Professional Documents

Culture Documents

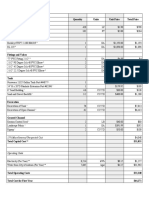

4334 Ton Year Treatment & Recycling Plant Financial Analysis B-1

4334 Ton Year Treatment & Recycling Plant Financial Analysis B-1

Uploaded by

mete0 ratings0% found this document useful (0 votes)

7 views1 pageThis document provides cost estimates for setting up a desalination plant over a 5 year contract period. It estimates capital costs of $7.8 million for equipment including tanks, generators, loaders and a construction camp. Operating costs are estimated at $4.9 million per year including diesel, transportation, and a processing rate of $133.64 per ton. Revenue from oil sales is estimated at $4.1 million per year from selling 3.9 million liters of diesel at $1.04 per liter.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides cost estimates for setting up a desalination plant over a 5 year contract period. It estimates capital costs of $7.8 million for equipment including tanks, generators, loaders and a construction camp. Operating costs are estimated at $4.9 million per year including diesel, transportation, and a processing rate of $133.64 per ton. Revenue from oil sales is estimated at $4.1 million per year from selling 3.9 million liters of diesel at $1.04 per liter.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views1 page4334 Ton Year Treatment & Recycling Plant Financial Analysis B-1

4334 Ton Year Treatment & Recycling Plant Financial Analysis B-1

Uploaded by

meteThis document provides cost estimates for setting up a desalination plant over a 5 year contract period. It estimates capital costs of $7.8 million for equipment including tanks, generators, loaders and a construction camp. Operating costs are estimated at $4.9 million per year including diesel, transportation, and a processing rate of $133.64 per ton. Revenue from oil sales is estimated at $4.1 million per year from selling 3.9 million liters of diesel at $1.04 per liter.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

1 B C D E F G H I J K L M N O P

2 Contract Volume, tons 260.040 KD KD USD

3 Contract Period, months 60 5 Year Mob 380.000 2 760.000 $ 2.546.000,00

4 Monthly Volume, tons 1 includes 10% allowable increase 4.334 Demob ‐ 2 ‐ $ ‐

5 Diesel Content 20 % by Volume Rent 32.800 120 3.936.000 $ 13.185.600,00 Total Process Average Per Year

6 Diesel for Desorber Operations 1% loss, 3% for plant operations and 1% for Camp 5 % by Volume Process Rate 13,00 260.040 3.380.520 $ 11.324.742,00 $ 24.510.342,00 $ 4.902.068,40

7 Diesel Volume for Sale / Month 325.050 liters Trans 256.500 2 513.000 $ 1.718.550,00

8 Oil Sales Price IRAQ $ 1,04 per liter Trans 81.756 2 163.512 $ 547.765,20

9 Trans 37.656 2 75.312 $ 252.295,20 Total Transport Average Per Year

10 Capital Cost Estimate Units Unit Cost Total Cost New Budget Difference Comments Trans 167.076 2 334.152 $ 1.119.409,20 $ 3.638.019,60 $ 727.603,92

Change offset by AVA units related reductions in cost.

11

TDU Equipment Value(12,000 lt x 2 Batch) AVA Split in two plants 2 $ 2.000.000 $ 4.000.000 $ 5.373.000 $ 1.373.000 Assumes purchase of SAR site for 3 million $ Total 9.162.496

12 Generators 4 $ 42.000 $ 168.000 $ 157.500 $ (10.500) Two 850 KVA Generators ‐ Actual Quote $ 30.694.361,60 4.581.248 Total KD Per Site

13 Air compressor 500 cfm with air tank 0 $ 25.000 25000 $ 25.000 $ ‐

14 Oil Tanks 4 $ 25.000 $ 100.000 $ 75.000 $ (25.000) Based on 3 tanks of 80m3 capacity each

15 Water Tanks 4 $ 25.000 $ 100.000 $ 25.000 $ (75.000) Based on 1 tank of 80m3 capacity each

16 Liquid Phase Tanks 0 $ ‐ $ ‐ $ 25.000 $ 25.000 Liters per Year Price/Liter Total per Year

17 Truck Scale 2 $ 30.000 $ 60.000 $ 22.000 $ (38.000) Only need one scale ‐ Actual Quote

18 Construction Camp Procurement & InstallationNapesco 0 $ ‐ $ ‐ $ ‐ $ 50.000 Was not previously considered

19 Diesel Tank 2 $ 25.000 $ 50.000 $ 25.000 $ (25.000) Only need one Oil Sales Revenue 3.900.600,00 $ 1,04 $ 4.056.624,00

20 Tube Chain Conv 1 $ 75.000 $ 75.000 $ 30.000 $ (45.000)

21 10 Ton Loader 3 $ 150.000 $ 450.000 $ 70.000 $ (380.000) Replaced with 2 m3 loader Rate per Ton $ 133,64

22 1 Ton Forklift 2 $ 25.000 $ 50.000 $ 15.000 $ (35.000) Only one needed

23 Civil works 150 $ 2.500 $ 375.000 $ 450.000 $ 75.000 Replaced with 50 twenty m3 boxes

24 Lab Equipment 1 $ 40.000 $ 40.000 $ 40.000 $ ‐

25 Camp with water and sewage tanks 1 $ 500.000 $ 500.000 $ 544.000 $ 44.000 Actual Quote

26 Vertical Drill Cutting Dewatering System 1 $ 715.524 $ 715.524 $ 400.000 $ (315.524)

27 TDU Steel Building 1 $ 550.000

28 $ 7.826.500

29

30

31 Mobilization Cost Number Persons Units/Days Unit Cost Total New Budget Difference Comments

32 LC Banking, Documentation Ahmad $72 k, Banking $30 K, Documentation $10 K $ 112.000 $ 112.000 Incurred to date by Scaltech

33 Consultant Costs $ 132.000 $ 132.000 New cost

34 Trucking of TDU 18 $ 5.000 $ 90.000 $ 90.000 $ ‐ Included in TDU Cap Cost

35 Cranes 60 $ 1.000 $ 60.000 $ 80.000 $ 20.000 Reduced for one site

36 Concrete Platform/Roads 2 $ 200.000 $ 400.000 $ ‐ $ (400.000) One site, final design, actual quote, includes fence

37 Pit Construction 0 $ 200.000 $ ‐ $ ‐ $ ‐

38 Expat Installation Experts 4 90 $ 1.080 $ 388.800 $ ‐ $ (388.800)Included in TDU Cap Cost

39 Supervisors, Project and Operation Managers 3 90 $ 300 $ 81.000 $ 123.000 $ 42.000 Included in TDU Cap Cost

40 Freight for Camp and TDU building $ 25.000 $ 25.000 Was before part of Cap Cost of Camp

41 Electricians 2 90 $ 120 $ 21.600 $ 25.000 $ 3.400 Included in TDU Cap Cost

42 Mechanics 5 90 $ 110 $ 49.500 $ 75.000 $ 25.500 Included in TDU Cap Cost

43 Helpers 10 90 $ 20 $ 18.000 $ 36.000 $ 18.000 Included in TDU Cap Cost

44 Welders 5 90 $ 110 $ 9.900 $ 25.000 $ 15.100 Included in TDU Cap Cost

45 Repair Material/Repair Labor/Hopper Replacement 1 $ 250.000 $ 250.000 $ ‐ $ (250.000)Included in TDU Cap Cost

46 Pick Up Rental 6 6 $ 1.000 $ 36.000 $ 36.000 $ ‐ Reduced to 4 units for 7 months

Camp and Scale Installation ($50K), Camp Operation for 3 months

47

Camp and Scale Installation and Fence 1,5 $ 250.000 $ 375.000 $ 100.000 $ (275.000) ($75k), excludes fence

48 Installation of Dewatering & Centrifuge Plant 0 $ ‐ $ ‐ $ ‐ $ ‐

49 Materials and Installation of Interconnecting

Piping and power distribution system 0 $ ‐ $ ‐ $ 100.000 $ 100.000 Includes site lighting

50 Building for TDU 2 $ 150.000 $ 300.000 $ ‐ $ (300.000) Revised design with moistening room and 10t overhead crane

Fire fighting system (water tank, hydrants,

51

pumps) 0 $ 150.000 $ 150.000 New item

52 Vac Boxes 0 $ ‐ $ ‐ $ ‐ $ ‐ For handling of process solids

53 Winch System 0 $ ‐ $ ‐ $ ‐ $ ‐ Four pieces to move vac boxes

54 Bus Rental 6 $ 3.100 $ 18.600 $ 12.400 $ (6.200) Reduced to one unit for 4 months

55 Total Mob Cost $ 2.098.400 $ 1.121.400 $ (977.000)

56 Total Capital and Mob Costs $ 8.947.900

57 Total in KD $ 2.711.485

Estimated monthly

58 Equipment on lease basis Q‐ty Unit cost Total Cost

lease cost

59 Air Vaccuum Truck 4 180000 $ 720.000 $ 14.400

60 Roll‐off truck 2 180000 $ 360.000 $ 7.200

61

62

63

64

65 Monthly Operations Cost Units Unit Cost Total Cost Changes

66 Project Manager, Expat 1 $ 10.000 $ 10.000

67 Senior Accountant 1 $ 3.000 $ 3.000

68 Junior Accountant 1 $ 1.500 $ 1.500 Addition

69 HSE Manager 1 $ 3.500 $ 3.500

70 HSE Inspectors 2 $ 1.750 $ 3.500 Increased by 1

71 Chemist 1 $ 3.000 $ 3.000

72 Operations Manager, Expat 1 $ 5.000 $ 5.000

73 Maintenance Engineer 1 $ 2.500 $ 2.500 Required due to equipment increase

74 Shift Supervisor/Senior Engineer, Expat 3 $ 2.750 $ 8.250

75 Plant Operator 3 $ 2.000 $ 6.000

76 Loader Operator 3 $ 2.500 $ 7.500

77 Helper 10 $ 800 $ 8.000

78 Truck Drivers 0 $ 1.500 $ ‐ Covers all Trucking needs

79 Mechanic 4 $ 2.500 $ 10.000

80 Guard 6 $ 800 $ 4.800 Increased to 6

81 Lab Technicians 3 $ 2.000 $ 6.000 Increased to 6

82 Electricians 3 $ 2.500 $ 7.500

83 Cook 2 $ 3.000 $ 6.000 Increased to 2

84 Kitchen Helper and Camp Cleaner 9 $ 800 $ 7.200 Increased to 9

85 Spare Parts 1 $ 30.000 $ 30.000

86 Diesel Use Recovered Diesel 0 $ 0 $ ‐

87 Fresh Water for Camp 8 $ 200 $ 1.600

88 Food and Camp Maintenance Material 55 $ 450 $ 24.750

89 Plane Tickets ‐ Annual Travel 50 $ 500 $ 2.083

90 Plane Tickets Expats Semi Annual Travel 5 $ 800 $ 8.000

91 Pick Ups/Buses 11 $ 1.000 $ 11.000

92 Insurance (all types) 1 $ 9.000 $ 9.000 Based on actual quotes

93 Trucks 6 $ 5.000 $ 30.000 İncreased 2.1

94 Total $ 219.683

95

96 Capital Cost Summary Revised Budget

97 Performance Bond $ 3.050.000

98 Working Capital (6 months of operations) $ 672.840,00

99 Mobilization $ 1.121.400,00

100 Equipment $ 550.000

101 Total Capital Excluding Bid Bond $ 5.394.240,00

102

103 27756,26087

104 Vertical Drill Cutting Dewatering System Centrifuge System

105 Equipment Description Unit Price Units Total Oil Water Separator $ 35.000 2 $ 70.000

106 Shaker $ 20.581 2 $ 41.162 Cone Tank $ 55.000 2 $ 110.000

107 15m3 hopper with internal screw conveyor $ 22.002 2 $ 44.004 Vertical Centrifuge System $ 2.000.000 1 $ 2.000.000

Horizontal Decanter System with Pieralisi

108 Screw conveyor Decanter

$ 27.756 2 $ 55.513 $ 250.000 1 $ 250.000

109 Vertical Cutting Dryer $ 64.131 2 $ 128.262 Decanter Stand with 2 Dorr Oliver Decanters $ 225.000 2 $ 450.000

110 Screw Pump $ 4.962 2 $ 9.924 Dual Compartment Mix Tank $ 120.000 2 $ 240.000

111 Cutting Dryer Skid $ 7.290 2 $ 14.580 Shaker including skid $ 35.000 1 $ 35.000

112 Solids Discharge Conveyor $ 11.111 2 $ 22.222 Effluent Tank with Transfer Pump $ 15.000 2 $ 30.000

Specialized tools and critical spare parts for

113

Effluent tank (pump is above) $ 10.038 $ 2 $ 20.076 centrifuge system $ 150.000 1 $ 150.000

114 Control system $ 13.161 2 $ 26.322 Storage Containers $ 5.000 2 $ 10.000

115 Transportation China to Kuwait $ 18.500 Control system $ 75.000 1 $ 75.000

116 Subtotal GN Solids Control $ 15.000 Total $ 3.420.000

117 Duty $ 750,00 Duty 5% $ 171.000,00

118 Complete Centrifuge Plant $ 3.644.500 1 $ 3.644.500 Shipping $ 53.500,00

119 Total $ 3.660.250 Total Centrifuge System $ 3.644.500,00

120

121 Need to Unit Verification

122

123 Per KOC Data ‐ Not Tender Volume % Density Calculation Weight % after Cutting Drier RECYCLED LOCAL PRICE

124 Solids 40 50 3,3 165 81,7% 0,008

125 Oil 35 20 0,85 17 8,4% 5 10,90 1,04 1,30 market prıce

126 Water 25 20 1 20 9,9% 5 8,40 0,26

127 90 2,02 Reduction in Weight 19,30 Percentage Points

128 Reduction in Volume 38,99 Percentage Points

129

130

131

Capacity of Two

132

Monthly Production Requirement 4.334 AVA Units

Cubic Meters

133

Less 36% water and oil ‐793,1 Furnace Size 10 each Furnace

134 Net Tons per Month for Furnaces 3540,9 Fill Level 75 %

Batches per day

135

per Furnace 4,0

Operating Days

136

per Month 25

137 Density 3,06

Total Capacity

138

per Month 4.590

139 Excess Capacity 30%

You might also like

- PDF PDFDocument7 pagesPDF PDFMikey MadRatNo ratings yet

- DCF Template BofA - VFDocument1 pageDCF Template BofA - VFHunter Hearst LevesqueNo ratings yet

- Chalice WinesDocument42 pagesChalice Winesdk.asal6361No ratings yet

- Aseptic - Decanter NX 904 Y2 5124786 - Spare Parts Catalogue PDFDocument55 pagesAseptic - Decanter NX 904 Y2 5124786 - Spare Parts Catalogue PDFGerman Cumpa JuarezNo ratings yet

- Aldec G2 PDFDocument2 pagesAldec G2 PDFJulio TovarNo ratings yet

- Revise - CostingDocument13 pagesRevise - CostingMgr. Accounts Dex-IntlNo ratings yet

- TR CapexDocument1 pageTR Capexrahul281081No ratings yet

- Ia 2 AssignmentDocument8 pagesIa 2 AssignmentJotaro KujoNo ratings yet

- Mileage Rates - May 2022Document1 pageMileage Rates - May 2022episonNo ratings yet

- Forecast, Budget Pu.Document5 pagesForecast, Budget Pu.Anonymous lmNm00Iwl3No ratings yet

- Economics Evaluation SpreadsheetDocument4 pagesEconomics Evaluation SpreadsheetTemitope BelloNo ratings yet

- RBS Case StudyDocument2 pagesRBS Case StudyVanshika Srivastava 17IFT017100% (1)

- HSBCDocument7 pagesHSBCaqswdeNo ratings yet

- SOBO Sept 6, 2017 AgendaDocument11 pagesSOBO Sept 6, 2017 AgendaOaklandCBDsNo ratings yet

- Working Papers Presentation-Ap-NpDocument6 pagesWorking Papers Presentation-Ap-NpAngelica Mae MarquezNo ratings yet

- Cost Estimate For Senior Design - Sheet1 1Document2 pagesCost Estimate For Senior Design - Sheet1 1api-400559384No ratings yet

- Cost Estimate For Senior Design - Sheet1 1Document2 pagesCost Estimate For Senior Design - Sheet1 1api-400559384No ratings yet

- Hitungan Kuis 6 Bethesda Mining CompanyDocument6 pagesHitungan Kuis 6 Bethesda Mining Companyrica100% (1)

- Ekonomi Hans DadiDocument279 pagesEkonomi Hans DadiHans DadiNo ratings yet

- Anderson Energy Announces 2010 Second Quarter Results: HighlightsDocument37 pagesAnderson Energy Announces 2010 Second Quarter Results: Highlightsikehenderson4879No ratings yet

- CH 11 - CF Estimation Mini Case Sols Excel 14edDocument36 pagesCH 11 - CF Estimation Mini Case Sols Excel 14edأثير مخوNo ratings yet

- Loan Analysis - Albertsons Shops at Cactus CornerDocument5 pagesLoan Analysis - Albertsons Shops at Cactus CornerderesensNo ratings yet

- Usman FileDocument4 pagesUsman FileManahil FayyazNo ratings yet

- FKGHDDKDocument2 pagesFKGHDDKKennedy HarrisNo ratings yet

- AOR Contrete WorksDocument1 pageAOR Contrete WorksAVINASH SAININo ratings yet

- Final Exam SFM (Reppi, Michelle Gladys)Document7 pagesFinal Exam SFM (Reppi, Michelle Gladys)Bervie RondonuwuNo ratings yet

- Navin Fluorine Advanced Sciences LTD - 346 - 22-11-2021Document1 pageNavin Fluorine Advanced Sciences LTD - 346 - 22-11-2021Pragnesh PrajapatiNo ratings yet

- Salem Data ServiceDocument2 pagesSalem Data ServiceSubhash MishraNo ratings yet

- Proposed Rate ChartDocument1 pageProposed Rate ChartmurliNo ratings yet

- Water Treatment PlantDocument27 pagesWater Treatment PlantSaeed Ahmed SoomroNo ratings yet

- Model #12 - Real Estate DCF ModelDocument7 pagesModel #12 - Real Estate DCF ModelRahul GopanNo ratings yet

- Math-Based Quiz Questions Worked OutDocument130 pagesMath-Based Quiz Questions Worked OutJ MNo ratings yet

- MT1 Ch25Document5 pagesMT1 Ch25api-3725162No ratings yet

- RHC Tando QaiserDocument6 pagesRHC Tando QaiserWajid MalikNo ratings yet

- Duke Bill Comparison - 46038 - DEI - Petitioner's Ex. 7 - Flick Direct - 040424Document1 pageDuke Bill Comparison - 46038 - DEI - Petitioner's Ex. 7 - Flick Direct - 040424Indiana Public Media NewsNo ratings yet

- Spartan Inc - German MotorsDocument4 pagesSpartan Inc - German MotorsFavian Maraville YadisaputraNo ratings yet

- CPG Annual Report 2018Document72 pagesCPG Annual Report 2018Anonymous 2vtxh4No ratings yet

- ALLIED SNP Statistics Week 45 06 - 11 - 2015 PDFDocument9 pagesALLIED SNP Statistics Week 45 06 - 11 - 2015 PDFDJNo ratings yet

- Solutions To IFM 2020 JanDocument4 pagesSolutions To IFM 2020 Janrahul krishnaNo ratings yet

- NPV-Analysis - Completed - 2020Document3 pagesNPV-Analysis - Completed - 2020Ashraf LokmaniNo ratings yet

- MT1 Ch22Document4 pagesMT1 Ch22api-3725162No ratings yet

- Master Decker: Expansion Opporttunities: Calculation of Differential Analysis For Deck BuildingDocument13 pagesMaster Decker: Expansion Opporttunities: Calculation of Differential Analysis For Deck BuildingRitam ChatterjeeNo ratings yet

- Annual Report 2020 FINAL - 1Document62 pagesAnnual Report 2020 FINAL - 1JA AlonsoNo ratings yet

- Project Report For Fish FarmingDocument6 pagesProject Report For Fish FarmingNilesh GordeNo ratings yet

- AHS Financial Model Annual FSDocument76 pagesAHS Financial Model Annual FSAditya IsmoyoNo ratings yet

- Bonds - January 25 2022Document3 pagesBonds - January 25 2022Lisle Daverin BlythNo ratings yet

- VD - IAS 36 (Gui SV) - Chua Co Dap AnDocument5 pagesVD - IAS 36 (Gui SV) - Chua Co Dap AnThiện PhátNo ratings yet

- Feasibility Study For Tank FarmDocument3 pagesFeasibility Study For Tank FarmFahmy ArdhiansyahNo ratings yet

- Bell Peppers JVDocument1 pageBell Peppers JVSara CooperNo ratings yet

- BROK - BO Tearsheet 2022-01-03Document7 pagesBROK - BO Tearsheet 2022-01-03slohariNo ratings yet

- Estimate No - 2020 - 54812Document3 pagesEstimate No - 2020 - 54812Ankan DharNo ratings yet

- CW SolutionsDocument103 pagesCW SolutionssalalNo ratings yet

- Micro FinanceDocument9 pagesMicro FinanceAssejerNo ratings yet

- Financial Model Template PowerDocument10 pagesFinancial Model Template Powerdarkkaizer23No ratings yet

- Sarvajal - Estados Financieros 211028-PDF-ENG-19Document1 pageSarvajal - Estados Financieros 211028-PDF-ENG-19Santiago et AlejandraNo ratings yet

- Budget Murujuy ApartmentsDocument15 pagesBudget Murujuy ApartmentsJaime CuelloNo ratings yet

- Deciding Appropriate Water Rate: Karauli CityDocument30 pagesDeciding Appropriate Water Rate: Karauli CityShashank BahiratNo ratings yet

- Bonds - March 24 2017Document6 pagesBonds - March 24 2017Tiso Blackstar GroupNo ratings yet

- Bonds - November 16 2022Document3 pagesBonds - November 16 2022Lisle BlythNo ratings yet

- Power Markets and Economics: Energy Costs, Trading, EmissionsFrom EverandPower Markets and Economics: Energy Costs, Trading, EmissionsNo ratings yet

- O PDFDocument165 pagesO PDFmario feuilladeNo ratings yet

- Aldec 45 - Manual - 2012 - enDocument134 pagesAldec 45 - Manual - 2012 - enCentrifugal SeparatorNo ratings yet

- Project Report On Bio EthanolDocument72 pagesProject Report On Bio Ethanolvodachemicals20No ratings yet

- Environment Management Plan: For Expansion of Grain Based Distillery Unit of M/s. Ankur Biochem (P) LimitedDocument35 pagesEnvironment Management Plan: For Expansion of Grain Based Distillery Unit of M/s. Ankur Biochem (P) LimitedMeghana SNo ratings yet

- Andritz Separation Large Decanter Power SavingsDocument2 pagesAndritz Separation Large Decanter Power Savingslimim56582No ratings yet

- NX 400 Series DecanterDocument2 pagesNX 400 Series DecanterImad MhannaNo ratings yet

- Dire Dawa University Institute of Technology School of Chemical and Bio EngineeringDocument266 pagesDire Dawa University Institute of Technology School of Chemical and Bio EngineeringEcy YghiNo ratings yet

- Decanter CentrifugeDocument4 pagesDecanter CentrifugekosunlucyNo ratings yet

- INEC 2022 Paper - Vaporise After Reading - Pyrolysis and Waste Management On Queen Elizabeth Class Carriers - Post Comments - 27.09.22Document11 pagesINEC 2022 Paper - Vaporise After Reading - Pyrolysis and Waste Management On Queen Elizabeth Class Carriers - Post Comments - 27.09.22Hayden C100% (1)

- STNXDocument4 pagesSTNXCaio NunesNo ratings yet

- Welcome To GEA: World-Leading Process TechnologyDocument44 pagesWelcome To GEA: World-Leading Process TechnologyAntonio RubioNo ratings yet

- Slop Oil and Oily Sludge Recovery Brochure - tcm11 68550Document16 pagesSlop Oil and Oily Sludge Recovery Brochure - tcm11 68550Irelena RomeroNo ratings yet

- Evaluation, Testing and Optimisation: Centrifuge FocusDocument3 pagesEvaluation, Testing and Optimisation: Centrifuge FocusCliver Santos Yupanqui MachacaNo ratings yet

- Vessels 6-10-2012Document26 pagesVessels 6-10-2012Mohammed.abudi1996No ratings yet

- CCM DesanderDocument7 pagesCCM DesanderTerry Tan100% (1)

- MAN Diesel: Treatment of Lubricating OilDocument2 pagesMAN Diesel: Treatment of Lubricating OilSona NarulaNo ratings yet

- Vibration Analysis Critical MachineryDocument19 pagesVibration Analysis Critical Machineryatif majeedNo ratings yet

- Linha Ucd Decanter GeaDocument20 pagesLinha Ucd Decanter Geacia sin kwangNo ratings yet

- DECANTER Weizenstaerke GBDocument8 pagesDECANTER Weizenstaerke GBpachis3No ratings yet

- 2-B-GNLW363CG Premium Decanter CentrifugeDocument6 pages2-B-GNLW363CG Premium Decanter CentrifugeGeorgeNo ratings yet

- Alfa Laval DecantercentrifugemanualDocument108 pagesAlfa Laval DecantercentrifugemanualPASEOS1372880% (5)

- 4Document13 pages4emy syafiqahNo ratings yet

- Product Leaflet - PLUS-Basic Decanter ControlDocument4 pagesProduct Leaflet - PLUS-Basic Decanter ControlShark1971No ratings yet

- Decanter Centrifuge - WikipediaDocument7 pagesDecanter Centrifuge - WikipediaYounas SardarNo ratings yet

- Short BowlDocument4 pagesShort BowlEray YILMAZNo ratings yet

- Ash Leaching - Operating Instruction ValmetDocument6 pagesAsh Leaching - Operating Instruction ValmetHenrique CostaNo ratings yet

- Alfa Laval Aldec g3 Decanter Product LeafletDocument4 pagesAlfa Laval Aldec g3 Decanter Product LeafletkapilNo ratings yet

- 3 Phase Decanter CentrifugeDocument14 pages3 Phase Decanter CentrifugeJamesNo ratings yet