Professional Documents

Culture Documents

GRI HANDBOOK-Installation

GRI HANDBOOK-Installation

Uploaded by

Jovan StefanovicOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GRI HANDBOOK-Installation

GRI HANDBOOK-Installation

Uploaded by

Jovan StefanovicCopyright:

Available Formats

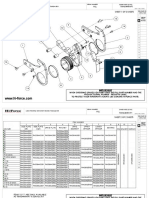

GRI/DURLON - Gasket Installation

GASKET RESOURCES INC.

®

DURLON GASKETING - BOLT TIGHTENING WORK SHEET

Location/Identification: Nominal Bolt Size:

Gasket Contact Surface Finish on Flange: ; Lubricant Used:

(Initial each step.)

1. Visually examine and clean flanges, bolts, nuts and washers. Replace components if necessary.

2. Lubricate bolts, nuts, AND flange surface AROUND BOLT HOLES, or use hardened steel washers.

3. Install new gasket. DO NOT REUSE OLD GASKET, OR USE MULTIPLE GASKETS.

4. Number bolts in cross-pattern sequence according to the appropriate sketch below.

5. IMPORTANT! HAND TIGHTEN; then PRE-TIGHTEN BOLTS to 10/20 FT-LBS torque, but DO NOT

EXCEED 20% of Target Torque.

6. Check gap for uniformity.

7. Use the appropriate cross-pattern tightening sequence in the sketch below for Rounds 1, 2, and 3

and/or Round 4 (each sequence constitutes a “Round”).

1 1 12 1 16 1 12 1 16 24 1

8 20 13 9

8 9 8 17

8 5 8 5

20 5

12 5

5 16 17 12

4 4 13

4 9 4 13 4 9 4 21

10 3 22 3

10 3 14 3

3 3 14 11

6 18 15

6 11 6 19

6 7 6 7

10 7 18 7

14 19

2 2 7 2 11 2 15 2 11

10

2 23 15

4-bolt 8-bolt 12-bolt 16-bolt 20-bolt 24-bolt

• Final Torque: ft-lbs

LUBRICATE, HAND TIGHTEN, PRE-TIGHTEN bolts

• Round 1 - Tighten to ft-lbs - 1st torque value in torque chart* (25% of final torque)

• Round 2 - Tighten to ft-lbs – 2nd torque value in torque chart (50% of final torque)

• Round 3 - Tighten to ft-lbs - Final torque value in torque chart (100% of final torque)

*Refer to torque chart on next page

Check gap around the circumference between each of these rounds, measured at every other bolt. If the

gap is not reasonably uniform around the circumference, make the appropriate adjustments by selective

bolt tightening before proceeding.

Final Rotational Round - 100% of Final Torque (same as Round 3 or 4 above). Use ROTATIONAL,

clockwise tightening sequence, starting with Bolt No. 1, for one complete round and continue until no

further nut rotation occurs at 100% of the Final Torque value for any nut.

Short-term bolt preload loss can occur between four to twenty-four hours after initial tightening due to bolt

relaxation. Consider retightening to help recover this loss.

TIGHTENING METHOD USED:

Hand Wrench Manual Torque Wrench Hydraulic Torque Wrench

Impact Wrench Other

Joint Assembler: Date:

For questions, or tightening patterns for large diameter flanges, contact GRI Technical Services at:

(713) 856-9445, or tech@durlon.com

** This page can be copied for use in the field **

DURLON ® Technical Handbook November 2009

© 2003-2009, Gasket Resources Inc., All Rights Reserved

GRI/DURLON - Bolt Lubricaton / Flange Torque

THE EFFECT OF BOLT LUBRICATION

Bolt lubrication greatly affects Bolt Preload vs. Torque

the torque values used when installing 60000

gaskets. To achieve the same gasket

compression, a much higher torque 50000

Molybdenum disulfide

value is required for a dry bolt versus

using an effective lubricant such as

molybdenum disulfide. 40000

Load, lbs

In a dry bolt up, or where an

inefficient lubricant is used, the effort 30000

used in tightening is overcome by the As Received

frictional forces between the bolts and 20000

nuts and to a greater extent between

the nuts and nut facings.

10000 Dry

This can result in a lower

gasket load and inadequate stress on

the bolts, which can result in torque 0

0 100 200 300 400

loss and eventual leakage in service. Torque, ft-lbs

TORQUE VALUES – ASME B16.5 RAISED FACE FLANGES

ANSI B16.21 - RING GASKETS

1/16” & 1/8” DURLON® Gasket Material - Torque: ft-lbs

ANSI B16.5 Class 150 RF ANSI B16.5 Class 300 RF

Flange Torque / Round (ft-lbs) Bolt Tighten Seq* Torque / Round (ft-lbs) Bolt Tighten Seq*

Size 1st 2nd Final Dwg*/No. Size 1st 2nd Final Dwg*/No. Size

1/2" 4 8 16 4-bolt 1/2" 4 8 16 4-bolt 1/2"

3/4" 6 12 23 4-bolt 1/2" 10 20 40 4-bolt 5/8"

1" 8 15 30 4-bolt 1/2" 10 20 40 4-bolt 5/8"

1-1/4" 12 24 45 4-bolt 1/2" 14 28 55 4-bolt 5/8"

1-1/2" 14 28 56 4-bolt 1/2" 20 40 90 4-bolt 3/4"

2" 25 50 113 4-bolt 5/8" 15 30 60 8-bolt 5/8"

2-1/2" 25 50 113 4-bolt 5/8" 20 45 90 8-bolt 3/4"

3" 30 65 130 4-bolt 5/8" 30 60 125 8-bolt 3/4"

3-1/2" 25 50 113 8-bolt 5/8" 35 70 140 8-bolt 3/4"

4" 25 50 113 8-bolt 5/8" 45 90 180 8-bolt 3/4"

6" 50 100 202 8-bolt 3/4" 45 90 190 12-bolt 3/4"

8" 55 118 236 8-bolt 3/4" 75 150 300 12-bolt 7/8"

10" 80 160 327 12-bolt 7/8" 75 155 310 16-bolt 1"

12" 80 160 327 12-bolt 7/8" 115 230 460 16-bolt 1-1/8"

14" 120 240 492 12-bolt 1" 100 200 400 20-bolt 1-1/8"

16" 120 240 492 16-bolt 1" 140 280 570 20-bolt 1-1/4"

18" 180 365 731 16-bolt 1-1/8" 160 320 645 24-bolt 1-1/4"

20" 180 365 731 20-bolt 1-1/8" 170 355 710 24-bolt 1-1/4"

24" 260 520 1036 20-bolt 1-1/4" 275 550 1100 24-bolt 1-1/2"

Note: It is assumed that new A193 Gr. 7 studs with 2H heavy hex nuts are used. And studs, nuts and the flange facings on the nuts are lubricated with

a never-seize type paste using the installation and bolt tightening practices outlined above. Lubricant should not be applied to the gasket or flange faces

as a release agent. Hardened steel washers are also recommended to reduce friction.

* Refer to the appropriate bolt tightening sequence drawing under gasket installation on the previous page for the number of bolts listed.

** A minimum gasket stress of 4800 psi or a torque value > 40% of bolt yield, whichever is higher, is recommended to reduce torque loss.

DURLON ® Technical Handbook November 2009

© 2003-2009, Gasket Resources Inc., All Rights Reserved

You might also like

- 2024 NCAA Men's Blank BracketDocument1 page2024 NCAA Men's Blank BracketThe Kansas City StarNo ratings yet

- 908 Bel Air Road - Most Recent Floor Plans McCleanDocument4 pages908 Bel Air Road - Most Recent Floor Plans McCleanwalterw100% (4)

- Kakuro - Volume 1 - 11-20 PDFDocument80 pagesKakuro - Volume 1 - 11-20 PDFgkp0% (1)

- The Toyota Kata Practice Guide: Practicing Scientific Thinking Skills for Superior Results in 20 Minutes a DayFrom EverandThe Toyota Kata Practice Guide: Practicing Scientific Thinking Skills for Superior Results in 20 Minutes a DayRating: 4.5 out of 5 stars4.5/5 (7)

- Lesson 2 - Determining The Progress Towards The Attainment of Learning OutcomesDocument89 pagesLesson 2 - Determining The Progress Towards The Attainment of Learning OutcomesDiana HernandezNo ratings yet

- Hyosung GT250 Parts CatalogueDocument118 pagesHyosung GT250 Parts CataloguePepito Grillo100% (2)

- UMC240 Marine Gear InputDocument4 pagesUMC240 Marine Gear InputBurik8No ratings yet

- Emc WaiverDocument1 pageEmc WaiverZumbaShellNo ratings yet

- Gasket Installation: DurlonDocument3 pagesGasket Installation: Durlonlorenzo100% (1)

- Hydraulic Drawing Raptor 55 2R - JMC-718Document10 pagesHydraulic Drawing Raptor 55 2R - JMC-718Ronald Perez OspinoNo ratings yet

- Plano Hidraulico Jmc-895Document10 pagesPlano Hidraulico Jmc-895Feudred AngNo ratings yet

- Planos Hidraulicos Troidon 66 - jmc-516Document12 pagesPlanos Hidraulicos Troidon 66 - jmc-516Maria Isabel Alzate RamirezNo ratings yet

- Anti FazesDocument29 pagesAnti Fazessipolet765No ratings yet

- Planos Hidráulicos Troidon 88 - JMC-695Document13 pagesPlanos Hidráulicos Troidon 88 - JMC-695Miguel RomoNo ratings yet

- 4945 VGF RingSizing-PDF VFDocument2 pages4945 VGF RingSizing-PDF VFcharlieg123No ratings yet

- Box TemplateDocument1 pageBox Templatecamila.zambrana.cNo ratings yet

- A B C de F G: Gspublisherversion 0.37.100.100Document1 pageA B C de F G: Gspublisherversion 0.37.100.100a gildas dossaNo ratings yet

- Sweep Picking Arpeggio StudyDocument2 pagesSweep Picking Arpeggio StudyGeorge TseliosNo ratings yet

- 1izracunaj Oboji 4Document1 page1izracunaj Oboji 4adisaNo ratings yet

- Now Pattern Chart - Stitch FiddleDocument3 pagesNow Pattern Chart - Stitch FiddlejasminzheaNo ratings yet

- Show Title Studio: SC. Cont Action 6 5 4 3 2 1Document1 pageShow Title Studio: SC. Cont Action 6 5 4 3 2 1Sk BonillaNo ratings yet

- Map Edit 22 Mar 24Document2 pagesMap Edit 22 Mar 24Shehan PereraNo ratings yet

- Manual Ariston Thermo Clas ONE 24 (80 Páginas)Document2 pagesManual Ariston Thermo Clas ONE 24 (80 Páginas)LiarxarNo ratings yet

- Type Z Pilot Regulators: Parts ListDocument4 pagesType Z Pilot Regulators: Parts ListCentro De Belleza Rizos EstiloNo ratings yet

- Transmision 11Document2 pagesTransmision 11Juan Carlos Moncada PáezNo ratings yet

- t2 M 2266 Coordinate Pictures Activity SheetsDocument4 pagest2 M 2266 Coordinate Pictures Activity SheetsElegbede AnthoniaNo ratings yet

- March MadnessDocument1 pageMarch MadnessD PatelNo ratings yet

- SsubnitsDocument8 pagesSsubnitsapi-376807747No ratings yet

- Beach Boys - Good VibrationsDocument2 pagesBeach Boys - Good VibrationsAlessandroNo ratings yet

- RainhaDocument2 pagesRainhaNeto SantosNo ratings yet

- Part List 5100 (SCM296)Document15 pagesPart List 5100 (SCM296)AstraluxNo ratings yet

- Tournament Bracket Template 01Document11 pagesTournament Bracket Template 01Faltu pilaNo ratings yet

- Radio CD Arkamys 3d RenaultDocument149 pagesRadio CD Arkamys 3d RenaultJONATHAN ALMEIDANo ratings yet

- Exploded Views and Parts List (ML-25 /X)Document13 pagesExploded Views and Parts List (ML-25 /X)Angel BorsaniNo ratings yet

- R00.01 ATS1201 8 To 32 Zones DGP Installation Sheet MLDocument40 pagesR00.01 ATS1201 8 To 32 Zones DGP Installation Sheet MLSergio Crevillén LópezNo ratings yet

- EF4e Beg Quick Test 3 AnswersheetDocument1 pageEF4e Beg Quick Test 3 AnswersheetBárbara MontenegroNo ratings yet

- EF4e Beg Quick Test 12 AnswersheetDocument1 pageEF4e Beg Quick Test 12 AnswersheetireneNo ratings yet

- Hydraulic Oil Control Valve, 4-Valve (1 9) (With ECSS) (#60638-)Document2 pagesHydraulic Oil Control Valve, 4-Valve (1 9) (With ECSS) (#60638-)Marcelo ArayaNo ratings yet

- Absensi Rapat Wirid Akbar Dan Isra Mi'RajDocument1 pageAbsensi Rapat Wirid Akbar Dan Isra Mi'RajPondok Pesantren Al-AqshaNo ratings yet

- Engine No.: 6642331Document1 pageEngine No.: 6642331geronimojuarez179No ratings yet

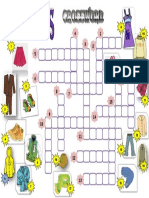

- Crossword 1st TemplateDocument2 pagesCrossword 1st TemplateMiguel Angel LarrinagaNo ratings yet

- Group 4 Disassembly and AssemblyDocument3 pagesGroup 4 Disassembly and AssemblyBuku DigitalNo ratings yet

- Absen MalamDocument14 pagesAbsen MalamPhi DeppezzNo ratings yet

- Group 4 Disassembly and Assembly Group 4 Disassembly and AssemblyDocument9 pagesGroup 4 Disassembly and Assembly Group 4 Disassembly and Assemblymãi bên emNo ratings yet

- Balasevic Djordje-Devojka Sa Cardas NogamaDocument14 pagesBalasevic Djordje-Devojka Sa Cardas NogamaApartman VedranNo ratings yet

- GT125PARTCATALOGUEDocument120 pagesGT125PARTCATALOGUEmauricio pachecoNo ratings yet

- TWH54NRH Spare Parts Sheet942016221232Document2 pagesTWH54NRH Spare Parts Sheet942016221232Heitor RibeiroNo ratings yet

- IMES Toshiba Aquilion Training Fall 18Document2 pagesIMES Toshiba Aquilion Training Fall 18Jawad SandhuNo ratings yet

- In The House: Fill in The Crossword and Find The Hidden WordsDocument1 pageIn The House: Fill in The Crossword and Find The Hidden Wordspopcake19No ratings yet

- Food PDFDocument2 pagesFood PDFHoang Hai ĐỗNo ratings yet

- de Voetpadkloof Map ADocument1 pagede Voetpadkloof Map AStephenNo ratings yet

- FeneisDocument10 pagesFeneisanton.karpytaNo ratings yet

- Clothes CrosswordDocument1 pageClothes CrosswordTanjaNo ratings yet

- FeneisDocument10 pagesFeneisaaaaabbbbbbaaaaaNo ratings yet

- ANSAMBLU AC AXA REFACERE-Model2Document1 pageANSAMBLU AC AXA REFACERE-Model2Iulian NgiNo ratings yet

- Hyosung GT 125 RAT Parts ListDocument126 pagesHyosung GT 125 RAT Parts ListRory NeilsonNo ratings yet

- (MEC8030) Figure 1. Truck Differential For Q2Document1 page(MEC8030) Figure 1. Truck Differential For Q2ali mortadaNo ratings yet

- 013-4600 02D Sisd2Document1 page013-4600 02D Sisd2FireBearGuitarsNo ratings yet

- Group 4 Disassembly and Assembly: 1. Brake PumpDocument6 pagesGroup 4 Disassembly and Assembly: 1. Brake PumpTaha RdmanNo ratings yet

- Chart TitleDocument4 pagesChart Titlecryovikas1975No ratings yet

- EF4e Beg Quick Test 11 AnswersheetDocument1 pageEF4e Beg Quick Test 11 AnswersheetireneNo ratings yet

- One Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialFrom EverandOne Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialNo ratings yet

- Sop For LP Pump (R1)Document6 pagesSop For LP Pump (R1)Sonrat100% (1)

- HEALTH MELCs Grade 3 PDFDocument3 pagesHEALTH MELCs Grade 3 PDFMarcelina Ellar50% (2)

- Influence of Sleep in Academic Performance - An Integrated Review of LiteratureDocument4 pagesInfluence of Sleep in Academic Performance - An Integrated Review of LiteratureIOSRjournalNo ratings yet

- Project Standard Specification: Packaged Cooling Towers 15640 - Page 1/9Document9 pagesProject Standard Specification: Packaged Cooling Towers 15640 - Page 1/9adel rihanaNo ratings yet

- 16 Calories Per Cup/90g (Cooked) : VeggiesDocument4 pages16 Calories Per Cup/90g (Cooked) : VeggiesChe Poblete CardenasNo ratings yet

- IDC 4U2 - Unit 3 Task 5 - SSDocument4 pagesIDC 4U2 - Unit 3 Task 5 - SSsavannah.e.stonehouseNo ratings yet

- Comparacion Polar y VO2 MaxDocument3 pagesComparacion Polar y VO2 MaxZilanyaid MontoyaNo ratings yet

- August Lunch MenuDocument1 pageAugust Lunch MenuJennifer AdamsNo ratings yet

- Activity No. 4 Module Cell Types and Cell ModificationsDocument7 pagesActivity No. 4 Module Cell Types and Cell ModificationsAryan Jovic DomingoNo ratings yet

- Fpsyt 14 1244451Document8 pagesFpsyt 14 1244451Gilvan RangelNo ratings yet

- Relationship Between Quality of Life and Social SupportDocument9 pagesRelationship Between Quality of Life and Social SupportDragos IvanNo ratings yet

- Personality Theories and ModelsDocument66 pagesPersonality Theories and ModelsAndrei Băcanu100% (1)

- Cii-Sorabji Green Business CentreDocument46 pagesCii-Sorabji Green Business CentremadhuNo ratings yet

- 014EBM Degracia DB EtallDocument17 pages014EBM Degracia DB EtallMarinel Piol MarasiganNo ratings yet

- Construction ContractsDocument3 pagesConstruction Contractskat kaleNo ratings yet

- Single Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) DoorsDocument84 pagesSingle Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) DoorsjuanNo ratings yet

- HHW Physics Xii B 2023-24Document3 pagesHHW Physics Xii B 2023-24CHILLE GAMINGNo ratings yet

- BSN 3G GRP 4 Research TitlesDocument6 pagesBSN 3G GRP 4 Research TitlesUjean Santos SagaralNo ratings yet

- Valvulas XT PDFDocument4 pagesValvulas XT PDFIsidro Gomez GarciaNo ratings yet

- Kelvion - Ficha TecnicaDocument76 pagesKelvion - Ficha TecnicaRusbel Dominguez AntonioNo ratings yet

- Maquina Do Wando PDFDocument76 pagesMaquina Do Wando PDFGlauber AquinoNo ratings yet

- Ultra Flash CSFB 10dec2020Document15 pagesUltra Flash CSFB 10dec2020hamadashraf301No ratings yet

- U1620G Thru U1660G: U1620G/U1630G/U1640G/U1660GDocument2 pagesU1620G Thru U1660G: U1620G/U1630G/U1640G/U1660GTeles SilvaNo ratings yet

- 8008 MSDSDocument5 pages8008 MSDSAhmed Emad AhmedNo ratings yet

- The Organization of Modern KitchensDocument9 pagesThe Organization of Modern KitchensJohnson Macayan FernándezNo ratings yet

- PMS - Data TTM Return Till May16bDocument15 pagesPMS - Data TTM Return Till May16bMoneylife FoundationNo ratings yet

- MESL - Algebra 2Document7 pagesMESL - Algebra 2Mark-Lorie Duculan NonesNo ratings yet

- Embryology FlashcardsDocument3 pagesEmbryology FlashcardsAisha YolaNo ratings yet