Professional Documents

Culture Documents

Saic A 1004

Saic A 1004

Uploaded by

pradeepthalava97Copyright:

Available Formats

You might also like

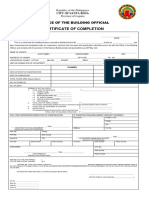

- Sta Rosa, Laguna Certificate of CompletionDocument2 pagesSta Rosa, Laguna Certificate of Completionjaja encisoNo ratings yet

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Saic A 1004Document2 pagesSaic A 1004Hussain Nasser Al- Nowiesser0% (1)

- Oil and Gas IndustryDocument5 pagesOil and Gas Industryaravindan_arrNo ratings yet

- Case Study of PWCDocument8 pagesCase Study of PWCnsthegamerNo ratings yet

- Tata Steel TOCDocument21 pagesTata Steel TOCsha_yadNo ratings yet

- Piping QC CVDocument3 pagesPiping QC CVMd Sharique100% (1)

- Saic A 1004 01Document1 pageSaic A 1004 01Akram ShaikhNo ratings yet

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 8-Nov-15 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 8-Nov-15 CivilAhsaan MughalNo ratings yet

- Saic A 1004Document3 pagesSaic A 1004Rauf ChaudharyNo ratings yet

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-17 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-17 Civilkarthi51289No ratings yet

- Saic A 1004Document3 pagesSaic A 1004Saragadam DilsriNo ratings yet

- Saic A 1004Document2 pagesSaic A 1004usmanNo ratings yet

- Saic A 1004Document3 pagesSaic A 1004Ansar Ali VemmullyNo ratings yet

- Saic A 1004Document2 pagesSaic A 1004Son AbanadorNo ratings yet

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-13 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 31-Nov-2019 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 31-Nov-2019 CivilyazNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilNaushad AlamNo ratings yet

- Saic-A-1005 Compaction TestingDocument2 pagesSaic-A-1005 Compaction TestingZia ur Rehman100% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistWaleed MedhatNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-13 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistMuhammadNo ratings yet

- Saic A 1003Document2 pagesSaic A 1003Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005pradeepthalava97No ratings yet

- Saic A 1005Document3 pagesSaic A 1005mohammadNo ratings yet

- SAIC-A-1005 Rev 7 (Final) Compaction TestingDocument2 pagesSAIC-A-1005 Rev 7 (Final) Compaction Testingryann mananquilNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Document3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Niel TanedoNo ratings yet

- Saic A 1005Document3 pagesSaic A 1005Naushad AlamNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005munibbarcaNo ratings yet

- Saic Q 1011Document2 pagesSaic Q 1011Hussain Nasser Al- Nowiesser100% (1)

- SAIC A 1005 Compaction TestDocument3 pagesSAIC A 1005 Compaction TestAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 31-Nov-2019 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 31-Nov-2019 CivilyazNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Son AbanadorNo ratings yet

- Saic A 1005.Document5 pagesSaic A 1005.Fazal HaqNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-17 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-17 Civilkarthi51289No ratings yet

- Saic A 1005.Document3 pagesSaic A 1005.Shazab NawazNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistyazNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Rauf ChaudharyNo ratings yet

- SAIC-Q-1040 Placement and Compaction of Sub-Base and Aggregate Base Course Materials InspectioDocument3 pagesSAIC-Q-1040 Placement and Compaction of Sub-Base and Aggregate Base Course Materials InspectioAbdul Hannan0% (1)

- Saic A 1003Document4 pagesSaic A 1003mohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 15-Nov-17 CivilDocument8 pagesSaudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 15-Nov-17 CivilAbdul HannanNo ratings yet

- Saic Q 1011Document2 pagesSaic Q 1011Shazab NawazNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistSajid ShaikhNo ratings yet

- Saudi Aramco Inspection ChecklistDocument11 pagesSaudi Aramco Inspection ChecklistleonysNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistNaushad AlamNo ratings yet

- Saic H 1003Document2 pagesSaic H 1003Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1003Document3 pagesSaic A 1003pradeepthalava97No ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMuhammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistJagdishNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 29-Jun-17Document2 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 29-Jun-17Zia ur Rehman100% (1)

- Saic A 1003Document4 pagesSaic A 1003Rauf ChaudharyNo ratings yet

- Saudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 30-Nov-17 CivilDocument4 pagesSaudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 30-Nov-17 CivilMD SHARIQUENo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 8-Nov-15 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 8-Nov-15 CivilAhsaan MughalNo ratings yet

- SAIC N 2025 in ProcessInspPneumaticallyAppliedRefract EL RevDocument3 pagesSAIC N 2025 in ProcessInspPneumaticallyAppliedRefract EL RevAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistHaroon odoodNo ratings yet

- Saic A 1003Document3 pagesSaic A 1003Son AbanadorNo ratings yet

- Saic A 1008Document4 pagesSaic A 1008jerinNo ratings yet

- SAIC A 1005 Compaction TestingDocument2 pagesSAIC A 1005 Compaction TestingwalidNo ratings yet

- Saic A 1008Document4 pagesSaic A 1008Naushad AlamNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Rauf ChaudharyNo ratings yet

- SAICbDocument2 pagesSAICbAfzal HussainNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Ansar Ali VemmullyNo ratings yet

- 5s Training PDFDocument66 pages5s Training PDFDhinakaranNo ratings yet

- 3D Printer DIY Kit User Manual (P802 V21)Document14 pages3D Printer DIY Kit User Manual (P802 V21)Alberto VegaNo ratings yet

- Chapter4 Q A Software Testing TechniquesDocument7 pagesChapter4 Q A Software Testing TechniquesShiva SoniyaNo ratings yet

- Best Practices in New Product DevelopmentDocument43 pagesBest Practices in New Product Developmenteasy_astronautNo ratings yet

- Raytheon Anschutz DISTRIBUTION UNIT COMPACT Type 138-126Document32 pagesRaytheon Anschutz DISTRIBUTION UNIT COMPACT Type 138-126smartstep100% (6)

- Aircraft Rescue and Fire Fighting CommunicationsDocument22 pagesAircraft Rescue and Fire Fighting CommunicationsMelissa Gonzalez TorresNo ratings yet

- Civil Engineering, Famous Bridges and TowersDocument10 pagesCivil Engineering, Famous Bridges and TowersJustin ZhaoNo ratings yet

- Energy Regulatory Commissi: Llocumt'Document18 pagesEnergy Regulatory Commissi: Llocumt'Mary Ann Farcon VelascoNo ratings yet

- ODs January 2022 Airbus Commercial AircraftDocument179 pagesODs January 2022 Airbus Commercial AircraftaliNo ratings yet

- Data Sheet - HoseX - Tornado SteelDocument1 pageData Sheet - HoseX - Tornado SteelranjithNo ratings yet

- Midterm Questions GPMT350Document9 pagesMidterm Questions GPMT350jcarter_573941No ratings yet

- Vacon AC Drive US Version Product Catalog BC00324CDocument180 pagesVacon AC Drive US Version Product Catalog BC00324CSteven TorrealbaNo ratings yet

- As Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-04 Rev No Rev DateDocument1 pageAs Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-04 Rev No Rev DaterohitNo ratings yet

- LOR Engineering Excellence Journal 2013Document77 pagesLOR Engineering Excellence Journal 2013marcinek77No ratings yet

- SpecialtyswitchesDocument7 pagesSpecialtyswitchesbo cephusNo ratings yet

- US Bangla Airlines Project With Bibiography ALL DONEDocument35 pagesUS Bangla Airlines Project With Bibiography ALL DONERaima KhanNo ratings yet

- BSIT 51 Previous Year Question Paper SolveDocument27 pagesBSIT 51 Previous Year Question Paper SolveKunal Patra100% (1)

- Thesis Topics For Civil Engineering StudentsDocument8 pagesThesis Topics For Civil Engineering Studentsoeczepiig100% (2)

- Application FormDocument99 pagesApplication FormFarly Vergel100% (1)

- Flow Visualization ExperimentDocument9 pagesFlow Visualization ExperimentPei Shan ChoongNo ratings yet

- Breathers and Filler BreathersDocument6 pagesBreathers and Filler BreathersKukuh Trisno AjiNo ratings yet

- Poplar House Demo PermitDocument15 pagesPoplar House Demo PermitthereadingshelfNo ratings yet

- Navedtra 14080 PDFDocument289 pagesNavedtra 14080 PDFsrollinsNo ratings yet

- Welding Rod DetailsDocument4 pagesWelding Rod DetailsFernando RomeroNo ratings yet

- Product Bulletin: (Microcrystalline Zinc-PhosphateDocument2 pagesProduct Bulletin: (Microcrystalline Zinc-PhosphateJason SonidoNo ratings yet

Saic A 1004

Saic A 1004

Uploaded by

pradeepthalava97Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic A 1004

Saic A 1004

Uploaded by

pradeepthalava97Copyright:

Available Formats

#

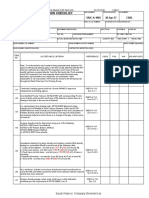

SAUDI ARAMCO ID/PIEU-31-Dec-2020 - REV.2020.12.00 (Standards Cutoff - Dec 31,2020) Rev 62 31-Dec-20

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Fill Placement and Compaction Inspection SAIC-A-1004 31-Jan-21 CIVIL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Fill Placement Inspection

SAES-A-114

A1 Fill material shall be placed in lifts not exceeding 200mm in loose depth.

Sec. 6.3..3.1

Fill material shall be placed in lifts not exceeding 100mm in loose depth SAES-A-114

A2

for hand-operated compaction. Sec. 6.3.3.3

Other lift thicknesses shall be allowed with approval by the Saudi Aramco

SAES-A-114

A3 Inspector based on a field test of the method, equipment and materials

Sec. 6.3.3.4

involved.

Fill and backfill adjacent to any type of structure shall not be compacted

SAES-A-114

A4 with heavy equipment; Hand operated equipment shall be used within 1.2

Sec. 6.3.5.1

meters of any structures.

Every effort shall be made to place backfill materials symmetrically and in

SAES-A-114

A5 uniform layers to prevent unnecessary eccentric loading on a structure or

Sec. 6.3.5.1

foundation.

Compacted surfaces of fill and backfill shall be finish graded to the cross SAES-A-114

A6

sections, lines, grades and elevations as indicated on the drawings. Sec. 6.3.7

Backfilling and removal of trench supports shall be accomplished by

backfilling up to a level allowing for removal of the lower braces; Another

SACSM

A7 layer of backfill shall then be positioned in the trench to the next layer of

Part II, Sec. 1.14

braces to be removed. (For underground utilities: Final survey of pipes

and Inspection release clearance acceptance prior to backfilling)

Removal of trench supports or shoring shall progress together with the

SACSM

A8 backfill from the bottom of the trench; In unstable soil, ropes shall be used

Part II, Sec. 1.14

to pull supporting materials from the trench.

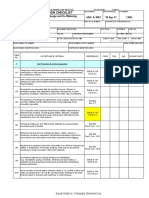

B Compaction Inspection

Compaction shall begin only after the fill or backfill has been properly

placed and the material to be compacted is at the proper moisture SAES-A-114

B1

content. +/- 3% of the optimum moisture content per ASTM D1557 or Sec. 6.3.4

ASTM D698, whichever is applicable. (PIP-CVS02100, Sec. 4.3.2.3)

SAES-A-114

B2 Compaction shall be performed with equipment compatible with soil type.

Sec. 6.3.5

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

#

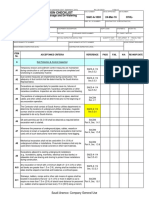

Fill or backfill placed beneath footings, grade beams, mats, buildings or

SAES-A-114

B3 process areas shall be compacted to at least 90% of the maximum

Sec. 6.3.6.1

Modified Proctor density as determined by ASTM D1557.

For cohesionless free draining soils, 70% relative density as determined

SAES-A-114

B4 by ASTM D4253 and ASTM D4254 shall be achieved under footings,

Sec. 6.3.6.1

grade beams, mats, buildings or process areas.

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

You might also like

- Sta Rosa, Laguna Certificate of CompletionDocument2 pagesSta Rosa, Laguna Certificate of Completionjaja encisoNo ratings yet

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Saic A 1004Document2 pagesSaic A 1004Hussain Nasser Al- Nowiesser0% (1)

- Oil and Gas IndustryDocument5 pagesOil and Gas Industryaravindan_arrNo ratings yet

- Case Study of PWCDocument8 pagesCase Study of PWCnsthegamerNo ratings yet

- Tata Steel TOCDocument21 pagesTata Steel TOCsha_yadNo ratings yet

- Piping QC CVDocument3 pagesPiping QC CVMd Sharique100% (1)

- Saic A 1004 01Document1 pageSaic A 1004 01Akram ShaikhNo ratings yet

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 8-Nov-15 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 8-Nov-15 CivilAhsaan MughalNo ratings yet

- Saic A 1004Document3 pagesSaic A 1004Rauf ChaudharyNo ratings yet

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-17 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-17 Civilkarthi51289No ratings yet

- Saic A 1004Document3 pagesSaic A 1004Saragadam DilsriNo ratings yet

- Saic A 1004Document2 pagesSaic A 1004usmanNo ratings yet

- Saic A 1004Document3 pagesSaic A 1004Ansar Ali VemmullyNo ratings yet

- Saic A 1004Document2 pagesSaic A 1004Son AbanadorNo ratings yet

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-13 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 31-Nov-2019 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 31-Nov-2019 CivilyazNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilNaushad AlamNo ratings yet

- Saic-A-1005 Compaction TestingDocument2 pagesSaic-A-1005 Compaction TestingZia ur Rehman100% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistWaleed MedhatNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-13 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistMuhammadNo ratings yet

- Saic A 1003Document2 pagesSaic A 1003Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005pradeepthalava97No ratings yet

- Saic A 1005Document3 pagesSaic A 1005mohammadNo ratings yet

- SAIC-A-1005 Rev 7 (Final) Compaction TestingDocument2 pagesSAIC-A-1005 Rev 7 (Final) Compaction Testingryann mananquilNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Document3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Niel TanedoNo ratings yet

- Saic A 1005Document3 pagesSaic A 1005Naushad AlamNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005munibbarcaNo ratings yet

- Saic Q 1011Document2 pagesSaic Q 1011Hussain Nasser Al- Nowiesser100% (1)

- SAIC A 1005 Compaction TestDocument3 pagesSAIC A 1005 Compaction TestAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 31-Nov-2019 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 31-Nov-2019 CivilyazNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Son AbanadorNo ratings yet

- Saic A 1005.Document5 pagesSaic A 1005.Fazal HaqNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-17 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-17 Civilkarthi51289No ratings yet

- Saic A 1005.Document3 pagesSaic A 1005.Shazab NawazNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistyazNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Rauf ChaudharyNo ratings yet

- SAIC-Q-1040 Placement and Compaction of Sub-Base and Aggregate Base Course Materials InspectioDocument3 pagesSAIC-Q-1040 Placement and Compaction of Sub-Base and Aggregate Base Course Materials InspectioAbdul Hannan0% (1)

- Saic A 1003Document4 pagesSaic A 1003mohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 15-Nov-17 CivilDocument8 pagesSaudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 15-Nov-17 CivilAbdul HannanNo ratings yet

- Saic Q 1011Document2 pagesSaic Q 1011Shazab NawazNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistSajid ShaikhNo ratings yet

- Saudi Aramco Inspection ChecklistDocument11 pagesSaudi Aramco Inspection ChecklistleonysNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistNaushad AlamNo ratings yet

- Saic H 1003Document2 pagesSaic H 1003Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1003Document3 pagesSaic A 1003pradeepthalava97No ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMuhammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistJagdishNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 29-Jun-17Document2 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 29-Jun-17Zia ur Rehman100% (1)

- Saic A 1003Document4 pagesSaic A 1003Rauf ChaudharyNo ratings yet

- Saudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 30-Nov-17 CivilDocument4 pagesSaudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 30-Nov-17 CivilMD SHARIQUENo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 8-Nov-15 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 8-Nov-15 CivilAhsaan MughalNo ratings yet

- SAIC N 2025 in ProcessInspPneumaticallyAppliedRefract EL RevDocument3 pagesSAIC N 2025 in ProcessInspPneumaticallyAppliedRefract EL RevAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistHaroon odoodNo ratings yet

- Saic A 1003Document3 pagesSaic A 1003Son AbanadorNo ratings yet

- Saic A 1008Document4 pagesSaic A 1008jerinNo ratings yet

- SAIC A 1005 Compaction TestingDocument2 pagesSAIC A 1005 Compaction TestingwalidNo ratings yet

- Saic A 1008Document4 pagesSaic A 1008Naushad AlamNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Rauf ChaudharyNo ratings yet

- SAICbDocument2 pagesSAICbAfzal HussainNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Ansar Ali VemmullyNo ratings yet

- 5s Training PDFDocument66 pages5s Training PDFDhinakaranNo ratings yet

- 3D Printer DIY Kit User Manual (P802 V21)Document14 pages3D Printer DIY Kit User Manual (P802 V21)Alberto VegaNo ratings yet

- Chapter4 Q A Software Testing TechniquesDocument7 pagesChapter4 Q A Software Testing TechniquesShiva SoniyaNo ratings yet

- Best Practices in New Product DevelopmentDocument43 pagesBest Practices in New Product Developmenteasy_astronautNo ratings yet

- Raytheon Anschutz DISTRIBUTION UNIT COMPACT Type 138-126Document32 pagesRaytheon Anschutz DISTRIBUTION UNIT COMPACT Type 138-126smartstep100% (6)

- Aircraft Rescue and Fire Fighting CommunicationsDocument22 pagesAircraft Rescue and Fire Fighting CommunicationsMelissa Gonzalez TorresNo ratings yet

- Civil Engineering, Famous Bridges and TowersDocument10 pagesCivil Engineering, Famous Bridges and TowersJustin ZhaoNo ratings yet

- Energy Regulatory Commissi: Llocumt'Document18 pagesEnergy Regulatory Commissi: Llocumt'Mary Ann Farcon VelascoNo ratings yet

- ODs January 2022 Airbus Commercial AircraftDocument179 pagesODs January 2022 Airbus Commercial AircraftaliNo ratings yet

- Data Sheet - HoseX - Tornado SteelDocument1 pageData Sheet - HoseX - Tornado SteelranjithNo ratings yet

- Midterm Questions GPMT350Document9 pagesMidterm Questions GPMT350jcarter_573941No ratings yet

- Vacon AC Drive US Version Product Catalog BC00324CDocument180 pagesVacon AC Drive US Version Product Catalog BC00324CSteven TorrealbaNo ratings yet

- As Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-04 Rev No Rev DateDocument1 pageAs Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-04 Rev No Rev DaterohitNo ratings yet

- LOR Engineering Excellence Journal 2013Document77 pagesLOR Engineering Excellence Journal 2013marcinek77No ratings yet

- SpecialtyswitchesDocument7 pagesSpecialtyswitchesbo cephusNo ratings yet

- US Bangla Airlines Project With Bibiography ALL DONEDocument35 pagesUS Bangla Airlines Project With Bibiography ALL DONERaima KhanNo ratings yet

- BSIT 51 Previous Year Question Paper SolveDocument27 pagesBSIT 51 Previous Year Question Paper SolveKunal Patra100% (1)

- Thesis Topics For Civil Engineering StudentsDocument8 pagesThesis Topics For Civil Engineering Studentsoeczepiig100% (2)

- Application FormDocument99 pagesApplication FormFarly Vergel100% (1)

- Flow Visualization ExperimentDocument9 pagesFlow Visualization ExperimentPei Shan ChoongNo ratings yet

- Breathers and Filler BreathersDocument6 pagesBreathers and Filler BreathersKukuh Trisno AjiNo ratings yet

- Poplar House Demo PermitDocument15 pagesPoplar House Demo PermitthereadingshelfNo ratings yet

- Navedtra 14080 PDFDocument289 pagesNavedtra 14080 PDFsrollinsNo ratings yet

- Welding Rod DetailsDocument4 pagesWelding Rod DetailsFernando RomeroNo ratings yet

- Product Bulletin: (Microcrystalline Zinc-PhosphateDocument2 pagesProduct Bulletin: (Microcrystalline Zinc-PhosphateJason SonidoNo ratings yet