulder

distress are unrelated to fatigue,

4. Triple axles can be considered in design. While the

conventional single-axle and tandemaxle config-

trations arestill the predominant loadson highways,

Use of triple axles (Iridems) is increasing, They

seen on some over-the-road trucks and on special

Toads used for hauling coal or other minerals. Ti-

ems may be more damaging from an erosion crite

tion (deflection) than from a fatigue criterion

Selection of an adequate thickness is dependent upon

tne choice of other design features -joimting system, type

Df subbace if needed, and shoulder type

With these additional design conditions, the thickness

requirements of design alternatives, which influence cost,

cam be directly compared

‘Chapter 2 describes how the factors needed forsulving

«design problem are determined. Chapter 3 deails the

{ull design procedure that is used when specific axle-load-

distribution data are known or estimated, If detailed

‘txlerload data are not available, the designean beaccom-

plished as described in Chapter 4, by the selection of one

fof several categories of data that represent a range of

pavement facilis varying from residential streets up to

busy interstate highways.

Computer Programs Available

Thickness design problems can be worked out by hand

with the tables and charts provided here or by computer

and microcomputer with programs that are available

from Portland Cement Association.

Basis for Design

‘The thickness design methods presented here are based

on knowledge of pavement theory, performance, and re-

search experience from the following sources:

1. Theoretical studies: of pavement slab, behavior by

Westergaard,!"* Pickett and Ray, "and recently

developed finite-element computer analyses, one of

which is used as the basis for this design procedure."

2, Model and full-scale tests such as Arlington Tests"

‘nd several research projects conducted by PCA and

‘ther agencies on subbases,"™ "joints" and con-

crete shoulders."

3. Experimental pavements subjected to controlled test

traffic, such as the Bates Test Road, the Pitts-

burg Test Highway.” the Maryland Road Test!"

the AASHO** Road Test," and studies of in

service highway pavements made by various state

departments of transportation.

4. The performance of normally constructed pave:

ments subject to normal mixed traffic.

All these sources of knowledge are useful. However,

the knowledge gained from performance of normally

constructed pavements is the most important. Accord

ingly, it is essential to examine the relationship between

the roles that performance and theory play in a design

procedure. Sophisticated theoretical methods developed

in recent years permit the responses of the pavement

Stresses, deflections, pressures to be more accurately

modeled. This theoretical analysis is a necessary part of

41 mechanistic design procedure, fr it allows considera~

tion of a full range of design-variable combinations. An

important second aspect of the design procedure is the

criteria applied to the theoretically computed values

the limiting or allowable values of stress, deflection, or

pressure. Defining the criteria so that design results are

Telated to pavement performance experienceand research

data is critical in developing a design procedure.

The theoretical parts of the design procedures given

here are based on a comprehensive analysis of concrete

stresses and deflections by a finite-element computer pro-

gram.” The program models the conventional design

factors of concrete properties, foundation support, aad

loadings, plus joint load transfer by dowels or aggregate

interlock and concrete shoulder, foraxle-load placements

at slab intetior, edge, joint, and corner.

The eriteria for the design procedures are based on the

pavement design, performance, and research experience

referenced above including relationships to performance

‘of pavements atthe AASHO Road Test" and to stud-

ies" * of the faulting of pavements

More information on development and basis of the de-

sign procedure is given in Appendix A and Reference 3.

Metric Version

A metric version of this publication is also available from

Portland Cement Association—publication EB209P.

jpetsript numbers in parentheses denote reerencesat the eas of

Now the American Associaton of State Highway and Transpo

tion Officials (AASHTO),

Pe

Pe

©

fe

fe

state

pave

rally

ders:

ns. An

is the

tues

Is are

search

given

ee pro-

desisn

rand

regate

> stud

thede-

nce 30.

le from

QP.

eens of

CHAPTER 2

Design Factors

After selection of the type of concrete pavement (plain

pavement with or without dowels. reinforced jointed

pavement with dowels, of continuously reinforced pave~

iment), type of subbase if needed, and type of shoulder

(with or without conerete shoulder, curb and gutter or

integral curb), thickness design is determined based on

four design factor =

1 Flexural strength of the conerete (modulus of rup-

ture, MR)

2 Strength of the subgrade, or subgrade and subbase

combination (k)

3. The weights, frequencies, and types of truck axle

loads that the pavement will carry

4° Désign period, which in this and other pavement de-

sign procedures is usually taken at 20 years, but may

bbe more or less

‘These design factors are discussed in more detail in the

following sections. Other design considerations in¢orpo-

rated in the procedure are discussed in Appendix A.

Flexural Strength of Concrete

Consideration of the flexural strength of the conerete is,

applicable in the design procedure for the fatigue crite~

rion, which controls cracking of the pavement under

repetitive truck loadings.

Bending of a concrete pavement under axle loads pro-

duces both compressive and flexural stresses, However,

the ratios of compressive stresses to compressivestrength

are too small to influence slab thickness design. Ratios of

flexural stress to flexural strength are much higher, often

‘exceeding values of 0.5. As a result, flexural stresses and

flexural strength of the conerete are used in thickness de-

sign, Flexural strength is determined by modulus of rup-

ture tests, usually made on 6x6x30-in, beams.

For specific projects, the concrete mix should be de-

jgned to give -both adequate durability and flexural

strength at the lowest possible cost. Mix design proce-

dures are described in the Portland Cement Association

publication Design and Control of Concrete Mixtures.

‘The modulus of rupture can be found by cantileve

center-point, of thied-point loading. An important di

ference in these test methods is that the third-point te

shows the minimum strength of the middle third of t

test beam, while the other two methods show strength

‘only one point. The value determined by the more co

servative thied-point method (American Society for Te>

ing and Materials, ASTM C78) is used for design in tt

procedure."

Modulus of rupture tests are commonly made at ~

2k, and 90 days. The 7-and 14-day test results are cor

pared with specification requirements for job control ar

for determining when pavements can be opened totraffi

‘The 28-day test results have been commonly used f

thickness design of highways and streets and are reco!

mended for use with this procedure; 90-day results 3

used for the design of airfields. These values are used t

‘cause thete are very few stress repetitions during the fi

28 or 90 days of pavement life as coripared to the millio

of stress repetitions that occur later.

Conerete continues to gain strength with age as shot

in Fig. |. Strength gain is shown by the solid curve, whi

represents average MR values for several series by le

oratory tests, feld-cured test beams, and sections of cc

crete taken from pavements in service.

In this design procedure the effects** of variations

concrete strength from point to point in the paveme

‘and-gains in conerete strength with age are incorporat

in the design charts and tables. The designer does not

rectly apply these effects but simply inputs the averc

28-day strength value.

Fora standard 30.n, beam, centerpoint-onding test a

about 15 pa higher, and cantleverdoncing test valve about 10

Figherahanthid-poit loading tex values These higher sales aft

minded tobe we - ten methods

intended tobe wed Tor design purposes, Ithese other et

‘ied, + downward adjustment should be made by establish

{atin to thied-poiavlond test valuct. 2a

"A Thes effects are discussed in Appendix A.

‘able 1. Effect of Untreated Subbage

129]

‘on k Values,

‘Subgrade ase valve, pol

ele Subgrad ‘Subbase A valve, pa

bel tin] _6m. Si. Tia,

50 oS 75 85 v0

L 100 130 0 162 0

200 zo | zo} 20 320

so se rR 309) sz0_| 30 370 330

2 de

30"

30 Soy

Fig. 1, Flexural strength, age, and design relationships.

Subgrade and Subbase Support

“The support given to concrete pavements by thesubgrade.

‘and the subbase where used, is the second factor in thick-

ress design. Subgrade and subbase support is defined in

terms of the Westergaard modulus of subgrade reaction

(4). Ih is equal to the load in pounds per square inch ona

Ioaded area (a 30-in.-diamieter plate) divided by the de-

flection in inches for thatload. The k valuesare expressed

‘4s pounds per square inch per inch (psi/in.) or, more

‘commonly, as pounds per cubic inch (pei). Equipment

‘and procedures for determining & values are given in

References 31 and 32.

Since the plate-loading testis time consuming and ex-

pensive, the & value is usually estimated by correlation to

Simpler tests such as the California Bearing Ratio (CBR)

for R-value tests, The result is valid because exact deter-

mination of the k valueis not required; normal variations

from an estimated value will not appreciably affect pave-

‘ment thickness requirements, The relationships shown!

Fig, 2 are satisfactory for design purposes.

‘The AASHO Road Test" gave a convincing demon-

stration that the reduced subgeade support during thaw

periods has little or no effect on the required thickness

‘of concrete pavements. This is true because the brief per-

jods when & values are low during spring thaws are more

than offset by the longer periods when the subgrade is

frozen and k values are much higher than assumed for

design, To avoid the tedious methods required to design,

for seasonal variations in k, normal summer- or fall-

weather k values are used as reasonable mean values.

It is not economical to use untreated subbases for the

sole purpose of increasing & values. Where a subbase is

tused,* there will be an increase in & that should be used

in the thickness design. If the subbase is an untreated

granular material, the approximate increase in k can be

taken from Table 1

‘The values shown in Table | are based on the Burmis-

9" analysis of two-layer systems and plate-loading

tests made to determine k values on subgrades and sub-

bases for full-scale test slabs."

Table 2. Design k Values for Cement-

Treated Subbases

Sabgrade Tubbaze F vive. ee

C am] Sim ain

50 170 0 a0

100 220 | 400 520

200 ao |_ 600 ao |

Coment-treated subbases are widely used for heavy-

duty concrete pavements. They are constructed from

AASHTO Soil Classes A-I, A-2-4, A-2-5, and A-3 granu-

lar materials, The cement content of cement-treated sub-

base is bused on standard ASTM laboratory freeze-thav:

and wetdry tests! “and PCA weight-loss criteria."

Other procedures that give anequivalent quality of mate-

rial can be used. Design k values for eement-treated sub-

bases meeting these are given in Table 2.

In recent years, the use of lean concrete subbases has

been on the increasé, Thickness design of concrete pave-

‘ments on these very stiff subbases represents a special

‘case that is covered in Appendix B.

Design Period

‘The terin design period is used in this publication rather

than pavement life. The latter is not subject to precise

definition. Some engineers and highway agencies cons

sider the life of a concrete pavement ended when the first

‘overlay is placed. The life of concrete pavements may

vary from less than 20 years on some projects that have

carried more traffic than originally estimated or have had

design, material, or construction defects to more than 40,

years on other projects where defects are absent

The term design period is sometimes considered to be

synonymous with the term traffic-analysis period. Since

traffic can probably not be predicted with much accuracy

for a longer period, a design period of 20 years is com-

monly used in pavement design procedures. However.

there are often cases where use of a shorter or longer de-

sign period may be economically justified. such as a spe-

cial haul road that will be used for only a few years, ora

of subbase is recommendel for projecis where condi

would eae modpumping preva f ,

‘should be used and how thick they should bese the PCA publication.

Subgrades and Subboses for Concrete Pavements.

or heavy=

ted from

“Beran.

ated sub-

e7e-thaw

"of mate-

ated sub-

2

bases has

ete pave-

a special

on rather

0 precise

the first

hat have

have had

ethan 40

nger de-

as 2 spe-

‘ubbases

beatin,

CALIFORNIA GEARING RATIO-CORI eae >

6 7890 1° 20 | as Sg0 ag c foie

ASTM SOIL CLASSFICATION SYSTEM‘)

| Untied Clatitzoton) |

LT]

ARSHTO SOL CLASSIFICATION 3)

|

FEDERAL AVIATION ADHNIS TRATION

SOW CLASSIFICATIONS?

| RESISTANCE VALUE=)

wo) 401 [- w 0

JMoouLus OF susGRADE REACTION-K PS! PER wy (6)

0 20 ee

i

CALIFORNIA BEARING RATIO- COR

oe se 3203s 30

£1 For na besiege, s00 0.5. Porter, “Foundations for Fesole Pavement

Moatng, 1302. Vol 22 bapes 160-136

(@) ASTM Designation 0248"

(3) “Ciatsteston of highway Subgeade Mater

nesee

(4) Anport Paving, US. Ospariment of Commerce, Federal Avision Agency, May 1848, pages 1-16. Extimated uting valute given in FAA Oz

‘stant for Airport Pavements {Formerly used FAA Classiieaon; Unied Glessileation now used) 20s tenia eae

di). ames, “Corian Batwen ave and kun unpusned Yep Porkond Gamat Asotin, esky Moule Nortoes

glen, Oztoser 1971 foes correlation with corectio for sturavon,

nd. Bantam, “So Tests for Design of Funny Pavements” Higimay Research Board Proceedings of tne Twe~t

second Anrin! Mosing. 1342, Vol 72 page 1

{7 See tem (6), page 18

"Highway Research Board Proceesings of the Twonty-racond Aa 2

Highway Research Board Proceedings of the TwoniylithAnnuAl Meeting: 1945. Yor 28. ea

Fig, 2. Approximate interrelationships of soll classifications‘and bearing values.

for which high lvel of performance

prem ene with ile or no pavement maintenanceis

fora longtime wi ter el thatthe desig pti for

desc. orhca highways should ben the range of 300

35 YEO sign period selected affects thickness design

since determines how many years and thus how many

Tui! the pavement must serve. Selection of the design

aif fora specific projects based on enginecringjudg-

Pen and economic analysts of pavement costs and Sr¥~

ice provided throughout the entire period,

premium facil

Traffic

“The numbers and weights of heavy axle loads expected

during the design life are major factors in the thickness

design of concrete pavement, These are derived fromesti-

mates of,

ADT (average daily traffic in both directions, all

vehicles)

ADTT (average daily truck trafficin both directions)

axle loads of trucks

Information on ADT is obtained from special traffic

counts or from state, county, or city traffic-volume maps.

This ADT is called the present or eurrent ADT. The de-

sign ADT is then estimated by the commonly used meth-

ods discussed here. However, any other method that gives

reasonable estimate of expected traffic during thedesign

life can be used.

Projection

‘One method for getting the traffic volume data (design

ADT) needed is 10 use yearly rates of traffic growth and

traffic projection factors. Table 3 shows relationships be-

tween yearly rates of growth and projection factors for

both 20- and 46-year design periods.

In a design problem, the projection factor is multiplied

by the present ADT to obtain adesign ADT representing

the average value for the design period. In some proce-

dures, this is called AADT (average annual daily traffic).

‘The following factors influence yearly growth rates and

traffic projections:

|. Attracted or diverted traffie—the increase overexist-

ing traffic because of improvement of an existing

roadway.

2. Normal traffic growth—the increase duetoincreased

numbers and usage of motor vehicles.

3. Generated traffic—the increase due to motor vehicle

trips that would not have been made ifthe new facil

ity had not been constructed

4, Development traffic—the increase due to changesin

land use due to construction of the new facility,

The combined effects will cause annual growth rates of

about 2% to 6%. These rates correspond to 20-year traf-

fic projection factors of 1.2 to 1.8 as’shown in Table 3

‘The planning survey sections of state highway depart-

ments are very useful sources of knowledge about traffic

growth and projection factors.

Table 3. Yearly Rates of Trattlc

Growth and Corresponding

Projection Factors™

Yearly

‘ate of

tate Projection

growth ‘actor,

m ao yeats 40 years

7 + 12

4 12 13

2 12 18 |

2 13 16

3 12 18

an 14 20

4 15 22 |

a 16 24 i

5 16 27 i

5% 17 29

6 18 32

Where there is some question about the ratc of growth.

i may be wise to use a fairly high rate, This is true oa

intercity routes and on urban projects where a high rate

of urban growth may cause a higher-than-expected rate

of traffic growth, However, the growth of truck volumes

may be less than that for passenger cars.

High growth rates donotapply ontwoslane-ruralroads

jential streets where the primary function island

use or abutting property service. Their growth ratesmay

be below 2% per year (projection factors of 1.1 to 1.3)

‘Some engincers suggest that the use of simple interese

‘growth rates may be appropriate, rather than compounc

interest rates, which when used with a long design perioc

may predict unrealistically heavy future traffic. |

Capacity

‘The other method of estimating design ADTis based o@

capacity—the maximum number of vehicles that can use

the pavement without unreasonable delay. This method

of estimating the volume of trafficis described in Appec |-

dix D and should be checked for specific projects wher= |

the projected traffic volume is high; more traffic lanes

may be needed if reasonable traffic flow is desired

ADTT

‘The average daily truck trafficin both directions(ADTT)

is needed in the design procedure. It may be expressed as

4 percentage of ADT or as an actual value, The ADTT

value includes only trucks with six tires or more and does

‘not include panel and pickup trucks and other four-tir®

vehicles. 7 ;

‘The data from state, county, or city traffic-volunne

maps may include, in addition to ADT, the percentage oof

te

th.

cle

the

hig

Th

sig

wh

fou

sys

wh

Tike

lary

Ta

growth.

high rate

cied rate |

volumes

rralroads

on is land

rates may

10 1.3).

>mpounc

gn petiog

based on

s method

n Appen-

cts where

ffic lanes

red.

(ADTT)

ressed 2

@ ADTT

and does

four-tire

tucks from which ADTT can be computed.

For design of major Interstate and primary system

projects, the planning survey sections of state depart

‘ments of transportation usually make specific traffic sur

veys. These data are then used to determine the percent

age relationship between ADTT and ADT.

‘ADTT percentages and other essential traffic data can

also be obtained from surveys conducted by the highway

department at specific locations on the state highway sys

tem. These locations, called loadometer stations, have

bbeen carefully selected to give reliable information on

traffic composition, truck weights, and axle loads. Sur-

vey results are compiled into a ser of tables from which

the ADT percentage can be determined for the highway

classes within a state. This makes it possible to compute

the ADTT percentage for each station. For example, a

highway department loadometer table (Table W-3) for a

Midwestern state yields the following vehicle count for a

loadometer station on their Interstate rural system:

All vehicles ADT 9492

Trucks:

All single units and combinations

Panels and pickups

Other four-tire single units»

Therefore, for this station:

1645

353

7

Te = 1645 ~ (953 + 76) = 1216

= 26 7

ADIT = B28 x 100 = 13%

This ADTT percentage would be appropriate for de-

sign of a project where factors influencing the gowth and

composition of traffic are similar to those at this load-

ometer station,

Another source of information on ADTT percentages

is the National Truck Characteristic Report." Table 4,

which is taken from this study, shows the percentages of

four-tire single units and trucks on the major highway

systems in the United States. The current publication,

which is updated periodically, shows that two-axle, four.

tire trucks comprise between 40% to 65% of the total

‘number of trucks, with a national average of 49%. It is

likely that the lower values on urban routes are due to

larger volumes of passesiger cars rather than fewer trucks.

Table 4. Percentages of Four-Tire Single Units and

Trucks (ADTT) on Various Highway Systems

For design purposes, the total number of rucks in the

n period is needed. This is obtained by multiplyice

design ADT by ADT percentage divided by 100. tims

the number of days in the design period (365 X design

period in years).

ies of four lanes or more, the ADT is ¢2

justed by the use of Fig. 3

100

‘ADT (One Diteton), THOUSANDS

a a a

PROPORTION OF TRUCKS WRIGHT LANE

Fig. 3. Proportion of trucks In right lane of a muttitane

divided highway. (Derived trom Relerence 38.)

~"VTrcks ences panels and pickups and other foursive vehi

Rural average sy vate | Urben average dally wats

ign Tora Totat

Syston wens | Tot Trucks | “ot

Grn | am (aor | botn

Interstate «| 2 pas we | 2

omer tegera | 4 |,

ore eee 3s | 2 | ow 9 | 2

Scotay’ | 0 | os | as | 14 e [2

PE ee et nmsued tase wis

In mor dein ra a atonattaly

a eae doesnt

a a aT AD TL Ts

may not be

Axle-Load Distribution

Data on the axleoad distribution of the truck traffic is

heeded to compute the numbers of single and tandem

cles" of various weights expected during the design per-

fod. These data can be determined in one of three ways

(1) special traffic studies to establish the loadometer data

for the specific project; (2) data from the state highway

department's loadometer weight stations (Table W-4) or

regh-in-motion studies on routes representing truck

Weights and types that are expected to be similar to the

project under design: (3) when axle-load distribution

Gata are not available, methods described in Chapter 4

based on categories of representative data for different

types of pavement facilities

The use of axle-load data is illustrated in Table 5 in

which Table W-4 data have been grouped by 2-kip and

4-kip increments for single- and tandemvaxle loads, re-

yectively. ‘The data under the heading “Axles per 1000

Trucks” are in a convenient form for computing the axle-

toad distribution. However, anadjustment must be made.

Column 2 of Tabie 5 gives values for all trucks, including

the unwanted values for panels, pickups, and other four-

tire vehicles, To overcome this difficulty, the tabulated

Values are adjusted as described in the Table 5 notes.

Column 4 of Table 5 gives the repetitions of various

single- and tandem-axle loads expected during a 20-year~

design period for the Design | sample problem given in

Chapter 3.

\ Load Safety Factors

In the design procedure, the axle loads determined in the

previous section are multiplied by a load safety factor

(LSF). These load safety factors are recommended:

* For Interstate and other multilane projects where

there will be uninterrupted traffic flow and high vol-

umes of truck traffic, LSF = 1.2

'* For highways and arterial streets where there will be

moderate volumes of truck traffic, LSF = 1.1.

'* For roads, residential streets, and other streets that

will carry small volumes of truck traffic, LSF = 1.0.

Aside from the load safety factors, a degree of conserv~

atism is provided in the design procedure to compensate

Table 5. Axle-Load Data

a @ a @

axis

Jantes por | 1:

fatetoad, | 1000 | truck ci

Noe | tucks | fadiustoc) | nenioe

Single axles

eu | om

26-28 065

2426 133

2228 2a

2022 an

re20 | 1040 oy

rere | tas6 |

vers | 1868

yore | 25.069 . “

wore ~ | 61.06.

152 O88

wea 188

soe sst ‘

asao | wes

3236 | 3908

2032 | 4106

zeze | 1307

rors | aes

w20 | seis |

ete | s9as |

{Golumns tand2aenveation

Slot tora wen counted wi

Gun grt 52/00)

{Colm «= Colum trucks

for such things as un

mal construction varia "

layer thicknesses. Abo’ ‘

(LSF = 1.0), the load sat

a greater allowance (

heavy truck loads anc

ment. serviceability

‘ment facilities

In special eases. th:

1.3 may be justified

level of pavement serie)

periéd. Anexample is « ‘

alternate detour route

better to provide a pre hay to. © seu

Tong time the need fo: 4

tenance that would 0) 0

TSee Appendix Cifitse

incloded i the talc fo

~~

182%.

and nor-

rties and

ervatism

? provide

oredicted

tof pave-

Pe pave-

sshighas

a-normal

ie design

y with no

(may be

rent for 2

cnt main-

CHAPTER 3

Design Procedure

(Axle-Load Data Available)

The methods in this chapter are used when detailed axle-

load- lade

f- 25

et

otic

otic 100e

Fig. 60, Erosion analysis—allowable load repetitions

based on erosion factor (with concrete shoulder.

PRISER cso CORRE HORI LPS 6

Calculation of Pavement Thickness 7

Design tte, Paass lass Latarstatia,, patel eee

[ove

12.2 Doweled oints: yes ——

is Cesian pericd ZO vears ms

Project

‘al thickness —

sunbase-subgrade # ——ZAP2

Modulus of eupture. MB BS.

in. cement Awake sible 7

per Conerete shoulder yes 0 =

wutioiea | expecteg — L |

|e eae Favgue, | Algae

[42 | j_ pea | tito

cs 2 oo ‘ ‘ee feel

sequuatentswess 46 7.- YoErosiontactor 2.72

rey a. sess rate ctor 2 25-7

$$ t

| 40 | eo, 4810 | 4222 220

ga [ase | 620 | alanitea’

| _zé | 24 eo |

- bLEVLO

22 | zee, Sete

| 20 | 240 | 235 4e@o }

i 2s 00 |

L“w@| vez) “22 S22

(“4 | 44) sg a0 | ___—

Loivz | see | 4837 2e@0 | —__—

18, Equweatent stress

$2, Suess ran fn

Tandem Axles

Use | Aa

SD a. 2

S2L A ft

a. 25 LAD

3 2.220 a

S Z. taal ia 3b.

; ic “ |

2 i rn

a d 7 L

Fig. 7. Design 10.

20

i Pees

Worksheets for the other variations of Design | are not

shown here but the results are compared as follows:

“Ticknes

95

shoulder

Sonbase Joins

pranular doweled

in. cementtreated | doweled aS

in. granular doweled | ye 85

in, comentreated | aggregate

interlock | no 190

in, cementarcated | aggregate

interlock | yes Bs

For Design 1 conditions, use of a cement-trcated sub-

base reduces the thickness Fequirement by L.Oin. (Design

TA versus IB); and concrete shoulders reduce the thick=

ness requirement by 1.0 0 1.5in. (Designs TA versus IC

land 1D versus IE), Use of agaregate-interlock joints in=

stead -of dowels increases the thickness requirement by

LS in, (Design 1B versus. ID). These effects will vary in

different design problems depending on the specific de~

sign conditions

Design 2

Project and Traflic Data:

Awo-lane-secondary road

Design period = 40 years

Current ADT = 600

Projection factor = 1.2

ADTT = 2.5% of ADT

‘Traffic Calculations

Design ADT = 600 X 1.2 = 720

ABET 720 0025 "18

Trick athe cach ay = 2

Fora doer design period

93 38 3A = 13.40 eek

Axle-load data are shown in Table 15, Category I.and

the expected number of axle-load repetitions are shown

in Fig. 8

Values Used to Calculate Thickness:

Design 2A: aggregrate-interlock joints, no subbase,* no

concrete shoulder

Clay subgrade, &

LSF = 10

Conerete MR. = 650 psi

00 pei

Design 2B: doweled joints.** no subbase,.no concrete

shoulder

~ Same as 2A except

Dovweled joints

‘Thickness Calculations:

For Design 2A, a trial thickness of 6 in. is evaluated by

completing the worksheet shewn in Fig. 8, according t

the procedure given on page 11. Table Ga and Fig. $ att

used for the fatigue analysisand Table 7b and Fig. 622¢¢

used for the erosion analysis.

For Design 2B, a worksheet is not shown here but th:

design was worked out for comparison with Design 24

Comments on Design 2

For Design 2A; (1) Totals of fatigue use and erosio

damage of 89% and 89%, respectively, show that the 6.0%

thickness is adequate. (2) Separate calculations show th

a 5.S:in, pavement would not be adequate because ©

excessive fatigue consumption. (3) The thickness de

is controlled by the fatigue analysis—which is usually

cease for light-truck-traflic facilities

The calculations for Design 2B, which is the same s

Design 2A except the joints are doweled, show Tatig.

and erosion values of 89% and 2%, respectively. Co™

ments: (1) The thickness requirement of 6.0in.is the

as for Design 2A. (2) The fatigue-analysis values are ¢

actly the same as in Design 2A.* (3) Because of the dos

cls, the erosion damage is reduced from 8% to 2%¢: ho’

fever, this is immaterial since the fatigue analysis contro

the design,

For the Design 2 situation, itis shown that dowex

joints are not required. This is borne out by pavemes

performance experience on light-truck-traffic facili,

Such as residential streets and secondary roacs and a:

bystudies"” ™ showing the effects of the number of trus

fon pavements with ageregate-interlock joints

“Performance experience tas shown that subbase) are 30424

sehen ruck tafie vers heh seethe PCA publication, Suterades«

Sunbases for Concree Pavements

Desi 20 shown for ilusatve purposes only. Doseies jo

are not nese where truck aie very ightsse the PCA pubs

Sein Design for Concree Highwas and Sven) Pavemert

{The typeof load transfer atthe joints—dowel, or apsrees<

Jost docs not afet the fatiguecaeulations sine the eval ani

postion for stress snd fatigue e wherethe axle loads are paced mips

fhent edge and migpanc, away (rom the joins See Appendix A

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design of Bridges - Krishna Raju PDFDocument462 pagesDesign of Bridges - Krishna Raju PDFravi kumar100% (7)

- InvoiceDocument1 pageInvoiceravi kumarNo ratings yet

- Fibretron BrochureDocument13 pagesFibretron Brochureravi kumarNo ratings yet

- Footing Design PDFDocument84 pagesFooting Design PDFravi kumarNo ratings yet

- Gad Box 9+600Document1 pageGad Box 9+600ravi kumarNo ratings yet

- RCC Drain - SteelDocument1 pageRCC Drain - Steelravi kumarNo ratings yet

- 2022 Ftswebinar Nolan GFRP RC - DesignDocument67 pages2022 Ftswebinar Nolan GFRP RC - Designravi kumarNo ratings yet

- 2019 ACI FRP Composites Competition Reinforcement Identification Guide and Product DatasheetsDocument7 pages2019 ACI FRP Composites Competition Reinforcement Identification Guide and Product Datasheetsravi kumarNo ratings yet

- 1.AASHTO-Guide For Mechanistic - Emperical Design PDFDocument35 pages1.AASHTO-Guide For Mechanistic - Emperical Design PDFravi kumarNo ratings yet

- TUF BAR BROCHURE 45 GPaDocument2 pagesTUF BAR BROCHURE 45 GParavi kumarNo ratings yet

- Two Way SlabDocument2 pagesTwo Way Slabravi kumarNo ratings yet

- Beam DesignDocument15 pagesBeam Designravi kumarNo ratings yet

- Pup 512+960 (512+930) RCDocument1 pagePup 512+960 (512+930) RCravi kumarNo ratings yet

- DN Pup 512+960Document53 pagesDN Pup 512+960ravi kumarNo ratings yet

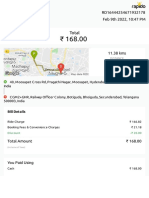

- Total: RD16444254671932178 Feb 9th 2022, 10:47 PM Ride ID Time of RideDocument3 pagesTotal: RD16444254671932178 Feb 9th 2022, 10:47 PM Ride ID Time of Rideravi kumarNo ratings yet

- Pup 512+960 (52+930) GadDocument2 pagesPup 512+960 (52+930) Gadravi kumarNo ratings yet

- Flexural-Torsional Buckling Assessment of Steel Beam-Columns Through A Stiffness Reduction MethodDocument30 pagesFlexural-Torsional Buckling Assessment of Steel Beam-Columns Through A Stiffness Reduction Methodravi kumarNo ratings yet

- DN - 28+757 - MNB - Box TypeDocument17 pagesDN - 28+757 - MNB - Box Typeravi kumarNo ratings yet

- The Orthogonality Relation: Appendix To A Radical Approach To Real Analysis 2 Edition C 2006 David M. BressoudDocument2 pagesThe Orthogonality Relation: Appendix To A Radical Approach To Real Analysis 2 Edition C 2006 David M. Bressoudravi kumarNo ratings yet

- Skew DesignDocument70 pagesSkew Designravi kumarNo ratings yet

- DN - 28+757 - MNBDocument46 pagesDN - 28+757 - MNBravi kumarNo ratings yet