Professional Documents

Culture Documents

Adobe Scan 16-Aug-2023

Adobe Scan 16-Aug-2023

Uploaded by

danishmiddya18Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adobe Scan 16-Aug-2023

Adobe Scan 16-Aug-2023

Uploaded by

danishmiddya18Copyright:

Available Formats

11 Introduction to Machine Tools

Learning Objectives

The contents of this chapter would enable the readers to:

Express the exact roles of machining and " List the elementary machining operations gen

machine tools in manufacturing. erally carried out in the conventional machine

Define machine tools, identify their common tools.

features and state the functions of their major Identify the major aspects associated with

Components. machine tools.

Visualize the basic configurations of the pri

mary machine tools.

11.1 Introduction

Finishing by machining through gradual material removal from blanks started about thousand years ago.

For instance, logs of irregular sizes and shapes were machincd to produce cylindrical rods with the required

dimensional accuracy and finish for specific advantageous applications. The machining was done by sharp

edged stones as cutting tool and employing reasonable tool-work motions and energy manually.

Need for strong and hard materials, such as various metals and alloys; innovation; development: and grow

ing demand for rapid production and good product quality result in improvement of design, development

and wide use of machine tools starting from centre lathes, drilling machines, shaping. planing and sloring

machines, milling machines and so on. With time and demand several other machine tools such as boring

machines, gear shaping and hobbing machines, broaching machines, etc. have also come up.

The common features of all such conventional machine tools include (a) firm holding of the job and the

tool, (b) kinematic system to transfer motions and power from the power source(s), mostly electric motors, to

the job and tool and () che strong and robust body structure. Anumber of machine tools are used to accom

plish different types of machining operations - turning, drilling, boring, shaping, milling, etc. - to produce

cylindrical surfaces, Aar surfaces, contour surfaces and parting, slitting, slotting, grooving,etc. Machine tool

engineering covers several aspects: planning, design, manufacture, installation, inspection, operation and

maintenance of machine tools. Allsuch points have been briefily highlighted in this chapter.

11.2 Definition and Role of Machine Tool

With the rapid and vast developments in science and technology, innumerable techniques and processes

of manufacturing products, of various materials, configuration and precision have been innovated and

420 Machining and Machine Tools

removal and

- forming, joining

incorporated." All these processes are grouped into four major categoricsmachining

by and grinding by which

rgeneratie.The removal process in manufacturing is accomplished

accuracy and surface finish for proper functioning,

jobs are semi-finished or finished to desired dimensional Preforming like casting, forging, rolling, etc.

improved performance and longer service life of the products. engineering products need machining after pre

cannot provide such accuracy and finish, hence most of the powerful and robust machines called machine

torming. Machining and grinding inevitably require use of come

tools. Therefore, without machine tools not only several engineering components but also other machines and

industries and socio-economy are extremely depen

cquipments cannot be produced. Hence, manufacturingseveral ways0; one comprehensive definition is:

dant on machine tools. Machine tool can be defined in to pro

machine tool is a non-portable and poweroperated device or system of devices in which energy is espendedblank(s)

A removing excess material from the preformed

duce jobsofdesired dimension and finish by machining, that is, work surface at contolled speeds and feeds.

the

in the form of chips with the help of cutingtool(s) moved past

and Their Functions

11.3 Major Components of Machine Tools

machine, etc.) essentially comprises some major

Any machine tool (e.g., lathe, drilling machine, milling

components as common features such as:

1. Devices for holding the blank and the cutting tool(s) properly and firmly.

workpiece.

2. Devices for providing motions and power to the tool(s) and the and power from the power source(s)

3. Kinematic system for transforming and transmitting the motions

to the tool(s) and workpiece.

4. Automation and control systems.

quite strongly, rigidly and safely.

5. Heavy structural body to support and accommodate those systems

between the workpiece and the

Machining in any machine tool needs proper contact and relative motions cutting power from the power

tool. The firmly held tool and the workpiece receive the desired motions and the number of mechanisms. The

drive of the machine through a kinematic system comprising various types and

slide along the guides provided on

cutting tool or workpiece may be mounted on a table, which is made tocomprises

the machine tool body. The robust structural body of the machine tool a base, bed, column, legs,

machine tool are firmly

etc. depending on the type and size of the machine tool. The base or columnsof the guides to enable

grouted on a proper foundation. The bed and columns of the machine tool are provided with

the slides holding the work or tool move in desired directions. Besides this, a machine tool essentially also

too-work motions.

possesses systems of varioustypes for manual or automatic control of the

11,4 General Configuration of Common Machine Tools

and Their Uses

11.4.1 Centre Lathes

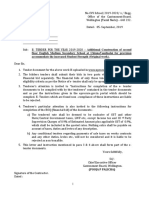

Lathes, especially centre lathes, are most widely used in machine shops for their versatility. General con

figuration of centre lathe is shown in Fig. 11.1. The major components and their functions in acentre lache

are as follows:

1. Headstock: This heavy housing, being mounted on the bed at its left end, receives power and motion

from the motor and transmits the same to the workpieces through a clutch, speed gear box (SGB)

Introduction to Machine Tools 421

Tool post Job(rod) Tailstock

Tool

Headstock

SGB

www

FGB +

Rack

-Feed rod

Leadscrew

Bed

Carriage

Figure 11.1 | Configuration and salient features of centre lathe.

and the spindle contained in the headstock housing, Thus, the headstock enables rotating the work

piece at different speeds as required.

2. Tailstock: This relatively smaller body can be shifted and fixed at any location on the lathe bed coaxi

ally with the headstock. The main functions of the tailstock are to provide support to long and heavy

workpieces and often hold and move some cutting tools for operations like driling, reaming, etc.

3. Carriage: This heavy part with a number of mechanisms and parts in it is made to slide along the

lathe bed. The carriage firmly holds the tools and moves it at different feed rates. The carriage derives

motions usually from the spindle through a feed gear box (FGB) and a feed rod or lead screw.

4 Bed: This rigid bulky horizontal beam stands firmly on two legs or columns. On the bed, the head

stock remains bolted, the tailstock is shifted and clamped and the carriage slides.

5. Work-tool holding devices: The blanks are usually mounted in berween centres or chucks, whereas

curting tools are generally held in the tool post which is mounted on the saddle. Tools are also offen

held in the tailstock quill.

The common and frequent uses of cenre lathes include the following:

1. Turning, which is of rwo types external and internal. These can be furher subdivided into straight,

taper, stepped, contour.

2. Facing, chamfering, grooving, parting, etc.

3. Centering, drilling, reaming, boring, etc.

4 Thread cutting: external and internal.

5. Knurling,

done in

Some of these operations are schematically shown in Fig. 11.2. Several other operations can also be

centre lathes using suitable attachments.

11.4.2 Shaping Machine

their

The general configuration of shaping machine' is shown in Fig. 11.3. The major components and

functions in a shaping machine are as follows:

Ram: This salient part is made to reciprocate horizontally along a fixed guide and provides the cut

ting motion to the tool being mounted in front of the ram.

422 Machining and Machine Tools

Grooving Forming Threading

Turning Facing

External

Internal

Figure 11.2 Some common machining operating done in centre lathe.

motions to the

2. Bed: This heavy rigid body moves slowly along the horizontal guides to provide feed

blank mounted on the bed.

main driving

3. Housing (body) with base: This hollow but rigid large structure accommodates the

mechanisms and provides support to the moving ram and the bed. mechanisms.

change

4. Power drive: It is the source of power and motion with spced and feed

Shaping machines are generally used for machining lat surfaces in different planes, grooving, splitting, etc.

of shaping machines has now-a-days been limited to

Because of poor productivity and process capability, useindustries.

only piece production and maintenance work in small

Clapperbox Ram

Tool

Job

Housing

Vice

Power drive

Bed

Base

Figure 11.3 Configuration of shaping machine.

11.4.3 Planing Machine

The general configuration of planing machine is shown in Fig. 11.4. Paning machines also do almost the

same type of machining operations as done in shaping machines. However there are some differences; the

major ones are as follows:

Introduction to Machine Tools 423

-Frame

Tool.

Job

Table

Power

Bed drive

Base

Figure 11.4 |General configuration of planing machine.

1. In planing, the table with the job reciprocates to impart cuting motion and the tool moves slowly

for the feed motion unlike in shaping machine.

2. Planing machines are usuallymuch larger and heavier than shaping machines and are used for large

jobs and heavy duty work.

11.4.4 Drilling Machine

Drilling machines are used!' mainly to produce straight cylindrical holes in solid bodies with the help of

drill bits. Drilling machines widely vary in configuration and size. Figure 11.5 typically shows configura

tion of a commonly used column type drilling machine. Drilling machine (column type) comprises the

following:

1. Column: A long hollow but rigid vertical structure which stands on its base and provides support to

theother components.

2. Drilling head: This box type body accommodates the power drive and the gear boxes to adjust speed

and feed.

3. Spindle: This rod-like component is rotated and axially moved along with the coaxially mounted

drill to impart both cutting motion and feed motion to the tool.

Drilling machines of different sizes and configurations are used

1. Mainly for creating or enlarging straight cylindrical holes.

2. Ocasionally for boring, counter boring, counter sinking, etc.

3. Often for cuting internal threads in objects like nuts using suitable attachments.

11.4.5 Milling Machine

The general coniguration of typical knee type conventional milling machinewith horizontal arbour is

shown in Fig. 11.6. Its major parts are as tollows:

1. Milling arbour to hold and rotate the cutter.

424 Machining and Machine Tools

Drilling Feed

head Speed gear

gear box

box

Spindle

Column

Drill

Bed

Base

Figure 11.5 | Configuration of a typical drilling machine.

Ram

Cutter

job

Speed

gear

Feed box

gear

box

Base

Flgure 11.8 | Contiguration of atypical drilling machine.

Introduction to Machine Tools 425

Surtacing Slotting Grooving Slitting Forming

Figure 11.7 Some common milling machines.

2. Ram to support the arbour.

3. Machine table on which job and job holding devices are mounted to provide the feed motions to

the job.

4. Power drive with speed and feed gear boxes to provide power and motions to the tool-work.

5. Bed which moves vertically upward and downward and accommodates the various drive

mechanisms.

6. Column with base which is the main structural body to support other parts.

Milling machines are also quite versatile and can do several operationssuch as:

1. Making Aat surfaces in different planes.

2. Grooving, slitting and parting.

3. Helical grooving.

4. Forming 2-D and 3-D contoured surfaces.

Figure 11.7 shows some of theaforesaid milling operations. More detailed discussions with several illustra

tions are provided in the subsequent chapters.

11.5 Major Aspects of Machine Tools

The major aspects of machine tools engincering and their functional interrelations are indicated in

Fig. 11.8. Amachine tool manufacturing industry first makes a proper planning and critically decides,

after thorough survey of the market demands and socio-economy, the category, type, capacity, precision,

automation, etc. of machine tools they will manufacture. After selection, the machine tools are designed

and then manufactured accordingly. Atdifferent stages and completion of manufacture, cach prototype is

inspected and tested. The customer or the users first select from these manufactured and available machine

tools according to their need and satisfaction. Afrer purchase, the machine tool is mounted and installed on

a suitable foundation. Before regular use or operation, the machine tool has to be properly commissioned

and tested. During and after operations, the performance of that machine tool is assessed mainly in terms

of productivity and product quality. If the performance is not sarisfactory, the causes are analysed and the

experts prepare a list of corrective measures to be undertaken by the operator, maintenance section or even

designer and manufactures of that machine, immediately or later for desirably good or better performance

of that machine tool.

426 Machining and Machine Tools

Foundation and installation

Design Manufacture Selection

Testing

Operation

Maintenance Assessment

Modification/

Corrective measure Analysis

improvement

Figure 11.8 Major aspects associated with machine tools.

SuMMARY

The roles of machining and machine tools in The general applications of the different classical

machine tools have been mentioned here.

manufacturing industries and on socio-economy

have been highlighted. A reasonable definition of Machine tool engineering has obviously become

machine tool has been provided. AIl the conven a great concern in manufacturing and a feld of pro

tional machine tools possess some common features fessional interest of several sections of people. The

and components for serving specific purposes. This major aspects and the interactive modules of activi

has been briefly addressed. The general configura ties that are associated with machine tool engineer

tion, major parts and their features and purposes ing have been highlighted in this chapter. The actual

have been presented with respect to some primary work done in machine tools through generation of

machines: drilling machine and milling machine. geometrical surface by using Generatrix, Directrix

The elementary machining operations that are car and tool-work motions is discussed in the next

ried out in these machine tools are also illustrated. chapter.

MULTIPLE CHOICE QUESTIONS

[Answers are provided in the CD]

1. Machine tool helps manufacturing products (c) Do not deal with any energy

by (d) Both produce and use energy

(a) Joining process 3. The machine that can be called machine

(b) Metal forming process tool is

(c) Removal process (a) Stamping machine

(d) Regenerative process (b) Shearing machine

2. Machine tools (c) Rolling machine

(a) Produce energy (d) All of the above

(b) Utilize energy (e) None of the above

Introduction to Machine Tools 427

4. While machining, the workpiece rotates in

(a) Lathes

(b) Drop forging

(c) Hot rolling

(b) Drilling machines (d) Machining

(c) Shaping machines 8. The operation that cannot be done in lathes is

(d) Milling machines (a) Enlarging cylindrical hole

5. While machining, the cutting tool always (b)

rotates in

Internal thread cutting

(c) Parting

(a) Centre lathes (d) Knurling

(b) Shaping machines (e) None of the above

(c) Planing machines 9. The oldest machine tool is

(d) Milling machines (a) Lathe

6. The process which cannot be called preform

(b) Shaping machine

ing is (c) Planing machine

(a) Rolling (d) Milling machine

(b) Forging 10. Flat surfaces are not produced in

(c) Machining (a) Lathe

() Welding (b) Drilling machine

7. Maximum dimensional accuracy and surface

(c) Shaping machine

finish can be achieved by (d) Milling machine

(a) Sand casting

REVIEw QUESTIONS

1. How can 'machine tool' be defined? What the tool, workpiece, base, spindle, column and

socio-economic roles are played by machine motor in that machine.

tools for the industries and the nation? 7. Show by line diagram, a milling machine and

2. Name the major components common to all visualize its ram, column, bed and tool-workpiece

conventional machine tools and the functions mounted in that machine.

of those components. 8. Show by suitable diagrams some (at least five)

3. Show by simple diagrams the various ma common machining operations that are con

chining operations that are generally done in ducted in milling machines.

lathes. 9. Where and how the cutting tool and he

4. State the locations and functions of the head workpiece are mounted in shaping machine

stock, tailstock and carriage in centre lathes. and planing machine?

5. How are planing machines different from 10. Describe briefly, with the help of a block dia

shaping machines? gram, the major aspects that are associated

6. By sketching a simple line diagram ofa drilling with machine tools engineering,. Also show the

machine, visualize the location and position of inter-connections amongst those aspeCts.

You might also like

- 2017 Yamaha MT-09 Workshop Manual.Document553 pages2017 Yamaha MT-09 Workshop Manual.Michael Ward100% (2)

- CNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopFrom EverandCNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopRating: 5 out of 5 stars5/5 (3)

- Design of Machine Tools (Me 541) NoteDocument52 pagesDesign of Machine Tools (Me 541) Notejimoh100% (1)

- Finite Element Analysis for Design Engineers, Second EditionFrom EverandFinite Element Analysis for Design Engineers, Second EditionNo ratings yet

- Alarmes - Fiberhome (Ok) PDFDocument282 pagesAlarmes - Fiberhome (Ok) PDFiury garcia100% (2)

- UNIT 1introductiontomachineandmachinetool PDFDocument18 pagesUNIT 1introductiontomachineandmachinetool PDFHaruna AbassNo ratings yet

- Introduction Machine ToolsDocument18 pagesIntroduction Machine ToolsMahesh JNo ratings yet

- UNIT 1introductiontomachineandmachinetoolDocument18 pagesUNIT 1introductiontomachineandmachinetoolBHAVESHNo ratings yet

- Machine Tools and Automation Machine Tools Operations Mod-3Document20 pagesMachine Tools and Automation Machine Tools Operations Mod-3code makerNo ratings yet

- Introduction To Machine and Machine ToolDocument18 pagesIntroduction To Machine and Machine ToolSachin ChaturvediNo ratings yet

- Manufacturing Engineering II Lecture TwoDocument19 pagesManufacturing Engineering II Lecture TwoEyu KalebNo ratings yet

- Unit - 1 Introduction To Machine Tools & MachinesDocument17 pagesUnit - 1 Introduction To Machine Tools & MachinesWeld Tech100% (1)

- Unit - 1: Introduction To Machine Tools & MachinesDocument21 pagesUnit - 1: Introduction To Machine Tools & MachinesGirmole Worku100% (1)

- Unit II - MCMTDocument50 pagesUnit II - MCMTSai RamNo ratings yet

- Unit 1 Introduction To Machine and Machine ToolDocument19 pagesUnit 1 Introduction To Machine and Machine ToolAtul GaurNo ratings yet

- Unit 2 Traditional Machine TheoryDocument80 pagesUnit 2 Traditional Machine Theorymandefro2No ratings yet

- Module 1 - Machining Science and Jigs & Fixtures (21me42)Document70 pagesModule 1 - Machining Science and Jigs & Fixtures (21me42)Manoj NNo ratings yet

- Module 6 Part 2 Bme-1Document17 pagesModule 6 Part 2 Bme-1joeste965No ratings yet

- Module 2Document10 pagesModule 2Shamanth M BabuNo ratings yet

- Unit 4Document19 pagesUnit 4Akhila ANo ratings yet

- Chapter 1Document14 pagesChapter 1Ali NoraizNo ratings yet

- Machine Tools Lab ManualDocument32 pagesMachine Tools Lab ManualPhani Gurijala100% (2)

- Personal Protective EquipmentDocument7 pagesPersonal Protective EquipmentJump ManNo ratings yet

- Buku Ajar Modul 4Document17 pagesBuku Ajar Modul 4Cynthia Sasmita DewiNo ratings yet

- 20 Shaping, Planing and Slotting Machines.Document16 pages20 Shaping, Planing and Slotting Machines.PRASAD326100% (2)

- Ijri Me 02 0010Document7 pagesIjri Me 02 0010ijripublishersNo ratings yet

- Classification of Machine ToolsDocument8 pagesClassification of Machine ToolsMuhammad Qasim Jameel100% (1)

- MSJF Mod-1Document20 pagesMSJF Mod-1abithek03No ratings yet

- Activity No.8 - Planer MachineDocument4 pagesActivity No.8 - Planer MachineDezza MarieNo ratings yet

- Sindhi Board of Technical Education Karachi: Diploma of Associate Engineer Technology:MechanicalDocument8 pagesSindhi Board of Technical Education Karachi: Diploma of Associate Engineer Technology:MechanicalMmmNo ratings yet

- Module 5 PDFDocument28 pagesModule 5 PDFkaushal shivaprakashNo ratings yet

- Machine Tools: Lathe & Lathe WorkDocument35 pagesMachine Tools: Lathe & Lathe WorkRahul Deb PalNo ratings yet

- Machine - Tools PDFDocument26 pagesMachine - Tools PDFAnonymous jpGaeT388100% (1)

- TurningDocument6 pagesTurningShivshankar Singh0% (1)

- Intelligent Design of Reconfigurable Machines: Majid Tolouei-RadDocument5 pagesIntelligent Design of Reconfigurable Machines: Majid Tolouei-RadBaitoiu George-MariusNo ratings yet

- MCMT Unit-IIDocument190 pagesMCMT Unit-IISai RamNo ratings yet

- Module 1Document21 pagesModule 1AzizNo ratings yet

- Unit 2 MEASUREMENT (BME) Basic Mechanical ENGINEERINGDocument8 pagesUnit 2 MEASUREMENT (BME) Basic Mechanical ENGINEERINGAlok Patel100% (2)

- DV09PUB1 Study GuideDocument5 pagesDV09PUB1 Study Guidesbbu agraNo ratings yet

- Lathe and Drilling MachineDocument99 pagesLathe and Drilling Machinesagar0% (1)

- 19 Kinematic System and Operations of Milling Machines.Document23 pages19 Kinematic System and Operations of Milling Machines.PRASAD326100% (5)

- Metal Machining and Automation (ME 3201)Document15 pagesMetal Machining and Automation (ME 3201)kasam santhosh prathikNo ratings yet

- Machine Tools Ind.Document9 pagesMachine Tools Ind.AbrahamNo ratings yet

- Turning: CHAPTER 2: Material Removal ProcessDocument66 pagesTurning: CHAPTER 2: Material Removal ProcessEbrahim AliNo ratings yet

- 2016 Winter Model Answer PaperDocument14 pages2016 Winter Model Answer PaperAditya KothimbireNo ratings yet

- Machine Tools LAB Manual PDFDocument77 pagesMachine Tools LAB Manual PDF5F2 SHAIK PALUR SAMEENANo ratings yet

- Chapter 1Document17 pagesChapter 1shubhanshuNo ratings yet

- Department of Mechanical Engineering: SJB Institute of TechnologyDocument54 pagesDepartment of Mechanical Engineering: SJB Institute of TechnologyChidu KNo ratings yet

- Theory of Lathe MachinesDocument12 pagesTheory of Lathe MachinesAman KumarNo ratings yet

- Chapter Two Traditional Material Removal Processes MachiningDocument21 pagesChapter Two Traditional Material Removal Processes MachiningkidusNo ratings yet

- 22 Use of Various Attachments in Machine Tools.Document19 pages22 Use of Various Attachments in Machine Tools.PRASAD326100% (5)

- Unit 3: Turning (Lathe), Shaping and Planning Machines: Classification, Constructional Features of Turret andDocument30 pagesUnit 3: Turning (Lathe), Shaping and Planning Machines: Classification, Constructional Features of Turret andNafees AhmedNo ratings yet

- RCBDocument35 pagesRCBNesarNo ratings yet

- M AchingDocument10 pagesM AchingSnehasishNo ratings yet

- Practicals Hand Book 2022Document45 pagesPracticals Hand Book 2022dhiviyamainanNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Practical, Made Easy Guide To Robotics & Automation [Revised Edition]From EverandPractical, Made Easy Guide To Robotics & Automation [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingFrom EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingRating: 5 out of 5 stars5/5 (2)

- Grinding Overview: Machinist Grinder Interview Questions and AnswersFrom EverandGrinding Overview: Machinist Grinder Interview Questions and AnswersNo ratings yet

- Micrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsFrom EverandMicrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsNo ratings yet

- Performance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisFrom EverandPerformance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisNo ratings yet

- Energy Conversion and Management: Gvidonas Labeckas, Stasys Slavinskas, Irena KanapkieneDocument25 pagesEnergy Conversion and Management: Gvidonas Labeckas, Stasys Slavinskas, Irena KanapkieneVỵ ĐặngNo ratings yet

- Cep PRC II 20 C 860Document44 pagesCep PRC II 20 C 860ImdadNo ratings yet

- S1-1-Design Considerations For Transformers in Unusual Service Condition-Prashant Kumar-ABBDocument6 pagesS1-1-Design Considerations For Transformers in Unusual Service Condition-Prashant Kumar-ABBMallikarjunNo ratings yet

- Delhi Building CollapseDocument5 pagesDelhi Building Collapsedaniyal rasheedNo ratings yet

- Specs Pmm101Document17 pagesSpecs Pmm101jacktor1No ratings yet

- MV RelaysDocument1 pageMV Relaysyadav_sctNo ratings yet

- JIR-12.a LDDocument48 pagesJIR-12.a LDAnderson OlivierNo ratings yet

- FMDS0796Document26 pagesFMDS0796Felipe Mees FaracoNo ratings yet

- Company Profile - InergyDocument11 pagesCompany Profile - InergyanilNo ratings yet

- Udyog ViharDocument12 pagesUdyog ViharAmit KanereNo ratings yet

- Techspecs fx180 240 EngDocument2 pagesTechspecs fx180 240 EngmjgosslerNo ratings yet

- Physics Grade 7Document6 pagesPhysics Grade 7hiscoreNo ratings yet

- Holographic TechnologyDocument23 pagesHolographic TechnologyShubhPatelNo ratings yet

- Ukfat 2013Document280 pagesUkfat 2013Bill JonesNo ratings yet

- Value Chain AnalysisDocument18 pagesValue Chain AnalysisjainsonaNo ratings yet

- Marine Transportation BS PresentationDocument49 pagesMarine Transportation BS PresentationGennel BatacanNo ratings yet

- Dishwasher Is A Machine For Cleaning Dishware and Cutlery Automatically. Unlike ManualDocument4 pagesDishwasher Is A Machine For Cleaning Dishware and Cutlery Automatically. Unlike ManualXMEN ツ MoRtAlNo ratings yet

- SMJ Product Catalogue 2019Document72 pagesSMJ Product Catalogue 2019Risma LaloNo ratings yet

- Tendernotice 1Document70 pagesTendernotice 1paulNo ratings yet

- Smooks User GuideDocument116 pagesSmooks User GuidePedroNo ratings yet

- Broadbent Sugar Centrifugal BrochureDocument0 pagesBroadbent Sugar Centrifugal BrochureHossam Mohamed KandilNo ratings yet

- Online Enrollment System For Cavite Maritime Institute DasmariÑas, Cavite ADocument105 pagesOnline Enrollment System For Cavite Maritime Institute DasmariÑas, Cavite Ajaz_0777802477% (30)

- Predefined Exception in Pl/sqlpredefined ExceptionsDocument4 pagesPredefined Exception in Pl/sqlpredefined Exceptionshari248668No ratings yet

- Progress Report: Project DetailsDocument4 pagesProgress Report: Project DetailsSOMNATH JANANo ratings yet

- Siswanto, Rian Wahyu Edi Sarwono, Aris Setyawan, Dedet Hermawan SetabudiDocument4 pagesSiswanto, Rian Wahyu Edi Sarwono, Aris Setyawan, Dedet Hermawan SetabudiGuntur PrawiraNo ratings yet

- TP Muhammad Baihaqi Bin Abd SomadDocument6 pagesTP Muhammad Baihaqi Bin Abd Somadapi-439620180No ratings yet

- Steps of Making WPSDocument51 pagesSteps of Making WPSmohammadkhairy0% (2)

- 101 Electronics Projects 1983 FallDocument100 pages101 Electronics Projects 1983 FallBenjamin Dover100% (3)

![Practical, Made Easy Guide To Robotics & Automation [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/253466853/149x198/4281882d40/1709916831?v=1)