Professional Documents

Culture Documents

Technical Spec - 33kV SWGR - EDF Final

Technical Spec - 33kV SWGR - EDF Final

Uploaded by

Arun dasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Spec - 33kV SWGR - EDF Final

Technical Spec - 33kV SWGR - EDF Final

Uploaded by

Arun dasCopyright:

Available Formats

Schedule of Requirements

400kV Circuit Breaker

DOCUMENT REFERENCE: 70114669-WSP-SP-EP-002

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

Document Control

SIGN OFF

Name (Role) Signature Date

DOCUMENT CONTROL

Document Number DMS document refer added here

Schedule of Requirements for Circuit Breaker for Solar Farms, Wind Farms, and Battery Energy

Document Title

Storage Systems

Rev. Date Description Prepared Checked Approved

[dd mmm

yyyy]

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 2 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

1 INTENT OF SPECIFICATION................................................................................................................

2 SCOPE OF WORK...............................................................................................................................

2.1 Scope of Supply.....................................................................................................................4

3 GENERAL REQUIREMENTS................................................................................................................

3.1 Codes and Standards.............................................................................................................4

3.2 Environmental Service Conditions.........................................................................................6

3.3 Design Life.............................................................................................................................6

3.4 Electrical System Data...........................................................................................................6

3.5 Schedule of Requirements.....................................................................................................8

4 NOTES.............................................................................................................................................

5 TECHNICAL COMPLIANCE...............................................................................................................

6 TESTING..........................................................................................................................................

7 QUANTITY.......................................................................................................................................

8 DOCUMENTATION..........................................................................................................................

9 SCHEDULE OF RECOMMENDED SPARES.........................................................................................

10 LIST OF SUPPLIERS..........................................................................................................................

11 APPENDIX B - DRAWING.................................................................................................................

12 SCHEDULE A....................................................................................................................................

13 SCHEDULE B....................................................................................................................................

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 3 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

1 INTENT OF SPECIFICATION

This specification is intended to cover the design, manufacture, assembly, testing at manufacturer's works, supply

& delivery, properly packed for transport to site of 400 KV CIRCUIT BREAKERS, complete with all materials and

accessories for efficient and trouble-free operation in a manner acceptable to Owner.

In the event of any discrepancy with listed documents, the stipulation of this specification shall govern.

The specification shall be read and construed in conjunction with other sections of bidding document.

2 SCOPE OF WORK

2.1 Scope of Supply

Type, rating, connections, etc. of the equipment shall be as detailed in the drawings and annexures. The

equipment shall be furnished in strict compliance with the same.

2.1.1 Each circuit breaker shall be furnished complete with:

a) Fittings and accessories.

b) Auxiliary equipment.

c) First filling of SF6 gas plus 20% spare.

2.1.2 Spares

2.1.3 All relevant drawings, data and instruction manuals.

3 GENERAL REQUIREMENTS

3.1 Codes and Standards

Equipment is to be NG type registered in line with the requirements of:

NG Specifications / Title Date / Issue

Policies

TS 1 Ratings & Requirements for Plant Issue 7

TS 2.01 Substations Issue 5 and

Addendum

TS 2.02 Switchgear Issue 5

TS 3.02.01 Circuit - Breakers Issue 5

(All associated standards within these documents are to be taken into consideration)

Standards

BS 381C Specification for Colours for Identification, Coding and Special Purposes

ENA TS 41-37 Switchgear for use on 66kV to 132kV distribution systems*

IEC 62271-100 High-voltage switchgear and Control gear - Part 100: Alternating current

circuit-breakers

IEC 62271-1 High-voltage Switchgear and Control gear: Part 1: Common Specification

IEC 62271-110 High voltage Switchgear and Control gear : Part 110 – inductive load

switching

IEC 60507 Artificial Pollution Tests On High-Voltage Ceramic and Glass Insulators To

Be Used On A.C. Systems.

IEC 60815-1 Selection And Dimensioning Of High-Voltage Insulators Intended For Use

In Polluted Conditions - Part 1: Definitions, Information and General

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 4 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

Principles

IEC 60815-2 Selection And Dimensioning Of High-Voltage Insulators Intended For Use

In Polluted Conditions - Part 2: Ceramic and Glass Insulators For A.C.

Systems

IEC 60815-3 Selection And Dimensioning Of High-Voltage Insulators Intended For Use

In Polluted Conditions - Part 3: Polymer Insulators For A.C. Systems

IEC 61936-1 Power Installation Exceeding 1kV a.c. Part 1: Common Rules

IEC 62271-302 High-Voltage Switchgear And Control gear - Part 302: Alternating Current

Circuit-Breakers With Intentionally Non-Simultaneous Pole Operation

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 5 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

3.2 Environmental Service Conditions

3.2.1 Common Data

1. Minimum Ambient Temperature °C -25

2. Maximum Ambient Temperature – at any time °C 40

3. Maximum Ambient Temperature – monthly average of the hottest month °C 30

4. Maximum Ambient Temperature – yearly average °C 20

5. Relative Humidity % ≤95

6. Altitude m ≤1000

7. Wind speed m/s 34

8. Ice coating / radial thickness mm 10

9. Ice density kg/m3 912

10. Site pollution severity class as IEC 60815 d

11. Location Outdoor

3.3 Design Life

The Circuit Breakers shall be designed for a minimum in service design life of 25 years.

3.4 Electrical System Data

3.4.1 Common System Data

1. Number of Phases - 3

2. System Frequency – nominal Hz 50

3. System Frequency – max. continuous Hz 51.0

4. System Frequency – min. continuous Hz 49.0

5. System Frequency – max. temporary frequency (15 mins.) Hz 51.5 – 52.0

6. System Frequency – max. temporary frequency (90 mins.) Hz 51.0 – 51.5

7. System Frequency – min. temporary frequency (20 sec.) Hz 47.0 - 47.5

8. System Frequency – min. temporary frequency (90 mins.) Hz 47.5 - 49.0

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 6 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

3.4.2 System Data

1. Nominal System Voltage kV 400

2. Maximum Continuous System Voltage kV 420

3. Minimum Continuous System Voltage kV 360

4. Neutral Earthing - Multiple

Direct

5. Short Circuit Capacity – current kA 63

6. Short Circuit Capacity – duration s 1

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 7 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

3.5 Schedule of Requirements

1. Type (AIS Indoor or Outdoor) AIS Outdoor

2. Number of Poles Three

3. Type of Operating Mechanism Spring (Single Pole

Operation)

4. Rated Voltage 420 kV

5. Rated Insulation Level

-Lightning Impulse Withstand (Phase/ Earth & Phase/Phase) 1425 kV Peak

-Lightning Impulse Withstand (Across Open Switching Device) 1425(+240) kV Peak

-Switching Impulse Withstand (Phase/ Earth) 1050 kV Peak

-Switching Impulse Withstand (Phase/Phase) 1575 kV Peak

-Switching Impulse Withstand (Across Open Switching Device) 900 (+345) kV Peak

-Power Frequency Withstand Voltage (Phase/ Earth & 520 kV

Phase/Phase)

-Power Frequency Withstand Voltage (Across Open Switching 610 kV

Device)

6. Rated Current 4000 A

7. Rated Short Circuit Breaking Current at Time constant 45ms 63 kA

8. Rated Peak withstand current (#) 170 kA Peak

9. Project specific Short Circuit Breaking Current and System Time

63kA /….ms

constant (If different from item 7)

10. Duration of Short Circuit 1s

11. First pole to clear factor (1/1.3/1.5) 1.3

12. Operating Sequence O-0.3s-CO-3min-CO

13. Suitable for three phase/single phase auto reclose Three Phase

14. Insulator type Porcelain/Brown

15. Insulator profile type ALS as per IEC 60815

16. Unified Specific Creepage Distance(USCD) In Accordance with IEC60815

43.3mm/kV

(43.3mm/kV for class D or 53.7mm/kV for class E pollution

See Note 4 (7)

environment)

17. Terminal Plate Fixing Details 2 Rows (50mm ctrs) of

4xØ14mm holes

(50mm ctrs)

18. Terminal Load, Static/Dynamic 2.5/5 KN

19. Mechanical Endurance Class (M1/M2) M2

20. Terminal Plate Orientation Vertical (upwards)

21. Closing Coils Nominal Voltage (+25/-30%) 110V DC

22. Tripping Coils Nominal Voltage (+25/-30%) 110V DC

23. Motor Voltage (+15%/-15%) 400V, 3ph/AC

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 8 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

24. Heater/Socket Voltage (110V AC or 240V AC) 110VAC

25. Closing Coils Connection Parallel

26. Number of Closing Coils 3

27. Tripping Coils Connection Parallel

28. Number of Coils, Tripping System 1 3

29. Number of Coils, Tripping System 2 3

30. Trip Circuit Supervision Resistor Yes, as per IEC

31. Number of Auxiliary contacts 12NO+12NC

32. Motor Protection Require (Pad lockable type) Yes

33. Heater Protection Yes

34. Lighting Protection Yes

35. Socket Outlet, (with 30mA RCD protection) Yes

230V AC

36. Isolation White Links in Closing and Tripping Circuits required Yes

37. Wiring Type LSZH

38. Terminals Type According to ENA- TS

39. Density Switch Two Stages

40. Pressure Gauge dial marking mPA / bar

41. Operational Counter Non-resettable

42. SF6 Filling Point Yes

43. Breaker Status Indication Symbol ‘I’ / ’O’

44. Local Control Cabinet enclosure rating IP55

45. Local Control Cabinet colour (shall be project specific) See Note 4 (4)

46. Steel Support Structure Required

47. “Local/Remote” Selector Switch (Lockable) required Yes

48. “Open/Neutral/Close” Control Switch (Spring return to Neutral)

Yes

required

49. Key Solenoid Lock Required No

50. Harting plug to be fitted by factory on Both cable ends / or One end

Both Ends

only

51. Phase spacing minimum (shall be project specific) 5m

52. Cable Length- Local Control Cabinet to Pole A Mech. Box See Figure 1

53. Cable Length-Local Control Cabinet to Pole B Mech. Box See Figure 1

54. Cable Length- Local Control Cabinet to Pole C Mech. Box See Figure 1

55. Gland Plate undrilled Yes

56. Circuit Breaker Type/FAT Testing As per Employer

Requirement / Section

Error: Reference

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 9 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

4 NOTES

1. All the design & installation works shall comply with UK safety & CDM regulations

2. Cable to suit arrangement as shown on Figure 1

3. Supplier to advise alternative cost effective solution which is technically suitable.

4. The corrosive environment of the equipment shall be classified as: ISO 12944, outdoor

C3-High Durability.

5. 1. Steel items shall be hot-dip galvanised to a zinc coverage of not less than 100 µm

whenever applicable, or stainless steel AISI 316.

2. Paint systems shall be BS EN ISO 12944-5: High durability class.

The finish shall be suitable for the lifetime of the installation with more than 15 years to

first major maintenance.

Paint systems surface colour: RAL 7032

6. All document/drawing numbers and tags will be supplied at later stage. Supplier shall

incorporate the same in the drawings/documents/equipments.

7. Correction factor for Insulator diameter Kad [Formerly Kd]

Da <300 mm: Ceramic, Glass and Polymer Insulator: Kad = 1

Da ≥ 300 mm: Ceramic and Glass Insulator: Kad = 0.0005 Da + 0.85

For Polymer Insulators: From Figure below.

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 10 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

5 TECHNICAL COMPLIANCE

The attached appendix ‘A’ technical compliance check sheet is to be provided as part of the clarified

quotation.

Appendix ‘A’ Technical compliance

Fully complying with this Technical specification requirements

Yes No

Fully complying with relevant NG specifications mentioned in section 3 above

Yes No

Documents including revisions are as listed in Clause 5 and 6:

Yes No

Equipment type registered:

Yes (____________) No

If ‘No’ please provide the details below in brief:

Table for Deviations.

Clause Equipment Deviation

6 TESTING

Supplier to comply Clause no 3 TEST REQUIREMENTS of NGTS TS 3.02.01, Issue 5

7 QUANTITY

Please refer to BOQ in ITT

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 11 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

8 DOCUMENTATION

All documentation to be issued through the agreed management system. Supplier shall be trained as

required.

Equipment identification as per agreed numbering system

Standard document / drawing templates with the numbering as per agreed system.

Below list shows the minimum requirements.

8.1.1 Tender Stage

1. List of deviations / clarifications

2. Main Technical Data Sheet

3. Preliminary General Arrangement drawing

4. 3D model in Autodesk Revit (.rvt) or Autocad Inventor (.iam) or step (.stp/step) format. (Only

outer peripheral geometry required; generally less than 10MB.)

8.1.2 Contract Stage

1 Contract Drawing List

2 Main Technical Data Sheet

3 Confirmed General Arrangement drawing

4 3D model in Autodesk Revit (.rvt) or Autocad Inventor (.iam) or step (.stp/step) format. (Only

outer peripheral geometry required; generally less than 10MB.)

5 Support structure input drawing

6 Detailed General arrangement drawing for Operating boxes & Control Cubicle

7 Schematics drawings

8 Inspection & Test Plan (ITP)

9 Quality Plan

10 Project Plan

11 Type and routine test reports

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 12 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

9 SCHEDULE OF RECOMMENDED SPARES

Sl. No. Description Quantity

1 Circuit Breaker 3

2 Fixed contacts 3

3 Moving contacts 3

4 Closing coil 6

5 Tripping coil 6

6 Spring Charging Motor 3

7 Auxiliary switch 2 Sets

8 Gas density monitor 2

9 SF6 Gas pressure switch 1

10 Contacts for circuit 1

11 MCB/MCCB for DC Circuit 1

12 MCB/MCCB for AC circuit 1

13 Spare fuses for each type & Rating 6 Sets

14 Auxiliary Relay 1Set

15 Complete set of Gaskets 2 Sets

16 Set of Seals 2 Sets

10 LIST OF SUPPLIERS

Sl. No. Description

1 Hitachi

2 Siemens

3 GE

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 13 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

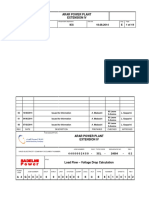

11 APPENDIX B - DRAWING

Figure 1

MK

LA LB LC

CU

CABLE TRENCH

LA – Operating Mechanism Compartment Pole LA

LB – Operating Mechanism Compartment Pole LB

LC – Operating Mechanism Compartment Pole LC

CU – Control Unit

MK – Bay Marshalling Kiosk

Cable (Armoured) Length

LA – CU = 12.5m

LB – CU = 2m

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 14 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

12 SCHEDULE A

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 15 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

SCHEDULE A1 FOR RATINGS DATA

A1.1 MANUFACTURER -

Circuit Breaker Designation (GIS or OT self-blast puffer

A1.2 -

etc)

A1.3 Circuit Breaker Type Reference: -

Year production

(month/year)

commenced

Year production ceased

(NGC use only)

A1.4 CIRCUIT BREAKER RATING

Rated Voltage kV

Rated Normal Current A

Rated short circuit current kA.rms

Rated short circuit making current kA.pk

Rated short circuit peak break current kA.pk

First-Pole-to-Clear Factor kpp

RRRV on 100% duty kV/μS /

D.C Component at contact separation (following 10ms

%

relay time and open time as A3 Cl 3.9)

X/R Test Ratio

Capacitive Current Switching Ability - Bank A

Voltage Factor for OHL Capacitive Current Duty p.u.

Non mandatory Shunt Reactor Switching Ability A

Non mandatory Series Reactor Switching Ability kA

RRRV on Series Reactor Duty - 3 phase kV/μS /

Out of Phase Switching Ability kA

RRRV Out of Phase Duty kV/μS /

Dielectric Withstand: -

(i) Lightning Impulse (1/50) kVp

(ii) Switching Impulse (250/2500) kVp

(iii) Power Frequency (wet and dry) kVrms

Mechanical Endurance Class

Bending Moment at base of support porcelian kN-m

A1.5 DRAWINGS -

3-phase arrangement drawing No -

Single-phase arrangement drawing No -

Control schematic drawing No -

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 16 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

SCHEDULE A2 FOR RATINGS DATA

A2 GENERAL TECHNICAL DETAILS

Interrupting Medium (e.g. SF6, Vacuum)

Insulating Medium if different to Interrupting Medium (e.g. SF6,

CO2)

A2.1 Number of Main Breaks/Phase -

A2.2 Shunt Capacitance/Break -

A2.3 Manufacturer and Type Reference of Capacitors -

A2.4 Number and Type of Fixed Contacts - Main -

Arcing -

A2.5 Number and Type of Moving Contacts - Main -

Arcing -

A2.6 Maximum Main Circuit Resistance μΩ

A2.7 Weight of Interrupter Module/Head kg

A2.8 Mass of Interrupter Unit kg

A2.9 Mass of Interrupter Porcelain kg

A2.1

Manufacturer of Interrupter Porcelain -

0

A2.1

Mass of Support Porcelain kg

1

A2.1

Manufacturer of Support Porcelain -

2

A2.1

Mass of Bushings (Open Terminal Dead Tank) kg

3

A2.1

Mass of Barrier (Metal Enclosed GIS) kg

4

A2.1

Mass of Circuit-breaker base/bases (per phase) kg

5

A2.1

Mass of Local Control Cubicle kg

6

A2.1

Mass of Single Phase Complete kg

7

A2.1

Mass of Complete Circuit-breaker without gas and oil kg

8

A2.1

Mass of Complete Circuit-breaker with gas and oil kg

9

A2.2

Type of Operating Mechanism, opening / closing - /

0

A2.2

Manufacturer and Type reference of Operating Mechanism -

1

A2.2

Mechanism Travel mm

2

A2.2

Operating Coils - Close

3

(i) Number and Type -

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 17 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

A2 GENERAL TECHNICAL DETAILS

(ii) Type Reference -

(iii) Power Consumption Rating W

A2.2

Power to Close (100% V and pressure/drive) W

4

(i) Rated Voltage to be 110 V d.c. V

(ii) Rated Pressure (if applicable) Barg

A2.2

Coil Current Characteristics when at Minimum Voltage A

5

A2.2

Operating Coils - Open

6

(i) Number and Type -

(ii) Type Reference -

(iii) Power Consumption Rating W

A2.2

Power to Open (100% V and pressure/drive) W

7

(i) Rated Voltage to be 110 V d.c. V

(ii) Rated Pressure (if applicable) Barg

A2.2

Coil Current Characteristics when at Minimum Voltage A

8

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 18 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

SCHEDULE A3 FOR INTERRUPTER TECHNICAL DATA

A3.1 Main Interrupter Travel mm

A3.2 Close Time (initiation to contact touch at rated pressure and rated voltage of ms

110 V d.c. as detailed in NGTS 2.2

A3.3 Maximum Spread Between interrupters on One Phase on Closing ms

A3.4 Maximum Spread Between Phases on Closing ms

A3.5 Close Speed at Contact Touch m/s

A3.6 Variation in Close Time with Control Voltage (at rated pressure) ms

A3.7 Variation in Close Time with Pressure (at rated control voltage) ms

A3.8 Variation in Close Time with Temperature (at rated pressure and voltage) 0 to -

25oC

0 to

20oC

20 to

40oC

A3.9 Opening time (initiation to contact part at rated pressure and rated voltage of ms

110 V d.c. as detailed in NGTS 2.2

A3.10 Maximum Spread Between Interrupters on One Phase on Opening ms

A3.11 Maximum Spread Between Phases on Opening ms

A3.12 Open Speed at Contact Part m/s

A3.13 Variation in Open Time with Control Voltage (at rated pressure) ms

A3.14 Variation in Open Time with Pressure (at rated control voltage) ms

A3.15 Variation in Open Time with Temperature (at rated pressure and voltage) 0 to -

25oC

0 to

20oC

20 to

40oC

A3.16 Live Time on Make-Break Duty (minimum) ms

A3.17 Maximum Arc Duration:

- Three Phase Symmetrical ms

- Single Phase Symmetrical ms

- SLF (L90) as Single Phase ms

A3.18 Maximum time to arc extinction (Break time) ms

Minimum time to arc extinction (Min Break time) ms

A3.19 Maximum time between close coil intiation & main contact making ms

Minimum time between close coil intiation & main contact making ms

A3.20 Auto Reclose Dead time s

A3.21 Noise Level at 25 metres (NGTS 3.2.1) dB

(Lin)

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 19 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

SCHEDULE A4 FOR SF6 Gas

A4.1 Design Pressure of Gas System Barg

A4.2 Operating Pressure of Relief Device (Size/Type) Barg

A4.3 Normal Pressure at 20degC Barg

A4.4 Close Lockout and Alarm pressure Barg

A4.5 Open (Trip) Lockout Pressure Barg

A4.6 Minimum Close Pressure when Isolated from the System Barg

A4.7 Minimum Open Pressure when Isolated from the System Barg

A4.8 Quantity of Gas - Mass (Class D Insulation) kg

Quantity of Gas - Mass (Class E Insulation)

Gas Volume - Referred to Normal Pressure as A4 4.3 (Class D

A4.9 ltrs

Insulation)

Gas Volume - Referred to Normal Pressure as A4 4.4 (Class E

ltrs

Insulation)

A4.10 Method of Monitoring Pressure and Temperature Compensation -

A4.11 Maximum Permissible Moisture Content in service - Dew Point o

C

- mg/kg mg/kg

A4.12 Maximum Permissible Acidity Level in service (HF) -

ltrs/s or

A4.13 Maximum Permissible Leak Rate (<1% per annum)

%

A4.14 Mass of Alumina/Molecular Sieve and Type Reference kg

A4.15 SF6 Pipework

- material -

- outside diameter mm

A4.16 Type and manufacturer of pipe couplings -

A4.17 Gas filling point coupling thread details -

A4.18 Gas filling point coupling: - manufacturer and type reference -

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 20 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

SCHEDULE A5 FOR AIR SYSTEM (IF APPLICABLE)

A5.1 Mechanisim Type Reference -

Bar

A5.2 Rated Pressure at 20 degC

g

A5.3 Local Air Reciever Volume m3

Bar

A5.4 Minimum Close Pressure

g

Bar

A5.5 Minimum Open Pressure

g

Bar

A5.6 Close Lockout Pressure

g

Bar

A5.7 Open (Trip) Lockout Pressure

g

Bar

A5.8 Forced Open (Trip) Setting

g

Bar

A5.9 Detent Alarm/Operate Setting (if applicable)

g

Bar

A5.10 Detent Reset Setting

g

Bar

A5.11 Pressure Drop on Open

g

Bar

A5.12 Air Consumption on Open

g

Bar

A5.13 Pressure Drop on Close

g

A5.14 Air Consumption on Close m3

A5.15 Method of Monitoring Pressure and Temperature Compensation -

A5.16 Maximum Permissible Dew Point Temperature o

C

A5.17 Air Pipework

OD mm

Material -

A5.18 Type and Manufacturer of Pipe Couplings -

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 21 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

SCHEDULE A6 FOR HYDRAULIC SYSTEM

A6.1 Mechanism: - Manufacturer and Type Reference -

A6.2 Pump Type: - Manufacturer and Type Reference -

A6.3 Rated Pressure at 20oC Barg

A6.4 Pump Cut In/Out Pressures Barg

A6.5 Close Lockout Pressure Barg

A6.6 Open (Trip) Lockout Pressure Barg

A6.7 Forced Open (Trip) Setting Barg

A6.8 Minimum Pressure for Close Barg

A6.9 Minimum Pressure for Open (Trip) Barg

A6.10 Relief Valve Operate/Reset Pressures Barg

A6.11 High Oil Pressure Alarm Setting Barg

A6.12 Pressure Drop on Close Barg

A6.13 Oil Consumption on Close ltrs

A6.14 Pressure Drop on Open Barg

A6.15 Oil Consumption on Open ltrs

A6.16 Detent Alarm Operate/Setting (if applicable) Barg

A6.17 Detent Reset Setting Barg

A6.18 Volume of Oil ltrs

A6.19 Recommended Oil Type -

Barg/

A6.20 Maximum Oil Pressure Leak Rate

m

Barg/

A6.21 Pumping Rate

m

A6.22 Time to Restore Normal Pressure after COCO Duty s

A6.23 Oil Pipework

OD mm

Material -

A6.24 Type and Manufacturer of Pipe Couplings -

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 22 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

SCHEDULE A7 FOR NITROGEN SYSTEM (IF APPLICABLE)

A7.1 Mechanism Type Reference -

A7.2 Volume of Nitrogen m3

Bar

A7.3 Precharge Pressure at 20oC

g

Bar

A7.4 Close Lockout Pressure (if applicable)

g

Bar

A7.5 Open (Trip) Lockout Pressure (if applicable)

g

A7.6 Method of Monitoring Pressure and Temperature Compensation -

A7.7 Nitrogen Pipework:

OD mm

Material -

A7.8 Manufacturer of Pipe Couplings -

A7.9 Type reference of pipe coupling -

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 23 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

SCHEDULE A8 FOR SPRING SYSTEM (IF APPLICABLE)

A8.1 Mechanism Type Reference -

A8.2 Method of Spring Charging -

A8.3 Charging Time: CO Sequence s

Charging Time: COCO Sequence s

A8.4 Starting Current for Charging Motor and Voltage (where applicable) A-V

A8.5 Method of Monitoring Charging System -

A8.6 Method of Damping Mechanism -

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 24 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

13 SCHEDULE B

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 25 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

SCHEDULE OF TYPE TESTS (CIRCUIT BREAKERS)

Product Description

Product Type

Test Duty or Test Document Test Object (offered Remarks Compliance (yes, no, n/a)

Requirement Reference or equivalent)

Item Procedure Witness

(1) (2) (3)

10% terminal fault

30% terminal fault

60% terminal fault

100% symmetrical

terminal fault

100% asymmetrical

terminal fault

90% short line fault

75% short line fault

peak making ability

out of phase

switching

short time current

withstand

peak current

withstand

capacitive line

switching

capacitive bank

switching

shunt reactor

switching (IEC 62271-

110)

series reactor

switching

continuous current

temperature rise

lightning impulse

switching impulse

power frequency

withstand

RIV

mechanical

endurance

High and Low

Temperature tests

Verification of IP

coding

Tightness test

EMC tests

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 26 OF 27

Schedule of Requirements – Circuit Breaker for Wind Farms,

Solar Farms, and Battery Energy Storage Systems

EDF RENEWABLES - BMS DOCUMENT REF : XXXXXXXX VERSION: 1.0

Test Duty or Test Document Test Object (offered Remarks Compliance (yes, no, n/a)

Requirement Reference or equivalent)

Item Procedure Witness

(1) (2) (3)

Test to prove the

operation under

severe ice conditions

Static terminal load

test

impulse noise level

grading capacitor test

data

insulator shed

shape/pollution

performance

operating manual(s)

routine test

specification

commissioning

schedule

outline drawings

(1) - Supplier to confirm item tested is identical to the item offered. Differences should be identified in the non-

conformance schedule

(2) - Suppler to confirm item has been tested in full compliance with the reference test specification. Differences

should be identified in the non-conformance schedule

(3) - Supplier to confirm tests have been independently witnessed

SoR Template Reference: ER-ENG-TEM-0043v1.0 Information Security Classification: C0 - Public PAGE 27 OF 27

You might also like

- Ukbp TP109Document51 pagesUkbp TP109Arun das100% (1)

- 32TMSS02R2Document62 pages32TMSS02R2Amjith MeerasNo ratings yet

- 16-SAMSS-502 - LV SwitchgearsDocument24 pages16-SAMSS-502 - LV SwitchgearsHatemS.MashaGbehNo ratings yet

- Electrical Wiring Diagram Home Lift 6600Document21 pagesElectrical Wiring Diagram Home Lift 6600MACRO TECH LLCNo ratings yet

- 16 Samss 504Document45 pages16 Samss 504AKGH2024No ratings yet

- Technical Submittal - 3 WAY & 4 WAY - RMUDocument149 pagesTechnical Submittal - 3 WAY & 4 WAY - RMUفارس معتوقNo ratings yet

- 14-SAMSS-534 Oh TransformerDocument8 pages14-SAMSS-534 Oh TransformerHatemS.MashaGbehNo ratings yet

- Technical Spec 400kV Current Transformer - EDF-08.01.2024Document17 pagesTechnical Spec 400kV Current Transformer - EDF-08.01.2024Arun dasNo ratings yet

- Technical Spec 400kV Capacitive Current Transformer - EDF-29.12.2023Document22 pagesTechnical Spec 400kV Capacitive Current Transformer - EDF-29.12.2023Arun dasNo ratings yet

- S Met CTVT - 00Document10 pagesS Met CTVT - 00HARINo ratings yet

- S Met CT - 00Document8 pagesS Met CT - 00HARINo ratings yet

- Technical Spec 400kV Disconnectors - EDF-10.01.2024Document30 pagesTechnical Spec 400kV Disconnectors - EDF-10.01.2024Arun dasNo ratings yet

- Technical Spec 400kV Surge Arresters - EDF-09.01.2024Document31 pagesTechnical Spec 400kV Surge Arresters - EDF-09.01.2024Arun dasNo ratings yet

- Specification For MV Switchboards / Motor Control CentresDocument33 pagesSpecification For MV Switchboards / Motor Control CentresDanish MohammedNo ratings yet

- Bd-Spc-Gen-El-1001 General Electrical Specification Rev0Document19 pagesBd-Spc-Gen-El-1001 General Electrical Specification Rev0benn savyasachiNo ratings yet

- 400kV CB - MSETCLDocument33 pages400kV CB - MSETCLVenkatNo ratings yet

- 16 Samss 507Document28 pages16 Samss 507HatemS.MashaGbehNo ratings yet

- 16 Samss 512Document40 pages16 Samss 512HatemS.MashaGbehNo ratings yet

- E17-S02 (IEC) Rev 2 Dec 2014 LV SwitchracksDocument10 pagesE17-S02 (IEC) Rev 2 Dec 2014 LV SwitchracksFerenc KovácsNo ratings yet

- 16 Samss 503Document42 pages16 Samss 503Jaikaran DanNo ratings yet

- 16 Samss 507 PDFDocument27 pages16 Samss 507 PDFnadeemNo ratings yet

- 16 Samss 503Document43 pages16 Samss 503HatemS.MashaGbehNo ratings yet

- June 30, 2010Document56 pagesJune 30, 2010mohamedNo ratings yet

- 16 Samss 503Document43 pages16 Samss 503Florante Nobleza100% (2)

- 32-'Msi-O3: Metal Clad Gas Insulated Medium Voltage Switchgear KV, 13.8 KV, 33 Kvor 34.5 KV)Document43 pages32-'Msi-O3: Metal Clad Gas Insulated Medium Voltage Switchgear KV, 13.8 KV, 33 Kvor 34.5 KV)Mahmoud Moez100% (1)

- S Gen Lightning 00Document15 pagesS Gen Lightning 00raviaggrawalla8727No ratings yet

- 16 Samss 502Document25 pages16 Samss 502paul reyesNo ratings yet

- 16 Samss 514Document17 pages16 Samss 514HatemS.MashaGbehNo ratings yet

- 32-SDMS-11 Rev.1Document56 pages32-SDMS-11 Rev.1Soumya ChaudhuryNo ratings yet

- 16 Samss 506Document40 pages16 Samss 506HatemS.MashaGbehNo ratings yet

- Bus 39195-13. RES - TS - 3.02.07 - I1Document3 pagesBus 39195-13. RES - TS - 3.02.07 - I1Sergio Henrique F. CArniettoNo ratings yet

- Gis 12-101Document19 pagesGis 12-101Jagatjeet MaanNo ratings yet

- PDFDocument20 pagesPDFmohamedNo ratings yet

- ETS12-01-01 - 12-24KV FuseLink HolderDocument12 pagesETS12-01-01 - 12-24KV FuseLink HolderTerex14253No ratings yet

- 16 Samss 504Document46 pages16 Samss 504HatemS.MashaGbehNo ratings yet

- GRN Technical Standard - Construction Specification Deployment Guide Rev2.3Document192 pagesGRN Technical Standard - Construction Specification Deployment Guide Rev2.3Joe HoangNo ratings yet

- 32-Sdms-09 (Gas Insulated Metal Clad MV Switchgear)Document50 pages32-Sdms-09 (Gas Insulated Metal Clad MV Switchgear)Haytham BafoNo ratings yet

- W-E-Ss-002 - Rev. 1Document26 pagesW-E-Ss-002 - Rev. 1Nael SwedanNo ratings yet

- 16 Samss 504Document42 pages16 Samss 504paul reyesNo ratings yet

- 14 Samss 533Document14 pages14 Samss 533HatemS.MashaGbehNo ratings yet

- 1-) 52-TMSS-01-Rev.00Document29 pages1-) 52-TMSS-01-Rev.00Orcun CalayNo ratings yet

- 52TMSS01R0Document29 pages52TMSS01R0Orcun CalayNo ratings yet

- Aramco SpecificationDocument21 pagesAramco SpecificationSuhaib Obeidat100% (2)

- Well-Site Power Supply and Distribution System User ManualDocument17 pagesWell-Site Power Supply and Distribution System User ManualAhmedNo ratings yet

- June 30, 2010Document41 pagesJune 30, 2010TTPL ProjectsNo ratings yet

- 16 Samss 502Document23 pages16 Samss 502samirNo ratings yet

- 15TMSS02R2 (Amendment) Suspension Type Insulators, Porcelain or GlassDocument18 pages15TMSS02R2 (Amendment) Suspension Type Insulators, Porcelain or GlassDominic Mukesh KumarNo ratings yet

- 32TMSS01R2Document44 pages32TMSS01R2Mahmoud MoezNo ratings yet

- June 30, 2010Document41 pagesJune 30, 2010mohamedNo ratings yet

- Pertamina MPHP: Project SpecificationDocument8 pagesPertamina MPHP: Project Specificationarsil5840No ratings yet

- Well-Site Power Supply and Distribution System User ManualDocument14 pagesWell-Site Power Supply and Distribution System User ManualYugandhar YuguNo ratings yet

- Spec For Low Voltage Switchboard-MCCDocument19 pagesSpec For Low Voltage Switchboard-MCCMohamed Jahirhussain50% (4)

- Vol 2 - C3.4.4 Standard Specifications For Electrical WorksDocument127 pagesVol 2 - C3.4.4 Standard Specifications For Electrical Worksashutosh ambeyNo ratings yet

- 14 Samss 531 2016Document25 pages14 Samss 531 2016Mohamed El AbasyNo ratings yet

- Sched-F3 General Electr substation & earthing reqDocument11 pagesSched-F3 General Electr substation & earthing reqyvNo ratings yet

- ADB (MCR5000) - Manual - MultiwireDocument129 pagesADB (MCR5000) - Manual - Multiwirecosteniuc75% (4)

- Ngts - 3 24 10Document41 pagesNgts - 3 24 10akmezimNo ratings yet

- 500kV, 275kV & 132kV Circuit BreakerDocument17 pages500kV, 275kV & 132kV Circuit Breakerlkt_pestechNo ratings yet

- CGMCOSMOS - Technical Specification 2016 ET-078-EN-04 Var.4Document40 pagesCGMCOSMOS - Technical Specification 2016 ET-078-EN-04 Var.4Alexander BakirovNo ratings yet

- Protection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsFrom EverandProtection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsNo ratings yet

- Handbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryFrom EverandHandbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryNo ratings yet

- Flexible Power Transmission: The HVDC OptionsFrom EverandFlexible Power Transmission: The HVDC OptionsRating: 5 out of 5 stars5/5 (1)

- 400kV Cable InstallationDocument24 pages400kV Cable InstallationArun dasNo ratings yet

- Single BB vs Double BBDocument11 pagesSingle BB vs Double BBArun dasNo ratings yet

- ECEPP Goods Two Stage 1.4 Eligibility and Qualification Criteria - NEPCO - 14.11.2021Document13 pagesECEPP Goods Two Stage 1.4 Eligibility and Qualification Criteria - NEPCO - 14.11.2021Arun dasNo ratings yet

- Solar Farm - Earthing DetailsDocument1 pageSolar Farm - Earthing DetailsArun dasNo ratings yet

- Bill of Quantities - Civil - Version 1REVISEDDocument8 pagesBill of Quantities - Civil - Version 1REVISEDArun dasNo ratings yet

- Solar Farm - Earthing LayoutDocument1 pageSolar Farm - Earthing LayoutArun dasNo ratings yet

- Technical Spec - Protection SystemDocument45 pagesTechnical Spec - Protection SystemArun dasNo ratings yet

- SpareDocument9 pagesSpareArun dasNo ratings yet

- Supplier ListDocument2 pagesSupplier ListArun dasNo ratings yet

- ECEPP Goods Two Stage 1.5.1 Tender Form Jun 21 - NEPCODocument5 pagesECEPP Goods Two Stage 1.5.1 Tender Form Jun 21 - NEPCOArun dasNo ratings yet

- ABB T 167 - SHT 0001Document1 pageABB T 167 - SHT 0001Arun dasNo ratings yet

- ABB T 055 - SHT 0001Document5 pagesABB T 055 - SHT 0001Arun dasNo ratings yet

- ECEPP Goods Two Stage 1.3 Evaluation Methodology - NEPCODocument8 pagesECEPP Goods Two Stage 1.3 Evaluation Methodology - NEPCOArun dasNo ratings yet

- 13.8Kv Cable Sizing Calculation Construction of New 380/132Kv S/S AD-DAWADMI BSP (9037)Document14 pages13.8Kv Cable Sizing Calculation Construction of New 380/132Kv S/S AD-DAWADMI BSP (9037)Arun dasNo ratings yet

- 2013ee0622 - Sirim QasDocument15 pages2013ee0622 - Sirim QasArun dasNo ratings yet

- 3CL - 24004-Load Flow - Voltage Drop CalculationDocument19 pages3CL - 24004-Load Flow - Voltage Drop CalculationArun dasNo ratings yet

- PS (T) 055Document20 pagesPS (T) 055Arun dasNo ratings yet

- ABB T 001 - SHT 0001Document5 pagesABB T 001 - SHT 0001Arun dasNo ratings yet

- 3CL - 24003-Short Circuit Current CalculationDocument26 pages3CL - 24003-Short Circuit Current CalculationArun dasNo ratings yet

- 3CL - 24001-DC System CalculationDocument6 pages3CL - 24001-DC System CalculationArun dasNo ratings yet

- CT and VT SIZING CALCULATIONDocument6 pagesCT and VT SIZING CALCULATIONArun dasNo ratings yet

- Meter Interface Device (Nebula) Schematic-05KE0014 BDocument1 pageMeter Interface Device (Nebula) Schematic-05KE0014 BArun dasNo ratings yet

- Argus 7SR22Document1 pageArgus 7SR22Arun dasNo ratings yet

- PASS 3 EndedDocument3 pagesPASS 3 EndedArun dasNo ratings yet

- TS 3.24.065Document8 pagesTS 3.24.065Arun dasNo ratings yet

- TGN (E) 205Document22 pagesTGN (E) 205Arun dasNo ratings yet

- TS 3.24.008Document51 pagesTS 3.24.008Arun dasNo ratings yet

- 132kV Cable Sizing For Ductbank in Reactor Area - R1Document10 pages132kV Cable Sizing For Ductbank in Reactor Area - R1Arun das100% (2)

- TS 3.24.075Document11 pagesTS 3.24.075Arun dasNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- Electrical Safety ChecklistDocument2 pagesElectrical Safety ChecklistmailxzNo ratings yet

- MEL ZG621 VLSI DESIGN (Lect 5)Document32 pagesMEL ZG621 VLSI DESIGN (Lect 5)2023ht80200No ratings yet

- Thank You For Downloading PPL Electric Utilities' (PPL EU) Application For Electric ServiceDocument7 pagesThank You For Downloading PPL Electric Utilities' (PPL EU) Application For Electric ServiceAsghar AliNo ratings yet

- NOTES Mod6Document16 pagesNOTES Mod6eeetistNo ratings yet

- Kexin-Si2312 C382307Document4 pagesKexin-Si2312 C382307balaicopierNo ratings yet

- Ed Lab ManualDocument27 pagesEd Lab ManualBonnieNo ratings yet

- ML11238A234Document21 pagesML11238A234foufou79No ratings yet

- RPM Meter For Automobiles Circuit Diagram - Electronic Circuits DiagramDocument1 pageRPM Meter For Automobiles Circuit Diagram - Electronic Circuits DiagramSantiago Argañaraz BoniniNo ratings yet

- Mercury Vapor LampsDocument24 pagesMercury Vapor LampsDale NapoNo ratings yet

- Rf/Rfs & RL/RLS: Class HDocument2 pagesRf/Rfs & RL/RLS: Class HFrank SemenukNo ratings yet

- LED Light BulbsDocument8 pagesLED Light BulbsJuvvilyynGraceMahomatNo ratings yet

- XEnergy Technical Guide en 158487Document88 pagesXEnergy Technical Guide en 158487Cris_eu09No ratings yet

- 05-EL - FTR - Insulation & Continuity TestDocument3 pages05-EL - FTR - Insulation & Continuity Testben sullivanNo ratings yet

- ALC Hydraulic GMV 3010 Electrical DiagramDocument20 pagesALC Hydraulic GMV 3010 Electrical Diagramمحمد حسينNo ratings yet

- Simulation On Induction Motor Driven Water Pump Fed by Solar Photovoltaic Array Using Boost ConverterDocument20 pagesSimulation On Induction Motor Driven Water Pump Fed by Solar Photovoltaic Array Using Boost ConverterJohnny Edward KingsleyNo ratings yet

- 100+100 Watts Stereo Amplifier Board DIY Toshiba 2SC5200 Transistor (Hindi) ELECTRO INDIA PDFDocument6 pages100+100 Watts Stereo Amplifier Board DIY Toshiba 2SC5200 Transistor (Hindi) ELECTRO INDIA PDFKulwinderNo ratings yet

- Data Sheet VaristorDocument6 pagesData Sheet VaristorLuis Guerra VegaNo ratings yet

- Installation Calculation Report: New - Project FullDocument28 pagesInstallation Calculation Report: New - Project FullDino MahmutovićNo ratings yet

- 15 AVC INX enDocument4 pages15 AVC INX enARah AtilehNo ratings yet

- VTXDocument6 pagesVTXHari Krishna.MNo ratings yet

- SI306-F016 Lighting and Receptacles Installation ChecklistDocument1 pageSI306-F016 Lighting and Receptacles Installation ChecklistBrookeNo ratings yet

- B01-TB16O-003 - TB16OUT Basic Installation Instructions - ENG - 1.1Document2 pagesB01-TB16O-003 - TB16OUT Basic Installation Instructions - ENG - 1.1Kien Nguyen TrungNo ratings yet

- Presentation MGC ProductsDocument58 pagesPresentation MGC ProductsHillary Mcgowan100% (1)

- 800 Transformer Coding Framing 12 K VDocument58 pages800 Transformer Coding Framing 12 K VMontree SupaphobNo ratings yet

- 200W True Sine Wave DC-AC Power Inverter: SeriesDocument2 pages200W True Sine Wave DC-AC Power Inverter: SeriesbbtrNo ratings yet

- Rew Grade C Exam SampleDocument38 pagesRew Grade C Exam SampleEdmond HungNo ratings yet

- Reflective Optoswitch: VTR17D1Document2 pagesReflective Optoswitch: VTR17D1Andy ZhuNo ratings yet

- Paper 03 GM 0984Document7 pagesPaper 03 GM 0984surojjNo ratings yet