Professional Documents

Culture Documents

Differential Pressure Flow Element - Case 2-24in - 50000

Differential Pressure Flow Element - Case 2-24in - 50000

Uploaded by

Mohammad TaherOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Differential Pressure Flow Element - Case 2-24in - 50000

Differential Pressure Flow Element - Case 2-24in - 50000

Uploaded by

Mohammad TaherCopyright:

Available Formats

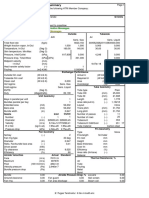

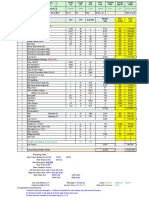

CONVAL® by F.I.R.S.T. Version 9.0 (Build 9.0.

10)

Differential pressure flow element: New calculation (1) 21/11/2023 01:01:48 ب.ظ

Calculation header

Identifier New calculation (1)

Tag No. Case#2_ 24 in_50000

Medium selection and state

Medium Air

State Gaseous

Gas Gas, dry (Standard conditions)

Standard conditions 0°C, 1013.25 mbar

Real gas factor (standard conditions) Zn 0.9994 -

Density (standard conditions, dry gas) ϱN 1.293 kg/m³

Specific gas constant R 287.07 J/(kg K)

Molecular weight M 28.963 kg/kmol

Specific gravity Sg 1.0 -

Critical temperature tc -140.52 °C

Critical pressure pc 37.85 bar(a)

Automatic phase detection

Properties at operating point

Operating temperature t1 152.0 °C

Operating pressure p1 1.65 bar(g)

Real gas factor (t1, p1) Z1 0.99988 -

Isentropic exponent (t1, p1) ϰ 1.401 -

Pipeline

Condition -

Pipe diameter Circular

Pipe inside diameter (20°C) Di 594.0 mm

Linear coefficient of thermal expansion αlin 13.168 E-6 1/K

Pipe roughness k 0.03 mm

Flow element - specification

Device type ISO device

Primary device Orifice with flange taps

Flow element - operating values

Calculation standard ISO 5167:2003

Calculation reference Recalculation: C and ε with qm

Calculated value Δp

Throttle orifice (20°C) d 432.0 mm

New calculation (1).CFM 1(3)

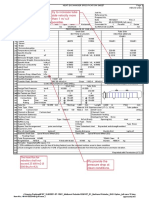

CONVAL® by F.I.R.S.T. Version 9.0 (Build 9.0.10)

Differential pressure flow element: New calculation (1) 21/11/2023 01:01:48 ب.ظ

Flow element - operating values (continued)

Pressure difference Δp 41.351 mbar

Mass flow rate qm 50,000.0 kg/h

Volume flow rate (standard conditions) qn 38,671.0 m³/h

Flow element - material

Linear coefficient of thermal expansion αlin,D 17.502 E-6 1/K

Edge radius (20°C) rk 0.1296 mm

Values table

Flow value table

Calculated auxiliary values

Discharge coefficient (*) C 0.59886 -

Residual pressure loss Δϖ 19.902 mbar

Power loss PΔϖ 12.714 kW

Mechanical stream power PΔp 26.523 kW

Flow velocity in pipeline uP 22.886 m/s

Flow velocity in flow element uF 43.219 m/s

Reynolds number (*) ReD 1.2261 E6 -

Reynolds number in device Red 1.6849 E6 -

Pipe inside diameter (t1) Di,t1 595.03 mm

Throttle orifice (t1) d,t1 433.0 mm

Diameter ratio β 0.72769 -

Relative pipe roughness kr 0.50417 -

Correction factor for pipe roughness br 1.0 -

Correction factor for edge radius bk 1.0 -

Expansion factor (*) ε 0.99449 -

Pressure ratio (*) τ 0.98447 -

In- and outlet section

Specify as factors

Presentation 0% additional uncertainty

Required inlet sections

One or two 90° bends, S≥30D 26,181.0 mm

Two 90° bends, 30D≥S≥5D, same plane 26,181.0 mm

Two 90° bends, 5D>S, same plane 26,181.0 mm

Two 90° bends, 30D≥S≥5D, perpendicular planes 26,181.0 mm

Two 90° bends, 5D>S, perpendicular planes 44,627.0 mm

New calculation (1).CFM 2(3)

CONVAL® by F.I.R.S.T. Version 9.0 (Build 9.0.10)

Differential pressure flow element: New calculation (1) 21/11/2023 01:01:48 ب.ظ

Required inlet sections (continued)

Single 90° tee 26,181.0 mm

One or two 45° bends, S>2D 26,181.0 mm

Reducer 7,735.4 mm

Diffusor 21,421.0 mm

Gate valve, completely open 14,281.0 mm

Abrupt diameter reduction 17,851.0 mm

Thermometer-pocket, Ø ≤ 0,03 Di 2,975.2 mm

Thermometer-pocket, Ø > 0,03 Di 11,901.0 mm

Required outlet section

Required outlet section 4,760.3 mm

Uncertainties

Unc. of operating temperature e,t1 1.0 %

Unc. of absolute pressure e,p1 0.6 %

Unc. of pipe diameter e,Di 0.4 %

Unc. of throttle orifice e,d 0.1 %

Unc. of pressure difference e,Δp 0.8 %

Unc. of operating density e,ϱ1 5.0 %

Unc. due to non-circularity of the pipe e,CiP 0.0 %

Unc. of correction factor br e,br 0.0 %

Unc. of correction factor bk e,bk 0.0 %

Unc. of expansion factor (*) e,ε 0.038789 %

Unc. of flow coefficient e,C 0.71281 %

Unc. of corrected flow coefficient e,Cb 0.71281 %

Unc. of mass flow rate e,qm 2.6635 %

Additional uncertainty e,ad 0.0 %

Confirmation:

The calculation complies with ISO 5167:2003.

Legend

Calculated value

Lookup value

Confirmation

New calculation (1).CFM 3(3)

You might also like

- Design and Construction of Pile Foundations - Code of PracticeDocument32 pagesDesign and Construction of Pile Foundations - Code of PracticeAkash Paradkar100% (1)

- Epa Calculation For TowersDocument11 pagesEpa Calculation For Towersfadil3m2422No ratings yet

- VG 320 Oil CoolerDocument32 pagesVG 320 Oil CoolergsdaundhNo ratings yet

- Insulated Pipe - Temperature Loss CalculationDocument5 pagesInsulated Pipe - Temperature Loss CalculationnopNo ratings yet

- Feasibility Study Kondominium Teluk Intan (10317)Document12 pagesFeasibility Study Kondominium Teluk Intan (10317)zikirabadiNo ratings yet

- SizingDocument3 pagesSizingheinfongNo ratings yet

- Prova 5Document3 pagesProva 5LorenzoNo ratings yet

- Samson SizingDocument1 pageSamson Sizingเต่า วีไอNo ratings yet

- Jpf5-E-0022 - 17 08 22Document10 pagesJpf5-E-0022 - 17 08 22pradeep yadavNo ratings yet

- IM10A (Globe Valves For LP&MP Service Ammonia)Document118 pagesIM10A (Globe Valves For LP&MP Service Ammonia)Gloria HamiltonNo ratings yet

- Calculation Header: Rtkcalc Powered by Conval® Version 2.0 (Build 2.0.2)Document3 pagesCalculation Header: Rtkcalc Powered by Conval® Version 2.0 (Build 2.0.2)Ahmed KhairiNo ratings yet

- FS22-002-Process Calculation For Chiller - Rev.A-Bundle OptionDocument3 pagesFS22-002-Process Calculation For Chiller - Rev.A-Bundle OptionJason DoNo ratings yet

- Heat Stable Reactor Heater 1.5 KG - HR (9.24 MM ID Tube)Document38 pagesHeat Stable Reactor Heater 1.5 KG - HR (9.24 MM ID Tube)Ravindra BarangeNo ratings yet

- Reporte de Diseño de Aeroenfriador 18-10Document27 pagesReporte de Diseño de Aeroenfriador 18-10Luis AlexanderNo ratings yet

- Surface Condenser Thermal Analysis (100914)Document11 pagesSurface Condenser Thermal Analysis (100914)amlanfacebookNo ratings yet

- Angle Monopole DesignDocument19 pagesAngle Monopole DesignSiva Saran100% (1)

- Chocolatos 2Document1 pageChocolatos 2Hariyono Rudi NovantoNo ratings yet

- 23-HA-103 - Rating Case - 1Document11 pages23-HA-103 - Rating Case - 1yadav yadavNo ratings yet

- Refrigerant Condenser - 25 - 01 - 2023 16 PMDocument30 pagesRefrigerant Condenser - 25 - 01 - 2023 16 PMahmad santosoNo ratings yet

- Example Calculation SheetDocument1 pageExample Calculation SheetIñaki EseberriNo ratings yet

- Rcuf250wzpy (7-12, 37-32)Document2 pagesRcuf250wzpy (7-12, 37-32)Đức Anh NguyễnNo ratings yet

- MHI Wall Split AC Unit Catalog (1) - 5Document1 pageMHI Wall Split AC Unit Catalog (1) - 5omar matnaniNo ratings yet

- Approved - Orifice - C650037Document3 pagesApproved - Orifice - C650037Hemanath CENo ratings yet

- Process Design Report SummaryDocument3 pagesProcess Design Report Summarymuhd.qasimNo ratings yet

- Drum - Vertical Wire Mesh Mist EliminatorDocument8 pagesDrum - Vertical Wire Mesh Mist EliminatorAnonymous oVRvsdWzfBNo ratings yet

- Ricis 2Document1 pageRicis 2Hariyono Rudi NovantoNo ratings yet

- Depressuring - Dynamics: Blowdown-Fire: ConnectionsDocument4 pagesDepressuring - Dynamics: Blowdown-Fire: ConnectionsNKNo ratings yet

- 1700 CFM TDocument3 pages1700 CFM TmahmadwasiNo ratings yet

- Calculation Header: Control Valve: P0-75PV3201 15-12-2023 13:49:03Document5 pagesCalculation Header: Control Valve: P0-75PV3201 15-12-2023 13:49:03nikhilkolapkar5No ratings yet

- 2 Inch OutputPCVDocument1 page2 Inch OutputPCVDuy Nguyễn VănNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Flow Meter AnalysisDocument2 pagesFlow Meter AnalysisMauricio Cuevas HinojosaNo ratings yet

- Evaporator (DX) : GACC RX 050.2/2SN/HNA7A.UNNNDocument2 pagesEvaporator (DX) : GACC RX 050.2/2SN/HNA7A.UNNNciprian ilieNo ratings yet

- En 21 242Document1 pageEn 21 242Zoltán SoósNo ratings yet

- Air Cooler AC2301 Thermal U StampDocument4 pagesAir Cooler AC2301 Thermal U Stampavvari sureshNo ratings yet

- 600RT LMTD 2 T20Document1 page600RT LMTD 2 T20syahmi yacobNo ratings yet

- TC 2212921 - Washtech Industries - 20.02 PDFDocument1 pageTC 2212921 - Washtech Industries - 20.02 PDFDevesh PathakNo ratings yet

- Output Summary: See Data Check Messages Report For Warning Messages. See Runtime Message Report For Warning MessagesDocument9 pagesOutput Summary: See Data Check Messages Report For Warning Messages. See Runtime Message Report For Warning MessagesTech DesignNo ratings yet

- TEMA Type E Heat Exchanger DesignDocument8 pagesTEMA Type E Heat Exchanger DesignLEONARDO MOLERO CLEMENTENo ratings yet

- PHE01 M6M 102P 1600kWDocument1 pagePHE01 M6M 102P 1600kWtsoomoo tsolmonNo ratings yet

- Output Summary: See Runtime Message Report For Warning MessagesDocument7 pagesOutput Summary: See Runtime Message Report For Warning MessagesVu TranNo ratings yet

- En - 13121 - Rectangular Tank DesignDocument7 pagesEn - 13121 - Rectangular Tank DesignMAYANK CHAUHANNo ratings yet

- See Runtime Message Report For Warning MessagesDocument1 pageSee Runtime Message Report For Warning MessagesAnonymous Q2hxfbghNo ratings yet

- GTB v6Document7 pagesGTB v6Chan Shiaw SyanNo ratings yet

- Heater White Liquor 20% Over DesignDocument34 pagesHeater White Liquor 20% Over DesignMALLURI SHRIDHARNo ratings yet

- Sizing Calculation FCVDocument3 pagesSizing Calculation FCVYawar QureshiNo ratings yet

- Technical Data of The Fan: DDM 9/7 E6G3603 3F 4P 1V +SCT 6N02WTDocument3 pagesTechnical Data of The Fan: DDM 9/7 E6G3603 3F 4P 1V +SCT 6N02WTmahmadwasiNo ratings yet

- PramonnoDocument1 pagePramonnoHariyono Rudi NovantoNo ratings yet

- Design Calculations Sheet - 12.75": SL .No. Symbol Value UnitDocument6 pagesDesign Calculations Sheet - 12.75": SL .No. Symbol Value UnitASHOK SWAMINo ratings yet

- Maxon RE25 Precious Metal Brushes 10wattDocument1 pageMaxon RE25 Precious Metal Brushes 10wattElectromateNo ratings yet

- Line SizingDocument20 pagesLine SizingAhmed HassanNo ratings yet

- Output Summary: SI UnitsDocument1 pageOutput Summary: SI Unitsdaboo sanatNo ratings yet

- Gacc RX 031 1 1WN Fha7a UnnnDocument2 pagesGacc RX 031 1 1WN Fha7a Unnnachmad.yogaNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- PSV Calculation: Capacity Corection Factor Due To Back Pressure (KB)Document1 pagePSV Calculation: Capacity Corection Factor Due To Back Pressure (KB)syamsudin2006No ratings yet

- Fórmulas para Cálculo (T - W - Strength - Calc - ASME - TW2010)Document1 pageFórmulas para Cálculo (T - W - Strength - Calc - ASME - TW2010)LowanNo ratings yet

- RicisDocument1 pageRicisHariyono Rudi NovantoNo ratings yet

- Heat Transfer Area For Fin Tube Heat Exchanger For FBDDocument8 pagesHeat Transfer Area For Fin Tube Heat Exchanger For FBDPrathmesh GujaratiNo ratings yet

- Condenser 7.5 (RATING)Document1 pageCondenser 7.5 (RATING)Madelyn BelbesNo ratings yet

- Typical Set of Wire Mesh Dimensions Pages From Ken Sutherland - Filters and Filtration Handbook (2008, Elsevier Science) - 2Document2 pagesTypical Set of Wire Mesh Dimensions Pages From Ken Sutherland - Filters and Filtration Handbook (2008, Elsevier Science) - 2Mohammad TaherNo ratings yet

- NSF 61-2002e ANSIDocument160 pagesNSF 61-2002e ANSIMohammad TaherNo ratings yet

- Pipe Drafting and DesignDocument38 pagesPipe Drafting and DesignMohammad TaherNo ratings yet

- BS en 558-2022Document56 pagesBS en 558-2022Mohammad TaherNo ratings yet

- Asme B16.11 2016 25Document1 pageAsme B16.11 2016 25Mohammad TaherNo ratings yet

- Asme B16.11 2016 17Document1 pageAsme B16.11 2016 17Mohammad TaherNo ratings yet

- BS 4368-4 1984Document9 pagesBS 4368-4 1984Mohammad TaherNo ratings yet

- ft4x View DatasheetDocument3 pagesft4x View DatasheetMohammad TaherNo ratings yet

- Asme B16.11 2016 22Document1 pageAsme B16.11 2016 22Mohammad TaherNo ratings yet

- Asme B16.11 2016 13Document1 pageAsme B16.11 2016 13Mohammad TaherNo ratings yet

- Asme B16.11 2016 29Document1 pageAsme B16.11 2016 29Mohammad TaherNo ratings yet

- Asme B16.11 2016 6Document1 pageAsme B16.11 2016 6Mohammad TaherNo ratings yet

- SB-366 - ASME BPVC 2021 Sección II Part BDocument10 pagesSB-366 - ASME BPVC 2021 Sección II Part BMohammad TaherNo ratings yet

- Asme B16.11 2016 12Document1 pageAsme B16.11 2016 12Mohammad TaherNo ratings yet

- Asme B16.11 2016 11Document1 pageAsme B16.11 2016 11Mohammad TaherNo ratings yet

- Asme B16.11 2016 10Document1 pageAsme B16.11 2016 10Mohammad TaherNo ratings yet

- Asme B16.11 2016 5Document1 pageAsme B16.11 2016 5Mohammad TaherNo ratings yet

- SB-619 - ASME BPVC 2021 Sección II Part BDocument8 pagesSB-619 - ASME BPVC 2021 Sección II Part BMohammad TaherNo ratings yet

- SA-105 - ASME BPVC 2021 Sección II Parte A-1Document8 pagesSA-105 - ASME BPVC 2021 Sección II Parte A-1Mohammad TaherNo ratings yet

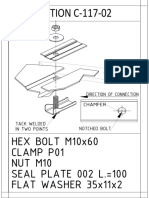

- CONNECTION C-117-02: Clamp P01 Nut M10 SEAL PLATE 002 L. 100 FLAT WASHER 35x11x2 HEX BOLT M10x60Document1 pageCONNECTION C-117-02: Clamp P01 Nut M10 SEAL PLATE 002 L. 100 FLAT WASHER 35x11x2 HEX BOLT M10x60Mohammad TaherNo ratings yet

- SA-181 - ASME BPVC 2021 Sección II Parte A-1Document6 pagesSA-181 - ASME BPVC 2021 Sección II Parte A-1Mohammad TaherNo ratings yet

- Connection C-207: Stud Bolt M10X40 2 X Nut M10 Seal Plate 50x20 Thk.2 Clamp M01Document1 pageConnection C-207: Stud Bolt M10X40 2 X Nut M10 Seal Plate 50x20 Thk.2 Clamp M01Mohammad TaherNo ratings yet

- Spiral Wound Gasket Visual GuideDocument1 pageSpiral Wound Gasket Visual GuideMohammad TaherNo ratings yet

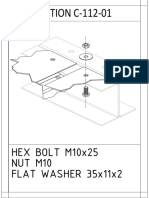

- CONNECTION C-112-01: HEX BOLT M10x25 Nut M10 FLAT WASHER 35x11x2Document1 pageCONNECTION C-112-01: HEX BOLT M10x25 Nut M10 FLAT WASHER 35x11x2Mohammad TaherNo ratings yet

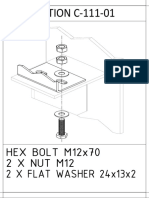

- CONNECTION C-111-01: HEX BOLT M12x70 2 X Nut M12 2 X FLAT WASHER 24x13x2Document1 pageCONNECTION C-111-01: HEX BOLT M12x70 2 X Nut M12 2 X FLAT WASHER 24x13x2Mohammad TaherNo ratings yet

- CECO Emtrol Buell FCCDocument5 pagesCECO Emtrol Buell FCCMohammad TaherNo ratings yet

- Ar 207Document54 pagesAr 207Mohammad TaherNo ratings yet

- DS MTE DemistersDocument2 pagesDS MTE DemistersMohammad TaherNo ratings yet

- Catalytic Products Bro WebDocument4 pagesCatalytic Products Bro WebMohammad TaherNo ratings yet

- 25mm PolypropyleneDocument1 page25mm PolypropyleneMohammad TaherNo ratings yet

- BA 001 R0A (Without Mezzanine)Document1 pageBA 001 R0A (Without Mezzanine)Muhammad Hassan TariqNo ratings yet

- Power Law and Log Law Velocity Profiles in Turbulent Boundary-Layer Flow: Equivalent Relations at Large Reynolds NumbersDocument2 pagesPower Law and Log Law Velocity Profiles in Turbulent Boundary-Layer Flow: Equivalent Relations at Large Reynolds NumbersManuel MejiaNo ratings yet

- 9 - Chapter-6 Final Artificial Recharge StructureDocument179 pages9 - Chapter-6 Final Artificial Recharge StructureRitwick Mishra100% (1)

- Moody Chart PDFDocument2 pagesMoody Chart PDFlhphong021191No ratings yet

- Billing of 20GK0022Document15 pagesBilling of 20GK0022Mae Ann GonzalesNo ratings yet

- B.4.4 - STD Spec For Steel StacksDocument6 pagesB.4.4 - STD Spec For Steel StacksEkta Sangule0% (1)

- Pipa/flangeDocument2 pagesPipa/flangeDimas Ageng PurnamaNo ratings yet

- Soundblox: Key Features and BenefitsDocument2 pagesSoundblox: Key Features and BenefitsBogdan ŞerbănescuNo ratings yet

- ARCC Module 2 HandoutsDocument30 pagesARCC Module 2 HandoutsChelsieCabansagNo ratings yet

- Calculation Sheet For Tower ProjectDocument23 pagesCalculation Sheet For Tower ProjectOsama NasserNo ratings yet

- Fluvial LandformsDocument125 pagesFluvial Landformsuapfa khomolaNo ratings yet

- AirCooled Scroll Chiller Global CO R410A MFL67285211 0BHW0-02B (Jan.2020)Document110 pagesAirCooled Scroll Chiller Global CO R410A MFL67285211 0BHW0-02B (Jan.2020)alexNo ratings yet

- Rain Water Harwasting by DR Rashid 2023Document11 pagesRain Water Harwasting by DR Rashid 2023Rima MisaNo ratings yet

- Srividya College of Engineering and Technology Lecture NotesDocument36 pagesSrividya College of Engineering and Technology Lecture NotestonydisojaNo ratings yet

- For Plastering, 260.00Document15 pagesFor Plastering, 260.00Hayeon KimNo ratings yet

- Residence Antilia: Special FeatureDocument8 pagesResidence Antilia: Special FeatureTanmay BhagatNo ratings yet

- Prestressed Concrete Design (SAB 4323) : Dr. Roslli Noor MohamedDocument22 pagesPrestressed Concrete Design (SAB 4323) : Dr. Roslli Noor MohamedJerryYanNo ratings yet

- Tài Liệu PDFDocument243 pagesTài Liệu PDFThanh HuyNo ratings yet

- SD10102-002 - Pile Cap Bar Bending Schedule and Details PDFDocument1 pageSD10102-002 - Pile Cap Bar Bending Schedule and Details PDFMohammed AdilNo ratings yet

- Project Proposal Carol RevisedDocument9 pagesProject Proposal Carol RevisedBart LuceñaNo ratings yet

- Shear Connectors DesignDocument8 pagesShear Connectors Designriaz16shaikNo ratings yet

- G12.1-2016 Guidelines To Design For ConstructabilityDocument63 pagesG12.1-2016 Guidelines To Design For ConstructabilityRuth Vargas Sosa100% (1)

- Ep3hts TCDocument2 pagesEp3hts TCClausio MeloNo ratings yet

- Assignment Estimation and SpecificationDocument26 pagesAssignment Estimation and SpecificationElsa kNo ratings yet

- Precision Spray Nozzles For The Chemical IndustryDocument36 pagesPrecision Spray Nozzles For The Chemical IndustryMirzaMuijNo ratings yet

- Fresh Air Stack FoundationDocument66 pagesFresh Air Stack FoundationManan MansoorNo ratings yet

- Lecture 1 - IntroductionDocument30 pagesLecture 1 - IntroductionNguyễn QuốcAnhNo ratings yet

- MT17603 - APPLIED Hydraulics and PneumaticsDocument38 pagesMT17603 - APPLIED Hydraulics and PneumaticsNarayananNanuNo ratings yet