Professional Documents

Culture Documents

Module 2: Solid Fossil Fuel (Coal) Lecture 13: Coal Liquefaction

Module 2: Solid Fossil Fuel (Coal) Lecture 13: Coal Liquefaction

Uploaded by

Muhammad Ayan MalikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module 2: Solid Fossil Fuel (Coal) Lecture 13: Coal Liquefaction

Module 2: Solid Fossil Fuel (Coal) Lecture 13: Coal Liquefaction

Uploaded by

Muhammad Ayan MalikCopyright:

Available Formats

1|Page

Module 2: Solid Fossil Fuel (Coal)

Lecture 13: Coal liquefaction

IIT Kharagpur NPTEL Phase – II Web Courses

2|Page

Keywords: Direct coal liquefaction, indirect coal liquefaction, EDS process, H-coal process

2.5 Coal liquefaction

Coal liquefaction is a process where coal is converted into liquid fuels, mainly to provide

substitutes for petroleum products, which may be either used directly as fuel or converted into

chemicals or other liquid fuels. Coal liquefaction processes were first developed in the early 20th

century. The crude petroleum rich countries may not need this process for fulfilling their

requirement of liquid fuel but the countries which are lacking of crude but have a good reserve of

solid fuel like coal, a large scale applications of coal liquefaction process is entertained. The few

countries, where this process is mainly running are Germany (during World War II) and South

Africa since the year 1960s. USA is also running coal to liquid fuel plant successfully. A plant

using more than six million tons of coal annually could produce more than 3.6 million barrels of

diesel and napththa. China has expended fifteen billion dollar for coal to diesel fuel conversion

plant with the aim of replacing 10% of its oil import with coal converted liquid oils by the year

2013. The threat of depletion of conventional oil sources is another major reason for renewed

interest in the production of oil substitutes from coal since last three decades.

Hydrocarbon type liquid fuels are obtained from solid fuel like coal by the following routes

mainly:

1) Hydrogenation of coal

2) Solvent extraction of coal and hydrogenation of coal extracts

3) Refining of tar and oil obtained from carbonization of various soild fuels and oil shales

4) Gasification of solid fuels into synthesis gas and conversion of the gas into liquid fuels

and chemicals.

IIT Kharagpur NPTEL Phase – II Web Courses

3|Page

The following block diagram (Figure 1) shows the options for coal to liquid conversion plants.

Fig. 1. Different routes of coal liquefaction

Coal liquefaction can be achieved either by direct or indirect processes. The difference between

these two processes lies in that, the indirect liquefaction process needs to go through gasification

first, while, direct liquefaction process involves producing partially refined synthetic oil from

coal. It is said by the technologists that, indirect liquefaction is more efficient than direct coal

liquefaction techniques which are currently available.

2.5.1 Direct liquefaction

Direct coal liquefaction was developed by Friedrich Bergius and it was started commercially in

Germany near World War II, to meet the huge demand of liquid fuel at that time.

Bergius process was modified and extended to fulfill today’s demand of liquid fuel. The coal is

ground so that it can be mixed into coal derived heavy oil recycled from the process to form a

coal-oil slurry feed. The slurry containing 30-50% coal is then heated in a reactor to about 450°C

IIT Kharagpur NPTEL Phase – II Web Courses

4|Page

in a hydrogen atmosphere between 14-22 MPa pressures for about one hour. Different catalyst

used are tungsten or molybdenum sulfides, tin or nickel oleate. The reaction produces heavy oil,

middle oil, gasoline and gases.

One tonne of coal yields about one-half tonne of liquids. Processes have been developed to use

coals from low rank lignites to high volatile bituminous coals. Higher-rank coals are less reactive

and anthracites are essentially non-reactive.

The liquids produced have molecular structures similar to those found in aromatic compounds

and need further upgrading to produce specification fuels such as gasoline and fuel oil.

Direct coal liquefaction is suitable for a wide range of feeds:

high volatile bituminous coals

sub-bituminous coals with low ash

lignites with low ash

Direct liquefaction is of two types, single stage and two stage processes.

In single-stage direct liquefaction process, one primary reactor is used to get distillates. Here a

hydrotreating reactor is also joined along with the primary reactor to improve the quality of the

distillate. The technology developers are

o H-Coal (HRI, USA)

o Exxon donor solvent (Exxon, USA)

o SRC-1 and II (Gulf Oil, USA)

o Conoco zinc chloride (Conoco, USA)

IIT Kharagpur NPTEL Phase – II Web Courses

5|Page

o Kohleoel (Ruhrkohle, Germany)

o NEDOL (NEDO, Japan)

Two reactors in series are used in two-stage direct liquefaction process. In the first stage, coal

dissolution is done where the process is operated either without a catalyst or with a low-activity

disposable catalyst. The heavy coal liquids produced in the first reactor are hydrotreated in the

second stage in the presence of a high-activity catalyst to produce desired distillate. The process

and technology developers include

o Catalytic two-stage liquefaction (US DOE and HTI, USA)

o Liquid solvent extraction (British Coal Corporation, UK)

o Brown coal liquefaction (NEDO, Japan)

o Consol synthetic fuel (Consol, USA)

o Lummus (Lummus, USA)

Among the different commercial processes, Exxon donor solvent process (EDS) and H-coal

process are discussed here.

EDS (Exxon Donor Solvent) process

In this process coal slurry is prepared using a recycled solvent and the slurry is mixed with H2,

preheated and fed to a simple up-flow tubular reactor. The reactor operates at 425-450 ºC and

2575 psig pressure. It is a non-catalytic process. The ligher product naphtha, a middle distillate

and a heavy distillate product are obtained. Heavy distillate mixed with some middle distillate

forms the recycle solvent. The recycle solvent is hydrogenated in a fixed-bed catalytic reactor

operated at 3700C and 1600 psig H2 pressure depending on the extent of hydrogenation, where

IIT Kharagpur NPTEL Phase – II Web Courses

6|Page

either nickel-molybdenum or cobalt-molybdenum on alumina support is used as a catalyst. A

flow diagram of EDS process is described in Fig 2.

Fig. 2. Flow diagram of EDS process

H-coal process

In this process, coal slurry is prepared with a recycle solvent that consists of a mixture of heavy

and middle distillates obtained by product fractionation and solids containing hydrocracker

product. H2 is added to the slurry, the mixture is preheated and fed to an ebullated bed

hydrocracker, which is the distinguishing feature of the process. The reaction conditions are :

temperature 425-455°C and H2 pressure 2900 psig. The catalyst used is either Ni-Mo or Co-Mo

IIT Kharagpur NPTEL Phase – II Web Courses

7|Page

supported on alumina. The catalyst is fluidized by H2 and a pumped internal recycle stream. This

recycle stream contains unreacted coal solids.

Fig 3. Process flow diagram of H-Coal process

H-coal process is described in Fig 3 in the form of a flow diagram. The advantages of ebullated-

bed reactor over fixed-bed reactors are that, the reactor contents are well mixed and temperature

can be monitored and controlled in better way in the previous one.

IIT Kharagpur NPTEL Phase – II Web Courses

8|Page

References:

nd

1. Fuels and combustion, S. Sarkar, 2 edition, Orient Longman Ltd., 1990.

2. Direct Coal Liquefaction Overview Presented to NETL, John Winslow and Ed Schmetz,

Leonardo Technologies Inc., US Department of Energy, March, 2000.

3. http://www.thecanadianencyclopedia.com/articles/coal-liquefaction

IIT Kharagpur NPTEL Phase – II Web Courses

You might also like

- MUCLecture 2022 42228583Document2 pagesMUCLecture 2022 42228583Muhammad Ayan Malik100% (1)

- 0.2 HydrocrackingDocument26 pages0.2 HydrocrackingEsteban Lopez Arboleda100% (1)

- Large-Scale Hydrogen ProductionDocument10 pagesLarge-Scale Hydrogen ProductionJulio DutraNo ratings yet

- Advantages of Each Type of Separator PDFDocument17 pagesAdvantages of Each Type of Separator PDFAHMED100% (4)

- YASREF Export Refinery ProjectDocument2 pagesYASREF Export Refinery ProjectSusilo Nur RachmadNo ratings yet

- MelamineDocument18 pagesMelamineSurjendu MaityNo ratings yet

- Module 2 Solid Fossil Fuel (Coal) PDFDocument8 pagesModule 2 Solid Fossil Fuel (Coal) PDFawangNo ratings yet

- Coal LiquificationDocument10 pagesCoal Liquificationfaizfrasat123No ratings yet

- Coal LiquefactionDocument48 pagesCoal LiquefactionMohammed Kabiruddin100% (2)

- Prospect Coal Liquefaction IndonesiaDocument14 pagesProspect Coal Liquefaction IndonesiaawangNo ratings yet

- Assignment 1 CHE685: Fuel and Energy TechnologyDocument11 pagesAssignment 1 CHE685: Fuel and Energy TechnologyDieyla AdillaNo ratings yet

- Coal To Methanol p2Document8 pagesCoal To Methanol p2moeeezNo ratings yet

- ESE-800 Clean Coal Technologies: Part1:Coal To Liquid (CTL)Document52 pagesESE-800 Clean Coal Technologies: Part1:Coal To Liquid (CTL)Hafeez Khan TareenNo ratings yet

- m2l14 PDFDocument7 pagesm2l14 PDFMuhammadIsmailNo ratings yet

- Coal LiquificationDocument28 pagesCoal LiquificationAugust mishraNo ratings yet

- m3l21 PDFDocument7 pagesm3l21 PDFrenger20150303No ratings yet

- Down-Hole Heavy Crude Oil Upgrading by CAPRI Effect of HydrogenDocument10 pagesDown-Hole Heavy Crude Oil Upgrading by CAPRI Effect of HydrogenAli ShahNo ratings yet

- Unit - II Process in Organic Chemical manufacture-II HydrogenationDocument15 pagesUnit - II Process in Organic Chemical manufacture-II HydrogenationMaahir AppNo ratings yet

- CrackingDocument32 pagesCrackingMuhammad HAmAd QureshiNo ratings yet

- Coal-To-Liquid (CTL) Technology: A Sustainable Route Towards Energy Security in IndiaDocument8 pagesCoal-To-Liquid (CTL) Technology: A Sustainable Route Towards Energy Security in Indiapradhith kattaNo ratings yet

- Fluid Catalytic Cracking and HydrocrackingDocument31 pagesFluid Catalytic Cracking and HydrocrackingIntanti Mulana PutriNo ratings yet

- Polk 2004Document49 pagesPolk 2004Ben Duncan Málaga EspichánNo ratings yet

- DCL and CTLDocument23 pagesDCL and CTLKhoirul SaputriNo ratings yet

- Cong Nghe ButamerDocument21 pagesCong Nghe Butamertunganh1110No ratings yet

- Coal Gasification PDFDocument8 pagesCoal Gasification PDFmrizalygani99No ratings yet

- Review of Methane Catalytic Cracking For Hydrogen ProductionDocument32 pagesReview of Methane Catalytic Cracking For Hydrogen ProductionVishal GoswamiNo ratings yet

- Lecture 6Document47 pagesLecture 6Musah HarunaNo ratings yet

- 27 Refined FOR I: 550-800°F Boiling Range, Passing The Mixture With Hydrogen Through A Preheat andDocument9 pages27 Refined FOR I: 550-800°F Boiling Range, Passing The Mixture With Hydrogen Through A Preheat andAnikes ToppoNo ratings yet

- Uop Unicracking Process For Hydrocracking: Donald AckelsonDocument12 pagesUop Unicracking Process For Hydrocracking: Donald AckelsonNguyễn Hoàng Bảo TrânNo ratings yet

- 1 s2.0 S001623612102771X MainDocument14 pages1 s2.0 S001623612102771X MainbrajaNo ratings yet

- Iliuta Et al-2013-AIChE JournalDocument14 pagesIliuta Et al-2013-AIChE JournalJuan Pa GuerreroNo ratings yet

- Abarasi Hart, Gary Leeke, Malcolm Greaves, Joseph Wood: HighlightsDocument10 pagesAbarasi Hart, Gary Leeke, Malcolm Greaves, Joseph Wood: HighlightsRifaldi BanjarnahorNo ratings yet

- Non-Catalytic and Catalytic Fast Pyrolysis of Low Grade Pakistani Coal For High Quality Fuels and ChemicalsDocument3 pagesNon-Catalytic and Catalytic Fast Pyrolysis of Low Grade Pakistani Coal For High Quality Fuels and ChemicalsSalman Raza NaqviNo ratings yet

- Overview of Hydrogen Production Technologies-Ahmed HarhashDocument13 pagesOverview of Hydrogen Production Technologies-Ahmed Harhashegyptian_scientistNo ratings yet

- Engine Technology and DesignDocument7 pagesEngine Technology and DesignRushanyukaNo ratings yet

- Hydrogen Production: P A R T 6Document34 pagesHydrogen Production: P A R T 6Bharavi K SNo ratings yet

- Chemical Technology-Mod5 PDFDocument9 pagesChemical Technology-Mod5 PDFSata AjjamNo ratings yet

- DecarbonisationTechnology PTLDocument6 pagesDecarbonisationTechnology PTLjmod7867No ratings yet

- 19.-Pyrolysis FurnaceDocument5 pages19.-Pyrolysis FurnaceWilfredo PastranaNo ratings yet

- Coal PyrolysisDocument3 pagesCoal PyrolysisSalman Raza NaqviNo ratings yet

- 5A1. Hydrogen Production by Reaction Integrated Novel Gasification Process (Hypr-Ring)Document2 pages5A1. Hydrogen Production by Reaction Integrated Novel Gasification Process (Hypr-Ring)TrifosaAjengRiswantiWulandariNo ratings yet

- 15 - Pub All Process For Coke DelayedDocument24 pages15 - Pub All Process For Coke DelayedaquiestoytambienNo ratings yet

- Coke Steam ReformingDocument13 pagesCoke Steam ReformingmukthiyarsNo ratings yet

- SPE 122028 Potential For Hydrogen Generation During in Situ Combustion of BitumenDocument14 pagesSPE 122028 Potential For Hydrogen Generation During in Situ Combustion of BitumenRoobinRZamirNo ratings yet

- Coal Gasification Using AspenDocument6 pagesCoal Gasification Using AspenTaniadi Suria100% (1)

- Synthetic Fuel Production by Indirect Coal LiquefactionDocument24 pagesSynthetic Fuel Production by Indirect Coal Liquefactionlux0008No ratings yet

- An Overview of Hydrogen Production From Biomass: Meng Ni, Dennis Y.C. Leung, Michael K.H. Leung, K. SumathyDocument12 pagesAn Overview of Hydrogen Production From Biomass: Meng Ni, Dennis Y.C. Leung, Michael K.H. Leung, K. SumathyNancy Eloisa RodriguezNo ratings yet

- Lecture 9Document11 pagesLecture 9KhanBangash11No ratings yet

- 48 - 2 - New York - 10-03 - 0684Document3 pages48 - 2 - New York - 10-03 - 0684phantomboyz_aipNo ratings yet

- Special Focus: Upgrading The Bottom of The BarrelDocument7 pagesSpecial Focus: Upgrading The Bottom of The BarrelОскар ЛинаресNo ratings yet

- HydrocrackingDocument33 pagesHydrocrackingNikita SeleznevNo ratings yet

- Jurnal Migas PresentasiDocument6 pagesJurnal Migas PresentasiYunus MNo ratings yet

- Uop Unicracking Process For Hydrocracking: Donald AckelsonDocument12 pagesUop Unicracking Process For Hydrocracking: Donald AckelsonBharavi K SNo ratings yet

- CTL FUELS Full PaperDocument6 pagesCTL FUELS Full PaperRohit ImandíNo ratings yet

- Experimental Study of The OxidativeDocument13 pagesExperimental Study of The OxidativeRafael RíosNo ratings yet

- Cost-Effective Methods For Hydrogen Production: (Received For Publication 5 October 1982)Document6 pagesCost-Effective Methods For Hydrogen Production: (Received For Publication 5 October 1982)ElshadNo ratings yet

- Module 3: Liquid Fossil Fuel (Petroleum) Lecture 20: Secondary ProcessingDocument8 pagesModule 3: Liquid Fossil Fuel (Petroleum) Lecture 20: Secondary Processingapi-256504985No ratings yet

- Topsoe Large Scale Hydrogen ProducDocument20 pagesTopsoe Large Scale Hydrogen ProducAnonymous j9s0eQ0uNo ratings yet

- CrackingDocument28 pagesCrackingzaraNo ratings yet

- 12 PDH - Process Vora UOP PDFDocument12 pages12 PDH - Process Vora UOP PDFstxordNo ratings yet

- Nanoporous Catalysts for Biomass ConversionFrom EverandNanoporous Catalysts for Biomass ConversionFeng-Shou XiaoNo ratings yet

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- Hydrogen Production TechnologiesFrom EverandHydrogen Production TechnologiesMehmet SankirNo ratings yet

- Green Carbon Dioxide: Advances in CO2 UtilizationFrom EverandGreen Carbon Dioxide: Advances in CO2 UtilizationGabriele CentiNo ratings yet

- Unveiling Your Ideal Student Haven in Europe A Guide For International Students ?? - PresentationDocument15 pagesUnveiling Your Ideal Student Haven in Europe A Guide For International Students ?? - PresentationMuhammad Ayan MalikNo ratings yet

- Wood Therapy Massage ToolDocument14 pagesWood Therapy Massage ToolMuhammad Ayan MalikNo ratings yet

- Sending Docs To Uni AssistDocument2 pagesSending Docs To Uni AssistMuhammad Ayan MalikNo ratings yet

- RN1 QMFa 1 AXJb YDbb T8 E1 HKWQDocument2 pagesRN1 QMFa 1 AXJb YDbb T8 E1 HKWQMuhammad Ayan MalikNo ratings yet

- Entrepreneur ProfileDocument8 pagesEntrepreneur ProfileMuhammad Ayan MalikNo ratings yet

- Resume BookletDocument70 pagesResume BookletMuhammad Ayan MalikNo ratings yet

- Tax Collector Correspondence3630268163398Document1 pageTax Collector Correspondence3630268163398Muhammad Ayan MalikNo ratings yet

- GridDocument2 pagesGridMuhammad Ayan MalikNo ratings yet

- Tax Collector Correspondence3630268163398Document1 pageTax Collector Correspondence3630268163398Muhammad Ayan MalikNo ratings yet

- GridDocument2 pagesGridMuhammad Ayan MalikNo ratings yet

- Consignee Copy: MultanDocument1 pageConsignee Copy: MultanMuhammad Ayan MalikNo ratings yet

- Viscardietal.-2020 IJRESDocument6 pagesViscardietal.-2020 IJRESMuhammad Ayan MalikNo ratings yet

- Consignee Copy: MultanDocument1 pageConsignee Copy: MultanMuhammad Ayan MalikNo ratings yet

- Wikisheet Reactive Distillation - RVODocument10 pagesWikisheet Reactive Distillation - RVOMuhammad Ayan MalikNo ratings yet

- GridDocument3 pagesGridMuhammad Ayan MalikNo ratings yet

- Consignee Copy: MultanDocument1 pageConsignee Copy: MultanMuhammad Ayan MalikNo ratings yet

- GridDocument2 pagesGridMuhammad Ayan MalikNo ratings yet

- Multan Bus Stand - 0Document1 pageMultan Bus Stand - 0Muhammad Ayan MalikNo ratings yet

- GridDocument2 pagesGridMuhammad Ayan MalikNo ratings yet

- GridDocument2 pagesGridMuhammad Ayan MalikNo ratings yet

- Choice of Plates or PackingDocument22 pagesChoice of Plates or PackingMuhammad Ayan MalikNo ratings yet

- Darz 1Document1 pageDarz 1Muhammad Ayan MalikNo ratings yet

- TR SummerDocument1 pageTR SummerMuhammad Ayan MalikNo ratings yet

- Lab VivaDocument3 pagesLab VivaMuhammad Ayan MalikNo ratings yet

- PA&O Term ReportDocument1 pagePA&O Term ReportMuhammad Ayan MalikNo ratings yet

- Signal Flow GraphsDocument13 pagesSignal Flow GraphsMuhammad Ayan MalikNo ratings yet

- Assignment SummerDocument1 pageAssignment SummerMuhammad Ayan MalikNo ratings yet

- Optimization 240122 191010Document18 pagesOptimization 240122 191010Muhammad Ayan MalikNo ratings yet

- DC DesignDocument12 pagesDC DesignMuhammad Ayan MalikNo ratings yet

- Bitumen & Asphalt: - Nilanjan MitraDocument15 pagesBitumen & Asphalt: - Nilanjan MitrassriramiitNo ratings yet

- Oxygene ConcentratorDocument17 pagesOxygene ConcentratoradeNo ratings yet

- Air ProductsDocument33 pagesAir Products22hubNo ratings yet

- Esab /oxweld Esab /oxweld: Style Replacement Tips Style Replacement TipsDocument1 pageEsab /oxweld Esab /oxweld: Style Replacement Tips Style Replacement TipsJhon Jairo Arango MarquezNo ratings yet

- 10 Worked ExamplesDocument24 pages10 Worked ExamplesTú NguyễnNo ratings yet

- Module3 Biomass Lecture Notes 2nd Sem. 16859692298740Document12 pagesModule3 Biomass Lecture Notes 2nd Sem. 16859692298740pavanbg78994No ratings yet

- Distillation-Assignemnt 2Document14 pagesDistillation-Assignemnt 2Sohail ZafarNo ratings yet

- Paper 2250Document1 pagePaper 2250BrianNo ratings yet

- Natural Gas Engineering: Prof - Pankaj TiwariDocument480 pagesNatural Gas Engineering: Prof - Pankaj Tiwaricamilion1No ratings yet

- Petroleum Refining Fourth Year DR - Aysar T. JarullahDocument5 pagesPetroleum Refining Fourth Year DR - Aysar T. JarullahSaad NadeemNo ratings yet

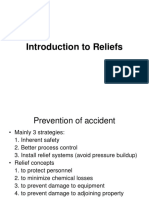

- Introduction To ReliefsDocument50 pagesIntroduction To Reliefsthiviya100% (1)

- Eng Chem Lecture NotesDocument2 pagesEng Chem Lecture NotesJunell TadinaNo ratings yet

- Seamanship 4Document2 pagesSeamanship 4Cham RosarioNo ratings yet

- Science: Pure Substances Vs MixturesDocument17 pagesScience: Pure Substances Vs MixturesDionne Sebastian DoromalNo ratings yet

- Performance Investigation of Magnesiumechloride Hybrid Thermochemical Cycle For Hydrogen ProductionDocument10 pagesPerformance Investigation of Magnesiumechloride Hybrid Thermochemical Cycle For Hydrogen ProductionAdrián Lume HuayllaniNo ratings yet

- Chapter 2 Is Matter Around Us Pure NotesDocument16 pagesChapter 2 Is Matter Around Us Pure NotesManjusha MathewNo ratings yet

- 01 Process ReactionDocument10 pages01 Process ReactionJacky WongNo ratings yet

- Alkyl HalideDocument28 pagesAlkyl HalideManish RoyNo ratings yet

- Heavy Oil UpgradingDocument6 pagesHeavy Oil UpgradingpiovioNo ratings yet

- The Cracking and Reforming of Crude Oil Fractions PresentationDocument23 pagesThe Cracking and Reforming of Crude Oil Fractions PresentationBrandeice BarrettNo ratings yet

- Rates of RXN Mark SchemeDocument34 pagesRates of RXN Mark Schemepaulcampbell37No ratings yet

- SCBA Wiki PDFDocument6 pagesSCBA Wiki PDFomar benounaNo ratings yet

- Fire InvestigationDocument126 pagesFire InvestigationAbcede IloiloNo ratings yet

- Oxy Acetylene WeldingDocument3 pagesOxy Acetylene WeldingMonika100% (1)

- Azeotropic DestillationDocument12 pagesAzeotropic DestillationBeca StarkNo ratings yet

- RP15C-toc 173390110917062932Document13 pagesRP15C-toc 173390110917062932manav mistryNo ratings yet

- Scrubber K-415 OverviewDocument8 pagesScrubber K-415 OverviewLuis ToponNo ratings yet