Professional Documents

Culture Documents

42560421fisatehnica 24921 41 1695258836

42560421fisatehnica 24921 41 1695258836

Uploaded by

Sebastian HAVASICopyright:

Available Formats

You might also like

- Reaction of LipidsDocument5 pagesReaction of LipidsJason Raquin Roque89% (9)

- Introductory Dynamical Oceanography by Pond Pickard P PDocument263 pagesIntroductory Dynamical Oceanography by Pond Pickard P PDiego Gámez Soto100% (2)

- Robocal Air VentDocument2 pagesRobocal Air Ventfarshan296015No ratings yet

- FilterDocument4 pagesFilterShivinder AggarwalNo ratings yet

- FILTROS Maxiflow - Series PARKERDocument5 pagesFILTROS Maxiflow - Series PARKERDaniel MarNo ratings yet

- WWW - Superiorelectric.in: Making MachinesDocument52 pagesWWW - Superiorelectric.in: Making MachinesPinali Mahendradas MistryNo ratings yet

- Control Valve Pn16: Series Vla300 and Vlb300Document5 pagesControl Valve Pn16: Series Vla300 and Vlb300SultanNo ratings yet

- Air Filter + Regulator + LubricatorDocument12 pagesAir Filter + Regulator + LubricatorbuddhivasuNo ratings yet

- Eliminador de AireDocument4 pagesEliminador de AiresusansueNo ratings yet

- Power Team PE60 CatalogDocument2 pagesPower Team PE60 CatalogTitanplyNo ratings yet

- ASTR Industrial Range The Hybrid RangeDocument2 pagesASTR Industrial Range The Hybrid RangeDennis CoonNo ratings yet

- Alfa Laval Alfa Laval LKRK Product Leaflet enDocument3 pagesAlfa Laval Alfa Laval LKRK Product Leaflet enfmahieuNo ratings yet

- Mustang Series M100 (Globe), M1100 (Angle) Specification SheetDocument3 pagesMustang Series M100 (Globe), M1100 (Angle) Specification SheetWattsNo ratings yet

- Automatic Air Vents Minical - Valcal: 5020 - 5021 - 5022 SeriesDocument2 pagesAutomatic Air Vents Minical - Valcal: 5020 - 5021 - 5022 SeriesGMSNo ratings yet

- f701 12e7gt m1 Parker Pneumatic Filter DatasheetDocument2 pagesf701 12e7gt m1 Parker Pneumatic Filter DatasheetOkti FirnawatiNo ratings yet

- 65328g10 PDFDocument7 pages65328g10 PDFbnNo ratings yet

- F101-03BA Watts Air Filter FilterDocument2 pagesF101-03BA Watts Air Filter FilterMROstop.comNo ratings yet

- Valvula Hi9draulica MeyanDocument4 pagesValvula Hi9draulica MeyanHECTOR ESCALLONNo ratings yet

- Caleffi 250 Series Solar Automatic Air Vent SpecificationsDocument2 pagesCaleffi 250 Series Solar Automatic Air Vent Specificationse-ComfortUSANo ratings yet

- CIM - 10 PolyhydronDocument2 pagesCIM - 10 PolyhydronJindal HydraulicsNo ratings yet

- Filtros Usr FB 018 025Document2 pagesFiltros Usr FB 018 025Marino AyalaNo ratings yet

- Manual For Installation M - 15 UkDocument17 pagesManual For Installation M - 15 UkAugustin GigelNo ratings yet

- Twin Mac CQ ArcoDocument5 pagesTwin Mac CQ ArcoNitin SeenauthNo ratings yet

- Pulsation Dampener PD8100 SeriesDocument2 pagesPulsation Dampener PD8100 SeriesDaniel ArgumedoNo ratings yet

- Filter MRS Tartarini EmersonDocument12 pagesFilter MRS Tartarini EmersonbayuNo ratings yet

- HDL-PSG3442-300 Filtro Solberg - Filtro de Descarga de Equipo PDFDocument1 pageHDL-PSG3442-300 Filtro Solberg - Filtro de Descarga de Equipo PDFYacila AlvaradoNo ratings yet

- Zracni Ventil Za RadijatorDocument2 pagesZracni Ventil Za Radijatorshadow_zeNo ratings yet

- Quick Exhaust Valves T70 Series: " " BSPP, NPTDocument4 pagesQuick Exhaust Valves T70 Series: " " BSPP, NPTAbhayy DevNo ratings yet

- ITAPTECH AUTOMATIC-AIR-VENT EngDocument14 pagesITAPTECH AUTOMATIC-AIR-VENT EngCarlos EspNo ratings yet

- H2 Product CatalogDocument14 pagesH2 Product CatalogVipul PanchalNo ratings yet

- Praher Superstar E-6000 - F2 PDFDocument12 pagesPraher Superstar E-6000 - F2 PDFForxánNo ratings yet

- A Polyhydron Group Company: Pilot Operated Check Valve Modular Construction Model: CIM10Document2 pagesA Polyhydron Group Company: Pilot Operated Check Valve Modular Construction Model: CIM10mdkhandaveNo ratings yet

- FRC With Internal AutodrainDocument3 pagesFRC With Internal AutodrainBiswanath LenkaNo ratings yet

- Check Valves: Check Valve and Pre - LL Valve Type FDocument2 pagesCheck Valves: Check Valve and Pre - LL Valve Type FSaeid MirNo ratings yet

- Filtrec F040 SeriesDocument8 pagesFiltrec F040 Serieshkhan10No ratings yet

- SinclairCollins K-Series 02 2016Document20 pagesSinclairCollins K-Series 02 2016Eduardo Ricardo Puga RomeroNo ratings yet

- Model AR: Smith Meter Air EliminatorsDocument4 pagesModel AR: Smith Meter Air EliminatorsGuillermo GutierrezNo ratings yet

- ISZ3000ILDocument4 pagesISZ3000ILDiana V. RosalesNo ratings yet

- Wastemaster Mit en 0715 EditDocument4 pagesWastemaster Mit en 0715 EditPablo DonariNo ratings yet

- Gfps-Dk-Technical Data Metal Butterfly Valve Type 039Document7 pagesGfps-Dk-Technical Data Metal Butterfly Valve Type 039Omar GuillenNo ratings yet

- Maxflow FRLDocument5 pagesMaxflow FRLGopalakrishnan Raju100% (1)

- Lead Free: Full Port Ductile Iron Single Chamber Basic ValveDocument3 pagesLead Free: Full Port Ductile Iron Single Chamber Basic ValveWattsNo ratings yet

- Alfa Laval Unique Mixproof Tank Outlet: Double Seat ValvesDocument7 pagesAlfa Laval Unique Mixproof Tank Outlet: Double Seat Valvesمیلاد قاسمیNo ratings yet

- CGX2003-07 enDocument7 pagesCGX2003-07 enJunianto PwNo ratings yet

- Homogenizer HPM Type B55 PDFDocument2 pagesHomogenizer HPM Type B55 PDFÑzñz RedesNo ratings yet

- Aa Manejadora Split Central Ciac 5TRDocument1 pageAa Manejadora Split Central Ciac 5TRPipe ValenciaNo ratings yet

- Angle Seat Valve Ycp (1)Document4 pagesAngle Seat Valve Ycp (1)Sarji-Biomedical sachinNo ratings yet

- Model P1000AXL, TP1100A, TP220, TP3000: Temperature & Pressure and Pressure Relief ValvesDocument2 pagesModel P1000AXL, TP1100A, TP220, TP3000: Temperature & Pressure and Pressure Relief Valvesmember1000No ratings yet

- Pi8300 enDocument4 pagesPi8300 enJamin SmtpngNo ratings yet

- Baker Floats PDFDocument14 pagesBaker Floats PDFDon BraithwaiteNo ratings yet

- Ucf A CTL PDFDocument12 pagesUcf A CTL PDFTH LEENo ratings yet

- Output Filters Nastec REV5 - ENDocument2 pagesOutput Filters Nastec REV5 - ENDiego Juarez GonzalesNo ratings yet

- Asco 8344 PDFDocument2 pagesAsco 8344 PDFOsman Lopez SalasNo ratings yet

- F105-03BG Watts Air FilterDocument2 pagesF105-03BG Watts Air FilterMROstop.comNo ratings yet

- Pressure Relief ValveDocument4 pagesPressure Relief ValveDiky AfriantNo ratings yet

- 54-13041r Ins 1Document16 pages54-13041r Ins 1Felipe ReyesNo ratings yet

- Blowout Prevention Equipment Check List: & 10 December 2006Document3 pagesBlowout Prevention Equipment Check List: & 10 December 2006بريجينيف خروتشوفNo ratings yet

- MaicoDocument9 pagesMaicoShiv KumarNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- Name: Rounak Barnwal Class: Xii A Roll No: SESSION:2022-2023Document11 pagesName: Rounak Barnwal Class: Xii A Roll No: SESSION:2022-2023Naman BarnwalNo ratings yet

- 9190-Uspe 2x10200kw Wartsila 20v32ts Hfo Diesel GensetDocument19 pages9190-Uspe 2x10200kw Wartsila 20v32ts Hfo Diesel Gensetpradeep kumarNo ratings yet

- Prediction of Oxygen Induced Corrosion in Industrial Waters 049020115-1Document6 pagesPrediction of Oxygen Induced Corrosion in Industrial Waters 049020115-1astromoNo ratings yet

- Spectrophotometric Determination of The Stoichiometry of A ComplexDocument6 pagesSpectrophotometric Determination of The Stoichiometry of A ComplexDean Dela CruzNo ratings yet

- Module 4 - Energy Transfer (Student Guide)Document11 pagesModule 4 - Energy Transfer (Student Guide)greggcllam619076No ratings yet

- Tut (2-3-4) Mech of Mach Winter 2011Document10 pagesTut (2-3-4) Mech of Mach Winter 2011Mahmoud El-MahdyNo ratings yet

- ENGINEERING DESIGN GUIDELINE - Distillation - Column - Rev05Document30 pagesENGINEERING DESIGN GUIDELINE - Distillation - Column - Rev05syazwanjohnmazlan100% (2)

- Iaea Nds 0206 200806Document92 pagesIaea Nds 0206 200806Umair RasheedNo ratings yet

- 12 Physics Electrostatics Test 01 Answer 5x7fDocument4 pages12 Physics Electrostatics Test 01 Answer 5x7fAshish BajpaiNo ratings yet

- Liquid Solution Board Booster Worksheet-2Document3 pagesLiquid Solution Board Booster Worksheet-2tarunNo ratings yet

- SOLN PurcellDocument7 pagesSOLN Purcelleddiejam1642No ratings yet

- CH 20 ThermodynamicsDocument11 pagesCH 20 ThermodynamicsElle QuizonNo ratings yet

- A-Frame Calculation Without CoverDocument6 pagesA-Frame Calculation Without CoverimsayaaNo ratings yet

- Sliding Mode Controller SMC Governed Speed Control of DC MotorDocument6 pagesSliding Mode Controller SMC Governed Speed Control of DC Motorraghav4life8724No ratings yet

- Iocl Haldia ReportDocument99 pagesIocl Haldia ReportArkadev GhoshNo ratings yet

- Liquid Chromatography: High Performance Liquid Chromatograhy (HPLC)Document94 pagesLiquid Chromatography: High Performance Liquid Chromatograhy (HPLC)Ali Issa OthmanNo ratings yet

- Supercritical Fluid Extraction of Organic Compounds From Solids and Aqueous Solutions PDFDocument60 pagesSupercritical Fluid Extraction of Organic Compounds From Solids and Aqueous Solutions PDFÁlvaro Cornejo PerdomoNo ratings yet

- Subject: General Chemistry Test,: Date: May 2015Document7 pagesSubject: General Chemistry Test,: Date: May 2015PHƯƠNG ĐẶNG YẾNNo ratings yet

- Colloid Chemistry - Chapter 1 - Introduction of Colloid ChemistryDocument29 pagesColloid Chemistry - Chapter 1 - Introduction of Colloid ChemistryKhang DuongNo ratings yet

- AstronomyformulaDocument30 pagesAstronomyformulapalharjeetNo ratings yet

- Ial WPH06 01 Oct19Document20 pagesIal WPH06 01 Oct19SumuduMPereraNo ratings yet

- O&m RGVDocument7 pagesO&m RGVNur NaziraNo ratings yet

- Analysisof Cicada Wing Surface - SuperHydrophobicDocument9 pagesAnalysisof Cicada Wing Surface - SuperHydrophobicNiroshanNo ratings yet

- Fluid Mechanics July 2013Document0 pagesFluid Mechanics July 2013Prasad C MNo ratings yet

- REMOTE Calculator Tool May 21 2013Document77 pagesREMOTE Calculator Tool May 21 2013Leyner Garcia MezquitaNo ratings yet

- Elkem 07 Magnesiun Contents in Ductile IronDocument2 pagesElkem 07 Magnesiun Contents in Ductile Ironmarcotulio123No ratings yet

- Experiment 6 Date 2/9/11: Determination of Numerical Aperture and Acceptance Angle of An Optical FiberDocument17 pagesExperiment 6 Date 2/9/11: Determination of Numerical Aperture and Acceptance Angle of An Optical FiberSanidhya PainuliNo ratings yet

- Solar Panel InstallationDocument10 pagesSolar Panel Installationpeculiarchild2020No ratings yet

42560421fisatehnica 24921 41 1695258836

42560421fisatehnica 24921 41 1695258836

Uploaded by

Sebastian HAVASIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

42560421fisatehnica 24921 41 1695258836

42560421fisatehnica 24921 41 1695258836

Uploaded by

Sebastian HAVASICopyright:

Available Formats

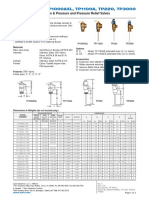

Radiator air vents and

drainage devices

series 505 - 5054 - 5055 - 5080 - 560

cert. n° 0003

ISO 9001

01056/01 GB

Function

Two types of device are covered here:

- Automatic or manual air vent valves.

- Radiator drain valve with extractor drain tube.

The purpose of the radiator air vent valve is to remove, either

manually or automatically, any air trapped inside the heat emitters

both during the filling of the system and in normal operation.

The drain valve, on the other hand, makes it possible to easily

discharge the water contained in the radiator, thanks to the

extractor which is inserted into the valve itself.

Product range

Series 505 Manual radiator air vent valve Sizes 1/8”, 1/4”, 3/8” M

Series 5054 Manual radiator air vent valve with revolving discharge Sizes 1/8”, 1/4”, 3/8” M

Series 5055 Manual radiator air vent valve with soft seat Sizes 1/8”, 1/4”, 3/8”, 1/2” M

Series 5080 Automatic hygroscopic radiator air vent valve Sizes 1/8”, 1/4”, 3/8”, 1/2” M

Code 560421 Radiator drain valve Size 1/2” M

Code 560000 Extractor drain tube

Technical specification

series ➫ 505 / 5054 5055 5080 560421

Materials:

- Body: brass UNI EN 12164 brass UNI EN 12164 brass UNI EN 12164 brass UNI EN 12164

CW614N; nickel plated CW614N; nickel plated CW614N; nickel plated CW614N; nickel plated

- Knob: POM POM POM

white RAL 9010 white RAL 9010 white RAL 9010

- Outer seal: PTFE PTFE PTFE EPDM

Performance:

- Max working pressure: 10 bar 10 bar 10 bar 10 bar

- Max working temperature: 90°C 90°C 100°C 100°C

Dimensions

E D B E D

A

A

C

F

C

F

F

G

B E D B

Code A B C D E F

Code A B C D E F Code A B C D E F G 505511 1/8” 30 18 7 23 Es.14

505111 1/8” 29 18 7 22 Es.13 505411 1/8” 36,5 18 7 29,5 Es.13 12 505521 1/4” 30 18 7 23 Es.14

505121 1/4” 29 18 7 22 Es.13 505421 1/4” 36,5 18 7 29,5 Es.13 12 505531 3/8” 33 18 7 26 Es.17

505131 3/8” 32 18 7 25 Es.17 505431 3/8 37 18 7 30 Es.17 12 505541 1/2” 35 18 10 25 Es.17

E D E D

A

C

A

F

F

B

G B

Code A B C D E F

508011 1/8” 30 18 10 20 Es.15

508021 1/4” 30 18 10 20 Es.15 Code A B C D E F G

508031 3/8" 30,5 18 10,5 20 Es.17 560421 1/2" 32,5 Es.22 21,5 11 8 p. 1 -

508041 1/2" 33 18 10 23 Es.17 560000 - - - - - 8 p. 1 205

Operating principle / Construction details

505 5055 (REG. MOD.)

Valve 505 operates manually. The knob is Once again, this model operates in the

turned until the air in the heat emitter is same way as the previous two. The

completely expelled and water starts to identifying detail of this valve is an

come out. internal seal in a special elastic

material which provides a tight seal in

relation to limited tightening of the knob

and possible temperature changes.

5054 The knob of the valve is shaped so as to be similar

This valve operates in the same way as in appearance to Caleffi thermostatic valve heads,

the series 505, but differs in having which enhances the uniformity of the range of

a 360° revolving discharge facility radiator components.

which makes air venting easier.

5080 560

Valve code 5080 can be used manually or The drain valve is applied to the lower connection of the radiator.

automatically. When inserting the extractor drain tube into the valve itself, the

The principle of manual discharge is the sliding piston which provides the outer seal must be screw-located

same as for the valves already described, and extracted, making the water flow outwards.

whilst automatic discharge is based on the

property of the cellulose fibre discs forming

the seal cartridge.

Valve closed

The manual discharge The automatic discharge

position is achieved by position, however, is achieved

Valve open

unscrewing the knob approx. with the knob fully closed.

one turn. Typical use of this

method is when refilling the

system. Use of the series 560 drain valve

The hygroscopic discs increase their volume by 50% when they are 1 1 Remove protective

cap

immersed in water.

s s+50% s

Dry Immersed Dried

disc disc disc

In this way, when the system is operating under normal conditions, 2 Screw on the drain

the discs are immersed and, thanks to their increase in volume, 2 tube provided

they close the valve. However, when air is present, the discs dry out

and allow the air to vent.

The hygroscopic discs close very quickly, in just a few seconds.

The drying times are such that there are no problems with the cycle

of formation and elimination of air.

Table of drying times

Water

temperature °C 40 50 60 70 80 90 100

Times in

hours 6 5 2 1/2 1 1/2 1 1/2 1/4 3

➡ 3 Pull out the tube,

turning it into a basin.

Replaceable cartridge

The valve is constructed in such

a way that the part containing the

hygroscopic discs can easily be

replaced without having to empty

the heat emitter. This may be

necessary because the discs can

deteriorate in time if there is

unfiltered or hard water present.

It is, in any case, advisable to

replace the disc cartridge at least

every 36 months.

SPECIFICATION SUMMARIES

Series 505

Radiator air vent valve. Threaded connection 1/8” M (from 1/8” to 3/8”) with PTFE seal. Brass body. Nickel

plated. White heat resistant knob in POM. Max working temperature 90°C. Max working pressure 10 bar.

Series 5054

Radiator air vent valve. Threaded connection 1/8” M (from 1/8” to 3/8”) with PTFE seal. Brass body. Nickel

plated. White heat resistant knob in POM. Max working temperature 90°C. Max working pressure 10 bar.

Rotable outlet.

Series 5055

Radiator air vent valve with EPDM soft seal. Threaded connection 1/8” M (from 1/8” to 1/2”) with PTFE seal.

Brass body. Nickel plated. White heat resistant knob in POM. Max working temperature 90°C. Max working

pressure 10 bar.

Series 5080

Automatic hygroscopic air vent valve. Threaded connection 1/8” M (from 1/8” to 1/2”) with PTFE seal. Brass

body. Nickel plated. White heat resistant knob in POM. Max working temperature 100°C. Max working pressure

10 bar. Replaceable hygroscopic cartridge.

Code 560421

Radiator drain valve. Threaded connection 1/2” M. EPDM seal. Brass body. Nickel plated. Max working

temperature 100°C. Max working pressure 10 bar. Designed for use with extractor drain tube.

Code 560000

Extractor drain tube for extraction of sliding piston from radiator drain valve.

We reserve the right to change our products and their relevant technical data, contained in this publication, at any time and without prior notice.

CALEFFI

S.S. 229 · Km 26,5 · I-28010 Fontaneto d’Agogna (NO) · Tel. Int. +39 0322 8491 · Fax +39 0322 863723

· Http://www.calef fi.com · E-mail:info@calef fi.it ·

You might also like

- Reaction of LipidsDocument5 pagesReaction of LipidsJason Raquin Roque89% (9)

- Introductory Dynamical Oceanography by Pond Pickard P PDocument263 pagesIntroductory Dynamical Oceanography by Pond Pickard P PDiego Gámez Soto100% (2)

- Robocal Air VentDocument2 pagesRobocal Air Ventfarshan296015No ratings yet

- FilterDocument4 pagesFilterShivinder AggarwalNo ratings yet

- FILTROS Maxiflow - Series PARKERDocument5 pagesFILTROS Maxiflow - Series PARKERDaniel MarNo ratings yet

- WWW - Superiorelectric.in: Making MachinesDocument52 pagesWWW - Superiorelectric.in: Making MachinesPinali Mahendradas MistryNo ratings yet

- Control Valve Pn16: Series Vla300 and Vlb300Document5 pagesControl Valve Pn16: Series Vla300 and Vlb300SultanNo ratings yet

- Air Filter + Regulator + LubricatorDocument12 pagesAir Filter + Regulator + LubricatorbuddhivasuNo ratings yet

- Eliminador de AireDocument4 pagesEliminador de AiresusansueNo ratings yet

- Power Team PE60 CatalogDocument2 pagesPower Team PE60 CatalogTitanplyNo ratings yet

- ASTR Industrial Range The Hybrid RangeDocument2 pagesASTR Industrial Range The Hybrid RangeDennis CoonNo ratings yet

- Alfa Laval Alfa Laval LKRK Product Leaflet enDocument3 pagesAlfa Laval Alfa Laval LKRK Product Leaflet enfmahieuNo ratings yet

- Mustang Series M100 (Globe), M1100 (Angle) Specification SheetDocument3 pagesMustang Series M100 (Globe), M1100 (Angle) Specification SheetWattsNo ratings yet

- Automatic Air Vents Minical - Valcal: 5020 - 5021 - 5022 SeriesDocument2 pagesAutomatic Air Vents Minical - Valcal: 5020 - 5021 - 5022 SeriesGMSNo ratings yet

- f701 12e7gt m1 Parker Pneumatic Filter DatasheetDocument2 pagesf701 12e7gt m1 Parker Pneumatic Filter DatasheetOkti FirnawatiNo ratings yet

- 65328g10 PDFDocument7 pages65328g10 PDFbnNo ratings yet

- F101-03BA Watts Air Filter FilterDocument2 pagesF101-03BA Watts Air Filter FilterMROstop.comNo ratings yet

- Valvula Hi9draulica MeyanDocument4 pagesValvula Hi9draulica MeyanHECTOR ESCALLONNo ratings yet

- Caleffi 250 Series Solar Automatic Air Vent SpecificationsDocument2 pagesCaleffi 250 Series Solar Automatic Air Vent Specificationse-ComfortUSANo ratings yet

- CIM - 10 PolyhydronDocument2 pagesCIM - 10 PolyhydronJindal HydraulicsNo ratings yet

- Filtros Usr FB 018 025Document2 pagesFiltros Usr FB 018 025Marino AyalaNo ratings yet

- Manual For Installation M - 15 UkDocument17 pagesManual For Installation M - 15 UkAugustin GigelNo ratings yet

- Twin Mac CQ ArcoDocument5 pagesTwin Mac CQ ArcoNitin SeenauthNo ratings yet

- Pulsation Dampener PD8100 SeriesDocument2 pagesPulsation Dampener PD8100 SeriesDaniel ArgumedoNo ratings yet

- Filter MRS Tartarini EmersonDocument12 pagesFilter MRS Tartarini EmersonbayuNo ratings yet

- HDL-PSG3442-300 Filtro Solberg - Filtro de Descarga de Equipo PDFDocument1 pageHDL-PSG3442-300 Filtro Solberg - Filtro de Descarga de Equipo PDFYacila AlvaradoNo ratings yet

- Zracni Ventil Za RadijatorDocument2 pagesZracni Ventil Za Radijatorshadow_zeNo ratings yet

- Quick Exhaust Valves T70 Series: " " BSPP, NPTDocument4 pagesQuick Exhaust Valves T70 Series: " " BSPP, NPTAbhayy DevNo ratings yet

- ITAPTECH AUTOMATIC-AIR-VENT EngDocument14 pagesITAPTECH AUTOMATIC-AIR-VENT EngCarlos EspNo ratings yet

- H2 Product CatalogDocument14 pagesH2 Product CatalogVipul PanchalNo ratings yet

- Praher Superstar E-6000 - F2 PDFDocument12 pagesPraher Superstar E-6000 - F2 PDFForxánNo ratings yet

- A Polyhydron Group Company: Pilot Operated Check Valve Modular Construction Model: CIM10Document2 pagesA Polyhydron Group Company: Pilot Operated Check Valve Modular Construction Model: CIM10mdkhandaveNo ratings yet

- FRC With Internal AutodrainDocument3 pagesFRC With Internal AutodrainBiswanath LenkaNo ratings yet

- Check Valves: Check Valve and Pre - LL Valve Type FDocument2 pagesCheck Valves: Check Valve and Pre - LL Valve Type FSaeid MirNo ratings yet

- Filtrec F040 SeriesDocument8 pagesFiltrec F040 Serieshkhan10No ratings yet

- SinclairCollins K-Series 02 2016Document20 pagesSinclairCollins K-Series 02 2016Eduardo Ricardo Puga RomeroNo ratings yet

- Model AR: Smith Meter Air EliminatorsDocument4 pagesModel AR: Smith Meter Air EliminatorsGuillermo GutierrezNo ratings yet

- ISZ3000ILDocument4 pagesISZ3000ILDiana V. RosalesNo ratings yet

- Wastemaster Mit en 0715 EditDocument4 pagesWastemaster Mit en 0715 EditPablo DonariNo ratings yet

- Gfps-Dk-Technical Data Metal Butterfly Valve Type 039Document7 pagesGfps-Dk-Technical Data Metal Butterfly Valve Type 039Omar GuillenNo ratings yet

- Maxflow FRLDocument5 pagesMaxflow FRLGopalakrishnan Raju100% (1)

- Lead Free: Full Port Ductile Iron Single Chamber Basic ValveDocument3 pagesLead Free: Full Port Ductile Iron Single Chamber Basic ValveWattsNo ratings yet

- Alfa Laval Unique Mixproof Tank Outlet: Double Seat ValvesDocument7 pagesAlfa Laval Unique Mixproof Tank Outlet: Double Seat Valvesمیلاد قاسمیNo ratings yet

- CGX2003-07 enDocument7 pagesCGX2003-07 enJunianto PwNo ratings yet

- Homogenizer HPM Type B55 PDFDocument2 pagesHomogenizer HPM Type B55 PDFÑzñz RedesNo ratings yet

- Aa Manejadora Split Central Ciac 5TRDocument1 pageAa Manejadora Split Central Ciac 5TRPipe ValenciaNo ratings yet

- Angle Seat Valve Ycp (1)Document4 pagesAngle Seat Valve Ycp (1)Sarji-Biomedical sachinNo ratings yet

- Model P1000AXL, TP1100A, TP220, TP3000: Temperature & Pressure and Pressure Relief ValvesDocument2 pagesModel P1000AXL, TP1100A, TP220, TP3000: Temperature & Pressure and Pressure Relief Valvesmember1000No ratings yet

- Pi8300 enDocument4 pagesPi8300 enJamin SmtpngNo ratings yet

- Baker Floats PDFDocument14 pagesBaker Floats PDFDon BraithwaiteNo ratings yet

- Ucf A CTL PDFDocument12 pagesUcf A CTL PDFTH LEENo ratings yet

- Output Filters Nastec REV5 - ENDocument2 pagesOutput Filters Nastec REV5 - ENDiego Juarez GonzalesNo ratings yet

- Asco 8344 PDFDocument2 pagesAsco 8344 PDFOsman Lopez SalasNo ratings yet

- F105-03BG Watts Air FilterDocument2 pagesF105-03BG Watts Air FilterMROstop.comNo ratings yet

- Pressure Relief ValveDocument4 pagesPressure Relief ValveDiky AfriantNo ratings yet

- 54-13041r Ins 1Document16 pages54-13041r Ins 1Felipe ReyesNo ratings yet

- Blowout Prevention Equipment Check List: & 10 December 2006Document3 pagesBlowout Prevention Equipment Check List: & 10 December 2006بريجينيف خروتشوفNo ratings yet

- MaicoDocument9 pagesMaicoShiv KumarNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- Name: Rounak Barnwal Class: Xii A Roll No: SESSION:2022-2023Document11 pagesName: Rounak Barnwal Class: Xii A Roll No: SESSION:2022-2023Naman BarnwalNo ratings yet

- 9190-Uspe 2x10200kw Wartsila 20v32ts Hfo Diesel GensetDocument19 pages9190-Uspe 2x10200kw Wartsila 20v32ts Hfo Diesel Gensetpradeep kumarNo ratings yet

- Prediction of Oxygen Induced Corrosion in Industrial Waters 049020115-1Document6 pagesPrediction of Oxygen Induced Corrosion in Industrial Waters 049020115-1astromoNo ratings yet

- Spectrophotometric Determination of The Stoichiometry of A ComplexDocument6 pagesSpectrophotometric Determination of The Stoichiometry of A ComplexDean Dela CruzNo ratings yet

- Module 4 - Energy Transfer (Student Guide)Document11 pagesModule 4 - Energy Transfer (Student Guide)greggcllam619076No ratings yet

- Tut (2-3-4) Mech of Mach Winter 2011Document10 pagesTut (2-3-4) Mech of Mach Winter 2011Mahmoud El-MahdyNo ratings yet

- ENGINEERING DESIGN GUIDELINE - Distillation - Column - Rev05Document30 pagesENGINEERING DESIGN GUIDELINE - Distillation - Column - Rev05syazwanjohnmazlan100% (2)

- Iaea Nds 0206 200806Document92 pagesIaea Nds 0206 200806Umair RasheedNo ratings yet

- 12 Physics Electrostatics Test 01 Answer 5x7fDocument4 pages12 Physics Electrostatics Test 01 Answer 5x7fAshish BajpaiNo ratings yet

- Liquid Solution Board Booster Worksheet-2Document3 pagesLiquid Solution Board Booster Worksheet-2tarunNo ratings yet

- SOLN PurcellDocument7 pagesSOLN Purcelleddiejam1642No ratings yet

- CH 20 ThermodynamicsDocument11 pagesCH 20 ThermodynamicsElle QuizonNo ratings yet

- A-Frame Calculation Without CoverDocument6 pagesA-Frame Calculation Without CoverimsayaaNo ratings yet

- Sliding Mode Controller SMC Governed Speed Control of DC MotorDocument6 pagesSliding Mode Controller SMC Governed Speed Control of DC Motorraghav4life8724No ratings yet

- Iocl Haldia ReportDocument99 pagesIocl Haldia ReportArkadev GhoshNo ratings yet

- Liquid Chromatography: High Performance Liquid Chromatograhy (HPLC)Document94 pagesLiquid Chromatography: High Performance Liquid Chromatograhy (HPLC)Ali Issa OthmanNo ratings yet

- Supercritical Fluid Extraction of Organic Compounds From Solids and Aqueous Solutions PDFDocument60 pagesSupercritical Fluid Extraction of Organic Compounds From Solids and Aqueous Solutions PDFÁlvaro Cornejo PerdomoNo ratings yet

- Subject: General Chemistry Test,: Date: May 2015Document7 pagesSubject: General Chemistry Test,: Date: May 2015PHƯƠNG ĐẶNG YẾNNo ratings yet

- Colloid Chemistry - Chapter 1 - Introduction of Colloid ChemistryDocument29 pagesColloid Chemistry - Chapter 1 - Introduction of Colloid ChemistryKhang DuongNo ratings yet

- AstronomyformulaDocument30 pagesAstronomyformulapalharjeetNo ratings yet

- Ial WPH06 01 Oct19Document20 pagesIal WPH06 01 Oct19SumuduMPereraNo ratings yet

- O&m RGVDocument7 pagesO&m RGVNur NaziraNo ratings yet

- Analysisof Cicada Wing Surface - SuperHydrophobicDocument9 pagesAnalysisof Cicada Wing Surface - SuperHydrophobicNiroshanNo ratings yet

- Fluid Mechanics July 2013Document0 pagesFluid Mechanics July 2013Prasad C MNo ratings yet

- REMOTE Calculator Tool May 21 2013Document77 pagesREMOTE Calculator Tool May 21 2013Leyner Garcia MezquitaNo ratings yet

- Elkem 07 Magnesiun Contents in Ductile IronDocument2 pagesElkem 07 Magnesiun Contents in Ductile Ironmarcotulio123No ratings yet

- Experiment 6 Date 2/9/11: Determination of Numerical Aperture and Acceptance Angle of An Optical FiberDocument17 pagesExperiment 6 Date 2/9/11: Determination of Numerical Aperture and Acceptance Angle of An Optical FiberSanidhya PainuliNo ratings yet

- Solar Panel InstallationDocument10 pagesSolar Panel Installationpeculiarchild2020No ratings yet