Professional Documents

Culture Documents

CERTILAS EN Edition2023 318

CERTILAS EN Edition2023 318

Uploaded by

Alireza Khodabandeh0 ratings0% found this document useful (0 votes)

5 views1 pageThis document provides information on various types of stick electrodes used for welding different metal alloys, including their mechanical properties, chemical composition limits, and typical applications. It describes electrodes for welding nickel-based alloys like Nickel 200 and 201, as well as alloys containing nickel, copper, chromium, iron, and molybdenum that are used in applications such as chemical processing equipment and shipbuilding.

Original Description:

Original Title

CERTILAS_EN_Edition2023_318

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information on various types of stick electrodes used for welding different metal alloys, including their mechanical properties, chemical composition limits, and typical applications. It describes electrodes for welding nickel-based alloys like Nickel 200 and 201, as well as alloys containing nickel, copper, chromium, iron, and molybdenum that are used in applications such as chemical processing equipment and shipbuilding.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

5 views1 pageCERTILAS EN Edition2023 318

CERTILAS EN Edition2023 318

Uploaded by

Alireza KhodabandehThis document provides information on various types of stick electrodes used for welding different metal alloys, including their mechanical properties, chemical composition limits, and typical applications. It describes electrodes for welding nickel-based alloys like Nickel 200 and 201, as well as alloys containing nickel, copper, chromium, iron, and molybdenum that are used in applications such as chemical processing equipment and shipbuilding.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

back to chapter overview / all chapters

1 STICK ELECTRODES

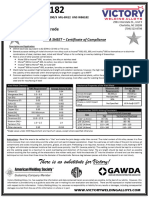

TYPE EN -ISO and ASME -AWS MECHANICAL

PROPERTIES

ANALYSIS APPLICATION

11. FOR NICKEL BASED ALLOYS

CEWELD 9606-1: FM6 T ~ 640 MPa C < 0,1 E NiTi3 is developed for welding and cladding Nickel 200 and Nickel 201. This alloy

E NiTi3 Sect IX QW-432: F-No. 41 Y > 370 MPa Mn < 0,7 is also suited for surfacing of steel. Dissimilar welding applications of filler metal

14172: E > 20% Fe < 0,7 NiTi 3 include joining Nickel 200 and 201 to stainless steels, copper-nickel alloys,

E Ni 2061 I > 120J (20 °C) Si < 1,2 and Monel alloys. It is also used for joining Monel alloys and copper-nickel alloys

(NiTi3) Ni > 92 to carbon steels, and for joining copper-nickel alloys to Inconel and Incoloy alloys.

A 5.11: Al < 1,0 Nickel Alloy 200-201, UNS Nr: N 02200-N 02201.

E Ni-1 Ti 1,0 - 4,0 DIN 17 742: Ni 99.6; Ni 99.2; LC-Ni99.6; LC-Ni99.

Cu < 0,2 W.no: 2.4066, 2.4068, 2.4061, 2.4060, 2.4050, 2.4062, 2.4106, 2.4110, 2.4122, 2.4116,

2.4128

CEWELD 9606-1: FM6 T ~ 640 MPa C < 0,15 E NiCu30Mn is suitable for welding Monel Alloys 400, R-405 end K-500. Also suitable

E NiCu30Mn Sect IX QW-432: F-No. 42 Y > 480 MPa Mn < 4,0 for dissimilar welding between Nickel 200-201, stainless steel, carbon steel, Inconel and

14172: E > 30% Fe < 2,5 Incoloy alloys, Nickel Copper and Copper nickel alloys. Also used for surfacing of steel.

E Ni 4060 (NiCu30Mn3Ti) Si < 1,5 Shipbuilding, seawater evaporation plants, tubes, pump building, offshore etc.

A 5.11: Cu 27 - 34 2.4360, 2.4375, NiCu30Fe, NiCu30Al, Monel 400, R405, alloy K500 and dissimilar

E NiCu-7 Ni 62 - 69 welding between these alloys.

Ti < 1,0

Al < 0,75

CEWELD 9606-1: ~ FM6 T > 620 MPa C 0,03 - 0,06 E Nicro HLS is a basic electrode well suited for maintenance and repair welding

E Nicro HLS Sect IX QW-432: F-No.~ 43 Y > 380 MPa Mn 4,0 - 6,0 applications in chemical, apparatus and heavy industry. First choice electrode for

14172: E > 35% Fe 3,0 –5,0 dissimilar welding of steel to Nickel alloys or repairing high carbon steels and white

~E Ni 6082 I > 90J (20 °C) Si < 0,8 cast irons. Working temperatures –196 °C up to 650 °C.

(NiCr20Mn3Nb) I > 70J (-196 °C) Ni > 63 Incoloy 800, DS - Inconel 600, 601, X8Ni9 - 12Ni19 - 10Ni 14 - NiCr15Fe - NiCr23Fe

A 5.11: Cr 18 - 22 - X10NiCrAITi3220 - X10CrNiMoNb18.12 - NiCr20Ti. W.no.:1.5662 - 1.5680 - 1.5637

~E NiCrFe-3 Nb 1,5 - 3,0 - 1.6582 - 1.4876 - 1.4583 - 2.4816 - 2.4851 - 2.4951, 2.4806, Alloy 82, 1.4816, 600L,

800H, AISI 4340, 4130, 8630

CEWELD 9606-1: FM6 T > 600 MPa C < 0,10 E NiCro A is used for welding nickel-iron-chromium Alloys of INCOLOY Alloys 800

E NiCro A Sect IX QW-432: F-No. 43 Y > 400 MPa Mn 1,0 - 3,5 and 800HT, INCONEL Alloys 600 and 601, and nickel steels. They may be used for

14172: E > 30% Fe < 12 applications at temperatures up to about 980 °C but do not offer optimum oxidation

E Ni 6133 I > 100J (20 °C) Si < 0,75 resistance and strength above 820 °C.

(NiCr16Fe12NbMo) I > 80J (-196 °C) Cu < 0,50 2.4816, 1.4876, 1.4859, 2.4951, 2.4952, NiCr15Fe, X10NiCrAlTi 32 20,

A 5.11: Ni > 62 G-X10NiCrNiNb 32 20, NiCr20Ti, NiCr20TiAl, Alloy 600/B168, Alloy 800/800H,

E NiCrFe-2 Cr 13 - 17 Alloy 75, Alloy 80A

Nb+Ta 0,5 - 3,0

Mo 0,5 - 2,5

CEWELD 9606-1: FM6 T ~ 640 MPa C < 0,10 E Nicro 600 electrodes are used for welding of nickel-chromium-iron alloys (Inconel

E Nicro 600 Sect IX QW-432: F-No. 43 Y > 370 MPa Mn 5,0 - 9,5 600, 601 and 690) to themselves, and for dissimilar welding between nickel-chro-

14172: E > 40% Fe < 10 mium-iron (Monel, Inconel and Incoloy) alloys and steels or stainless steels. The

E Ni 6182 I > 100J (20 °C) Si < 1,0 applications include surfacing as well as cladding. High manganese of this weld deposit

(NiCr15Fe6Mn) I > 80J (-196 °C) Ni > 60 reduces the possibility of micro fissures. High manganese reduces creep strength, which

5.11: Cr 13 - 17 limits its usage up to 480 °C.

E NiCrFe-3 Nb+Ta 1,0 - 2,5

CEWELD 9606-1: FM6 T ~ 630 MPa C < 0,03 E Nicro 825 is used for welding copper-alloyed austenitic stainless chromium-nickel-mo-

E Nicro 825 Sect IX QW-432: - - Y > 240 MPa Mn 1,0 - 3,0 lybdenum alloys and have excellent corrosion-resistant properties so it make the alloy to

14172: E > 22% Fe < 30 a suitable choice for a variety of difficult applications. Uses include fabricated equipment

E Ni 8165 I > 70J (-196 °C) Si < 0,7 found in chemical and petrochemical processing, pulp and paper manufacturing, flue

(NiCr25Fe30Mo) Cu 1,5 - 3,0 gas desulphurization systems and metal pickling operations.

A 5.11: - Ni 37 - 42 G-X7NiCrMo20, X1NiCrMoCuN25 20 6, X1NiCrMoCuN25 20 5, NiCr21Mo, X1NiCrM-

Cr 23 - 27 oCu 31 27 4, N08926, N08904, ALLOY 825, N08028, UNS N08825 W.Nr: 1.4500,

Mo 3,5 - 7,5 1.4529, 1.4539 (904L), 2.4858, 1.4563, 1.4465, 1.4577 (310Mo), 1.4133, 1.4500,

1.4503, 1.4505, 1.4506, 1.4531, 1.4536, 1.4585, 1.4586 CuNb 25

CEWELD 9606-1: FM6 T > 690 MPa C < 0,02 E NiCrMo 622 electrodes are used for welding of nickel-chromium-molybdenum

E NiCrMo Sect IX QW-432: F-No. 43 Y > 300 MPa Mn < 1,0 alloys as well as for overlay cladding on carbon, low alloy, or stainless steels. They are

622 14172: E > 25% Fe 2,0 – 6,0 also used for dissimilar joints between nickel-chromium-molybdenum alloys and stain-

E Ni 6022 I > 100J (20 °C) Si < 0,2 less, carbon, or low alloy steels.

(NiCr21Mo13W3) I > 80J (-196 °C) Ni > 49 Inconel 622, 625, Alloy 25-6Mo, Incoloy 825, dissimilar joints of Nickel Alloys,

A 5.11: Co < 2,5 Hastelloy Alloy C276, C22, C4, 2.4611, Typical specifications for the

E NiCrMo-10 Cu < 0,5 Nickel-Chromium-Molybdenum base metals are ASTM, F574, B619, B622 and B626

Cr 20 - 22,5 - All of which have UNS Number N06022.

Mo 12,5 - 14,5

W 2,5 - 3,5

1/12

You might also like

- Special Metals - Product CatalogDocument65 pagesSpecial Metals - Product Catalogilham_metallurgy6744No ratings yet

- Conmed Sabre 180Document54 pagesConmed Sabre 180ClaudiaNavarreteNo ratings yet

- Drug-Induced Diseases PDFDocument1,135 pagesDrug-Induced Diseases PDFGiang Vớ Vẩn100% (1)

- CERTILAS EN Edition2023 315Document1 pageCERTILAS EN Edition2023 315Alireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 320Document1 pageCERTILAS EN Edition2023 320Alireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 314Document1 pageCERTILAS EN Edition2023 314Alireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 313Document1 pageCERTILAS EN Edition2023 313Alireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 316Document1 pageCERTILAS EN Edition2023 316Alireza KhodabandehNo ratings yet

- UTP For OffshoreDocument16 pagesUTP For Offshorekamals55No ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohNo ratings yet

- E NiCro 600 Product-SheetDocument2 pagesE NiCro 600 Product-SheetAmr FaroukNo ratings yet

- Special Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresDocument10 pagesSpecial Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresCarlos PadillaNo ratings yet

- MIP Bohler Welding Austria 364Document1 pageMIP Bohler Welding Austria 364c131508No ratings yet

- item8-LNT NiCro60.20Document1 pageitem8-LNT NiCro60.20VVan TanNo ratings yet

- Thermanit Nimo C 24 (ERNiCrMo3) GTAWDocument1 pageThermanit Nimo C 24 (ERNiCrMo3) GTAWNiranjan Fakirchand YadavNo ratings yet

- Selectarc B90: Inconel Type Electrode For Fabrication and RepairDocument1 pageSelectarc B90: Inconel Type Electrode For Fabrication and RepairjmsmechNo ratings yet

- Böhler Nibas 625 PW-FD: DescriptionDocument1 pageBöhler Nibas 625 PW-FD: DescriptionBBalopesabbNo ratings yet

- CERTILAS EN Edition2023 312Document1 pageCERTILAS EN Edition2023 312Alireza KhodabandehNo ratings yet

- 5 - Duplex Stainless Steels and Nickel AlloysDocument44 pages5 - Duplex Stainless Steels and Nickel AlloysdennykvgNo ratings yet

- Thermanit Nicro 82: TIG Rods, Nickel-AlloyDocument2 pagesThermanit Nicro 82: TIG Rods, Nickel-AlloyMaximiliano Ezequiel LopezNo ratings yet

- UTP A 6222 MoDocument1 pageUTP A 6222 MoKara WhiteNo ratings yet

- Metrode Instructions For 625 Wires D20Document5 pagesMetrode Instructions For 625 Wires D20haran2000No ratings yet

- 12 - Vdmee E69 4Document10 pages12 - Vdmee E69 4el_tirano_regresa7359100% (1)

- EsabbDocument1 pageEsabbkismikloshun55No ratings yet

- ESAB ENiCiFe-3Document1 pageESAB ENiCiFe-3Sadhasivam VeluNo ratings yet

- ER316L Ss en 1Document1 pageER316L Ss en 1brayanNo ratings yet

- CMI WeldingChartsDocument1 pageCMI WeldingChartsnitinNo ratings yet

- CMI WeldingChartsDocument1 pageCMI WeldingChartsnitinNo ratings yet

- Technical Update Welding of Nickel Nikel AlloysDocument15 pagesTechnical Update Welding of Nickel Nikel AlloysrezaNo ratings yet

- Alloy 625 ConsumablesDocument4 pagesAlloy 625 ConsumablesRodrigo CarneiroNo ratings yet

- 2.0 The Alloys: 4 - Copper-Nickel Welding and FabricationDocument1 page2.0 The Alloys: 4 - Copper-Nickel Welding and FabricationsatnamNo ratings yet

- item11-LNT NiCroMo 59.23Document1 pageitem11-LNT NiCroMo 59.23VVan TanNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardschetanNo ratings yet

- TNI2TIDocument2 pagesTNI2TIKureiNo ratings yet

- UTP For Chemical IndustryDocument12 pagesUTP For Chemical Industrykamals55No ratings yet

- Copper Nickel Alloy 7030 E28093 UNS C71500 E28093 CupronickelDocument6 pagesCopper Nickel Alloy 7030 E28093 UNS C71500 E28093 CupronickelSantosh TiwariNo ratings yet

- Sandvik 2re10Document7 pagesSandvik 2re10himan_chongiNo ratings yet

- 1 Selectarc b90 FT Web AnglaisDocument1 page1 Selectarc b90 FT Web AnglaisfoxmancementNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Label StandardschetanNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- 308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsDocument1 page308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsFilipe CordeiroNo ratings yet

- T Thermanit Nicro 82 Gtaw 01 01 enDocument2 pagesT Thermanit Nicro 82 Gtaw 01 01 enKathir VelNo ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- Nickel and HT Alloys For Petrochemical Applications PDFDocument39 pagesNickel and HT Alloys For Petrochemical Applications PDFganeshNo ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- Material No.: EscriptionDocument2 pagesMaterial No.: EscriptionMd Omar FaruqueNo ratings yet

- Weldability of Materials - Nickel and Nickel AlloysDocument5 pagesWeldability of Materials - Nickel and Nickel AlloysmanimaranNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- U Utp A 786 Gmaw 01Document1 pageU Utp A 786 Gmaw 01RPNo ratings yet

- Material No. EN Symbol (Short) DIN Symbol Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) DIN Symbol Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Stainarc 308L-17 (Rev 1)Document1 pageStainarc 308L-17 (Rev 1)LIM hoon boonNo ratings yet

- Kevinsteel SA 1210Document4 pagesKevinsteel SA 1210meisamNo ratings yet

- Inconel 112-DatasheetDocument1 pageInconel 112-DatasheetrobertNo ratings yet

- 479Document7 pages479ElMacheteDelHuesoNo ratings yet

- Pinnacle Alloys ENiCrFe 3 12.16Document2 pagesPinnacle Alloys ENiCrFe 3 12.16satnamNo ratings yet

- Mig WiresDocument4 pagesMig Wirespipat .sNo ratings yet

- Stainarc 309L-17 (Rev 1)Document1 pageStainarc 309L-17 (Rev 1)LIM hoon boonNo ratings yet

- Consumables For Duplex Stainless SteelDocument6 pagesConsumables For Duplex Stainless SteelMohamed FaragNo ratings yet

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- Fox - FFDocument1 pageFox - FFGustavo NietoNo ratings yet

- Bending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiDocument1 pageBending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- 23Document1 page23Alireza KhodabandehNo ratings yet

- Wall Thickness and Material Grade Selection: GeneralDocument1 pageWall Thickness and Material Grade Selection: GeneralAlireza KhodabandehNo ratings yet

- Finite Element Analysis: Pipeline Installation by Tow or PullDocument1 pageFinite Element Analysis: Pipeline Installation by Tow or PullAlireza KhodabandehNo ratings yet

- 16 Qiang Bai and Yong Bai: Pipeline InstallationDocument1 page16 Qiang Bai and Yong Bai: Pipeline InstallationAlireza KhodabandehNo ratings yet

- Untitled 3Document1 pageUntitled 3Alireza KhodabandehNo ratings yet

- References: 20 Qiang Bai and Yong BaiDocument1 pageReferences: 20 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- Rec Erc 84 36Document1 pageRec Erc 84 36Alireza KhodabandehNo ratings yet

- Pipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleDocument1 pagePipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleAlireza KhodabandehNo ratings yet

- Untitled 6Document1 pageUntitled 6Alireza KhodabandehNo ratings yet

- Untitled 1Document1 pageUntitled 1Alireza KhodabandehNo ratings yet

- Untitled 2Document1 pageUntitled 2Alireza KhodabandehNo ratings yet

- Rec Erc 84 322Document1 pageRec Erc 84 322Alireza KhodabandehNo ratings yet

- Rec Erc 84 329Document1 pageRec Erc 84 329Alireza KhodabandehNo ratings yet

- Rec Erc 84 334Document1 pageRec Erc 84 334Alireza KhodabandehNo ratings yet

- Rec Erc 84 332Document1 pageRec Erc 84 332Alireza KhodabandehNo ratings yet

- Rec Erc 84 317Document1 pageRec Erc 84 317Alireza KhodabandehNo ratings yet

- Rec Erc 84 315Document1 pageRec Erc 84 315Alireza KhodabandehNo ratings yet

- Rec Erc 84 313Document1 pageRec Erc 84 313Alireza KhodabandehNo ratings yet

- Fig. 1.8 A Proposed Circuit Diagram, B Parallel Connection of Four SPHDocument1 pageFig. 1.8 A Proposed Circuit Diagram, B Parallel Connection of Four SPHAlireza KhodabandehNo ratings yet

- Rec Erc 84 311Document1 pageRec Erc 84 311Alireza KhodabandehNo ratings yet

- 14 S. K. Gawali Et AlDocument1 page14 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- Rec Erc 84 35Document1 pageRec Erc 84 35Alireza KhodabandehNo ratings yet

- 1.3 Characterization of Developed Build Platform: 1.3.1 Temperature Distribution TestingDocument1 page1.3 Characterization of Developed Build Platform: 1.3.1 Temperature Distribution TestingAlireza KhodabandehNo ratings yet

- Rec Erc 84 33Document1 pageRec Erc 84 33Alireza KhodabandehNo ratings yet

- Rec Erc 84 38Document1 pageRec Erc 84 38Alireza KhodabandehNo ratings yet

- 1.2.1 Design Methodology: 6 S. K. Gawali Et AlDocument1 page1.2.1 Design Methodology: 6 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- Investigations On The Development of Heated Build Platform For Additive Manufacturing of Large-Size PartsDocument1 pageInvestigations On The Development of Heated Build Platform For Additive Manufacturing of Large-Size PartsAlireza KhodabandehNo ratings yet

- 2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingDocument1 page2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingAlireza KhodabandehNo ratings yet

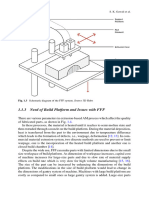

- 1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlDocument1 page1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- Yokogawa RAGN ManualDocument46 pagesYokogawa RAGN ManualJohn AdewaleNo ratings yet

- Adverse Effects of Gadgets On KidsDocument1 pageAdverse Effects of Gadgets On Kidsnicole bejasaNo ratings yet

- Partlist Eq114Document16 pagesPartlist Eq114180976No ratings yet

- Pentavitin - DSMDocument3 pagesPentavitin - DSMRnD Roi SuryaNo ratings yet

- Definition of Terms Mine SurveyingDocument2 pagesDefinition of Terms Mine Surveyingaquariuspj25100% (3)

- Monograph COBIOGUM I Rev00Document1 pageMonograph COBIOGUM I Rev00DIANELANo ratings yet

- Gordon's Functional HealthDocument2 pagesGordon's Functional HealthReina ArabelleNo ratings yet

- Chapter 7 - Morphing Skin Foams - 2018 - Morphing Wing TechnologiesDocument24 pagesChapter 7 - Morphing Skin Foams - 2018 - Morphing Wing TechnologiesRichardNo ratings yet

- Appendix 66 Rpci Updated Ues JehanDocument58 pagesAppendix 66 Rpci Updated Ues JehanOmar Gulam JrNo ratings yet

- Printable Cosmetology LawbookDocument42 pagesPrintable Cosmetology LawbookCaro TNo ratings yet

- Simulation Study of LPG Cooking BurnerDocument3 pagesSimulation Study of LPG Cooking BurnerBensinghdhas Sathiya Dhas100% (1)

- Steril DiskDocument3 pagesSteril DisklukasjoNo ratings yet

- Bacteria ProfileDocument18 pagesBacteria ProfileNOR-FATIMAH BARATNo ratings yet

- Chap 3.1 Physics of SemiconductorsDocument14 pagesChap 3.1 Physics of SemiconductorsAhmed AlsharifNo ratings yet

- Nutrition Factor in Women in Backward AreasDocument7 pagesNutrition Factor in Women in Backward AreaspranjalNo ratings yet

- Vibration Measurement and Analysis of Rotational Machines: at Makstil Hotplate MillDocument4 pagesVibration Measurement and Analysis of Rotational Machines: at Makstil Hotplate MillMarija PetkovskaNo ratings yet

- Unit IV-Alternative Laboratory ExerciseDocument11 pagesUnit IV-Alternative Laboratory ExerciseFloralde RyanNo ratings yet

- Chapter 2 Lesson 21 Animals That Live On LandDocument17 pagesChapter 2 Lesson 21 Animals That Live On LandRoxan S. Pumphrey0% (1)

- TLE Cookery10 Q4 W3 V4Document7 pagesTLE Cookery10 Q4 W3 V4Maria Rose Tariga Aquino100% (2)

- Calibration of Dosimeters Used in Radiation TherapyDocument122 pagesCalibration of Dosimeters Used in Radiation TherapySOHON SINHA MAHAPATRANo ratings yet

- All About StarDocument9 pagesAll About StarRukanuzzaman RaselNo ratings yet

- Chapter 14 Test Bank - Version1Document25 pagesChapter 14 Test Bank - Version1mjjongh103No ratings yet

- 31122018HE0QRKXJChaptersFinalEIAsingalPdf PDFDocument272 pages31122018HE0QRKXJChaptersFinalEIAsingalPdf PDFChitti NenavathNo ratings yet

- Sample ReviewDocument5 pagesSample Reviewdawit gebreyohansNo ratings yet

- Copper (RJ-45) SFP: Technical SpecificationsDocument1 pageCopper (RJ-45) SFP: Technical SpecificationsDanielLopezNo ratings yet

- Activity 1: Measuring The Volume of Irregularly Shaped ObjectsDocument4 pagesActivity 1: Measuring The Volume of Irregularly Shaped ObjectsBamPanggatNo ratings yet

- Past Life Regression Therapist Training WorkshopDocument3 pagesPast Life Regression Therapist Training WorkshopDrManjiree Gokhale50% (2)

- Beyond The Five Stages of Grief - Class 6 DocumentDocument2 pagesBeyond The Five Stages of Grief - Class 6 DocumentoksanaNo ratings yet