Professional Documents

Culture Documents

Aggregate Planning

Aggregate Planning

Uploaded by

mohamed matarCopyright:

Available Formats

You might also like

- Komatsu Pw75r2 Shop ManualDocument20 pagesKomatsu Pw75r2 Shop ManualHeather98% (60)

- Tema Engl - RezolvatDocument2 pagesTema Engl - RezolvatPopa Andreea75% (4)

- Acc311 Excel Week3 Project 1Document3 pagesAcc311 Excel Week3 Project 1Lilian LNo ratings yet

- Super ProjectDocument1 pageSuper ProjectVaibhav SaithNo ratings yet

- Alko Case Study AnswersDocument9 pagesAlko Case Study AnswersPiyush SinghNo ratings yet

- Aa2e Hal Testbank Ch04Document26 pagesAa2e Hal Testbank Ch04jayNo ratings yet

- Planning QuestionDocument8 pagesPlanning Questionbassant_hegaziNo ratings yet

- Aggregate Planning ExerciseDocument8 pagesAggregate Planning ExerciseMichael WijayaNo ratings yet

- Financial A/C Cost A/C Management A/C DIT: 70 + 60-70 50-60 40-50 Fail Grand Total 595 595 595 526Document17 pagesFinancial A/C Cost A/C Management A/C DIT: 70 + 60-70 50-60 40-50 Fail Grand Total 595 595 595 526Mihir ShahNo ratings yet

- Quiz Sistem Produksi DestaDocument4 pagesQuiz Sistem Produksi DestaAldi WahyuNo ratings yet

- HR Plant Setting UpDocument3 pagesHR Plant Setting Upadi809here100% (2)

- Job Order Customer Date Order Received Production Days Needed Date Order DUE Job SequenceDocument6 pagesJob Order Customer Date Order Received Production Days Needed Date Order DUE Job SequenceStephenNo ratings yet

- .g.,1, Continuous To Continuous: Table 1Document5 pages.g.,1, Continuous To Continuous: Table 1जय यादवNo ratings yet

- Assginment 2 - OmDocument6 pagesAssginment 2 - OmAaron WagiuNo ratings yet

- OM II Chapter 11 - Problem - SolutionDocument3 pagesOM II Chapter 11 - Problem - SolutionParal Fabio MikhaNo ratings yet

- Production and Operations Analysis 6th Edition Nahmias Solutions Manual instant download all chapterDocument69 pagesProduction and Operations Analysis 6th Edition Nahmias Solutions Manual instant download all chapterrekerfauser100% (1)

- Templete Cash FlowDocument5 pagesTemplete Cash FlowRobby Abdul MalikNo ratings yet

- M-Pesa Tariffs Govt Levy A2 4 enDocument1 pageM-Pesa Tariffs Govt Levy A2 4 enALIKIBA followingsNo ratings yet

- Dsi Stressing Record - Bridge IC12Document29 pagesDsi Stressing Record - Bridge IC12Rama Subba Rao chebroluNo ratings yet

- Sprint 1 Burndown Chart: Days Tasks Done Remaining Ideal Velocity Initial Value Ideal Done Per DayDocument2 pagesSprint 1 Burndown Chart: Days Tasks Done Remaining Ideal Velocity Initial Value Ideal Done Per DayRanda S JowaNo ratings yet

- Tugas Forecasting Penjualan Tahun 2004-2005: No Tahun PCT CTMDocument3 pagesTugas Forecasting Penjualan Tahun 2004-2005: No Tahun PCT CTMEva SefianaNo ratings yet

- Cost Per Unit: Aggregate PlanningDocument4 pagesCost Per Unit: Aggregate PlanningDaniela RinconNo ratings yet

- Transportation Model - HO - REV01Document42 pagesTransportation Model - HO - REV01SendriFebriyansyahNo ratings yet

- Business Target 2008-2009.xls HoangDocument3 pagesBusiness Target 2008-2009.xls Hoangapi-19624207No ratings yet

- Acf Final Manish 42987Document24 pagesAcf Final Manish 42987Raman SrinivasanNo ratings yet

- ACDocument5 pagesACDoli AnsyahNo ratings yet

- Vianur TSPDocument4 pagesVianur TSPsyaifaeza.jbgNo ratings yet

- Frecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresDocument4 pagesFrecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresMauricio TamezNo ratings yet

- Standard Loading Procedure and Format of Data Recording SheetDocument2 pagesStandard Loading Procedure and Format of Data Recording Sheetbdaminda6701No ratings yet

- CCC LingDocument1 pageCCC LingCindyNo ratings yet

- CrionDocument6 pagesCrionPreticia ChristianNo ratings yet

- Frecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresDocument4 pagesFrecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresJulian David HurtadoNo ratings yet

- Komatsu Pc130 7 Shop ManualDocument20 pagesKomatsu Pc130 7 Shop Manualtamara100% (59)

- Production and Operations Analysis 6Th Edition Nahmias Solutions Manual Full Chapter PDFDocument67 pagesProduction and Operations Analysis 6Th Edition Nahmias Solutions Manual Full Chapter PDFlasherdiedral.7cqo100% (10)

- Exercise Problem 1 - Group 5Document2 pagesExercise Problem 1 - Group 5Paral Fabio MikhaNo ratings yet

- FluidDocument8 pagesFluidsgngdth2qgNo ratings yet

- Traditional Costing Method Vs ABC Costing Ice-Mint Paan ElaichiDocument11 pagesTraditional Costing Method Vs ABC Costing Ice-Mint Paan ElaichiI.E. Business SchoolNo ratings yet

- Nama: L.Muh - Khaerunnizar NIM: 518061151 Kelas: Perencanaan & Pengendalian Produksi / DDocument8 pagesNama: L.Muh - Khaerunnizar NIM: 518061151 Kelas: Perencanaan & Pengendalian Produksi / DKhaerunnizarNo ratings yet

- 13 Um PP 190 4653 RPM 13 Um PP 99 4653 RPM 17NOV2015Document1 page13 Um PP 190 4653 RPM 13 Um PP 99 4653 RPM 17NOV2015faisalNo ratings yet

- Frecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresDocument4 pagesFrecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresAnaly CabreraNo ratings yet

- Om ExerciseDocument6 pagesOm Exercisekristel lei diamanteNo ratings yet

- Least Total Cost: Week Req Production Qty End Inv Holding CostDocument3 pagesLeast Total Cost: Week Req Production Qty End Inv Holding CostStaticNo ratings yet

- Master Template v1Document79 pagesMaster Template v1KiranNo ratings yet

- Komatsu Pc290lc 6k Pc290nlc 6k Shop Manual 2Document20 pagesKomatsu Pc290lc 6k Pc290nlc 6k Shop Manual 2richard100% (57)

- Less Than Ogive: Sum (X) 200 1.000Document5 pagesLess Than Ogive: Sum (X) 200 1.000NprantoNo ratings yet

- MOHAMADOU AWALOU PGE 5 Forage 16A181EMDocument13 pagesMOHAMADOU AWALOU PGE 5 Forage 16A181EMAwalou MohamadNo ratings yet

- Komatsu Hydraulic Excavator Pc290lc 290nlc 6k Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc290lc 290nlc 6k Shop Manualmallory100% (56)

- Chase, Overtime, CAPACITY 130Document8 pagesChase, Overtime, CAPACITY 130Jane DizonNo ratings yet

- Komatsu Pc210 210lc 240lc 240nlc 6k Shop ManualDocument20 pagesKomatsu Pc210 210lc 240lc 240nlc 6k Shop ManualThomas100% (55)

- Confusion Plcs SolutionsDocument8 pagesConfusion Plcs SolutionsJen Hang WongNo ratings yet

- Base Salary Count - Base Salary 150-159 1 160-169 3 170-179 7 180-189 5 190-199 1 200-209 2 210-219 1Document6 pagesBase Salary Count - Base Salary 150-159 1 160-169 3 170-179 7 180-189 5 190-199 1 200-209 2 210-219 1Devilish LuciferNo ratings yet

- Variable Costs R/tonneDocument3 pagesVariable Costs R/tonneChemEngGirl89No ratings yet

- Pid SimuladorDocument10 pagesPid SimuladorDavid Romero VacaNo ratings yet

- List of Equipment For Captive RMC Set Up: SR No Equipment Description Units Approx Cost (Inr) Total Capex (Inr)Document7 pagesList of Equipment For Captive RMC Set Up: SR No Equipment Description Units Approx Cost (Inr) Total Capex (Inr)shakeelNo ratings yet

- Cost of Production ReportDocument7 pagesCost of Production ReportVash MalijanNo ratings yet

- Komatsu Hydraulic Excavator Pc450 6k 34000 Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc450 6k 34000 Shop Manualterrance100% (60)

- Wa320-3mc A31001 ShopDocument727 pagesWa320-3mc A31001 ShopCarlos Zuñiga100% (2)

- POE Problemset5Document4 pagesPOE Problemset5Duc Chinh LuongNo ratings yet

- Indikator KeekonomianDocument4 pagesIndikator KeekonomianM FaisalNo ratings yet

- Juggernaut Method Base TemplateDocument3 pagesJuggernaut Method Base TemplatePatbarbellNo ratings yet

- Om Exercise AnswerDocument6 pagesOm Exercise Answerkristel lei diamanteNo ratings yet

- Fin Model Class9 Merger Model Using DCF MethodologyDocument1 pageFin Model Class9 Merger Model Using DCF MethodologyGel viraNo ratings yet

- CHAPTER 12 Maintain Inventory Records: Examining and Working Through Different Methods of Accounting For InventoriesDocument18 pagesCHAPTER 12 Maintain Inventory Records: Examining and Working Through Different Methods of Accounting For InventoriesCJNo ratings yet

- Problem 11-2Document6 pagesProblem 11-2Moe Alnaim33% (3)

- Instruction Manual Inventory ControlDocument20 pagesInstruction Manual Inventory ControlpaulNo ratings yet

- Facility LayoutDocument16 pagesFacility LayoutViraj DhuriNo ratings yet

- Inventory Valuation: SUBMITED BY:Tufail KhanDocument20 pagesInventory Valuation: SUBMITED BY:Tufail KhanTufail KhanNo ratings yet

- Chap 009Document11 pagesChap 009dbjn100% (1)

- Gary Earle ResumeDocument2 pagesGary Earle Resumeapi-310096159No ratings yet

- Aashita - Inventory Management Homework PDFDocument6 pagesAashita - Inventory Management Homework PDFAashita JainNo ratings yet

- Principle of Accounting 11Document131 pagesPrinciple of Accounting 11ibrahim JimaleNo ratings yet

- Curriculum Vitae Saumitra AichDocument4 pagesCurriculum Vitae Saumitra Aichshiv sharmaNo ratings yet

- Intacc Quiz 1Document6 pagesIntacc Quiz 1Rhea YugaNo ratings yet

- Audit-Of Inventory ACHA - KJDocument47 pagesAudit-Of Inventory ACHA - KJKhrisna Joy AchaNo ratings yet

- A Campus Bookstore Sells The Palm m505 Handheld For 399Document1 pageA Campus Bookstore Sells The Palm m505 Handheld For 399Amit PandeyNo ratings yet

- CH - 09 - Inventories Additional Valuation IssuesDocument37 pagesCH - 09 - Inventories Additional Valuation IssuesJoseph Gaspard100% (1)

- Ma Chapter 5 New Multiple Choice For TestbankDocument4 pagesMa Chapter 5 New Multiple Choice For TestbankJimmy Jamero Jr.100% (1)

- Pre Finals Quiz PDFDocument4 pagesPre Finals Quiz PDFRona S. Pepino - AguirreNo ratings yet

- Process Costing-Practice SheetDocument37 pagesProcess Costing-Practice SheetSuvro Avro100% (3)

- Project Report On Operations RetailDocument50 pagesProject Report On Operations RetailJimmy JaganiNo ratings yet

- Acc 441 DraftDocument13 pagesAcc 441 DraftMahinChowdhuryNo ratings yet

- FisherDocument13 pagesFisherrainbabe50% (2)

- Meaning of ABC Analysis: What Is ABC Analysis? Advantages ABC Analysis and Disadvantages ABC AnalysisDocument10 pagesMeaning of ABC Analysis: What Is ABC Analysis? Advantages ABC Analysis and Disadvantages ABC AnalysisSigei Leonard0% (1)

- B2B Distribution NetworkDocument14 pagesB2B Distribution NetworkAbhijit Prabhu PatturhallimathNo ratings yet

- Non Valuated StockDocument4 pagesNon Valuated StockGK SKNo ratings yet

- Inventory Management STUDocument13 pagesInventory Management STUansukrNo ratings yet

- Goods Receipt Handling Without Reference To Inbound DeliveryDocument3 pagesGoods Receipt Handling Without Reference To Inbound DeliveryBLNo ratings yet

- A Study of Q Chart For Short Run PDFDocument37 pagesA Study of Q Chart For Short Run PDFEd100% (1)

- Inventory Fa1Document30 pagesInventory Fa1Gurjinder BajwaNo ratings yet

Aggregate Planning

Aggregate Planning

Uploaded by

mohamed matarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aggregate Planning

Aggregate Planning

Uploaded by

mohamed matarCopyright:

Available Formats

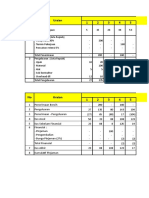

1- Aggregate planning

Optimal cost = Periods Excess

Capacity

$19,200 1 2 3 4 5 6 Capacity

1 RegTime 150 150

1 Overtime 20 20

2 RegTime 150 150

2 Overtime 10 10 20

3 RegTime 10 140 0 150

3 Overtime 20 20

4 RegTime 150 150

4 Overtime 20 20

5 RegTime 130 0 20 150

5 Overtime 20 20

6 RegTime 150 150

6 Overtime 20 20

Demand 180 170 140 150 130 150 100

Optimal Cost= $19,200

Aggregate planning summary

Method Units Cost

Production

costs

Initial

0 0

Inventory

Regular time 880 17600

Overtime 40 1200

Subcontract 0 0

Prod Cost

920 18800

Subtotals

Unit-Pds Held 0 0

Unit-Pds

20 400

Short

Total cost 19,200

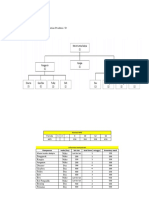

2- Master Schedule

145 1 2 3 4 5 6 7 8

Forecast 100 100 120 120 150 150 180 180

Customer Orders 106 94 65 40 21 9 2 0

Project on hand 39 189 69 199 49 149 219 39

inventory

MPS 250 250 250 250

Available to Promises 39 91 189 241 248

inventory uncomittmented

Week Inventory from Forecast NET inventory MPS Projected on hand

previous week or demand before MPS inventory

1 145 106 39

2 39 100 -61 250 189

3 189 120 69 69

4 69 120 -51 250 199

5 199 150 49 49

6 49 150 -101 250 149

7 149 180 -31 250 219

8 219 180 39 39

You might also like

- Komatsu Pw75r2 Shop ManualDocument20 pagesKomatsu Pw75r2 Shop ManualHeather98% (60)

- Tema Engl - RezolvatDocument2 pagesTema Engl - RezolvatPopa Andreea75% (4)

- Acc311 Excel Week3 Project 1Document3 pagesAcc311 Excel Week3 Project 1Lilian LNo ratings yet

- Super ProjectDocument1 pageSuper ProjectVaibhav SaithNo ratings yet

- Alko Case Study AnswersDocument9 pagesAlko Case Study AnswersPiyush SinghNo ratings yet

- Aa2e Hal Testbank Ch04Document26 pagesAa2e Hal Testbank Ch04jayNo ratings yet

- Planning QuestionDocument8 pagesPlanning Questionbassant_hegaziNo ratings yet

- Aggregate Planning ExerciseDocument8 pagesAggregate Planning ExerciseMichael WijayaNo ratings yet

- Financial A/C Cost A/C Management A/C DIT: 70 + 60-70 50-60 40-50 Fail Grand Total 595 595 595 526Document17 pagesFinancial A/C Cost A/C Management A/C DIT: 70 + 60-70 50-60 40-50 Fail Grand Total 595 595 595 526Mihir ShahNo ratings yet

- Quiz Sistem Produksi DestaDocument4 pagesQuiz Sistem Produksi DestaAldi WahyuNo ratings yet

- HR Plant Setting UpDocument3 pagesHR Plant Setting Upadi809here100% (2)

- Job Order Customer Date Order Received Production Days Needed Date Order DUE Job SequenceDocument6 pagesJob Order Customer Date Order Received Production Days Needed Date Order DUE Job SequenceStephenNo ratings yet

- .g.,1, Continuous To Continuous: Table 1Document5 pages.g.,1, Continuous To Continuous: Table 1जय यादवNo ratings yet

- Assginment 2 - OmDocument6 pagesAssginment 2 - OmAaron WagiuNo ratings yet

- OM II Chapter 11 - Problem - SolutionDocument3 pagesOM II Chapter 11 - Problem - SolutionParal Fabio MikhaNo ratings yet

- Production and Operations Analysis 6th Edition Nahmias Solutions Manual instant download all chapterDocument69 pagesProduction and Operations Analysis 6th Edition Nahmias Solutions Manual instant download all chapterrekerfauser100% (1)

- Templete Cash FlowDocument5 pagesTemplete Cash FlowRobby Abdul MalikNo ratings yet

- M-Pesa Tariffs Govt Levy A2 4 enDocument1 pageM-Pesa Tariffs Govt Levy A2 4 enALIKIBA followingsNo ratings yet

- Dsi Stressing Record - Bridge IC12Document29 pagesDsi Stressing Record - Bridge IC12Rama Subba Rao chebroluNo ratings yet

- Sprint 1 Burndown Chart: Days Tasks Done Remaining Ideal Velocity Initial Value Ideal Done Per DayDocument2 pagesSprint 1 Burndown Chart: Days Tasks Done Remaining Ideal Velocity Initial Value Ideal Done Per DayRanda S JowaNo ratings yet

- Tugas Forecasting Penjualan Tahun 2004-2005: No Tahun PCT CTMDocument3 pagesTugas Forecasting Penjualan Tahun 2004-2005: No Tahun PCT CTMEva SefianaNo ratings yet

- Cost Per Unit: Aggregate PlanningDocument4 pagesCost Per Unit: Aggregate PlanningDaniela RinconNo ratings yet

- Transportation Model - HO - REV01Document42 pagesTransportation Model - HO - REV01SendriFebriyansyahNo ratings yet

- Business Target 2008-2009.xls HoangDocument3 pagesBusiness Target 2008-2009.xls Hoangapi-19624207No ratings yet

- Acf Final Manish 42987Document24 pagesAcf Final Manish 42987Raman SrinivasanNo ratings yet

- ACDocument5 pagesACDoli AnsyahNo ratings yet

- Vianur TSPDocument4 pagesVianur TSPsyaifaeza.jbgNo ratings yet

- Frecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresDocument4 pagesFrecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresMauricio TamezNo ratings yet

- Standard Loading Procedure and Format of Data Recording SheetDocument2 pagesStandard Loading Procedure and Format of Data Recording Sheetbdaminda6701No ratings yet

- CCC LingDocument1 pageCCC LingCindyNo ratings yet

- CrionDocument6 pagesCrionPreticia ChristianNo ratings yet

- Frecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresDocument4 pagesFrecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresJulian David HurtadoNo ratings yet

- Komatsu Pc130 7 Shop ManualDocument20 pagesKomatsu Pc130 7 Shop Manualtamara100% (59)

- Production and Operations Analysis 6Th Edition Nahmias Solutions Manual Full Chapter PDFDocument67 pagesProduction and Operations Analysis 6Th Edition Nahmias Solutions Manual Full Chapter PDFlasherdiedral.7cqo100% (10)

- Exercise Problem 1 - Group 5Document2 pagesExercise Problem 1 - Group 5Paral Fabio MikhaNo ratings yet

- FluidDocument8 pagesFluidsgngdth2qgNo ratings yet

- Traditional Costing Method Vs ABC Costing Ice-Mint Paan ElaichiDocument11 pagesTraditional Costing Method Vs ABC Costing Ice-Mint Paan ElaichiI.E. Business SchoolNo ratings yet

- Nama: L.Muh - Khaerunnizar NIM: 518061151 Kelas: Perencanaan & Pengendalian Produksi / DDocument8 pagesNama: L.Muh - Khaerunnizar NIM: 518061151 Kelas: Perencanaan & Pengendalian Produksi / DKhaerunnizarNo ratings yet

- 13 Um PP 190 4653 RPM 13 Um PP 99 4653 RPM 17NOV2015Document1 page13 Um PP 190 4653 RPM 13 Um PP 99 4653 RPM 17NOV2015faisalNo ratings yet

- Frecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresDocument4 pagesFrecuencias Xi fi X*fi (X-μ) ² (X-μ) ² *fi Marcas de Clase: Sueldo emn miles de pesos trabajadoresAnaly CabreraNo ratings yet

- Om ExerciseDocument6 pagesOm Exercisekristel lei diamanteNo ratings yet

- Least Total Cost: Week Req Production Qty End Inv Holding CostDocument3 pagesLeast Total Cost: Week Req Production Qty End Inv Holding CostStaticNo ratings yet

- Master Template v1Document79 pagesMaster Template v1KiranNo ratings yet

- Komatsu Pc290lc 6k Pc290nlc 6k Shop Manual 2Document20 pagesKomatsu Pc290lc 6k Pc290nlc 6k Shop Manual 2richard100% (57)

- Less Than Ogive: Sum (X) 200 1.000Document5 pagesLess Than Ogive: Sum (X) 200 1.000NprantoNo ratings yet

- MOHAMADOU AWALOU PGE 5 Forage 16A181EMDocument13 pagesMOHAMADOU AWALOU PGE 5 Forage 16A181EMAwalou MohamadNo ratings yet

- Komatsu Hydraulic Excavator Pc290lc 290nlc 6k Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc290lc 290nlc 6k Shop Manualmallory100% (56)

- Chase, Overtime, CAPACITY 130Document8 pagesChase, Overtime, CAPACITY 130Jane DizonNo ratings yet

- Komatsu Pc210 210lc 240lc 240nlc 6k Shop ManualDocument20 pagesKomatsu Pc210 210lc 240lc 240nlc 6k Shop ManualThomas100% (55)

- Confusion Plcs SolutionsDocument8 pagesConfusion Plcs SolutionsJen Hang WongNo ratings yet

- Base Salary Count - Base Salary 150-159 1 160-169 3 170-179 7 180-189 5 190-199 1 200-209 2 210-219 1Document6 pagesBase Salary Count - Base Salary 150-159 1 160-169 3 170-179 7 180-189 5 190-199 1 200-209 2 210-219 1Devilish LuciferNo ratings yet

- Variable Costs R/tonneDocument3 pagesVariable Costs R/tonneChemEngGirl89No ratings yet

- Pid SimuladorDocument10 pagesPid SimuladorDavid Romero VacaNo ratings yet

- List of Equipment For Captive RMC Set Up: SR No Equipment Description Units Approx Cost (Inr) Total Capex (Inr)Document7 pagesList of Equipment For Captive RMC Set Up: SR No Equipment Description Units Approx Cost (Inr) Total Capex (Inr)shakeelNo ratings yet

- Cost of Production ReportDocument7 pagesCost of Production ReportVash MalijanNo ratings yet

- Komatsu Hydraulic Excavator Pc450 6k 34000 Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc450 6k 34000 Shop Manualterrance100% (60)

- Wa320-3mc A31001 ShopDocument727 pagesWa320-3mc A31001 ShopCarlos Zuñiga100% (2)

- POE Problemset5Document4 pagesPOE Problemset5Duc Chinh LuongNo ratings yet

- Indikator KeekonomianDocument4 pagesIndikator KeekonomianM FaisalNo ratings yet

- Juggernaut Method Base TemplateDocument3 pagesJuggernaut Method Base TemplatePatbarbellNo ratings yet

- Om Exercise AnswerDocument6 pagesOm Exercise Answerkristel lei diamanteNo ratings yet

- Fin Model Class9 Merger Model Using DCF MethodologyDocument1 pageFin Model Class9 Merger Model Using DCF MethodologyGel viraNo ratings yet

- CHAPTER 12 Maintain Inventory Records: Examining and Working Through Different Methods of Accounting For InventoriesDocument18 pagesCHAPTER 12 Maintain Inventory Records: Examining and Working Through Different Methods of Accounting For InventoriesCJNo ratings yet

- Problem 11-2Document6 pagesProblem 11-2Moe Alnaim33% (3)

- Instruction Manual Inventory ControlDocument20 pagesInstruction Manual Inventory ControlpaulNo ratings yet

- Facility LayoutDocument16 pagesFacility LayoutViraj DhuriNo ratings yet

- Inventory Valuation: SUBMITED BY:Tufail KhanDocument20 pagesInventory Valuation: SUBMITED BY:Tufail KhanTufail KhanNo ratings yet

- Chap 009Document11 pagesChap 009dbjn100% (1)

- Gary Earle ResumeDocument2 pagesGary Earle Resumeapi-310096159No ratings yet

- Aashita - Inventory Management Homework PDFDocument6 pagesAashita - Inventory Management Homework PDFAashita JainNo ratings yet

- Principle of Accounting 11Document131 pagesPrinciple of Accounting 11ibrahim JimaleNo ratings yet

- Curriculum Vitae Saumitra AichDocument4 pagesCurriculum Vitae Saumitra Aichshiv sharmaNo ratings yet

- Intacc Quiz 1Document6 pagesIntacc Quiz 1Rhea YugaNo ratings yet

- Audit-Of Inventory ACHA - KJDocument47 pagesAudit-Of Inventory ACHA - KJKhrisna Joy AchaNo ratings yet

- A Campus Bookstore Sells The Palm m505 Handheld For 399Document1 pageA Campus Bookstore Sells The Palm m505 Handheld For 399Amit PandeyNo ratings yet

- CH - 09 - Inventories Additional Valuation IssuesDocument37 pagesCH - 09 - Inventories Additional Valuation IssuesJoseph Gaspard100% (1)

- Ma Chapter 5 New Multiple Choice For TestbankDocument4 pagesMa Chapter 5 New Multiple Choice For TestbankJimmy Jamero Jr.100% (1)

- Pre Finals Quiz PDFDocument4 pagesPre Finals Quiz PDFRona S. Pepino - AguirreNo ratings yet

- Process Costing-Practice SheetDocument37 pagesProcess Costing-Practice SheetSuvro Avro100% (3)

- Project Report On Operations RetailDocument50 pagesProject Report On Operations RetailJimmy JaganiNo ratings yet

- Acc 441 DraftDocument13 pagesAcc 441 DraftMahinChowdhuryNo ratings yet

- FisherDocument13 pagesFisherrainbabe50% (2)

- Meaning of ABC Analysis: What Is ABC Analysis? Advantages ABC Analysis and Disadvantages ABC AnalysisDocument10 pagesMeaning of ABC Analysis: What Is ABC Analysis? Advantages ABC Analysis and Disadvantages ABC AnalysisSigei Leonard0% (1)

- B2B Distribution NetworkDocument14 pagesB2B Distribution NetworkAbhijit Prabhu PatturhallimathNo ratings yet

- Non Valuated StockDocument4 pagesNon Valuated StockGK SKNo ratings yet

- Inventory Management STUDocument13 pagesInventory Management STUansukrNo ratings yet

- Goods Receipt Handling Without Reference To Inbound DeliveryDocument3 pagesGoods Receipt Handling Without Reference To Inbound DeliveryBLNo ratings yet

- A Study of Q Chart For Short Run PDFDocument37 pagesA Study of Q Chart For Short Run PDFEd100% (1)

- Inventory Fa1Document30 pagesInventory Fa1Gurjinder BajwaNo ratings yet