Professional Documents

Culture Documents

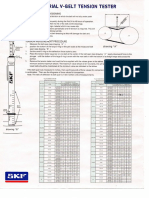

Belt Tension Gauge Instructions

Belt Tension Gauge Instructions

Uploaded by

Todor HuklevOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Belt Tension Gauge Instructions

Belt Tension Gauge Instructions

Uploaded by

Todor HuklevCopyright:

Available Formats

Belt Tension Checker

Warning! Caution!

• Read and follow all instructions carefully. • Periodic inspections should be performed. Failure to perform proper

• Disconnect and lock-out power before installation and maintenance. maintenance can result in premature product failure and personal

Working on or near energized equipment can result in severe injury injury.

or death. • To avoid damage, supporting structure including shafts and bearings

• Do not operate equipment without guards in place. Exposed must be designed to handle transmitted loads and belt tension(s).

equipment can result in severe injury or death.

Tensioning V-Belt Drives

General rules of tensioning

1. Ideal tension is the lowest tension at which the belt will not slip under

peak load conditions.

2. Check tension frequently during the first 24 hours of operation.

Check after jog start or 1-3 minutes of operation, at 8 hours, 24 hours,

100 hours and periodically thereafter are recommended.

3. Over tensioning shortens belt and bearing life.

4. Keep belts free of foreign material which may cause slip. Part Number: “Tension Gauge”

5. Make v-drive inspection on a periodic basis. Under-tensioned belt

drives often produce audible squeal noise. Tension when slipping.

Never apply belt dressing as this will damage the belt and cause early

failure.

Tension Measurement Procedure

1. Measure the belt span (see sketch).

2. Position bottom of the large o-ring on the span scale at the measured

belt span.

3. Set the small o-ring on the deflection force scale to zero.

4. Place the tension checker squarely on one belt at the center of the

belt span. Apply a force on the plunger and perpendicular to the belt

span until the bottom of the large o-ring is even with the top of the

adjacent (next) belt or with the bottom of a straight edge laid across

the outside diameters of the v-belt sheaves.

5. Remove the tension checker and read the force applied from the

bottom of the small o-ring on the deflection force scale.

6. Compare the force you have applied with the values given in the

tables on the back of this page. The force should be between the min-

imum and maximum shown. The maximum value is shown for “New

Belt” and new belts should be tensioned at this value to allow for

expected tension loss. “New Belt” tensions should be used at inital

installation and after jog start or 1-3 minutes of operation. Used belts

should be maintained at the minimum value as indicated in the chart.

“Used Belt” tensions should be used for the 8 hour and subsequent

checks. If the belt span was measured in inches, then use the force

values for comparison. If the belt span was measured in centimeters,

then use the kilograms of force values for comparison.

Note: The ratio of deflection to belt span is 1:64 in either units of

measurement.

7. Whenever possible, jog start for a few revolutions or preferably run

drive for approximately 1-3 minutes and then re-tension in

accordance with steps 1-6. Running the drive for a few revolutions

or minutes will help seat the belt(s) in the groove(s). This relatively

early re-tensioning may reduce or minimize the amount of

re-tensioning required in the first 24 hours of drive service.

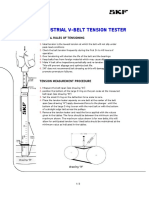

Note:

For banded (multiple or banded belts), the belt deflection force in the below tables must be multiplied by the number of ribs in the gripband. Lay a narrow steel bar such

as keystock across the gripband belt and apply the belt deflection force to the bar such that all the individual ribs are deflected evenly.

Sheave Diameter - Inches Sheave Diameter - Millimeters

Deflection Force - Lbs. Deflection Force - Kg.

Belt Deflection Force Belt Deflection Force

Smallest Super Gripbelts Gripnotch Belts Smallest Super Gripbelts Gripnotch Belts

Belt

Belt Cross Sheave RPM and Unnotched and Notched Sheave RPM and Unnotched and Notched

Cross

Section Diameter Range Gripbands Gripbands Diameter Range Gripbands Gripbands

Section

Range Used New Used New Range Used New Used New

Belt Belt Belt Belt Belt Belt Belt Belt

1000-2500 3.7 5.5 4.1 6.1 1000-2500 1.7 2.5 1.9 2.8

3.0 - 3.6 75 - 90

2501-4000 2.8 4.2 3.4 5.0 2501-4000 1.3 1.9 1.5 2.3

1000-2500 4.5 6.8 5.0 7.4 1000-2500 2.0 3.1 2.3 3.4

A, AX 3.8 - 4.8 A, AX 91 - 120

2501-4000 3.8 5.7 4.3 6.4 2501-4000 1.7 2.6 2.0 2.9

1000-2500 5.4 8.0 5.7 8.4 1000-2500 2.4 3.6 2.6 3.8

5.0 - 7.0 121 - 175

2501-4000 4.7 7.0 5.1 7.6 2501-4000 2.1 3.2 2.3 3.4

860-2500 - - 4.9 7.2 860-2500 - - 2.2 3.3

3.4 - 4.2 85 - 105

2501-4000 - - 4.2 6.2 2501-4000 - - 1.9 2.8

860-2500 5.3 7.9 7.1 10.5 860-2500 2.4 3.6 3.2 4.8

B, BX 4.4 - 5.6 B, BX 106 - 140

2501-4000 4.5 6.7 6.1 19.1 2501-4000 2.0 3.0 2.8 4.1

860-2500 6.3 9.4 8.5 12.6 860-2500 2.9 4.3 3.9 5.7

5.8 - 8.6 141 - 220

2501-4000 6.0 8.9 7.3 10.9 2501-4000 2.7 4.0 3.3 4.9

500-1740 11.5 17.0 14.7 21.8 500-1740 5.2 7.7 6.7 9.9

7.0 - 9.0 175 - 230

1741-3000 9.4 13.8 11.9 17.5 1741-3000 4.3 6.3 5.4 7.9

C, CX C, CX

500-1740 14.1 21.0 15.9 23.5 500-1740 6.4 9.5 7.2 10.7

9.5 - 16.0 231 - 400

1741-3000 12.5 18.5 14.6 21.6 1741-3000 5.7 8.4 6.6 9.8

200-850 24.9 37.0 - - 200-850 11.3 16.8 - -

12.0 - 16.0 305 - 400

851-1500 21.2 31.3 - - 851-1500 9.6 14.2 - -

D D

200-850 30.4 45.2 - - 200-850 13.8 20.5 - -

18.0 - 20.0 401 - 510

851-1500 25.6 38.0 - - 851-1500 11.6 17.2 - -

1000-2500 - - 3.3 4.9 1000-2500 - - 1.5 2.2

2.2 - 2.4 55 - 60

2501-4000 - - 2.9 4.3 2501-4000 - - 1.3 2.0

1000-2500 3.6 5.1 4.2 6.2 1000-2500 1.6 2.3 1.9 2.8

3V, 3VX 2.65 - 3.65 3V, 3VX 61 - 90

2501-4000 3.0 4.4 3.8 5.6 2501-4000 1.4 2.0 1.7 2.5

1000-2500 4.9 7.3 5.3 7.9 1000-2500 2.2 3.3 2.4 3.6

4.12 - 6.90 91 - 175

2501-4000 4.4 6.6 4.9 7.3 2501-4000 2.0 3.0 2.2 3.3

500-1749 - - 10.2 15.2 500-1749 - - 4.6 6.9

4.4 - 6.7 1750-3000 - - 8.8 13.2 110 - 170 1750-3000 - - 4.0 6.0

3001-4000 - - 5.6 8.5 3001-4000 - - 2.5 3.9

5V, 5VX 500-1740 12.7 18.9 14.8 22.1 5V, 5VX 500-1740 5.8 8.6 6.7 10.0

7.1 - 10.9 171 - 275

1741-3000 11.2 16.7 13.7 20.1 1741-3000 5.1 7.6 6.2 9.1

500-1740 15.5 23.4 17.1 25.5 500-1740 7.0 10.6 7.8 11.6

11.8 - 16.0 276 - 400

1741-3000 14.6 21.8 16.8 25.0 1741-3000 6.6 9.9 7.6 11.3

200-850 33.0 49.3 - - 200-850 15.0 22.4 - -

12.5 - 17.0 315 - 430

851-1500 26.8 39.9 - - 851-1500 12.2 18.1 - -

8V 8V

200-850 39.6 59.2 - - 200-850 18.0 26.8 - -

18.0 - 22.4 431 - 570

851-1500 35.3 52.7 - - 851-1500 16.0 23.9 - -

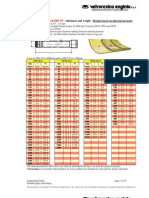

Sheave Diameter - Inches

Deflection Force - Lbs.

Smallest Belt Deflection Force

Belt

Sheave

Cross Used

Diameter New Belt

Section Belt

Range

1.25 - 1.75 3/8 5/8

3L 2.00 - 2.25 3/4 1 1/4

2.50 - 3.00 1 1 1/2

2.10 - 2.80 5/8 1

4L 3.00 - 3.50 1 5/8 2 1/2

3.70 - 5.00 2 3

3.00 - 4.20 1 1/2 2 5/8

5L

4.50 - 5.20 2 1/2 3 1/2

You might also like

- Lab 5 - Atmospheric RetentionDocument11 pagesLab 5 - Atmospheric RetentionCailey Crum100% (2)

- Tabla de Fuerzas Medidor de Tensión de FajasDocument1 pageTabla de Fuerzas Medidor de Tensión de Fajasmatrix1x100% (1)

- Tabla de Fuerzas Medidor de Tensión de Fajas PDFDocument1 pageTabla de Fuerzas Medidor de Tensión de Fajas PDFLuis Caballero67% (3)

- SKF Industrial V Belt Tension Tester PDFDocument3 pagesSKF Industrial V Belt Tension Tester PDFVeeresh nayakNo ratings yet

- William Hackett Grade PDFDocument16 pagesWilliam Hackett Grade PDFThanhdong DoNo ratings yet

- Tadano Rough Terrain Crane GR-800EX - S - G PDFDocument16 pagesTadano Rough Terrain Crane GR-800EX - S - G PDFlesantiago100% (1)

- 011 Chapter 9Document10 pages011 Chapter 9xiaomiNo ratings yet

- V-Belt Installation-Maintenance-StorageDocument7 pagesV-Belt Installation-Maintenance-StoragedzkamiraNo ratings yet

- 1206 Bando V Belt Tension Gauge Instructions 2017-10-09Document2 pages1206 Bando V Belt Tension Gauge Instructions 2017-10-09dzkamiraNo ratings yet

- 1206 Bando V Belt Tension Gauge InstructionsDocument2 pages1206 Bando V Belt Tension Gauge InstructionsJasperken2xNo ratings yet

- 1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFDocument2 pages1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFrabmusukeNo ratings yet

- 1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFDocument2 pages1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFboyka yuriNo ratings yet

- 1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFDocument2 pages1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFBeni MulyanaNo ratings yet

- Allrig Lifting ChainDocument14 pagesAllrig Lifting ChainAwanNo ratings yet

- Industrial V-Belt Tension Tester: General Rules of TensioningDocument3 pagesIndustrial V-Belt Tension Tester: General Rules of Tensioningdaniel castilloNo ratings yet

- Tension Card Vbelt Drives Aus NZ June 2013Document2 pagesTension Card Vbelt Drives Aus NZ June 2013Matheus SantosNo ratings yet

- UNIT NO. 5.4 Allowable Stresses: Fibres Compressed Neutral AxisDocument9 pagesUNIT NO. 5.4 Allowable Stresses: Fibres Compressed Neutral AxisYax ArogeNo ratings yet

- Product CatalogueDocument44 pagesProduct CatalogueTo Van TinhNo ratings yet

- Wire Rope Sling Capacity Charts PDFDocument18 pagesWire Rope Sling Capacity Charts PDFRiko Bin Zulkifli100% (3)

- gp0104 ImDocument9 pagesgp0104 ImSultan TipuNo ratings yet

- Single Core Cables - 600/1000 V: Dimensions & WeightsDocument5 pagesSingle Core Cables - 600/1000 V: Dimensions & WeightsMohan KNo ratings yet

- ASME Flange WeightDocument1 pageASME Flange WeightAlipasha GeramifardNo ratings yet

- ChainDocument46 pagesChainDilip SudevNo ratings yet

- Belt Routing GuideDocument87 pagesBelt Routing GuideBYRONGOSNo ratings yet

- EibachDocument44 pagesEibachFranciscoNo ratings yet

- Rigging Plan and Lifting Plan 8000 Crane 25Document5 pagesRigging Plan and Lifting Plan 8000 Crane 25Agung PermanaNo ratings yet

- How To Choose The Right Gauge Block ComparatorDocument15 pagesHow To Choose The Right Gauge Block ComparatorneramopNo ratings yet

- Cat Yoke g100Document20 pagesCat Yoke g100ALEJANDRO QUIROGA CAVAZOSNo ratings yet

- 27102B473JO0 (Capacitor)Document2 pages27102B473JO0 (Capacitor)MUHAMMAD SISWANTORONo ratings yet

- Chain User's ManualDocument60 pagesChain User's ManualJMFGSNo ratings yet

- Chain Slings ManualDocument60 pagesChain Slings ManualPedro Almeida100% (1)

- CI2400 BS2400 Product DataDocument6 pagesCI2400 BS2400 Product DataDaniel BrownNo ratings yet

- 2021.05.29 - Martinetto T22-726 Man - CE e Collaudo ENGDocument9 pages2021.05.29 - Martinetto T22-726 Man - CE e Collaudo ENGEdomNo ratings yet

- Obstacle LimitDocument1 pageObstacle LimitPaolo TWIXNo ratings yet

- BetsDocument18 pagesBetskahandawalaNo ratings yet

- Installation and Maintenance Instructions For Three Phase Induction MotorsDocument9 pagesInstallation and Maintenance Instructions For Three Phase Induction MotorsAnibal QuezadaNo ratings yet

- MM T Frame Maintenance ManualDocument9 pagesMM T Frame Maintenance Manualneomar BaptistaNo ratings yet

- Maintenance Specifications: 6.1. Tightening TorqueDocument9 pagesMaintenance Specifications: 6.1. Tightening TorqueWshop2 AdminNo ratings yet

- Manual Wedge Action Grips: 2716-01x, - 02x, and 2736-01x SeriesDocument3 pagesManual Wedge Action Grips: 2716-01x, - 02x, and 2736-01x SeriesJc GarciaNo ratings yet

- Flushmax Running ProcedureDocument5 pagesFlushmax Running ProceduretonyNo ratings yet

- SafariDocument20 pagesSafarizahiruddinNo ratings yet

- FileDocument10 pagesFileharoub_nasNo ratings yet

- Manitowoc Crawler Cranes Spec 1d9bbaDocument8 pagesManitowoc Crawler Cranes Spec 1d9bbaNatheer AiedNo ratings yet

- Manual Wedge Action Grips - 2716-01X-02X and 2736-01XDocument3 pagesManual Wedge Action Grips - 2716-01X-02X and 2736-01XLALO MNo ratings yet

- Manual Wedge Action Grips - 2716-01X-02X and 2736-01XDocument3 pagesManual Wedge Action Grips - 2716-01X-02X and 2736-01XLALO MNo ratings yet

- Actuadores Neumaticos TS - AdasDocument25 pagesActuadores Neumaticos TS - AdasDaniel SanNo ratings yet

- Perforating Casing Collar Locator (CCL) : Titan Division - InstrumentsDocument2 pagesPerforating Casing Collar Locator (CCL) : Titan Division - InstrumentsGermanRobladilloNo ratings yet

- Chapter 3 Swingaway DINDocument166 pagesChapter 3 Swingaway DINJosé barriosNo ratings yet

- Wire Rope Cutting ChartDocument8 pagesWire Rope Cutting ChartAkash SharmaNo ratings yet

- Fiber Rope SlingsDocument8 pagesFiber Rope SlingsLeudys Palma100% (1)

- TM-ZT1005H S G PDFDocument5 pagesTM-ZT1005H S G PDFEdwardhutaurukNo ratings yet

- AnchorchainDocument5 pagesAnchorchainRicardo Cesar Bueno BertichevicNo ratings yet

- Admet Catalogue 2600-Series-3Document1 pageAdmet Catalogue 2600-Series-3Atikela AkhilNo ratings yet

- With World Class Quality: GasketsDocument12 pagesWith World Class Quality: GasketsblahblahNo ratings yet

- A 906 - A 906m - 99 - Qtkwni9bota2ts1sruqDocument8 pagesA 906 - A 906m - 99 - Qtkwni9bota2ts1sruqZam DresNo ratings yet

- The Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsFrom EverandThe Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsNo ratings yet

- Understanding Your Boats Systems and Choices.From EverandUnderstanding Your Boats Systems and Choices.Rating: 3 out of 5 stars3/5 (1)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Watch Repairing, Cleaning and Adjusting - A Practical HandbookFrom EverandWatch Repairing, Cleaning and Adjusting - A Practical HandbookNo ratings yet

- The Mechanics of Clockwork - Lever Escapements, Cylinder Escapements, Verge Escapements, Shockproof Escapements, and Their Maintenance and RepairFrom EverandThe Mechanics of Clockwork - Lever Escapements, Cylinder Escapements, Verge Escapements, Shockproof Escapements, and Their Maintenance and RepairRating: 5 out of 5 stars5/5 (1)

- A Comparative Study of A 6-Pulse Converter and A 12-Pulse Converter For HVDC Station.Document6 pagesA Comparative Study of A 6-Pulse Converter and A 12-Pulse Converter For HVDC Station.Naveen JainNo ratings yet

- 62 - Marketing Strategy ModelsDocument54 pages62 - Marketing Strategy ModelsHamis Rabiam MagundaNo ratings yet

- CSE Curriculum - IIIT HyderabadDocument20 pagesCSE Curriculum - IIIT HyderabadSuperdudeGauravNo ratings yet

- Metformin HCL BPDocument4 pagesMetformin HCL BPLia Arifiani100% (1)

- Configuring The Oracle Network EnvironmentDocument44 pagesConfiguring The Oracle Network Environmentyairr100% (3)

- Nosql - Journey Ahead!: Origin: Punch Cards To DbmsDocument54 pagesNosql - Journey Ahead!: Origin: Punch Cards To DbmsParijat SaurabhNo ratings yet

- Pw2 Signal FinalDocument7 pagesPw2 Signal FinalSharifah SyazwaniNo ratings yet

- Diodos Zener SMDDocument4 pagesDiodos Zener SMDvampiro_yiyoNo ratings yet

- Resume Nikhil DikshitDocument1 pageResume Nikhil DikshitNikhil DikshitNo ratings yet

- Precipitation Titration AnalysisDocument17 pagesPrecipitation Titration Analysisgondanepranjal60No ratings yet

- Research Methodology SyllabusDocument1 pageResearch Methodology SyllabusYogeshRavalNo ratings yet

- Categories For The Working Mathematician: Saunders Mac LaneDocument5 pagesCategories For The Working Mathematician: Saunders Mac LaneFakeaNo ratings yet

- Siu Lim Tao / Siu Nim Tao (Little Idea)Document3 pagesSiu Lim Tao / Siu Nim Tao (Little Idea)biboy70No ratings yet

- B.tech (IT)Document57 pagesB.tech (IT)coolvar90No ratings yet

- Future-Series - Operation Manual 1 - Fie-2000-01-Om1 - Scan3Document71 pagesFuture-Series - Operation Manual 1 - Fie-2000-01-Om1 - Scan3Centrifugal SeparatorNo ratings yet

- Three Moment Equation PaperDocument9 pagesThree Moment Equation PaperAkash SoodNo ratings yet

- 3do m2Document4 pages3do m2asfghNo ratings yet

- Rothoblaas - Alumidi Bracket With Holes - Item Specification - enDocument4 pagesRothoblaas - Alumidi Bracket With Holes - Item Specification - enAndrei GheorghicaNo ratings yet

- Chm271 - Tutorial 5 - Chemical KineticsDocument6 pagesChm271 - Tutorial 5 - Chemical Kineticsfiefy zmrNo ratings yet

- Frustrated Lewis PairsDocument42 pagesFrustrated Lewis PairsGoutham RNo ratings yet

- Cortex-M3/M4 ArchitectureDocument37 pagesCortex-M3/M4 Architecturesuhaskakade0075745No ratings yet

- Class8 Science Sample Question Paper 2017Document2 pagesClass8 Science Sample Question Paper 2017deep_72No ratings yet

- The Basics of Reading Music by Kevin MeixnerDocument23 pagesThe Basics of Reading Music by Kevin Meixnerbusyfreeman100% (2)

- Sadtem - Catalogue - Transformateurs de Courant Intérieurs - 2009Document24 pagesSadtem - Catalogue - Transformateurs de Courant Intérieurs - 2009ZorbanfrNo ratings yet

- Paper Sludge PDFDocument13 pagesPaper Sludge PDFDanie RoyNo ratings yet

- ActivityDocument4 pagesActivityJayson Ryan LinoNo ratings yet

- P6Document2 pagesP6Dimitri SaundersNo ratings yet

- AssignmentDocument15 pagesAssignmentNaeem Ul HassanNo ratings yet