Professional Documents

Culture Documents

2021 Milling Strategy Guides EN2 Web

2021 Milling Strategy Guides EN2 Web

Uploaded by

nigay.labOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2021 Milling Strategy Guides EN2 Web

2021 Milling Strategy Guides EN2 Web

Uploaded by

nigay.labCopyright:

Available Formats

DOCUMENT:

MILLING GUIDES

PREPARED FOR: ALIEN INSIDERS

CLASSIFICATION: TOP SECRET

ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 1 OF 28

#MILLMOREUNITS ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 3 OF 28

MILLING STRATEGY

GUIDELINES

In an effort to get the best results out of your AlienTools, we have provided some general guidelines to go by when

developing your milling strategy. Obviously these are guidelines for users with open CAM systems who can change

these parameters; for users with closed systems we have developed our tools to best match the parameters already

given by the machine manufacturer.

Keep in mind that the guides below are recommended maximums, meaning that if you already have a strategy that

works for you that is more conservative than this then there is nothing you need to change. If your current strategy

is more aggressive than the following guidelines it does not mean that the tool will not work, just that you may

not get the full lifespan that the tool can achieve. You should, however, pay close attention to the strategy on tools

with considerably longer Reach Lengths than your current tools. Our tools are designed to deliver the best milled

results by getting into those hard-to-reach areas, so for these tools your strategy should not be far off from our

recommendations.

If you have any questions or feedback to these guides please let us know...and happy milling!

#MILLMOREUNITS ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 5 OF 28

HARD ZIRCONIA

ZIRCONIA MILLING STRATEGY GUIDES

Every zirconia is slightly different and depending on the pre-sintering levels by the manufacturer it will affect the hardness of the material. The easiest way to see

this is in the shrinkage factor...the higher the number the softer the material is. This is why we have two different recommendations for zirconia depending on

the hardness.

GENERAL NOTES:

- Normal Milling Direction: INSIDE to OUTSIDE

- Milling Direction on Crown Cavity: OUTSIDE to INSIDE

- Milling Direction for 0.3 and 0.6 mm Tools on Occlusial Grooves and Margins: OUTSIDE TO INSIDE

- Optional for 1 mm Tools on Margins: 15 mm/sec Feed Rate, 0.05 Depth Step, Direction OUTSIDE TO INSIDE

FOR HARD ZIRCONIA (SHRINKAGE FACTOR <1.235)

CUTTING CUTTING NR. OF SPINDLE SPEED FEED RATE DEPTH STEP SIDE STEP OFFSET

DIAMETER GEOMETRY FLUTES (OVERLAP %)

2.5 mm BALL 2 20,000 rpm 25 mm/sec 0.5 mm 1.0 mm (60%) 0.05 mm

YOUR ADJUSTED VALUES ->

2.0 mm BALL 2 22,000 rpm 25 mm/sec 0.5 mm 0.9 mm (55%) 0 mm

YOUR ADJUSTED VALUES ->

1.0 mm BALL 2 25,000 rpm 20 mm/sec* 0.1-0.2 mm* 0.1 mm (90%) 0 mm

YOUR ADJUSTED VALUES ->

0.6 mm BALL 2 27,000 rpm 15 mm/sec** 0.1 mm** 0.08 mm (87%) 0 mm

YOUR ADJUSTED VALUES ->

0.5 mm BALL 2 27,000 rpm 15 mm/sec 0.08 mm 0.08 mm (84%) 0 mm

YOUR ADJUSTED VALUES ->

0.3 mm BALL 2 29,000 rpm 10 mm/sec 0.05-0.07 mm 0.05 mm (83%) 0 mm

YOUR ADJUSTED VALUES ->

*For 1mm tools with the longer 20mm Reach Length (RL), reduce the Feed Rate and Depth Step approximately 20% to avoid tool breakage.

**For 0.6mm tools with the longer 10mm Reach Length (RL), reduce the Feedrate and Depth Step approximately 10-15% to avoid tool breakage.

NOTES:

#MILLMOREUNITS ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 7 OF 28

SOFT ZIRCONIA

ZIRCONIA MILLING STRATEGY GUIDES

Every zirconia is slightly different and depending on the pre-sintering levels by the manufacturer it will affect the hardness of the material. The easiest way to see

this is in the shrinkage factor...the higher the number the softer the material is. This is why we have two different recommendations for zirconia depending on

the hardness.

GENERAL NOTES:

- Normal Milling Direction: INSIDE to OUTSIDE

- Milling Direction on Crown Cavity: OUTSIDE to INSIDE

- Milling Direction for 0.3 and 0.6 mm Tools on Occlusial Grooves and Margins: OUTSIDE TO INSIDE

- Optional for 1 mm Tools on Margins: 15 mm/sec Feed Rate, 0.05 Depth Step, Direction OUTSIDE TO INSIDE

FOR SOFTER ZIRCONIA (SHRINKAGE FACTOR >1.235)

CUTTING CUTTING NR. OF SPINDLE SPEED FEED RATE DEPTH STEP SIDE STEP OFFSET

DIAMETER GEOMETRY FLUTES (OVERLAP %)

2.5 mm BALL 2 21,000 rpm 30 mm/sec 0.6 mm 1.1 mm (56%) 0.1 mm

YOUR ADJUSTED VALUES ->

2.0 mm BALL 2 23,000 rpm 30 mm/sec 0.6 mm 0.95 mm (53%) 0 mm

YOUR ADJUSTED VALUES ->

1.0 mm BALL 2 26,000 rpm 25 mm/sec* 0.1-0.2 mm* 0.1 mm (90%) 0 mm

YOUR ADJUSTED VALUES ->

0.6 mm BALL 2 28,000 rpm 20 mm/sec** 0.1 mm** 0.08 mm (87%) 0 mm

YOUR ADJUSTED VALUES ->

0.5 mm BALL 2 28,000 rpm 20 mm/sec 0.08 mm 0.08 mm (84%) 0 mm

YOUR ADJUSTED VALUES ->

0.3 mm BALL 2 30,000 rpm 15 mm/sec 0.05-0.07 mm 0.05 mm (83%) 0 mm

YOUR ADJUSTED VALUES ->

*For 1mm tools with the longer 20mm Reach Length (RL), reduce the Feed Rate and Depth Step approximately 20% to avoid tool breakage.

**For 0.6mm tools with the longer 10mm Reach Length (RL), reduce the Feedrate and Depth Step approximately 10-15% to avoid tool breakage.

NOTES:

#MILLMOREUNITS ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 9 OF 28

COBALT CHROME

CoCr MILLING STRATEGY GUIDES

GENERAL NOTES:

- Normal Milling Direction: INSIDE to OUTSIDE

- Milling Direction on Crown Cavity: OUTSIDE to INSIDE

- Milling Direction for 0.6 mm Tools on Occlusial Grooves and Margins: OUTSIDE TO INSIDE

WARNINGS:

- Values, especially by Feed Rate and Depth Step, rely heavily on the machine model

- Maximum values only to be used with machines that have very little vibration and strong spindles

- Especially by ‘harder’ CoCr blanks (tungsten > 3%) the Spindle Speed, Feed Rate, and Depth Step should all be reduced

CUTTING INDICATION CUTTING NR. OF SPINDLE SPEED FEED RATE DEPTH STEP SIDE STEP OFFSET

DIAMETER GEOMETRY FLUTES (OVERLAP %)

3.0 mm HI-SPEED TORIC (BULL) 3 10,200 rpm 30 mm/sec 0.20-0.25 mm 1.2 mm (60%) 0.05 mm

ROUGHING

YOUR ADJUSTED VALUES ->

3.0 mm ROUGHING BALL 2 13,700 rpm 20-25 mm/sec 0.12-0.24 mm 1.2 mm (60%) 0.05 mm

YOUR ADJUSTED VALUES ->

2.0 mm HI-SPEED TORIC (BULL) 3 14,500 rpm 28-30 mm/sec 0.12-0.20 mm 0.7 mm (65%) 0.03 mm

ROUGHING

YOUR ADJUSTED VALUES ->

2.0 mm ROUGHING BALL 2 15,900 rpm 20-23 mm/sec 0.15-0.20 mm 0.9 mm (55%) 0.03 mm

YOUR ADJUSTED VALUES ->

2.0 mm FINISHING TORIC (BULL) 4 16,000 rpm 26-28 mm/sec 0.1-0.12 mm 0.7 mm (65%) 0 mm

YOUR ADJUSTED VALUES ->

1.5 mm FINISHING TORIC (BULL) 4 21,200 rpm 11 mm/sec 0.03 mm 0.3 mm (80%) 0 mm

YOUR ADJUSTED VALUES ->

1.5 mm FINISHING BALL 2 20,500 rpm 15-20 mm/sec 0.08-0.12 mm 0.15 mm (90%) 0 mm

YOUR ADJUSTED VALUES ->

1.0 mm FINISHING BALL 2 23,200 rpm 15-18 mm/sec 0.05-0.07 mm 0.05 mm (83%) 0 mm

YOUR ADJUSTED VALUES ->

0.6 mm FINISHING BALL 2 25,000 rpm 15-16 mm/sec 0.05 mm 0.04 mm (93%) 0 mm

YOUR ADJUSTED VALUES ->

NOTES:

#MILLMOREUNITS ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 11 OF 28

TITANIUM

TITANIUM MILLING STRATEGY GUIDES

GENERAL NOTES:

- Normal Milling Direction: INSIDE to OUTSIDE

- Milling Direction on Crown Cavity: OUTSIDE to INSIDE

- Milling Direction for 0.6 mm Tools on Occlusial Grooves and Margins: OUTSIDE TO INSIDE

WARNINGS:

- Values, especially by Feed Rate and Depth Step, rely heavily on the machine model

- Maximum values only to be used with machines that have very little vibration and strong spindles

CUTTING INDICATION CUTTING NR. OF SPINDLE SPEED FEED RATE DEPTH STEP SIDE STEP OFFSET

DIAMETER GEOMETRY FLUTES (OVERLAP %)

3.0 mm ROUGHING BALL 2 15,500 rpm 15 mm/sec 0.25 mm 0.7 mm (77%) 0.1 mm

YOUR ADJUSTED VALUES ->

2.0 mm ROUGHING BALL 2 17,500 rpm 11 mm/sec 0.15 mm 0.45 mm (78%) 0.05 mm

YOUR ADJUSTED VALUES ->

1.0 mm FINISHING BALL 2 20,000 rpm 6 mm/sec 0.05 mm 0.05 mm (83%) 0 mm

YOUR ADJUSTED VALUES ->

NOTES:

#MILLMOREUNITS ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 13 OF 28

PMMA

PMMA MILLING STRATEGY GUIDES

GENERAL NOTES:

- Normal Milling Direction: INSIDE to OUTSIDE

- Milling Direction on Crown Cavity: OUTSIDE to INSIDE

- Milling Direction for 0.5mm and 0.6 mm Tools on Occlusial Grooves and Margins: OUTSIDE TO INSIDE

CUTTING CUTTING NR. OF SPINDLE SPEED FEED RATE DEPTH STEP SIDE STEP OFFSET

DIAMETER GEOMETRY FLUTES (OVERLAP %)

4.0 mm FLAT 1 16,000 rpm 25 mm/sec 1.5 mm 2.5 mm (38%) 0.1 mm

YOUR ADJUSTED VALUES ->

2.5 mm BALL 2 12,000 rpm 32 mm/sec 1 mm 1 mm (60%) 0.1 mm

YOUR ADJUSTED VALUES ->

2.0 mm BALL 2 13,000 rpm 30 mm/sec 1 mm 0.8 mm (60%) 0.05 mm

YOUR ADJUSTED VALUES ->

1.0 mm BALL 2 17,000 rpm 25 mm/sec 0.10-0.15 mm 0.1 mm (90%) 0 mm

YOUR ADJUSTED VALUES ->

0.6 mm BALL 2 18,000 rpm 20 mm/sec 0.08 mm 0.08 mm (87%) 0 mm

YOUR ADJUSTED VALUES ->

0.5 mm BALL 2 18,000 rpm 20 mm/sec 0.08 mm 0.08 mm (84%) 0 mm

YOUR ADJUSTED VALUES ->

NOTES:

#MILLMOREUNITS ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 15 OF 28

PEEK

PEEK MILLING STRATEGY GUIDES

GENERAL NOTES:

- Normal Milling Direction: INSIDE to OUTSIDE

- Milling Direction on Crown Cavity: OUTSIDE to INSIDE

- Milling Direction for 0.5mm and 0.6 mm Tools on Occlusial Grooves and Margins: OUTSIDE TO INSIDE

CUTTING CUTTING NR. OF SPINDLE SPEED FEED RATE DEPTH STEP SIDE STEP OFFSET

DIAMETER GEOMETRY FLUTES (OVERLAP %)

4.0 mm FLAT 1 16,000 rpm 25 mm/sec 1.5 mm 2.5 mm (38%) 0.1 mm

YOUR ADJUSTED VALUES ->

2.5 mm BALL 2 13,000 rpm 32 mm/sec 1 mm 0.9 mm (64%) 0.05 mm

YOUR ADJUSTED VALUES ->

2.0 mm BALL 2 16,000 rpm 30 mm/sec 0.5 mm 0.7 mm (65%) 0.05 mm

YOUR ADJUSTED VALUES ->

1.0 mm BALL 2 22,000 rpm 25 mm/sec 0.07-0.1 mm 0.07 mm (93%) 0 mm

YOUR ADJUSTED VALUES ->

0.6 mm BALL 2 23,000 rpm 20 mm/sec 0.05 mm 0.05 mm (92%) 0 mm

YOUR ADJUSTED VALUES ->

0.5 mm BALL 2 23,000 rpm 20 mm/sec 0.05 mm 0.05 mm (90%) 0 mm

YOUR ADJUSTED VALUES ->

NOTES:

#MILLMOREUNITS ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 17 OF 28

BLANK STRATEGY

TABLES

The following pages are where you can add any custom strategies that you’ve worked out. Have fun exploring and always MillMoreUnits..

MATERIAL:

ARTICLE NUMBER INDICATION CUTTING CUTTING NR. OF SPINDLE SPEED FEED RATE DEPTH STEP SIDE STEP OFFSET

DIAMETER GEOMETRY FLUTES (OVERLAP %)

NOTES:

#MILLMOREUNITS ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 19 OF 28

BLANK STRATEGY

TABLES

MATERIAL:

ARTICLE NUMBER INDICATION CUTTING CUTTING NR. OF SPINDLE SPEED FEED RATE DEPTH STEP SIDE STEP OFFSET

DIAMETER GEOMETRY FLUTES (OVERLAP %)

NOTES:

#MILLMOREUNITS ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 21 OF 28

BLANK STRATEGY

TABLES

MATERIAL:

ARTICLE NUMBER INDICATION CUTTING CUTTING NR. OF SPINDLE SPEED FEED RATE DEPTH STEP SIDE STEP OFFSET

DIAMETER GEOMETRY FLUTES (OVERLAP %)

NOTES:

#MILLMOREUNITS ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 23 OF 28

BLANK STRATEGY

TABLES

MATERIAL:

ARTICLE NUMBER INDICATION CUTTING CUTTING NR. OF SPINDLE SPEED FEED RATE DEPTH STEP SIDE STEP OFFSET

DIAMETER GEOMETRY FLUTES (OVERLAP %)

NOTES:

#MILLMOREUNITS ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 25 OF 28

#MILLMOREUNITS ALIENTOOLS MILLING STRATEGY GUIDES MSGEN02 PAGE 27 OF 28

ALIEN TOOLS GMBH

PLAUENER STR. 163-165

GEB. 5, AUFG. E, 3. OG

13053, BERLIN, GERMANY

PHONE: +49 30 549 09787 POWERED BY

INFO@ALIEN-TOOLS.COM

ALIEN-TOOLS.COM

You might also like

- Cincom L32 Post ManualDocument56 pagesCincom L32 Post Manualshivanagaprakash67% (3)

- Cincom L12 Post ManualDocument39 pagesCincom L12 Post Manualshivanagaprakash100% (4)

- 1 ADocument10 pages1 ApedroNo ratings yet

- Condensed Zeiss Cookbook Probing Strategies: METAL PLANE Probing Strategies (Z400L) Active HeadDocument3 pagesCondensed Zeiss Cookbook Probing Strategies: METAL PLANE Probing Strategies (Z400L) Active HeadGabriel Teleptean100% (1)

- CH 7 AnswersDocument32 pagesCH 7 AnswersSuckaKing100% (1)

- MCX9 Mill Lesson 7Document76 pagesMCX9 Mill Lesson 7RubenNo ratings yet

- Dmap2gcode ManualDocument8 pagesDmap2gcode ManualJoel Antonio Lopez LopezNo ratings yet

- Supply Digimatic Micrometer PDFDocument3 pagesSupply Digimatic Micrometer PDFBonage DattaNo ratings yet

- Z-CARB MD SpeedFeedDocument1 pageZ-CARB MD SpeedFeedalphatoolsNo ratings yet

- An Externally Mounted Flange Facing Machine For All Types of Flange Facings, Seal Groove Machining, Weld Preparation and Counter BoringDocument3 pagesAn Externally Mounted Flange Facing Machine For All Types of Flange Facings, Seal Groove Machining, Weld Preparation and Counter BoringManish MohananNo ratings yet

- Ukuran Jarak Renggang Celah Klep Sepeda MotorDocument2 pagesUkuran Jarak Renggang Celah Klep Sepeda MotorErossNo ratings yet

- Bonded App Gear GrindingDocument7 pagesBonded App Gear GrindingvengadeshNo ratings yet

- Measurimg InstrumentsDocument2 pagesMeasurimg InstrumentsparinkhonaNo ratings yet

- DIN16742 2013A Eng Plastics Moulded Parts Tolerance Acceptance ConditionsDocument1 pageDIN16742 2013A Eng Plastics Moulded Parts Tolerance Acceptance ConditionsNoe MarinNo ratings yet

- Mitutoyo Micrometer PDFDocument32 pagesMitutoyo Micrometer PDFElmer VillegasNo ratings yet

- C56 SpecsDocument3 pagesC56 SpecsFelipe CINo ratings yet

- Climax Od Mount Flange Facers: Versatility. Durability. SafetyDocument12 pagesClimax Od Mount Flange Facers: Versatility. Durability. SafetyGerlianeNo ratings yet

- CoroMill 425 92023Document41 pagesCoroMill 425 92023Nelson SanchezNo ratings yet

- OKW Tolerances enDocument1 pageOKW Tolerances enbaskaran.marieNo ratings yet

- 1 ADocument8 pages1 ApedroNo ratings yet

- Linear Optical Scale PDFDocument1 pageLinear Optical Scale PDFPavan AryaNo ratings yet

- Catalogo ATADocument32 pagesCatalogo ATALUIS JAVIER SIERRA CEPEDANo ratings yet

- Micrometer List of Products Move To Other ProductsDocument47 pagesMicrometer List of Products Move To Other ProductsLuis Enrique Aguilar MontoyaNo ratings yet

- CL-151-Cert RICI LabDocument16 pagesCL-151-Cert RICI LabzipaganredentorefreniiNo ratings yet

- Contact Tachometer: Model: DT-2235BDocument2 pagesContact Tachometer: Model: DT-2235Bnisne0730No ratings yet

- Block 75 Betalghat - ResourceRate - Material PDFDocument16 pagesBlock 75 Betalghat - ResourceRate - Material PDFManojNo ratings yet

- Tochometer DT 2234bDocument2 pagesTochometer DT 2234bdawoodNo ratings yet

- Photo Tachometer: Model: DT-2234BDocument2 pagesPhoto Tachometer: Model: DT-2234BAdarsha CalibrationsNo ratings yet

- Tete Precitec 1638883537Document2 pagesTete Precitec 1638883537muhittincakirrrrNo ratings yet

- Taller 4, Tablas DerivasDocument3 pagesTaller 4, Tablas DerivasevebarazarteNo ratings yet

- Standards and Service Limits: 2005-06 General InformationDocument21 pagesStandards and Service Limits: 2005-06 General Informationvadim vadim100% (1)

- 324 Prespan Weidmann 7Document2 pages324 Prespan Weidmann 7hiren_mistry55No ratings yet

- Water Jet PortfoliaDocument7 pagesWater Jet PortfoliaSagar KumarNo ratings yet

- ESAB ExtractPage20-21cDocument8 pagesESAB ExtractPage20-21cDries VandezandeNo ratings yet

- 9851 3586 01 - Cop MD20Document4 pages9851 3586 01 - Cop MD20Guifo salvadorNo ratings yet

- 9851 3586 01 COP MD20 BrochureDocument4 pages9851 3586 01 COP MD20 BrochureEduardo MassainiNo ratings yet

- LampiranDocument22 pagesLampiranSyafrizal FauzyNo ratings yet

- Block 89 Khatima - ResourceRate - Material PDFDocument22 pagesBlock 89 Khatima - ResourceRate - Material PDFGirish lohaniNo ratings yet

- EC480D - Swing Gearbox, Maintenance StandardDocument4 pagesEC480D - Swing Gearbox, Maintenance Standardeck yuwanNo ratings yet

- XEBEC Technical Crosshole-BrushDocument4 pagesXEBEC Technical Crosshole-BrushferNo ratings yet

- Refacing Report Senoro.r123Document28 pagesRefacing Report Senoro.r123Ismail KarmanaNo ratings yet

- Whale Enterprises-29.01.13Document4 pagesWhale Enterprises-29.01.13Rajkumar RajendranNo ratings yet

- 05 Cable Tray Calculations 25 Nov 2021Document31 pages05 Cable Tray Calculations 25 Nov 2021مهندز مانNo ratings yet

- Product Features: Image ImageDocument2 pagesProduct Features: Image ImageFallo SusiloNo ratings yet

- MM300e UK 1.4 DS 039 0418Document3 pagesMM300e UK 1.4 DS 039 0418Tharathip SamakkeeNo ratings yet

- Quality Control Check ListDocument3 pagesQuality Control Check ListVarun MalhotraNo ratings yet

- Milling Speed & Feed Calculator - Inch To MetricDocument16 pagesMilling Speed & Feed Calculator - Inch To Metricசரவணகுமார் மாரியப்பன்100% (1)

- MitutoyoDocument32 pagesMitutoyoharisNo ratings yet

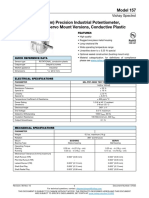

- Model 157: Vishay SpectrolDocument4 pagesModel 157: Vishay SpectrolJulio Vazquez MorenoNo ratings yet

- Metorology Lab 1 Experiment 2Document7 pagesMetorology Lab 1 Experiment 2Mathan kuttyNo ratings yet

- Specs - ABSDocument3 pagesSpecs - ABSBurak KececiNo ratings yet

- 1387 05Document19 pages1387 05rp801113717No ratings yet

- Portable Cutting Machine VCM 200 Portable Cutting Machine: Type 101 One Piece Acetylene NozzleDocument2 pagesPortable Cutting Machine VCM 200 Portable Cutting Machine: Type 101 One Piece Acetylene NozzleDries VandezandeNo ratings yet

- Specification Table: Standards and Service LimitsDocument11 pagesSpecification Table: Standards and Service Limitsvadim vadimNo ratings yet

- Data Sheet Ultradrill DentoolsDocument2 pagesData Sheet Ultradrill DentoolsHugo Sousa DiasNo ratings yet

- Aggregates FMDocument5 pagesAggregates FMabualamalNo ratings yet

- Habasitlink M2480 Flush Grid 1": (1.6") PossibleDocument2 pagesHabasitlink M2480 Flush Grid 1": (1.6") PossiblerizqiNo ratings yet

- ZMTEC-NTC NewDocument2 pagesZMTEC-NTC Newvijay.victorysolutions01No ratings yet

- C4.4 Medida Cigüeñal PermitidasDocument3 pagesC4.4 Medida Cigüeñal PermitidasLuis GutiérrezNo ratings yet

- CL 273 Cert - 2Document17 pagesCL 273 Cert - 2rohanmanimaniNo ratings yet

- Engine Electrical Service Limits Chart Item Measurement Qualification Standard or New Service LimitDocument86 pagesEngine Electrical Service Limits Chart Item Measurement Qualification Standard or New Service LimitWSMengine WSMengine100% (1)

- 2008 Honda CR-V: Engine AssemblyDocument7 pages2008 Honda CR-V: Engine Assemblyfrancisco Alba100% (1)

- Grinding Process BoreDocument22 pagesGrinding Process Boremaulikgadara50% (2)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Level 9 - Mechanical TechnologyDocument17 pagesLevel 9 - Mechanical TechnologyFajiza JuarezaNo ratings yet

- 12 Machinery Ebook PDFDocument135 pages12 Machinery Ebook PDFTeuku Andy Nur IsaNo ratings yet

- Plasma Arc MachiningDocument24 pagesPlasma Arc MachiningArnav SharmaNo ratings yet

- Production Technology Objective Questions With Answers - Set 26 - ObjectiveBooksDocument8 pagesProduction Technology Objective Questions With Answers - Set 26 - ObjectiveBookskunda chabotaNo ratings yet

- Outokumpu Machining Guidelines For Forta LDX2404Document2 pagesOutokumpu Machining Guidelines For Forta LDX2404chavico113No ratings yet

- Victory 11: CNC Single Spindle Drilling LineDocument16 pagesVictory 11: CNC Single Spindle Drilling LineReinaldo Javier Ramirez ValienteNo ratings yet

- Surface Roughness Model For St37Document4 pagesSurface Roughness Model For St37fitraskaNo ratings yet

- Literature Review Cryogenic MachiningDocument5 pagesLiterature Review Cryogenic MachiningSaad100% (1)

- CKE6150-Operation Manual (MAQCHIN)Document65 pagesCKE6150-Operation Manual (MAQCHIN)Vanessa Rivera100% (1)

- First Year Metalwork.: Class Notes and Homework WorkbookDocument117 pagesFirst Year Metalwork.: Class Notes and Homework Workbookbrian DeckerNo ratings yet

- Gyroscopic EffectDocument13 pagesGyroscopic EffectRavinder SinghNo ratings yet

- JJ104 Workshop Technology Chapter6 Milling MachineDocument27 pagesJJ104 Workshop Technology Chapter6 Milling MachineAh Tiang100% (3)

- Roland PNC 3100Document55 pagesRoland PNC 3100Gonzalo Margeli CelmaNo ratings yet

- Heidenhain TNC Machine DataDocument11 pagesHeidenhain TNC Machine DatamovaliyarushilkumarNo ratings yet

- Reference Tables For Normal and OEM CodesDocument20 pagesReference Tables For Normal and OEM CodesMagnetor50% (2)

- TECHNICAL FehlmannDocument5 pagesTECHNICAL FehlmannSahrul RomadonNo ratings yet

- Chip Formation and Tool LifeDocument37 pagesChip Formation and Tool Lifeneelesh singh100% (10)

- Proceedings of International Conference On Intelligent ManufacturingDocument831 pagesProceedings of International Conference On Intelligent Manufacturingenock-readersNo ratings yet

- Question Bank MSDDocument2 pagesQuestion Bank MSDragygataNo ratings yet

- Assignment No 1 (ME 461)Document6 pagesAssignment No 1 (ME 461)Jayant Raj SauravNo ratings yet

- PG - 1102 - en (Programming Guide 11 - 2002 Edition)Document504 pagesPG - 1102 - en (Programming Guide 11 - 2002 Edition)mikadoturkNo ratings yet

- Pereira 2016Document36 pagesPereira 2016WILMER LLMUTASIGNo ratings yet

- MECH 360 Homework 2 W14Document5 pagesMECH 360 Homework 2 W14Samuel JiménezNo ratings yet

- GSK218MC Programming and Opration ManualDocument340 pagesGSK218MC Programming and Opration ManualAlbertoQuezadaNo ratings yet

- EPP201 Pass Paper Revision Questions 1Document9 pagesEPP201 Pass Paper Revision Questions 1Boey Keen HuangNo ratings yet