Professional Documents

Culture Documents

Hisopos ATP Liquidos

Hisopos ATP Liquidos

Uploaded by

Neidy FloresCopyright:

Available Formats

You might also like

- Olt AbencoadaDocument2 pagesOlt AbencoadaRamon ProduçõesNo ratings yet

- Lab Policies Cobas C311 Routine Operation Lab 4014 PDFDocument3 pagesLab Policies Cobas C311 Routine Operation Lab 4014 PDFATUL DESHMUKH33% (3)

- Scrib 2Document4 pagesScrib 2Aldwin Abidin50% (2)

- Design Solutions and Innovations in Temporary Structures Robert BealeDocument518 pagesDesign Solutions and Innovations in Temporary Structures Robert Bealerenzo divendra100% (1)

- Aqualab Series 3 Water Activity Meter Standard Operating ProcedureDocument4 pagesAqualab Series 3 Water Activity Meter Standard Operating ProcedureCarlos CastroNo ratings yet

- Stago Satellite User GuideDocument14 pagesStago Satellite User GuideT86% (7)

- (Geoff Reiss) Programme Management Demystified Ma (BookFi) PDFDocument272 pages(Geoff Reiss) Programme Management Demystified Ma (BookFi) PDFWinarti Nur SetiawatiNo ratings yet

- List of Filipino ArchitectsDocument12 pagesList of Filipino ArchitectsSussybelle Bandoy100% (2)

- Maggi ComebackDocument7 pagesMaggi ComebackAnikNo ratings yet

- ATP AquaSnap Free TotalDocument3 pagesATP AquaSnap Free TotalGeoff EricksonNo ratings yet

- CareStart Training Slides 002 719655 7Document18 pagesCareStart Training Slides 002 719655 7Luis SanchezNo ratings yet

- CobasDocument3 pagesCobaskigm mkj100% (1)

- DigitalRefractometer CareMaintenance 2015 11Document4 pagesDigitalRefractometer CareMaintenance 2015 11ATWIINE LURVIN ELISHANo ratings yet

- Immulite 2000 Top: 1. Principle: The IMMULITE 2000 Automated Immunoassay Analyzer IsDocument3 pagesImmulite 2000 Top: 1. Principle: The IMMULITE 2000 Automated Immunoassay Analyzer IsFaryalBalochNo ratings yet

- DownloadDocument1 pageDownloadfreedNo ratings yet

- Monitor Wellch Allyn-101-150Document50 pagesMonitor Wellch Allyn-101-150jmsm22No ratings yet

- User MaintenanceDocument3 pagesUser Maintenancenidhal amamiNo ratings yet

- 2013-013-00 Rev ZD JOULE Operator Manual LR (2) Sterilization RCADocument3 pages2013-013-00 Rev ZD JOULE Operator Manual LR (2) Sterilization RCAEsteban PradaNo ratings yet

- Ultrasnap Surface Atp Test: For Use With Hygiena Atp Monitoring SystemsDocument10 pagesUltrasnap Surface Atp Test: For Use With Hygiena Atp Monitoring Systemsmoh.elmourabitNo ratings yet

- Protocols Cleaning Disinfection SterilizationDocument23 pagesProtocols Cleaning Disinfection SterilizationGeneSegoviaNo ratings yet

- Chapter 6 Maintenance, Cleaning and DisinfectionDocument18 pagesChapter 6 Maintenance, Cleaning and DisinfectionArrigo PrietoNo ratings yet

- BC-5000&BC-5150 Operation Instructions and Precautions V1.0 enDocument2 pagesBC-5000&BC-5150 Operation Instructions and Precautions V1.0 enJose Rolando Orellana RodriguezNo ratings yet

- Afinion HbA1c Quick GuideDocument2 pagesAfinion HbA1c Quick GuideShadi MahmoudNo ratings yet

- Cleantrace Surface ATP Hygiene Prod InsertDocument13 pagesCleantrace Surface ATP Hygiene Prod Insertvictoria.ricolactNo ratings yet

- AutoQuant 100i Operator ManualDocument96 pagesAutoQuant 100i Operator ManualFermin Tafur LliuyaNo ratings yet

- Ins Proclean Rev G All LanguagesDocument10 pagesIns Proclean Rev G All LanguagesBerry CheraNo ratings yet

- SOP For UV-Vis SpectrophotometerDocument7 pagesSOP For UV-Vis SpectrophotometerArchana PatraNo ratings yet

- Fiber Optic Laryngoscope Handles Directions For UseDocument7 pagesFiber Optic Laryngoscope Handles Directions For UseManuel FloresNo ratings yet

- ATP AquaSnap Free TotalDocument10 pagesATP AquaSnap Free TotalWilfried ApianeNo ratings yet

- Catalyst One Quick Reference Guide enDocument1 pageCatalyst One Quick Reference Guide enbiomedicaNo ratings yet

- BI-W-116B RAPIDPOINT 500 Blood Gas Education - RCHDocument2 pagesBI-W-116B RAPIDPOINT 500 Blood Gas Education - RCHنجلاء الطلحيNo ratings yet

- Standard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisDocument11 pagesStandard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisAbuNo ratings yet

- Standard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisDocument11 pagesStandard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisAbuNo ratings yet

- Conv - INIFU SunMed Conventional Reusable Laryngoscope Rev.2Document2 pagesConv - INIFU SunMed Conventional Reusable Laryngoscope Rev.2Maria Jose Marin Castaño100% (1)

- Ins0079 - Snapshot Hy Lite Rev CDocument1 pageIns0079 - Snapshot Hy Lite Rev CRustam AlyaskarovNo ratings yet

- CHM 421 - Topic 2Document97 pagesCHM 421 - Topic 2CtNo ratings yet

- Spirolab: UK Version - User ManualDocument40 pagesSpirolab: UK Version - User ManualMuhammad awaludin syahNo ratings yet

- CS-T240Plus Maintenance ManualDocument3 pagesCS-T240Plus Maintenance ManualAlbeiro PiraquiveNo ratings yet

- eCL8000 Maintenance GuideDocument24 pageseCL8000 Maintenance Guidegerente soportecNo ratings yet

- v03 Afinion Lipid Panel Quick Guide - AfinioDocument2 pagesv03 Afinion Lipid Panel Quick Guide - AfinioShadi MahmoudNo ratings yet

- 86831F BioSonic UC125 OGDocument70 pages86831F BioSonic UC125 OGAdolfoNo ratings yet

- ENG - Syringe Pump Cleaning and Disinfection Protocol-20200331Document1 pageENG - Syringe Pump Cleaning and Disinfection Protocol-20200331Farrel AlfayyedNo ratings yet

- Welch Allyn 60300 Standard Laryngoscope Handles Instruction ManualDocument5 pagesWelch Allyn 60300 Standard Laryngoscope Handles Instruction ManualA. A.G.No ratings yet

- CS-T240Plus Operation ManualDocument2 pagesCS-T240Plus Operation ManualAlbeiro PiraquiveNo ratings yet

- Shutdown and Startup SummaryDocument18 pagesShutdown and Startup SummaryRicardo RicardoNo ratings yet

- Routine Cleaning of ACQUITY UPC SystemsDocument1 pageRoutine Cleaning of ACQUITY UPC Systemseelainemartins.oNo ratings yet

- Endoscopes Lab 4Document24 pagesEndoscopes Lab 4Baron WhitNo ratings yet

- 710 03 - 04dynabeads Anti Ecoli O157 (Rev010)Document2 pages710 03 - 04dynabeads Anti Ecoli O157 (Rev010)pratechNo ratings yet

- Lx400 ManualDocument27 pagesLx400 ManualDiana MirandaNo ratings yet

- BS3000MDocument15 pagesBS3000MAjay Narayan SharmaNo ratings yet

- CHM 421 - Topic 2Document94 pagesCHM 421 - Topic 2Najmi NasirNo ratings yet

- B40 Limpieza y Mantenimiento PDFDocument11 pagesB40 Limpieza y Mantenimiento PDFArea Biomedica Clinica BaruNo ratings yet

- Elf 51Document3 pagesElf 51ShimaaNo ratings yet

- Immulite 2000 Xpi Demo Script7-13 FinalDocument6 pagesImmulite 2000 Xpi Demo Script7-13 FinalОлександр100% (3)

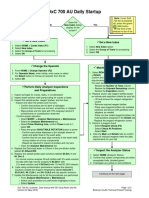

- DXC 700 Au Daily Startup: Set A New Index Set A New IndexDocument2 pagesDXC 700 Au Daily Startup: Set A New Index Set A New IndexGassem SumiliNo ratings yet

- Flow Sensor Addendum UM 2095125-MULTI CDocument371 pagesFlow Sensor Addendum UM 2095125-MULTI CTuấn NôngNo ratings yet

- 05 - Ch-01 unit name 0318Document7 pages05 - Ch-01 unit name 0318Nguyễn Danh DungNo ratings yet

- Quick Guide NanodropDocument3 pagesQuick Guide Nanodropsk_bravoNo ratings yet

- Fanem 1186 Infant Incubator - User Manual (1) (62-78) (05-17)Document13 pagesFanem 1186 Infant Incubator - User Manual (1) (62-78) (05-17)alexis Ramirez100% (1)

- Cobas c311Document5 pagesCobas c311riri100% (1)

- Hemocue HB 201+ Cleaning and Maintenance: Page 1 of 3Document3 pagesHemocue HB 201+ Cleaning and Maintenance: Page 1 of 3JUAN ISAINo ratings yet

- Standard Operating Procedure For Cleaning of Microbiological LabDocument5 pagesStandard Operating Procedure For Cleaning of Microbiological LabMohsin AliNo ratings yet

- AwDocument3 pagesAwluis angel chuquispuma garciaNo ratings yet

- Ins Allersnap Rev I All LanguagesDocument10 pagesIns Allersnap Rev I All LanguagesJuan Carlos QuilaNo ratings yet

- Pool Maintenance: A Complete Beginners GuideFrom EverandPool Maintenance: A Complete Beginners GuideRating: 4 out of 5 stars4/5 (1)

- Seminar ReportDocument29 pagesSeminar ReportUrja DhabardeNo ratings yet

- Affidavit of Disinterested PersonDocument2 pagesAffidavit of Disinterested PersonDexter John SuyatNo ratings yet

- Digital Electronics: Course Description and ObjectivesDocument3 pagesDigital Electronics: Course Description and ObjectivesMaxNo ratings yet

- The Verb Have GotDocument2 pagesThe Verb Have GotIsabel Dias100% (1)

- Control Your Advantages With Unimac Washers: Features Unilinc™ T-Series M30 M9 M4 Ux P-SeriesDocument2 pagesControl Your Advantages With Unimac Washers: Features Unilinc™ T-Series M30 M9 M4 Ux P-SeriesAdrianaMtzRNo ratings yet

- A Study of Consumer Preferences Towards FrootiDocument11 pagesA Study of Consumer Preferences Towards Frootisidyans12No ratings yet

- Research On Administrative CompetenceDocument2 pagesResearch On Administrative Competencehastim rosianaNo ratings yet

- My Personal Learning GoalsDocument2 pagesMy Personal Learning GoalsAva HalloranNo ratings yet

- CreativityDocument10 pagesCreativitySamithaDYNo ratings yet

- Robotic Aid For Commando OperationDocument23 pagesRobotic Aid For Commando OperationShafi PulikkalNo ratings yet

- Karnataka Minimum Wages For The Year 2021Document1 pageKarnataka Minimum Wages For The Year 2021Anusree RoyNo ratings yet

- Concrete Technology Homework 2 PDFDocument3 pagesConcrete Technology Homework 2 PDFXiaoman TuNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- Mousa 2015Document16 pagesMousa 2015Mohammed YahyaNo ratings yet

- 3kV Cabinet Housed Traction RectifierDocument4 pages3kV Cabinet Housed Traction Rectifierandy_mickNo ratings yet

- Sample Resume ITMDocument2 pagesSample Resume ITMRajveer RajNo ratings yet

- Ijert Ijert: Design of 6 Bit Vedic Multiplier Using Vedic SutraDocument8 pagesIjert Ijert: Design of 6 Bit Vedic Multiplier Using Vedic Sutraerparveenkaur86No ratings yet

- Unit 3 HTML - RM - PDFDocument41 pagesUnit 3 HTML - RM - PDFlucifermorningstar2092000No ratings yet

- Prefect Handbook 2015Document10 pagesPrefect Handbook 2015Patience NgwatoNo ratings yet

- Multiple Choice Questions: Chronic Obstructive Pulmonary Disease and Anaesthesia Anaesthesia For Awake CraniotomyDocument4 pagesMultiple Choice Questions: Chronic Obstructive Pulmonary Disease and Anaesthesia Anaesthesia For Awake CraniotomyEliza AmandoNo ratings yet

- Afar 2704 Home Office Branch AgencyDocument33 pagesAfar 2704 Home Office Branch Agencylijeh312No ratings yet

- Woosung LOVD 36Document52 pagesWoosung LOVD 36sayeem bikashNo ratings yet

- BLP EntrepDocument3 pagesBLP EntrepGlaiza Dalayoan Flores100% (1)

- Analysis of Balance Sheet and Calculation of PBFDocument9 pagesAnalysis of Balance Sheet and Calculation of PBFverinderksharmaNo ratings yet

Hisopos ATP Liquidos

Hisopos ATP Liquidos

Uploaded by

Neidy FloresOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hisopos ATP Liquidos

Hisopos ATP Liquidos

Uploaded by

Neidy FloresCopyright:

Available Formats

Liquid Sampling Device

GENERAL DESCRIPTION device washing the sample off the swab tip and into the

collection tube.

The LIGHTNING MVP ICON Liquid Sampling Device is a self‐

contained device for the analysis of liquid samples (i.e. rinse (b) Insert the liquid sampling device into the MVP ICON or

water) using the LIGHTNING MVP ICON™ or LIGHTNING MVP® MVP and read the results. When inserting in the MVP

systems. The MVP ICON and MVP systems detect food and ICON, ensure the flat sides of the sampling device base

microbiological residue by measuring Adenosine triphosphate chamber face left and right in the instrument.

(ATP) using luciferase bioluminescence. ATP is found in most Note: Results should be read within two minutes of

food residues and all bacteria, yeast and mold cells. activation. Please refer to the MVP ICON User Guide or MVP

Part No. 64004‐100 (100 tests) System Guide for operating instructions.

KIT COMPONENTS INTERPRETING RESULTS

One box of 100 liquid sampling devices Always run background controls prior to testing liquid

samples (see Background Control) as the default pass/fail

IMPORTANT USAGE GUIDELINES thresholds may not apply. Samples that give a reading 0.5

It is critical to insert the sampling device Zones over the background control indicate a positive result.

into the MVP ICON with the two flat (a) If the background control tests below 2.1 Zones,

Flat Side

sides of the sampling device’s base BioControl recommends using a minimum cutoff of 2.6

chamber facing left and right. Improper Zones for a positive result.

sampling device orientation may result in

damage to the instrument. (b) Negative results may read the same as background

results.

Do not insert wet or contaminated

sampling devices into the instrument. Wipe condensate from CONTROLS

exterior of device before use with a clean, lint‐free cloth.

Controls should be run prior to testing certain liquid samples

Avoid handling the device with wet or contaminated hands.

(e.g. rinse water) to establish baselines.

Always remove sampling devices from instrument after

reading.

A. Background Control: The Zone reading found with

source water indicates the baseline reading. Running

Do not store the MVP ICON or MVP instrument on its side or background controls every day prior to testing is

back. Avoid storing in humid areas where water leaks are recommended.

possible.

B. Positive Control: A vial of LIGHTNING MVP ICON ATP

TEST PROCEDURE Positive Control (Part No. 64001‐25) is reconstituted with 80

µL of tap water.

A. Collecting Sample

(a) To do so, remove and discard the positive control vial cap

(a) Twist to remove liquid sampling device from body tube.

and add 80 µL of tap water. Let stand for one minute.

The swab tip will be dry. Be careful not to touch the tip

or inside the liquid test device with fingers. (b) Swirl gently at least five times to mix.

(b) Insert the swab tip into the liquid sample until tip is fully (c) Insert MVP ICON Liquid Sampling Device swab tip and

submerged. Hold the tip in the sample for 5 seconds. The follow positive control instructions for use. The expected

MVP ICON Liquid Sampling Device will capture 100 µL of reading should be between 3.1 – 4.3 Zones.

sample in the swab tip. Reinsert the liquid sampling

device into the body tube using a twisting motion to

PRECAUTIONS

ensure it is sealed. If sanitizers are used as a final rinse solution, test 100 µL of

Note: After swabbing the liquid sample, device is stable for the sanitizer at working concentration from CIP system prior

one hour prior to activation and reading results. to flushing processing lines. Results should be within 0.2

Zones of the background control.

B. Activating Device

The appearance of a yellow band on the tip is normal and will

(a) To activate the liquid sampling device, hold upright and not affect performance.

push the plunger down until it is fully depressed. The

If accidental activation prior to sample collection occurs, do

reagents will be dispensed through the liquid sampling

not use the sampling device.

Hold sampling device upright when activating.

Always insert the sampling device into the MVP ICON with

the base chamber’s two flat sides facing left‐to‐right.

Read sampling device within two minutes of activation.

Exterior surfaces of sampling device must be dry before

inserting into the MVP ICON or MVP system.

When reading the sampling device, the MVP ICON or MVP

must be kept upright (no greater than a 45° angle). See MVP

ICON User Guide or MVP System Guide for additional

information.

STORAGE

Sampling devices should be stored at a temperature between

2 ºC – 30 ºC (36 ºF – 86 ºF). Protect from direct sunlight.

Unused devices must be resealed in the foil bags.

WARRANTY

BioControl Systems, Inc. (BCS) warrants this product to be

free from defects in materials and workmanship, when stored

under labeled conditions and used as intended until the

expiration of the date stated on the package. BCS agrees

during the applicable warranty period to replace all defective

products after return to BCS. BCS shall not have obligation

under this Limited Warranty to make replacements which

result, in whole or in part, from negligence of the Buyer, or

from improper use of the products, or use of the product in a

manner for which it was not indicated. Buyer shall notify BCS

of any products which it believes to be defective during the

warranty period. At BCS option, such products shall be

returned to BCS, transportation and insurance prepaid. BCS

shall replace any such product found to be defective, at no

charge. Should BCS examination not disclose any defect

covered by the foregoing warranty, BCS shall so advise Buyers

and dispose of the product in accordance with Buyer’s

instructions.

©BioControl Systems, Inc. 2013. Printed in USA. LIGHTNING

MVP ICON is a trademark of BioControl, pending registration.

LIGHTNING MVP is a registered trademark of BioControl. US

patents No. 7,399,984; 7,544,961; 7,030,403; 6924498.

Australian patents 2002357107; 2003231770. New Zealand

patents 533051, 535819. Japanese patents 4,467,304;

4,431,034. Mexico patents 259897; 246269; 272356. All rights

reserved.

IF YOU REQUIRE MORE INFORMATION ABOUT THE

LIGHTNING MVP ICON LIQUID SAMPLING DEVICE, ITS USE OR

OTHER BIOCONTROL PRODUCTS, PLEASE CONTACT:

Part No. 64004‐100

55230.R001.052015

You might also like

- Olt AbencoadaDocument2 pagesOlt AbencoadaRamon ProduçõesNo ratings yet

- Lab Policies Cobas C311 Routine Operation Lab 4014 PDFDocument3 pagesLab Policies Cobas C311 Routine Operation Lab 4014 PDFATUL DESHMUKH33% (3)

- Scrib 2Document4 pagesScrib 2Aldwin Abidin50% (2)

- Design Solutions and Innovations in Temporary Structures Robert BealeDocument518 pagesDesign Solutions and Innovations in Temporary Structures Robert Bealerenzo divendra100% (1)

- Aqualab Series 3 Water Activity Meter Standard Operating ProcedureDocument4 pagesAqualab Series 3 Water Activity Meter Standard Operating ProcedureCarlos CastroNo ratings yet

- Stago Satellite User GuideDocument14 pagesStago Satellite User GuideT86% (7)

- (Geoff Reiss) Programme Management Demystified Ma (BookFi) PDFDocument272 pages(Geoff Reiss) Programme Management Demystified Ma (BookFi) PDFWinarti Nur SetiawatiNo ratings yet

- List of Filipino ArchitectsDocument12 pagesList of Filipino ArchitectsSussybelle Bandoy100% (2)

- Maggi ComebackDocument7 pagesMaggi ComebackAnikNo ratings yet

- ATP AquaSnap Free TotalDocument3 pagesATP AquaSnap Free TotalGeoff EricksonNo ratings yet

- CareStart Training Slides 002 719655 7Document18 pagesCareStart Training Slides 002 719655 7Luis SanchezNo ratings yet

- CobasDocument3 pagesCobaskigm mkj100% (1)

- DigitalRefractometer CareMaintenance 2015 11Document4 pagesDigitalRefractometer CareMaintenance 2015 11ATWIINE LURVIN ELISHANo ratings yet

- Immulite 2000 Top: 1. Principle: The IMMULITE 2000 Automated Immunoassay Analyzer IsDocument3 pagesImmulite 2000 Top: 1. Principle: The IMMULITE 2000 Automated Immunoassay Analyzer IsFaryalBalochNo ratings yet

- DownloadDocument1 pageDownloadfreedNo ratings yet

- Monitor Wellch Allyn-101-150Document50 pagesMonitor Wellch Allyn-101-150jmsm22No ratings yet

- User MaintenanceDocument3 pagesUser Maintenancenidhal amamiNo ratings yet

- 2013-013-00 Rev ZD JOULE Operator Manual LR (2) Sterilization RCADocument3 pages2013-013-00 Rev ZD JOULE Operator Manual LR (2) Sterilization RCAEsteban PradaNo ratings yet

- Ultrasnap Surface Atp Test: For Use With Hygiena Atp Monitoring SystemsDocument10 pagesUltrasnap Surface Atp Test: For Use With Hygiena Atp Monitoring Systemsmoh.elmourabitNo ratings yet

- Protocols Cleaning Disinfection SterilizationDocument23 pagesProtocols Cleaning Disinfection SterilizationGeneSegoviaNo ratings yet

- Chapter 6 Maintenance, Cleaning and DisinfectionDocument18 pagesChapter 6 Maintenance, Cleaning and DisinfectionArrigo PrietoNo ratings yet

- BC-5000&BC-5150 Operation Instructions and Precautions V1.0 enDocument2 pagesBC-5000&BC-5150 Operation Instructions and Precautions V1.0 enJose Rolando Orellana RodriguezNo ratings yet

- Afinion HbA1c Quick GuideDocument2 pagesAfinion HbA1c Quick GuideShadi MahmoudNo ratings yet

- Cleantrace Surface ATP Hygiene Prod InsertDocument13 pagesCleantrace Surface ATP Hygiene Prod Insertvictoria.ricolactNo ratings yet

- AutoQuant 100i Operator ManualDocument96 pagesAutoQuant 100i Operator ManualFermin Tafur LliuyaNo ratings yet

- Ins Proclean Rev G All LanguagesDocument10 pagesIns Proclean Rev G All LanguagesBerry CheraNo ratings yet

- SOP For UV-Vis SpectrophotometerDocument7 pagesSOP For UV-Vis SpectrophotometerArchana PatraNo ratings yet

- Fiber Optic Laryngoscope Handles Directions For UseDocument7 pagesFiber Optic Laryngoscope Handles Directions For UseManuel FloresNo ratings yet

- ATP AquaSnap Free TotalDocument10 pagesATP AquaSnap Free TotalWilfried ApianeNo ratings yet

- Catalyst One Quick Reference Guide enDocument1 pageCatalyst One Quick Reference Guide enbiomedicaNo ratings yet

- BI-W-116B RAPIDPOINT 500 Blood Gas Education - RCHDocument2 pagesBI-W-116B RAPIDPOINT 500 Blood Gas Education - RCHنجلاء الطلحيNo ratings yet

- Standard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisDocument11 pagesStandard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisAbuNo ratings yet

- Standard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisDocument11 pagesStandard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisAbuNo ratings yet

- Conv - INIFU SunMed Conventional Reusable Laryngoscope Rev.2Document2 pagesConv - INIFU SunMed Conventional Reusable Laryngoscope Rev.2Maria Jose Marin Castaño100% (1)

- Ins0079 - Snapshot Hy Lite Rev CDocument1 pageIns0079 - Snapshot Hy Lite Rev CRustam AlyaskarovNo ratings yet

- CHM 421 - Topic 2Document97 pagesCHM 421 - Topic 2CtNo ratings yet

- Spirolab: UK Version - User ManualDocument40 pagesSpirolab: UK Version - User ManualMuhammad awaludin syahNo ratings yet

- CS-T240Plus Maintenance ManualDocument3 pagesCS-T240Plus Maintenance ManualAlbeiro PiraquiveNo ratings yet

- eCL8000 Maintenance GuideDocument24 pageseCL8000 Maintenance Guidegerente soportecNo ratings yet

- v03 Afinion Lipid Panel Quick Guide - AfinioDocument2 pagesv03 Afinion Lipid Panel Quick Guide - AfinioShadi MahmoudNo ratings yet

- 86831F BioSonic UC125 OGDocument70 pages86831F BioSonic UC125 OGAdolfoNo ratings yet

- ENG - Syringe Pump Cleaning and Disinfection Protocol-20200331Document1 pageENG - Syringe Pump Cleaning and Disinfection Protocol-20200331Farrel AlfayyedNo ratings yet

- Welch Allyn 60300 Standard Laryngoscope Handles Instruction ManualDocument5 pagesWelch Allyn 60300 Standard Laryngoscope Handles Instruction ManualA. A.G.No ratings yet

- CS-T240Plus Operation ManualDocument2 pagesCS-T240Plus Operation ManualAlbeiro PiraquiveNo ratings yet

- Shutdown and Startup SummaryDocument18 pagesShutdown and Startup SummaryRicardo RicardoNo ratings yet

- Routine Cleaning of ACQUITY UPC SystemsDocument1 pageRoutine Cleaning of ACQUITY UPC Systemseelainemartins.oNo ratings yet

- Endoscopes Lab 4Document24 pagesEndoscopes Lab 4Baron WhitNo ratings yet

- 710 03 - 04dynabeads Anti Ecoli O157 (Rev010)Document2 pages710 03 - 04dynabeads Anti Ecoli O157 (Rev010)pratechNo ratings yet

- Lx400 ManualDocument27 pagesLx400 ManualDiana MirandaNo ratings yet

- BS3000MDocument15 pagesBS3000MAjay Narayan SharmaNo ratings yet

- CHM 421 - Topic 2Document94 pagesCHM 421 - Topic 2Najmi NasirNo ratings yet

- B40 Limpieza y Mantenimiento PDFDocument11 pagesB40 Limpieza y Mantenimiento PDFArea Biomedica Clinica BaruNo ratings yet

- Elf 51Document3 pagesElf 51ShimaaNo ratings yet

- Immulite 2000 Xpi Demo Script7-13 FinalDocument6 pagesImmulite 2000 Xpi Demo Script7-13 FinalОлександр100% (3)

- DXC 700 Au Daily Startup: Set A New Index Set A New IndexDocument2 pagesDXC 700 Au Daily Startup: Set A New Index Set A New IndexGassem SumiliNo ratings yet

- Flow Sensor Addendum UM 2095125-MULTI CDocument371 pagesFlow Sensor Addendum UM 2095125-MULTI CTuấn NôngNo ratings yet

- 05 - Ch-01 unit name 0318Document7 pages05 - Ch-01 unit name 0318Nguyễn Danh DungNo ratings yet

- Quick Guide NanodropDocument3 pagesQuick Guide Nanodropsk_bravoNo ratings yet

- Fanem 1186 Infant Incubator - User Manual (1) (62-78) (05-17)Document13 pagesFanem 1186 Infant Incubator - User Manual (1) (62-78) (05-17)alexis Ramirez100% (1)

- Cobas c311Document5 pagesCobas c311riri100% (1)

- Hemocue HB 201+ Cleaning and Maintenance: Page 1 of 3Document3 pagesHemocue HB 201+ Cleaning and Maintenance: Page 1 of 3JUAN ISAINo ratings yet

- Standard Operating Procedure For Cleaning of Microbiological LabDocument5 pagesStandard Operating Procedure For Cleaning of Microbiological LabMohsin AliNo ratings yet

- AwDocument3 pagesAwluis angel chuquispuma garciaNo ratings yet

- Ins Allersnap Rev I All LanguagesDocument10 pagesIns Allersnap Rev I All LanguagesJuan Carlos QuilaNo ratings yet

- Pool Maintenance: A Complete Beginners GuideFrom EverandPool Maintenance: A Complete Beginners GuideRating: 4 out of 5 stars4/5 (1)

- Seminar ReportDocument29 pagesSeminar ReportUrja DhabardeNo ratings yet

- Affidavit of Disinterested PersonDocument2 pagesAffidavit of Disinterested PersonDexter John SuyatNo ratings yet

- Digital Electronics: Course Description and ObjectivesDocument3 pagesDigital Electronics: Course Description and ObjectivesMaxNo ratings yet

- The Verb Have GotDocument2 pagesThe Verb Have GotIsabel Dias100% (1)

- Control Your Advantages With Unimac Washers: Features Unilinc™ T-Series M30 M9 M4 Ux P-SeriesDocument2 pagesControl Your Advantages With Unimac Washers: Features Unilinc™ T-Series M30 M9 M4 Ux P-SeriesAdrianaMtzRNo ratings yet

- A Study of Consumer Preferences Towards FrootiDocument11 pagesA Study of Consumer Preferences Towards Frootisidyans12No ratings yet

- Research On Administrative CompetenceDocument2 pagesResearch On Administrative Competencehastim rosianaNo ratings yet

- My Personal Learning GoalsDocument2 pagesMy Personal Learning GoalsAva HalloranNo ratings yet

- CreativityDocument10 pagesCreativitySamithaDYNo ratings yet

- Robotic Aid For Commando OperationDocument23 pagesRobotic Aid For Commando OperationShafi PulikkalNo ratings yet

- Karnataka Minimum Wages For The Year 2021Document1 pageKarnataka Minimum Wages For The Year 2021Anusree RoyNo ratings yet

- Concrete Technology Homework 2 PDFDocument3 pagesConcrete Technology Homework 2 PDFXiaoman TuNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- Mousa 2015Document16 pagesMousa 2015Mohammed YahyaNo ratings yet

- 3kV Cabinet Housed Traction RectifierDocument4 pages3kV Cabinet Housed Traction Rectifierandy_mickNo ratings yet

- Sample Resume ITMDocument2 pagesSample Resume ITMRajveer RajNo ratings yet

- Ijert Ijert: Design of 6 Bit Vedic Multiplier Using Vedic SutraDocument8 pagesIjert Ijert: Design of 6 Bit Vedic Multiplier Using Vedic Sutraerparveenkaur86No ratings yet

- Unit 3 HTML - RM - PDFDocument41 pagesUnit 3 HTML - RM - PDFlucifermorningstar2092000No ratings yet

- Prefect Handbook 2015Document10 pagesPrefect Handbook 2015Patience NgwatoNo ratings yet

- Multiple Choice Questions: Chronic Obstructive Pulmonary Disease and Anaesthesia Anaesthesia For Awake CraniotomyDocument4 pagesMultiple Choice Questions: Chronic Obstructive Pulmonary Disease and Anaesthesia Anaesthesia For Awake CraniotomyEliza AmandoNo ratings yet

- Afar 2704 Home Office Branch AgencyDocument33 pagesAfar 2704 Home Office Branch Agencylijeh312No ratings yet

- Woosung LOVD 36Document52 pagesWoosung LOVD 36sayeem bikashNo ratings yet

- BLP EntrepDocument3 pagesBLP EntrepGlaiza Dalayoan Flores100% (1)

- Analysis of Balance Sheet and Calculation of PBFDocument9 pagesAnalysis of Balance Sheet and Calculation of PBFverinderksharmaNo ratings yet