Professional Documents

Culture Documents

CERTILAS EN Edition2023 316

CERTILAS EN Edition2023 316

Uploaded by

Alireza KhodabandehOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CERTILAS EN Edition2023 316

CERTILAS EN Edition2023 316

Uploaded by

Alireza KhodabandehCopyright:

Available Formats

back to chapter overview / all chapters

1 STICK ELECTRODES

TYPE EN -ISO and ASME -AWS MECHANICAL

PROPERTIES

ANALYSIS APPLICATION

9. FOR HEAT-RESISTANT STAINLESS STEEL

CEWELD 9606-1: FM5 T ~ 700 MPa C < 0,15 4820-AC is a rutile-basic electrode for joint- and hard face welding on equal or 25% Cr

4820 AC 3581-A: Y > 500 MPa Mn 0,5 - 2,5 alloys. The weld-deposit is resistant to air and exhaust gases up to 1150 °C. Also in a

E 25 4 R 32 E > 20% Cr 24 - 27 sulphuric environment at high temperatures.

I > 27J (20 °C) Ni 4,0 - 6,0

180 HB

CEWELD 9606-1: FM5 T ~ 550 MPa C < 0,04 4332-R is suitable for joining heat resistant CrNi-steels of the same kind and also

4332 R Sect IX QW-432: F-No. 4 Y > 400 MPa Mn 0,5 - 2,5 joining dissimilar metals such as steel to stainless steel. Cladding on low alloyed steels

3581-A: E > 30% Cr 22 - 23 in case a 18/8 CrNi layer is required in the first layer. Scale resistant up to 1050 °C.

E 23 12 LR 32 I > 47J (20 °C) Ni 11 - 14 W.no: 1.4541, 1.4550, 1.4710, 1.4712, 1.4727, 1.4729, 1.4740, 1.4742, 1.4780, 1.4825,

A 5.4: Si < 1,2 1.4826, 1.4828, 1.4878

E 309L-17

CEWELD 9606-1: FM5 T ~ 550 MPa C < 0,04 4332-Ti is a rutile basic electrode for joining heat resistant CrNi-steels of the same

4332 Ti Sect IX QW-432: F-No. 1 Y > 400 MPa Mn 0,5 - 2,5 kind and also joining dissimilar metals such as steel to stainless steel. Cladding on low

3581-A: E > 30% Cr 22 - 23 alloyed steels in case a 18/8 CrNi layer is required in the first layer. Scale resistant up

E 23 12 LR 32 I > 55J (20 °C) Ni 11 - 14 to 1050 °C.

A 5.4: Si < 1,2 W.no: 1.4541, 1.4550, 1.4710, 1.4712, 1.4727, 1.4729, 1.4740, 1.4742, 1.4780, 1.4825,

E 309L-26 1.4826, 1.4828, 1.4878

CEWELD 9606-1: FM5 T ~ 650 MPa C < 0,12 4829-MoTi is suitable for joining heat resistant CrNi(Mo)-steels of the same kind and

4829 MoTi Sect IX QW-432: F-No. 1 Y > 480 MPa Mn 0,5 - 2,5 also joining dissimilar alloys such as steel to stainless steel. Cladding on low alloyed

3581-A: E > 25% Cr 23 - 25 steels in case a 18/8/2 CrNiMo layer is required in the first layer.

E 23 12 2 LR 32 I > 32J (-20 °C) Ni 13 - 14 W.no: 1.4401, 1.4404, 1.4406, 1.4410, 1.4437, 1.4571, 1.4580

A 5.4: Mo 2,0 - 3,0

E 309Mo-26

CEWELD 9606-1: FM5 T ~ 600 MPa C 0,06 - 0,2 4842-Ti is a rutile/basic electrode for welding heat-resistant austenitic steels of the 25%

4842 Ti Sect IX QW-432: F-No. 4 Y > 410 MPa Mn 1,0 - 2,5 Cr, 20% Ni types. Scale resistance up to 1150 °C. No resistance in sulphuric environ-

3581-A: E > 29% Cr 25 - 27 ments. This alloy can withstand relatively severe thermal shock, and is superior to type

E 25 20 R 32 I > 70J (20 °C) Ni 20 - 22 309 L.

A 5.4: Si < 0,75 W.no:1.4823, 1.4826, 1.4828, 1.4832, 1.4840, 1.4841, 1.4846, 1.4848, 1.4837, 1.4710,

E 310-16 Mo < 0,75 1.4713, 1.4724, 1.4726, 1.4742, 1.4745, 1.4762, 1.4845, 1.4849

CEWELD 9606-1: FM5 T ~ 650 MPa C 0,06 - 0,2 4842 Kb is a basic electrode for welding heat-resistant austenitic steels of the 25% Cr,

4842 Kb Sect IX QW-432: F-No. 4 Y > 410 MPa Mn 1,0 - 2,5 20% Ni types. Scale resistance up to 1150 °C. No resistance in sulphuric environ-

3581-A: E > 29% Cr 25 - 27 ments. This alloy can withstand relatively severe thermal shock, and is superior to type

E 25 20 B 12 I > 70J (20 °C) Ni 20 - 22 309 L.

A 5.4: I > 32J (-196 °C) Si < 0,75 W.no: 1.4823, 1.4826, 1.4828, 1.4832, 1.4840, 1.4841, 1.4846, 1.4848, 1.4837, 1.4710,

E 310-15 Mo < 0,75 1.4713, 1.4724, 1.4726, 1.4742, 1.4745, 1.4762, 1.4845, 1.4849 heat resistant stain-

less steel, AISI 305, 310, 314, ASTM A297 HF, A297 HJ

CEWELD 9606-1: FM5 T ~ 600 MPa C 0,12 - 0,18 4850 Kb offers high corrosion resistance and excellent weldability on both AC and DC+.

4850 Kb 3581-A: Y > 380 MPa Cr 21 - 23 The weld deposit is scale resistant up to 1050 ºC.

~EZ 21 33 Nb B 32 E > 25% Ni 32 - 35 W.no: 1.4859 – GX10NiCrNb32-20; 1.4876 – X10NiCrAlTi32-20; X10NiCrAlTi32-20 –

I > 50J (20 °C) Nb 0,9 –1,2 Alloy 800 H, 1.4861

Mn ~ 4,5

CEWELD 9606-1: FM5 T ~ 700 MPa C 0,3 - 0,5 4853 Kb is suitable for joining and cladding high heat resistant CrNi-steels of the same

4853 Kb 3581-A: Y > 460 MPa Mn 0,9 - 1,1 kind and cast steels in a low sulphuric environment.

~EZ 25 35 Nb B 32 E > 8% Cr 25 - 27 W.no:1.4852, 1.4853 G-X 40 NiCrNb 35 25, 1.4857, G-X 40 NiCrSi 35 25, 1.4837,

Ni 34 - 36 G-X40CrNiSi25-12, 1.4848, G-X40CrNiSi25--20, 1.4849, G-X40NiCr38-18, G-

Si ~ 0,9 X40NiCrNb35-25, cast steels, HK40, HK45, UNS: J93503, J94204, N08705

Nb 1,2 -1,5

1/10

You might also like

- It App Coursera QuizDocument47 pagesIt App Coursera QuizD'Orphic100% (1)

- 824 DQ IQ OQ PQ Protocol Mowden Rev 0Document31 pages824 DQ IQ OQ PQ Protocol Mowden Rev 0Manolo Moreno100% (4)

- Manual Tecnico ZF 4WG-260Document52 pagesManual Tecnico ZF 4WG-260Miguel Bustamante93% (29)

- Airtel - A Case StudyDocument30 pagesAirtel - A Case StudyTanya Dutta57% (7)

- CERTILAS EN Edition2023 315Document1 pageCERTILAS EN Edition2023 315Alireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 313Document1 pageCERTILAS EN Edition2023 313Alireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 314Document1 pageCERTILAS EN Edition2023 314Alireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 320Document1 pageCERTILAS EN Edition2023 320Alireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 318Document1 pageCERTILAS EN Edition2023 318Alireza KhodabandehNo ratings yet

- Fox - FFDocument1 pageFox - FFGustavo NietoNo ratings yet

- Consumables For Duplex Stainless SteelDocument6 pagesConsumables For Duplex Stainless SteelMohamed FaragNo ratings yet

- T Thermanit Nicro 82 Gtaw 01 01 enDocument2 pagesT Thermanit Nicro 82 Gtaw 01 01 enKathir VelNo ratings yet

- UTP For OffshoreDocument16 pagesUTP For Offshorekamals55No ratings yet

- CERTILAS EN Edition2023 312Document1 pageCERTILAS EN Edition2023 312Alireza KhodabandehNo ratings yet

- 5 - Duplex Stainless Steels and Nickel AlloysDocument44 pages5 - Duplex Stainless Steels and Nickel AlloysdennykvgNo ratings yet

- Metrode Cryogenic ER316 B-38Document5 pagesMetrode Cryogenic ER316 B-38Claudia MmsNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Supranox Rs 347: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageSupranox Rs 347: MMA Electrodes Stainless and Heat Resistant SteelsGogo PNo ratings yet

- MIP Bohler Welding Austria 364Document1 pageMIP Bohler Welding Austria 364c131508No ratings yet

- FOX CN 23-12 Mo-ADocument1 pageFOX CN 23-12 Mo-AVIRPOPNo ratings yet

- 78 PDFDocument1 page78 PDFGogo PNo ratings yet

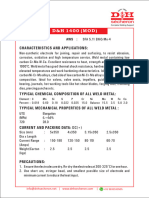

- DH 1400modDocument1 pageDH 1400modGopiNathNo ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- D-Met 04 Welding of Stainless Steels, CI and Dissimilar WeldDocument42 pagesD-Met 04 Welding of Stainless Steels, CI and Dissimilar WeldTrepend Simplifying BusinessNo ratings yet

- Böhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantDocument1 pageBöhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantSerhii MishchenkoNo ratings yet

- Böhler Nibas 625 PW-FD: DescriptionDocument1 pageBöhler Nibas 625 PW-FD: DescriptionBBalopesabbNo ratings yet

- Fox CN 23-12-ADocument1 pageFox CN 23-12-AVIRPOPNo ratings yet

- Special Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresDocument10 pagesSpecial Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresCarlos PadillaNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- Basinox 318: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageBasinox 318: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Metrode 410NiMo B-11Document4 pagesMetrode 410NiMo B-11Claudia MmsNo ratings yet

- MIG 80SB2: ClassificationDocument1 pageMIG 80SB2: ClassificationElMacheteDelHuesoNo ratings yet

- 308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsDocument1 page308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsFilipe CordeiroNo ratings yet

- Carbo 4842 Ac-E310Document1 pageCarbo 4842 Ac-E310ali torabiNo ratings yet

- UTP For Chemical IndustryDocument12 pagesUTP For Chemical Industrykamals55No ratings yet

- Utp 63Document1 pageUtp 63Eileen TylerNo ratings yet

- Selectarc Selectarc Selectarc Selectarc: Inox 2509mobDocument1 pageSelectarc Selectarc Selectarc Selectarc: Inox 2509mobGogo PNo ratings yet

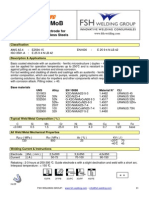

- FSH TigDocument105 pagesFSH TigChee WeiNo ratings yet

- 2005 Stainless SteelsDocument76 pages2005 Stainless SteelsAnonymous 98vSKYTaDgNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- UTP Chemical GBDocument12 pagesUTP Chemical GBajaychackotecsoNo ratings yet

- Avesta 2205 AC DCDocument1 pageAvesta 2205 AC DCpipedown456No ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- Thermanit Nicro 82: TIG Rods, Nickel-AlloyDocument2 pagesThermanit Nicro 82: TIG Rods, Nickel-AlloyMaximiliano Ezequiel LopezNo ratings yet

- Classifications: For Atmospheric Corrosion Resisting SteelDocument1 pageClassifications: For Atmospheric Corrosion Resisting Steelhuynh thanh truongNo ratings yet

- L1 12783 en Thermanit 25 09 CuT 1SC6A00G 3394780 ENDocument1 pageL1 12783 en Thermanit 25 09 CuT 1SC6A00G 3394780 ENcycsi02No ratings yet

- Product Data Sheet OK Tigrod 13.09: W 'Tungsten Inert Gas Arc Welding'Document2 pagesProduct Data Sheet OK Tigrod 13.09: W 'Tungsten Inert Gas Arc Welding'Adis ZenNo ratings yet

- S-23804-Eng - 22 12 HTDocument2 pagesS-23804-Eng - 22 12 HTbiliboi5No ratings yet

- Product Data Sheet OK Tigrod 316L: W 'Tungsten Inert Gas Arc Welding'Document2 pagesProduct Data Sheet OK Tigrod 316L: W 'Tungsten Inert Gas Arc Welding'soft4gsmNo ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- EJ Handbook.A5Document261 pagesEJ Handbook.A5ElMacheteDelHuesoNo ratings yet

- Esab DublexDocument8 pagesEsab DublexSuphi YükselNo ratings yet

- Tig Welding W19 12 3 LSiDocument2 pagesTig Welding W19 12 3 LSiKoen BidlotNo ratings yet

- Welding PresentationDocument48 pagesWelding Presentationedu_canete100% (2)

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- item8-LNT NiCro60.20Document1 pageitem8-LNT NiCro60.20VVan TanNo ratings yet

- Böhler Foxa7 Fox A 7Cn: DescriptionDocument1 pageBöhler Foxa7 Fox A 7Cn: Description2003vinayNo ratings yet

- L1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1Document1 pageL1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1cristian popescuNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- 23Document1 page23Alireza KhodabandehNo ratings yet

- Wall Thickness and Material Grade Selection: GeneralDocument1 pageWall Thickness and Material Grade Selection: GeneralAlireza KhodabandehNo ratings yet

- Rec Erc 84 329Document1 pageRec Erc 84 329Alireza KhodabandehNo ratings yet

- Untitled 3Document1 pageUntitled 3Alireza KhodabandehNo ratings yet

- Bending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiDocument1 pageBending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- Finite Element Analysis: Pipeline Installation by Tow or PullDocument1 pageFinite Element Analysis: Pipeline Installation by Tow or PullAlireza KhodabandehNo ratings yet

- References: 20 Qiang Bai and Yong BaiDocument1 pageReferences: 20 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- Untitled 2Document1 pageUntitled 2Alireza KhodabandehNo ratings yet

- 16 Qiang Bai and Yong Bai: Pipeline InstallationDocument1 page16 Qiang Bai and Yong Bai: Pipeline InstallationAlireza KhodabandehNo ratings yet

- Untitled 1Document1 pageUntitled 1Alireza KhodabandehNo ratings yet

- Pipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleDocument1 pagePipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleAlireza KhodabandehNo ratings yet

- Rec Erc 84 317Document1 pageRec Erc 84 317Alireza KhodabandehNo ratings yet

- Rec Erc 84 332Document1 pageRec Erc 84 332Alireza KhodabandehNo ratings yet

- Rec Erc 84 334Document1 pageRec Erc 84 334Alireza KhodabandehNo ratings yet

- Untitled 6Document1 pageUntitled 6Alireza KhodabandehNo ratings yet

- Rec Erc 84 322Document1 pageRec Erc 84 322Alireza KhodabandehNo ratings yet

- Rec Erc 84 311Document1 pageRec Erc 84 311Alireza KhodabandehNo ratings yet

- Rec Erc 84 313Document1 pageRec Erc 84 313Alireza KhodabandehNo ratings yet

- Rec Erc 84 35Document1 pageRec Erc 84 35Alireza KhodabandehNo ratings yet

- Rec Erc 84 315Document1 pageRec Erc 84 315Alireza KhodabandehNo ratings yet

- Rec Erc 84 36Document1 pageRec Erc 84 36Alireza KhodabandehNo ratings yet

- Rec Erc 84 38Document1 pageRec Erc 84 38Alireza KhodabandehNo ratings yet

- Fig. 1.8 A Proposed Circuit Diagram, B Parallel Connection of Four SPHDocument1 pageFig. 1.8 A Proposed Circuit Diagram, B Parallel Connection of Four SPHAlireza KhodabandehNo ratings yet

- Rec Erc 84 33Document1 pageRec Erc 84 33Alireza KhodabandehNo ratings yet

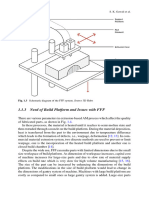

- Investigations On The Development of Heated Build Platform For Additive Manufacturing of Large-Size PartsDocument1 pageInvestigations On The Development of Heated Build Platform For Additive Manufacturing of Large-Size PartsAlireza KhodabandehNo ratings yet

- 14 S. K. Gawali Et AlDocument1 page14 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- 1.2.1 Design Methodology: 6 S. K. Gawali Et AlDocument1 page1.2.1 Design Methodology: 6 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- 1.3 Characterization of Developed Build Platform: 1.3.1 Temperature Distribution TestingDocument1 page1.3 Characterization of Developed Build Platform: 1.3.1 Temperature Distribution TestingAlireza KhodabandehNo ratings yet

- 2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingDocument1 page2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingAlireza KhodabandehNo ratings yet

- 1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlDocument1 page1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- HW4 Solutions 2014 2Document15 pagesHW4 Solutions 2014 2Kallu Badmash100% (2)

- Final Exam Mass Transfer (7oct2020)Document16 pagesFinal Exam Mass Transfer (7oct2020)Nurul IzzatiNo ratings yet

- bq25896 etcTIDocument64 pagesbq25896 etcTIyuni supriatinNo ratings yet

- Contextual Analysis of Renato Constantino's "Veneration Without Understanding"Document3 pagesContextual Analysis of Renato Constantino's "Veneration Without Understanding"3rddi S.No ratings yet

- Unit 0 - Prioritize - Reasonable Adjustments and Special Considerations PolicyDocument4 pagesUnit 0 - Prioritize - Reasonable Adjustments and Special Considerations PolicyChloe ReyesNo ratings yet

- Clutches Brakes CtenDocument156 pagesClutches Brakes CtenRiz WanNo ratings yet

- Energy Savings Through Retrofit From Constant-Volume Terminal Reheat To Variable Air Volume SystemDocument5 pagesEnergy Savings Through Retrofit From Constant-Volume Terminal Reheat To Variable Air Volume Systemmashark2610No ratings yet

- Nigeria Energy 2023 Leadership Summit Post Conference ProceedingsDocument14 pagesNigeria Energy 2023 Leadership Summit Post Conference ProceedingsAfrah SaiboNo ratings yet

- Business Model Innovation in A Circular Economy Reasons For Non-Acceptance of Circular Business ModelsDocument12 pagesBusiness Model Innovation in A Circular Economy Reasons For Non-Acceptance of Circular Business ModelsAndres ValdezNo ratings yet

- Mathematics Es1 Scope and Sequence Approach 1Document9 pagesMathematics Es1 Scope and Sequence Approach 1Jobelle De Vera TayagNo ratings yet

- Part 3 (CLO3) : Complexity of AlgorithmDocument9 pagesPart 3 (CLO3) : Complexity of AlgorithmengrrhasanNo ratings yet

- ATP Star DPP Math 2Document360 pagesATP Star DPP Math 2shriteshNo ratings yet

- Cost and Management Accounting Individual AssignmentDocument3 pagesCost and Management Accounting Individual AssignmentKIASHA NAIDUNo ratings yet

- Methodology For Product Design PDFDocument45 pagesMethodology For Product Design PDFCherun ChesilNo ratings yet

- Past 3 ManualDocument275 pagesPast 3 ManualdrtareksNo ratings yet

- On Of: Final Report The Safety Assessment TEA-Lauryl SulfateDocument25 pagesOn Of: Final Report The Safety Assessment TEA-Lauryl SulfateCarlos Gonzalez CastroNo ratings yet

- Schools of PsychopathologyDocument16 pagesSchools of PsychopathologynasibdinNo ratings yet

- PDF The History of Civil Engineering Philippines DDDocument47 pagesPDF The History of Civil Engineering Philippines DDRAIZZNo ratings yet

- Conscience: Mr. Jose A. Procalla JR., MsmeDocument17 pagesConscience: Mr. Jose A. Procalla JR., MsmeStella SalvadorNo ratings yet

- Basics of PythonDocument36 pagesBasics of Python4029 BHARATH KUMAR BNo ratings yet

- Report of Large Motor ReliabilityDocument28 pagesReport of Large Motor Reliabilitythawatchai11222512100% (1)

- Chapter 20 Sustainable Marketing: Social Responsibility and EthicsDocument45 pagesChapter 20 Sustainable Marketing: Social Responsibility and EthicsKAIVALYA PAINo ratings yet

- Nureg 1061 Vol 4Document393 pagesNureg 1061 Vol 4Abhinav OjhaNo ratings yet

- Case Incidents of Chapter 2 ORGANIZATIONAL BEHAVIORDocument16 pagesCase Incidents of Chapter 2 ORGANIZATIONAL BEHAVIORShoumik DassNo ratings yet

- AP Psychology Module 6Document16 pagesAP Psychology Module 6Klein ZhangNo ratings yet

- INT 220 Business Brief Course ProjectDocument5 pagesINT 220 Business Brief Course ProjectTeddy jeremyNo ratings yet