Professional Documents

Culture Documents

TeroCote Low Temperature Hardfacing

TeroCote Low Temperature Hardfacing

Uploaded by

kehlmathias07Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TeroCote Low Temperature Hardfacing

TeroCote Low Temperature Hardfacing

Uploaded by

kehlmathias07Copyright:

Available Formats

Innovative low temperature hardfacing

®

TeroCote

Enduring Performance…

Brazing

Stronger, with

Castolin Eutectic

High-performance anti-wear products

Low temperature Ni based alloys require less heat input

Easy to apply

TeroCote®

TeroCote® 7888 LT

TeroCote® 7888 LT is a flexible rope coated with tungsten carbides in a nickel based matrix. 7888 LT utilizes the

newest advancement in low temperature nickel alloys, and has a fusion temperature of 940°C, which is about

100°C below that of existing products on the market today.

7888 LT (low temperature) is an advance for wearfac- Industry Examples

ing technologies. Mining and earth moving: ripper teeth.

7888 LT combines the excellent wear resistance of Oil exploration and extraction: drill bits, stabilizers.

7888 T with a newly developed low temperature nick- Brick and cement making: mixer and scraper blades,

el alloy. This new alloy flows at 100 °C lower than simi- extrusion press screws.

lar products found on the market today. Mineral processing: conveyor or decanter screws,

Lower temperatures mean less heating, less structur- pump rotors and sleeves.

al change of the base metals and carbides, less ther- Iron and steel: guides and scraper blades.

mal stress and faster application. Agriculture: cutting edges on plough shares.

7888 LT is very easy to apply and leaves a very smooth,

dense and homogeneous coating. By having a smooth

surface, less post-brazing grinding will be required (if

required at all).

Properties

Hardness, matrix (HV30) ~400

Micro-hardness, carbides (HV1) >2300

Carbide granulometry - 5,0 mm 0,2 - 0,7

Carbide granulometry - 6,0 mm 5,0

Carbide granulometry - 8,0 mm 1,2

Max. service Temperature (°C) ~700

TeroCote® 7888 LT is the result of several years of development. Independant studies show that the Castolin

Eutectic TeroCote® products out perform competitor products by over 50%.

2 Stronger, with Castolin Eutectic

www.castolin.com www.eutectic.com

TeroCote® 7888 T

TeroCote® 7888T is a high-performance anti-wear product in the form of a flexible cord, comprising a nickel

core wire, covered with an elastic binder containing a mixture of carbides and nickel alloy powder providing

effective protection against erosive and abrasive attack by a wide variety of materials.

The matrix composition helps to absorb impact and Industry Examples

improves resistance to corrosion, while the angular Mining and earth moving: ripper teeth.

profile of the finely crystallized carbides makes it very Oil exploration and extraction: drill bits, stabilizers.

difficult to dislocate them from the matrix. Brick and cement making: mixer and scraper blades,

7888 T deposits an extremely durable protective coat- extrusion press screws.

ing comprising a dense mass of ultra-hard tungsten Mineral processing: conveyor or decanter screws,

carbides embedded in a tough nickel-chromium alloy pump rotors and sleeves.

matrix. This structure offers extremely effective pro- Iron and steel: guides and scraper blades.

tection against erosive and abrasive attack by a wide Agriculture: cutting edges on plough shares.

variety of materials.

Properties

Hardness, matrix (HV30) ~400

Micro-hardness, carbides (HV1) >2300

Carbide granulometry - 5,0 mm 0,2 - 0,7

Carbide granulometry - 6,0 mm 5,0

Carbide granulometry - 8,0 mm 1,2

Max. service Temperature (°C) ~700

TeroCote® 7888 T out performs a “leading competitor” by 52%.

Stronger, with Castolin Eutectic 3

www.castolin.com www.eutectic.com

TeroCote®

TeroCote® 7620

7620 T is a high-performance anti-wear product in the form of a rod, comprising a nickel rod, covered with an

elastic binder containing a mixture of carbides and nickel alloy powder providing effective protection against

erosive and abrasive attack by a wide variety of materials.

The matrix composition helps to absorb impact and Industry Examples

improves resistance to corrosion, while the angular Mining and earth moving: ripper teeth.

profile of the finely crystallised carbides makes it very Oil exploration and extraction: drill bits, stabilizers.

difficult to dislocate them from the matrix. Brick and cement making: mixer and scraper blades,

extrusion press screws.

Mineral processing: conveyor or decanter screws,

pump rotors and sleeves.

Iron and steel: guides and scraper blades.

Agriculture: cutting edges on plough shares.

Properties

Hardness, matrix (HV30) ~400

Micro-hardness, carbides (HV1) >2300

Carbide granulometry - 3,5 mm 0,85

Carbide granulometry - 5,0 mm 0,85

Carbide granulometry - 8,0 mm 1,5

Max. service Temperature (°C) ~700

4 Stronger, with Castolin Eutectic

www.castolin.com www.eutectic.com

TeroCote® 8811

A carbide containing rod for producing the ultimate in abrasion resistance due to the high concentration of

hard, wear resistant carbides within a self fluxing metallic matrix. For use on steels, stainless steel and cast

iron components using Oxyacetylene, TIG and Eutalloy processes.

This unique alloy form provides a welded protective Industry Examples

coating without dilution by the base metal. High Mining and earth moving: ripper teeth.

density of carbide hard phases. Sound, crack free de- Oil exploration and extraction: drill bits, stabilizers.

posit. No deformation of the workpiece. Rod identifi- Brick and cement making: mixer and scraper blades,

cation: Dark grey coating. extrusion press screws.

Mineral processing: conveyor or decanter screws,

pump rotors and sleeves.

Iron and steel: guides and scraper blades.

Agriculture: cutting edges on plough shares.

Properties

Hardness, matrix (HV30) ~400

Micro-hardness, carbides (HV1) >2300

Carbide granulometry - 5,0 mm 0,2 - 0,7

Carbide granulometry - 6,0 mm 5,0

Carbide granulometry - 8,0 mm 1,5

Max. service Temperature (°C) ~700

Stronger, with Castolin Eutectic 5

www.castolin.com www.eutectic.com

TeroCote®

History of Castolin Eutectic

1906 Foundation of Castolin in Lausanne, Switzer-land by Jean-Pierre

Wasserman. His stroke of genius : to discover a way of welding

cast iron at low temperature. In the following years, this inno-

vation was further developed for all industrial metals including

aluminium alloys.

1940 Foundation of Eutectic Welding Alloys Corpo-ration in New York .

1952 Foundation of Castolin France.

1959 Foundation of Eutectic Japan Ltd.

1962 Foundation of Eutectic India Ltd.

1960’s International consolidation under Castolin Eutectic.

1970’s Creation of training centers for Maintenance & Repair technologies.

1978 Establishment of World Head Quarters in St-Sulpice, Switzerland.

2000 Merger with Messer Cutting & Welding and creation of the MEC

Group - Messer Eutectic Castolin.

2005 Part of the Messer World.

2006 100 years.

Castolin Eutectic received the Frost

& Sullivan triple awards in recogni-

tion of demonstrated excellence in

Customer Service Leadership and

Product Market Growth Leadership

within the European Repair &

Maintenance Welding industry.

These awards reflect the close col-

Together with our sister com- laboration with our customers, and

panies, the Messer Group, can their satisfaction for more than a

Frost & Sullivan award 2011

offer customers a very powerful century.

range of products and services.

Being Part of the Messer World

means :

Investment of

over € 420 million

More than 6,000 motivated

employees

Over 100 factories to meet

customer needs

Technical sales support in

over 120 countries

2,000 technical sales people

in the field with our

customers every day

6 Stronger, with Castolin Eutectic

www.castolin.com www.eutectic.com

Notes

Stronger, with Castolin Eutectic 7

www.castolin.com www.eutectic.com

TeroCote®

Stronger with...

Castolin Eutectic

WEAR & FUSION TECHNOLOGY

Your resource for protection, repair and joining solutions

Statement of Liability: Due to variations inherent in specific applications, the technical information contained herein, including any information as to suggest pro-

duct applications or results, is presented without representation or warranty, expressed or implied. Without limitation, there are no warranties of merchantability

or of fitness for a particular purpose. Each process and application must be fully evaluated by the user in all respects, including suitability, compliance with applica-

ble law and non-infringement of the rights of others, and Castolin Eutectic and its affiliates shall have no liability in respect there of.

www.castolin.com www.eutectic.com

8 Stronger, with Castolin Eutectic

www.castolin.com www.eutectic.com

You might also like

- Hastelloy C276 / Alloy C276 / UNS N10276 / DIN 2.4819Document3 pagesHastelloy C276 / Alloy C276 / UNS N10276 / DIN 2.4819SamkitNo ratings yet

- VEGA - Indonesia PresentationDocument62 pagesVEGA - Indonesia PresentationSteve WanNo ratings yet

- General Chemistry 1: First Quarter-Module 3: Writing and Naming Chemical FormulasDocument19 pagesGeneral Chemistry 1: First Quarter-Module 3: Writing and Naming Chemical FormulasAlessandra Gabrielle Garez100% (1)

- DSM-0329.1 WokaDur NiE ElectrodeDocument4 pagesDSM-0329.1 WokaDur NiE ElectrodeAlireza KhodabandehNo ratings yet

- Eural-6082-EN RohsDocument1 pageEural-6082-EN RohsRoger ColomaNo ratings yet

- Welding Consumable DSMW-0024.1 - WokaDur - S80-Ni-TIG - ElectrodeDocument3 pagesWelding Consumable DSMW-0024.1 - WokaDur - S80-Ni-TIG - ElectrodeJOLLY JAYA SENTOSANo ratings yet

- 035 DEW FerTit Be Hinweis GBDocument24 pages035 DEW FerTit Be Hinweis GBKedves SzabolcsNo ratings yet

- Schmidthammer: Elektrokohle GMBHDocument20 pagesSchmidthammer: Elektrokohle GMBHudhayNo ratings yet

- GN 001 India A4Document2 pagesGN 001 India A4Shanmukganathan ManickamNo ratings yet

- Adhesive and Sealant 11Document3 pagesAdhesive and Sealant 11AsrinNo ratings yet

- NortonCatalog PortableBeltsDocument2 pagesNortonCatalog PortableBeltsherysyam1980No ratings yet

- Abratec 6710 XHD: Multi-Carbide Hardfacing ElectrodeDocument2 pagesAbratec 6710 XHD: Multi-Carbide Hardfacing ElectrodeCasa de Adoración ConcepciónNo ratings yet

- EQT Plates ProductDocument12 pagesEQT Plates Productroberto.cruzNo ratings yet

- Microsoft PowerPoint - Deloro Stellite Advances in Wear Resistant Alloys and Products PDFDocument56 pagesMicrosoft PowerPoint - Deloro Stellite Advances in Wear Resistant Alloys and Products PDFamitNo ratings yet

- TMT BarsDocument24 pagesTMT BarslakshanNo ratings yet

- Monel 400 / UNS N44000 / DIN 2.4360: Industrial Piping ProductsDocument3 pagesMonel 400 / UNS N44000 / DIN 2.4360: Industrial Piping ProductsSamkitNo ratings yet

- EM MOULDS English CatalogueDocument15 pagesEM MOULDS English CataloguekovvadkrishnaNo ratings yet

- TDS Hardcarb 70 (#ET - EN - 20.1)Document2 pagesTDS Hardcarb 70 (#ET - EN - 20.1)Jimit ShahNo ratings yet

- 61 5002 8453 6 PowertrainDocument16 pages61 5002 8453 6 PowertrainThuanNo ratings yet

- 2205 Duplex Data Sheet: Specifications Mechanical Properties FeaturesDocument2 pages2205 Duplex Data Sheet: Specifications Mechanical Properties FeaturesJairo BarragánNo ratings yet

- Hastelloy X / Alloy X / UNS N06002 / DIN 2.4619Document3 pagesHastelloy X / Alloy X / UNS N06002 / DIN 2.4619SamkitNo ratings yet

- Strenx 700 MC: Advanced High Strength SteelDocument2 pagesStrenx 700 MC: Advanced High Strength SteeldbaNo ratings yet

- EutecDur N 6070Document2 pagesEutecDur N 6070shadabkhan5557No ratings yet

- CDP 4666 PDFDocument2 pagesCDP 4666 PDFVitor Rigueira de GodoyNo ratings yet

- Aisi 304 Stainless SteelDocument3 pagesAisi 304 Stainless SteelfarhadNo ratings yet

- Coatings 09 00812 s001Document9 pagesCoatings 09 00812 s001cavoixanh89No ratings yet

- Ds Wear Creusabro8000Document6 pagesDs Wear Creusabro8000Zackaria El IdrissiNo ratings yet

- ASTM C90700 - CuSn11 - Tin Bronze AlloysDocument1 pageASTM C90700 - CuSn11 - Tin Bronze Alloysİrem Şebnem SorucuNo ratings yet

- Merkel Omegat OMK-MR 01Document13 pagesMerkel Omegat OMK-MR 01Ana Tereza Holzhausen GrönerNo ratings yet

- 304 / 304L Stainless: Technical DatasheetDocument1 page304 / 304L Stainless: Technical DatasheettadilakshmikiranNo ratings yet

- End Mill Series: Newly Developed "Impact Miracle Coating"Document32 pagesEnd Mill Series: Newly Developed "Impact Miracle Coating"Deepak ShekarNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- Knock OUT: IntroducingDocument10 pagesKnock OUT: IntroducingMuhammad QusyairiNo ratings yet

- Recommended Rotational Speed Range RPM - TC Burrs For High-Performance ApplicationsDocument1 pageRecommended Rotational Speed Range RPM - TC Burrs For High-Performance ApplicationsLeandro BatistaNo ratings yet

- Techplate NC® Crack-Free Smooth Wear PlateDocument4 pagesTechplate NC® Crack-Free Smooth Wear PlateВадим ЛободаNo ratings yet

- CDP 4666Document2 pagesCDP 4666sareddytejaaeNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338minhyen88No ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Karan NanwaniNo ratings yet

- DS WRS Creusabro 8000 12 2022Document6 pagesDS WRS Creusabro 8000 12 2022johndupNo ratings yet

- Super Duplex Stainless Steel 32750 Data SheetDocument2 pagesSuper Duplex Stainless Steel 32750 Data SheetPrem EditsNo ratings yet

- DSMTS-0010.6 ZN WireDocument4 pagesDSMTS-0010.6 ZN WireMario Cortes FariasNo ratings yet

- Wear Reducing Technology in Severe Pumping ServicesDocument29 pagesWear Reducing Technology in Severe Pumping ServicesDaniel EsparzaNo ratings yet

- Standard Tungsten Carbide Cladding Formulas - OilfieldDocument2 pagesStandard Tungsten Carbide Cladding Formulas - OilfieldTamara Maria Ortiz MendezNo ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- Tungsten Carbide Mill Rolls and Guide RollersDocument2 pagesTungsten Carbide Mill Rolls and Guide RollersQuy SopNo ratings yet

- Astm A182 A182m f904lDocument1 pageAstm A182 A182m f904lestimationNo ratings yet

- Nedal Alloy Datasheet EN AW 7108ADocument1 pageNedal Alloy Datasheet EN AW 7108ANico VazquezNo ratings yet

- Zirconia MaterialsDocument2 pagesZirconia MaterialsFlexiblecsiNo ratings yet

- Castings For Industrial Sector PDFDocument12 pagesCastings For Industrial Sector PDFJuliete Maria TaparelloNo ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- Manufacturing Technology MaterialDocument72 pagesManufacturing Technology Materialabhishekray6370No ratings yet

- Data Sheet Dual Phase High Ductility Steels Voestalpine en 171022Document3 pagesData Sheet Dual Phase High Ductility Steels Voestalpine en 171022mandal.sankhadipNo ratings yet

- SF-0015.1 IGT HPT Abradables ENDocument8 pagesSF-0015.1 IGT HPT Abradables ENThanaraj SanmughamNo ratings yet

- M.E.I.M 2017 362 Cutting Tools (PM)Document42 pagesM.E.I.M 2017 362 Cutting Tools (PM)rohanNo ratings yet

- Super 00Cr Stainless Steel Sucker Rod IntroductionDocument15 pagesSuper 00Cr Stainless Steel Sucker Rod IntroductionKevin XuNo ratings yet

- Bumax Material Presentation - 04!05!16Document49 pagesBumax Material Presentation - 04!05!16matteo_1234No ratings yet

- Hastelloy C22 / Alloy C22 / UNS N06022 / DIN 2.4602Document3 pagesHastelloy C22 / Alloy C22 / UNS N06022 / DIN 2.4602SamkitNo ratings yet

- ME-III 3351903 Lab ManualDocument54 pagesME-III 3351903 Lab ManualBgmi TacticianNo ratings yet

- Nodular Iron Rolls - Hitachi Metals America, Ltd.Document2 pagesNodular Iron Rolls - Hitachi Metals America, Ltd.hsyna38No ratings yet

- Aldehyde Ketone and AcidDocument15 pagesAldehyde Ketone and AcidAbir DuttaNo ratings yet

- Tent, Arctic, 10 Man MIL-DTL-12354GDocument29 pagesTent, Arctic, 10 Man MIL-DTL-12354Gcjnjr1No ratings yet

- SABP X 003 LatestDocument41 pagesSABP X 003 Latestjwoch100% (2)

- Mnemonics For JeeDocument2 pagesMnemonics For JeeAdarsh VargheseNo ratings yet

- Recent Developments in High-Strength Titanium Fasteners For Aerospace ApplicationsDocument21 pagesRecent Developments in High-Strength Titanium Fasteners For Aerospace Applicationskman0722No ratings yet

- Newmont March 2017 Merian-Investor-Presentation - FinalDocument23 pagesNewmont March 2017 Merian-Investor-Presentation - FinalkaiselkNo ratings yet

- ASTM B846 19a Standard Terminology For Copper and Copper AlloysDocument18 pagesASTM B846 19a Standard Terminology For Copper and Copper AlloysRasim Göker Işık100% (1)

- Inverno08 FeitaisVMS EGDocument28 pagesInverno08 FeitaisVMS EGItalo MelgarNo ratings yet

- 7075 Aluminium AlloyDocument3 pages7075 Aluminium AlloyjcetmechanicalNo ratings yet

- CO-ORDINATED SCIENCES 0654/12 Paper 1 Multiple Choice (Core)Document20 pagesCO-ORDINATED SCIENCES 0654/12 Paper 1 Multiple Choice (Core)José Antonio Álvarez CuberoNo ratings yet

- AP-24 Toothpastes PIPDocument2 pagesAP-24 Toothpastes PIPTorito ZalgadoNo ratings yet

- 6063 Aluminium Alloy - WikipediaDocument3 pages6063 Aluminium Alloy - WikipediaNinad PawarNo ratings yet

- Indo-German Tool Room, Aurangabad: Chapter OutlineDocument15 pagesIndo-German Tool Room, Aurangabad: Chapter OutlinejishnuNo ratings yet

- AQA GCSE Chem End of Topic C5Document9 pagesAQA GCSE Chem End of Topic C5joeNo ratings yet

- Rev 1 January 2010 Terms and Definitions © TWI LTD 2010Document18 pagesRev 1 January 2010 Terms and Definitions © TWI LTD 2010Srinivasa RaoNo ratings yet

- Nkana Cobalt Cu SXDocument7 pagesNkana Cobalt Cu SXKroya HunNo ratings yet

- Artisan Plating Gold Plating - Artisan PlatingDocument7 pagesArtisan Plating Gold Plating - Artisan PlatingbirgulNo ratings yet

- Repair of Rails On Site by Welding XA00127720Document20 pagesRepair of Rails On Site by Welding XA00127720wpsssamsungNo ratings yet

- 31003Document4 pages31003Elliott RussellNo ratings yet

- Chapter 1 - ProcessesDocument6 pagesChapter 1 - ProcessesAnonymous dh6DITNo ratings yet

- List of Public Sector Undertakings in IndiaDocument45 pagesList of Public Sector Undertakings in IndiaGeetu KumariNo ratings yet

- Tungsten CarbideDocument9 pagesTungsten CarbideIzwan HanafiNo ratings yet

- Star Control: Origins Alien Locations & MoreDocument13 pagesStar Control: Origins Alien Locations & MoreTommy CashmanNo ratings yet

- Eer 1201Document9 pagesEer 1201Hüseyin KaradağNo ratings yet

- Dinen 10079 - 200706 - enDocument46 pagesDinen 10079 - 200706 - enAnonymous dvrhf5No ratings yet

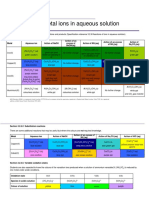

- Reactions of Metal Ions in Aqueous Solution: Chemistry A-Level (7405)Document2 pagesReactions of Metal Ions in Aqueous Solution: Chemistry A-Level (7405)SAMANNo ratings yet

- NHQ459 B 146347 Sev1Document1 pageNHQ459 B 146347 Sev1Sir MarketNo ratings yet

- RBC Rolling Element Bearings WebDocument152 pagesRBC Rolling Element Bearings WebspirogrujicNo ratings yet

- Boiler Phosphate TreatmentDocument4 pagesBoiler Phosphate TreatmentSilvina C. Gómez Correa0% (1)