Professional Documents

Culture Documents

Design Calculations Insulation Thickness Rev 1 PDF Free

Design Calculations Insulation Thickness Rev 1 PDF Free

Uploaded by

abdeslem mouloudjOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Calculations Insulation Thickness Rev 1 PDF Free

Design Calculations Insulation Thickness Rev 1 PDF Free

Uploaded by

abdeslem mouloudjCopyright:

Available Formats

Owner MB POWER (Madhya Pardesh) Unit 1 & 2 (2 x 600 MW )

EPC Lanco Infratech Limited

FO Contractor Moser Baer Engineering & Constructions Limited

Title Design Calculation - INSULATION THICKNESS

Doc No LITL - 020 - MEV-213 - R - 41807 REV-0 DATE 03.08.2011

O-1107-MBFO-CL-09 REV-1 DATE 14.10.2011

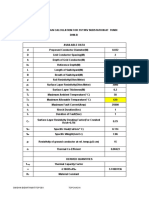

CALCULATIONS FOR INSULATION THICKNESS

HFO LINES HFO LINE BOILER STEAM AT 3.5 STEAM AT 13 CONDENSATE CONDENSATE HFO STORAGE

FROM STORAGE HEATER RETURN TO KG/SQCM(g) KG/SQCM(g) FROM 3.5 FROM 13 & DRAIN OIL

UNLOADING TANK TO OUTLET TO STORAGE KG/SQCM(g) KG/SQCM(g) TANK

BASIC DATA

AREA TO LINE BOILER TANK STEAM STEAM

STORAGE HEATER

TANK INLET

Ambient temperature (min) 6.5 6.5 6.5 6.5 6.5 6.5 6.5 6.5 6.5 deg C

Ambient temperature (max) 42.2 42.2 42.2 42.2 42.2 42.2 42.2 42.2 42.2 deg C

Maximum cladding temperature 60 60 60 60 60 60 60 60 60 deg C

Fluid temperature 45 60 120 120 147.2 360 147.2 360 45 deg C

Mean temperature 43.6 51.1 81.1 81.1 94.7 201.1 94.7 201.1 43.6 deg C

Value of K from IS:8183 for LRB of 81-120 0.43 0.43 0.52 0.52 0.62 0.73 0.52 0.73 0.43 mW/cm*degC

kg/cum density

Value of K from IS:8183 for LRB of 81-120 0.037 0.037 0.045 0.045 0.053 0.063 0.045 0.063 0.037 kcal/m*degC

kg/cum density

Insulating material Light resin bonded mineral wool as per IS:8183

Density 120 kg/cum

Cladding material Aluminum sheets of 24 gauge thickness

Factor f for aluminum surface

Heat loss per unit area of shell surface

q= kcal/hr*m2

th-tm / {d/2k*ln (d1/d) + 1/ f(d/d1)}

where

th deg C Temp of hot surface

tm deg C Ambient temp (min) for worst case

f 4.89 Kcal/hr*m2 Factor for aluminum surface from IS: 7413

d m Outer dia of pipe

Insulation thickness m Insulation thickness

d1 m OD of insulated pipe

k kcal/m deg C Thermal conductivity at mean temp

Temp rise over ambient temp

t= (q*d) / (d1*f)

where

q kcal/hr*m2 Heat loss per unit area

d m Outer dia of pipe

d1 m OD of insulated pipe

Caldding temperature at min ambient, tc tmin+t

(min)=

Caldding temperature at max ambient, tc tmax+t

(max)=

Insulation thickness for HFO LINES FROM UNLOADING AREA TO HFO STORAGE TANK & DRAIN OIL LINES

Pipe size Thermal Pipe OD Thickness of Mean dia OD th-tm d / 2k ln(d1/d) (d/d1) 1/f(d/d1) {d/2k*ln (d1/d) + Heat loss Temp rise Cladding Cladding

Conductivity insulation 1/ f(d/d1)} temp at temp at

minimum maximum

ambient temp ambient temp

k d d1 q t tc (min) tc (max)

NB m m m m deg C kcal / hr*m2 deg C deg C deg C

15 0.037 0.022 0.025 0.047 0.072 38.5 0.297 1.186 0.306 0.669 1.022 37.67 1.68 8.18 43.88

25 0.037 0.034 0.025 0.059 0.084 38.5 0.460 0.904 0.405 0.505 0.921 41.80 2.47 8.97 44.67

50 0.037 0.06 0.025 0.085 0.11 38.5 0.811 0.606 0.545 0.375 0.867 44.42 3.54 10.04 45.74

80 0.037 0.089 0.025 0.114 0.139 38.5 1.203 0.446 0.640 0.319 0.856 44.98 4.21 10.71 46.41

100 0.037 0.115 0.025 0.14 0.165 38.5 1.555 0.361 0.697 0.293 0.855 45.04 4.59 11.09 46.79

150 0.037 0.165 0.025 0.19 0.215 38.5 2.231 0.265 0.767 0.266 0.857 44.93 5.04 11.54 47.24

Insulation thickness for HFO LINES FROM STORAGE TANK TOLINE HEATER INLET

Pipe size Thermal Pipe OD d Thickness of Mean dia OD th-tm d/2k ln(d1/d) (d/d1) 1/f(d/d1) {d/2k*ln (d1/d) + Heat loss Temp rise Cladding Cladding

Conductivity insulation d1 1/ f(d/d1)} temp at temp at

minimum maximum

ambient temp ambient temp

NB m m m m deg C q t tc (min) tc (max)

15 0.037 0.022 0.025 0.047 0.072 53.5 0.297 1.186 0.306 0.669 1.022 52.35 2.34 8.84 44.54

25 0.037 0.034 0.025 0.059 0.084 53.5 0.460 0.904 0.405 0.505 0.921 58.09 3.44 9.94 45.64

50 0.037 0.06 0.025 0.085 0.11 53.5 0.811 0.606 0.545 0.375 0.867 61.73 4.92 11.42 47.12

80 0.037 0.089 0.025 0.114 0.139 53.5 1.203 0.446 0.640 0.319 0.856 62.51 5.85 12.35 48.05

100 0.037 0.115 0.025 0.14 0.165 53.5 1.555 0.361 0.697 0.293 0.855 62.59 6.38 12.88 48.58

150 0.037 0.165 0.025 0.19 0.215 53.5 2.231 0.265 0.767 0.266 0.857 62.43 7.00 13.50 49.20

Insulation thickness for HFO LINES FROM LINE HEATER TO BOILER

Pipe size Thermal Pipe OD d Thickness of Mean dia OD th-tm d/2k ln(d1/d) (d/d1) 1/f(d/d1) {d/2k*ln (d1/d) + Heat loss Temp rise Cladding Cladding

Conductivity insulation d1 1/ f(d/d1)} temp at temp at

minimum maximum

ambient temp ambient temp

NB m m m m deg C q t tc (min) tc (max)

15 0.045 0.022 0.025 0.047 0.072 113.5 0.246 1.186 0.306 0.669 0.961 118.12 5.28 11.78 47.48

25 0.045 0.034 0.025 0.059 0.084 113.5 0.380 0.904 0.405 0.505 0.849 133.68 7.91 14.41 50.11

50 0.045 0.06 0.025 0.085 0.11 113.5 0.671 0.606 0.545 0.375 0.782 145.23 11.58 18.08 53.78

80 0.045 0.089 0.025 0.114 0.139 113.5 0.995 0.446 0.640 0.319 0.763 148.75 13.92 20.42 56.12

100 0.045 0.115 0.030 0.145 0.175 113.5 1.286 0.420 0.657 0.311 0.851 133.37 12.81 19.31 55.01

150 0.045 0.165 0.030 0.195 0.225 113.5 1.845 0.310 0.733 0.279 0.851 133.37 14.30 20.80 56.50

Insulation thickness for HFO LINES FROM BOILER RETURN TO STORAGE TANK

Pipe size Thermal Pipe OD d Thickness of Mean dia OD th-tm d/2k ln(d1/d) (d/d1) 1/f(d/d1) {d/2k*ln (d1/d) + Heat loss Temp rise Cladding Cladding

Conductivity insulation d1 1/ f(d/d1)} temp at temp at

minimum maximum

ambient temp ambient temp

NB m m m m deg C q t tc (min) tc (max)

15 0.045 0.022 0.025 0.047 0.072 113.5 0.246 1.186 0.306 0.669 0.961 118.12 5.28 11.78 47.48

25 0.045 0.034 0.025 0.059 0.084 113.5 0.380 0.904 0.405 0.505 0.849 133.68 7.91 14.41 50.11

50 0.045 0.06 0.025 0.085 0.11 113.5 0.671 0.606 0.545 0.375 0.782 145.23 11.58 18.08 53.78

80 0.045 0.089 0.025 0.114 0.139 113.5 0.995 0.446 0.640 0.319 0.763 148.75 13.92 20.42 56.12

100 0.045 0.115 0.030 0.145 0.175 113.5 1.286 0.420 0.657 0.311 0.851 133.37 12.81 19.31 55.01

150 0.045 0.165 0.030 0.195 0.225 113.5 1.845 0.310 0.733 0.279 0.851 133.37 14.30 20.80 56.50

Insulation thickness for STEAM LINES OF 3.5 KG/SQCM(g) & CONDENSATE LINES

Pipe size Thermal Pipe OD d Thickness of Mean dia OD th-tm d/2k ln(d1/d) (d/d1) 1/f(d/d1) {d/2k*ln (d1/d) + Heat loss Temp rise Cladding Cladding

Conductivity insulation d1 1/ f(d/d1)} temp at temp at

minimum maximum

ambient temp ambient temp

NB m m m m deg C q t tc (min) tc (max)

15 0.053 0.022 0.025 0.047 0.072 140.7 0.206 1.186 0.306 0.669 0.914 153.96 6.88 13.38 49.08

25 0.053 0.034 0.025 0.059 0.084 140.7 0.319 0.904 0.405 0.505 0.794 177.29 10.49 16.99 52.69

50 0.053 0.06 0.040 0.1 0.14 140.7 0.563 0.847 0.429 0.477 0.954 147.50 9.24 15.74 51.44

80 0.053 0.089 0.040 0.129 0.169 140.7 0.835 0.641 0.527 0.388 0.924 152.35 11.73 18.23 53.93

100 0.053 0.115 0.040 0.155 0.195 140.7 1.078 0.528 0.590 0.347 0.916 153.57 13.24 19.74 55.44

150 0.053 0.165 0.040 0.205 0.245 140.7 1.547 0.395 0.673 0.304 0.915 153.72 15.14 21.64 57.34

Insulation thickness for STEAM LINES OF 13.0 KG/SQCM(g) & CONDENSATE LINES

Pipe size Thermal Pipe OD d Thickness of Mean dia OD th-tm d/2k ln(d1/d) (d/d1) 1/f(d/d1) {d/2k*ln (d1/d) + Heat loss Temp rise Cladding Cladding

Conductivity insulation d1 1/ f(d/d1)} temp at temp at

minimum maximum

ambient temp ambient temp

NB m m m m deg C q t tc (min) tc (max)

15 0.063 0.022 0.040 0.062 0.102 353.5 0.175 1.534 0.216 0.948 1.217 290.49 9.16 15.66 51.36

25 0.063 0.034 0.040 0.074 0.114 353.5 0.271 1.210 0.298 0.686 1.013 348.87 15.21 21.71 57.41

50 0.063 0.06 0.060 0.12 0.18 353.5 0.478 1.099 0.333 0.613 1.138 310.50 15.13 21.63 57.33

80 0.063 0.089 0.100 0.189 0.289 353.5 0.709 1.178 0.308 0.664 1.499 235.84 10.62 17.12 52.82

100 0.063 0.115 0.100 0.215 0.315 353.5 0.916 1.008 0.365 0.560 1.483 238.36 12.72 19.22 54.92

150 0.063 0.165 0.100 0.265 0.365 353.5 1.314 0.794 0.452 0.452 1.496 236.34 15.62 22.12 57.82

Insulation thickness for HFO STORAGE & DRAIN OIL TANK

TANK DIA Thermal TANK OD Thickness of Mean dia OD th-tm d/2k ln(d1/d) (d/d1) 1/f(d/d1) {d/2k*ln (d1/d) + Heat loss Temp rise Cladding Cladding

Conductivity d insulation d1 1/ f(d/d1)} temp at temp at

minimum maximum

ambient temp ambient temp

m m m m m deg C q t tc (min) tc (max)

16 0.037 16.02 0.040 16.06 16.1 38.5 216.604 0.005 0.995 0.206 1.284 29.97 4.36 10.86 46.56

1.8 0.037 1.812 0.040 1.852 1.892 38.5 24.500 0.043 0.958 0.214 1.272 30.27 4.24 10.74 46.44

You might also like

- Plate Heat Exchanger Design in ExcelDocument6 pagesPlate Heat Exchanger Design in ExcelSteve WanNo ratings yet

- Inbreathing OutbreathingDocument17 pagesInbreathing OutbreathingInggit100% (3)

- AHU ChecklistDocument11 pagesAHU Checklistaneesh50% (2)

- Calculate Heat Loss From Insulated Hot Pipe - Excel Sheet On Request To SCRDocument2 pagesCalculate Heat Loss From Insulated Hot Pipe - Excel Sheet On Request To SCRscranderiNo ratings yet

- Print Page - Serbian Professor Savic Sonic Water Heater Replication COP 12Document334 pagesPrint Page - Serbian Professor Savic Sonic Water Heater Replication COP 12Bastien Gall de SilléNo ratings yet

- Design Calculations - Insulation Thickness REV-1Document4 pagesDesign Calculations - Insulation Thickness REV-1delMAK100% (1)

- Insulated Pipe - Temperature Loss CalculationDocument5 pagesInsulated Pipe - Temperature Loss CalculationnopNo ratings yet

- Design Heat Exchanger Shell and Tube TheDocument8 pagesDesign Heat Exchanger Shell and Tube ThezatamaqeelNo ratings yet

- Heating Coil Sizing For Fuel Oil TankDocument2 pagesHeating Coil Sizing For Fuel Oil TankPouria Sabbagh100% (1)

- Kompendium PDFDocument142 pagesKompendium PDFsiladharmaNo ratings yet

- 25 Clicker QuestionsDocument20 pages25 Clicker QuestionsFuentesBrisbaneNo ratings yet

- CM 43-95Document4 pagesCM 43-95Batara L ToruanNo ratings yet

- Design Calculation For Coil in The HFO Tank - TK14 & TK 15Document4 pagesDesign Calculation For Coil in The HFO Tank - TK14 & TK 15chintanNo ratings yet

- Design. Ref - Decuments: API 650, 11TH - ED M09Document9 pagesDesign. Ref - Decuments: API 650, 11TH - ED M09hgagNo ratings yet

- HMT SMS ManualDocument33 pagesHMT SMS ManualMurariNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument7 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument13 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- Earthmat CalculationDocument4 pagesEarthmat CalculationpradipNo ratings yet

- Simulation An OptimizationDocument28 pagesSimulation An Optimizationalmoanna97100% (1)

- Method For Predicting Temperature in A Room Fire With Natural VentilationDocument10 pagesMethod For Predicting Temperature in A Room Fire With Natural VentilationJohn ANo ratings yet

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocument30 pagesJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj75% (4)

- Kiln Performance - Efficiency FormulasDocument12 pagesKiln Performance - Efficiency FormulasMohamed ZayedNo ratings yet

- Data Sheet For PheDocument1 pageData Sheet For PheCarlosCostaNo ratings yet

- Attachment 3: Calculation of Inner Space VentilationDocument4 pagesAttachment 3: Calculation of Inner Space VentilationDuy VuNo ratings yet

- Insulation Thickness-20.10.2020 PDFDocument1 pageInsulation Thickness-20.10.2020 PDFEmandi RajeshNo ratings yet

- #2. 열교환기 Design sheetDocument5 pages#2. 열교환기 Design sheet배광득0% (1)

- 02.2 Temperature FVDocument16 pages02.2 Temperature FVjovanivanNo ratings yet

- LPH Data Sheet For 660 MWDocument7 pagesLPH Data Sheet For 660 MWproloy biswasNo ratings yet

- Ael-2597-Mec-Cl-0305-R1 - Sizing Calculation of Heating CoilDocument3 pagesAel-2597-Mec-Cl-0305-R1 - Sizing Calculation of Heating CoilpavanNo ratings yet

- B X L or D A: Calculation of Earth Grid Conductor Area As Per IEEE-80 258.40 3.744 475.39 SQMMDocument1 pageB X L or D A: Calculation of Earth Grid Conductor Area As Per IEEE-80 258.40 3.744 475.39 SQMMVamsi ManojNo ratings yet

- Bottom & Annular Plate Design: We Will Use Bottom Witout AnularDocument25 pagesBottom & Annular Plate Design: We Will Use Bottom Witout AnularhgagNo ratings yet

- Surface Condenser Thermal Analysis (100914)Document11 pagesSurface Condenser Thermal Analysis (100914)amlanfacebookNo ratings yet

- Smoke - Ventilation CalculationsDocument8 pagesSmoke - Ventilation CalculationsdasmechNo ratings yet

- Kiln FormulasDocument53 pagesKiln FormulasSHRAVAN KUMARNo ratings yet

- Model Hvac Design Load Calculation JMLDocument39 pagesModel Hvac Design Load Calculation JMLladaojm100% (1)

- Steam Calculation On Basis of Flow-Temperature (1) 2222Document5 pagesSteam Calculation On Basis of Flow-Temperature (1) 2222hmaza shakeelNo ratings yet

- Forced Convection Heat TransferDocument6 pagesForced Convection Heat TransferHani BanatNo ratings yet

- Slno Description Symbol Unit Value: Calculation of Shell ThicknessDocument2 pagesSlno Description Symbol Unit Value: Calculation of Shell ThicknessalvinchuanNo ratings yet

- DEBA-DD-EL-CC-3141-0.1-flexible Conductor Size CalculationDocument4 pagesDEBA-DD-EL-CC-3141-0.1-flexible Conductor Size Calculationjie zhangNo ratings yet

- Thyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetDocument3 pagesThyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetShariq KhanNo ratings yet

- Crude Oil Storage Tank Heating CoilDocument3 pagesCrude Oil Storage Tank Heating CoilbadelitamariusNo ratings yet

- Electric Discharge Machining (EDM)Document52 pagesElectric Discharge Machining (EDM)MaheshNo ratings yet

- Steam Consumption and Line SizingDocument3 pagesSteam Consumption and Line SizingpavanNo ratings yet

- 3200a LT Busduct Sizing CalculationDocument3 pages3200a LT Busduct Sizing CalculationRamji RamakrishnanNo ratings yet

- HE Spiral KuroseDocument53 pagesHE Spiral Kurosefannychoirudin1993No ratings yet

- Steam Coil SizingDocument2 pagesSteam Coil Sizingpavan100% (1)

- Earthing Calculation: A General Design DataDocument14 pagesEarthing Calculation: A General Design Dataمحمد الأمين سنوساوي100% (2)

- PHE DesignDocument53 pagesPHE Designchgourishankar2000100% (1)

- 230kv Cable Sizing 1Document6 pages230kv Cable Sizing 1Thirunavukkarasu VaratharajanNo ratings yet

- Methanol Recovery Calculation 31-12-2023 R1Document1 pageMethanol Recovery Calculation 31-12-2023 R1Preetpal SinghNo ratings yet

- Thermal Lab-2 Manual CompletedDocument69 pagesThermal Lab-2 Manual CompletedSiva RamanNo ratings yet

- Application Note AN-1057: Heatsink CharacteristicsDocument17 pagesApplication Note AN-1057: Heatsink CharacteristicsAndre LimaNo ratings yet

- Earthing Calcs - Master FileDocument8 pagesEarthing Calcs - Master FilenewattelectricNo ratings yet

- Cement Kiln Pyro BalanceDocument40 pagesCement Kiln Pyro BalanceGanapathy SubramaniamNo ratings yet

- Thermic Fluid Heater Data Sheet - Rev 0Document10 pagesThermic Fluid Heater Data Sheet - Rev 0Dhamotharan ChinnaduraiNo ratings yet

- Nouveau Document 2019-03-04 20.55.50Document8 pagesNouveau Document 2019-03-04 20.55.50abdeslem mouloudjNo ratings yet

- PS End Suction Pump Brochure EN Oct18Document6 pagesPS End Suction Pump Brochure EN Oct18abdeslem mouloudjNo ratings yet

- Qdoc - Tips - Sws Gpsa Engineering Data Book 12th EdDocument3 pagesQdoc - Tips - Sws Gpsa Engineering Data Book 12th Edabdeslem mouloudjNo ratings yet

- Data Sheet For Instrument Air Package 15Bv-63-Pk-201: Doc. No.: Engineering Company Rev. No.: DateDocument2 pagesData Sheet For Instrument Air Package 15Bv-63-Pk-201: Doc. No.: Engineering Company Rev. No.: Dateabdeslem mouloudjNo ratings yet

- Fabrication, Installation, Commissioning & Testing of Compressed Air System With Associated ComponentsDocument7 pagesFabrication, Installation, Commissioning & Testing of Compressed Air System With Associated Componentsabdeslem mouloudjNo ratings yet

- InfiniSolar WP LV 6KW ManualDocument78 pagesInfiniSolar WP LV 6KW ManualHussnain NadeemNo ratings yet

- Appendix F - Steam TableDocument42 pagesAppendix F - Steam TableAhmad Asfahani50% (2)

- F Ma Lab2Document3 pagesF Ma Lab2Fiona LiuNo ratings yet

- Local Media3983018567083363738Document6 pagesLocal Media3983018567083363738Venus Kate GevaNo ratings yet

- Workshop 5: Analyzing DC Circuits Solutions: in OutDocument12 pagesWorkshop 5: Analyzing DC Circuits Solutions: in OutvichuNo ratings yet

- Room Checksums by ArshadDocument4 pagesRoom Checksums by Arshadmeesam1No ratings yet

- Green Methods For Hydrogen ProductionDocument18 pagesGreen Methods For Hydrogen ProductionSpafiu Paula Raluca100% (2)

- Surface ChargesDocument7 pagesSurface ChargesAnuragNo ratings yet

- Uyo Transmission StationDocument19 pagesUyo Transmission StationDon SagaciousNo ratings yet

- Difference Between Homogeneous and Heterogeneous ReactionDocument13 pagesDifference Between Homogeneous and Heterogeneous ReactionMeet ZinzuvadiyaNo ratings yet

- Ch-10 Elasticity - DPP 02Document3 pagesCh-10 Elasticity - DPP 02Gajendra YadavNo ratings yet

- Types of Dynamometer: Name: M. Hassan Bhatti Lab. Attendant: Sir Wasif Roll #: 2016-ME-24 Subject: IC EngineDocument2 pagesTypes of Dynamometer: Name: M. Hassan Bhatti Lab. Attendant: Sir Wasif Roll #: 2016-ME-24 Subject: IC EngineMohammad Zia Nasir BhuttaNo ratings yet

- 16 Vapour Absorption Refrigeration Systems Based On Ammonia-Water PairDocument22 pages16 Vapour Absorption Refrigeration Systems Based On Ammonia-Water PairPRASAD326100% (4)

- JAKKA - Resetke I Anemostati Kompletan CenovnikDocument68 pagesJAKKA - Resetke I Anemostati Kompletan CenovnikAndjela StojanovicNo ratings yet

- Wa0015.Document18 pagesWa0015.agnooryNo ratings yet

- Plant Berkapasitas 1.500 Metrik Ton Per Jam, Stockpile Untuk 120.000 Metrik Ton, PelabuhanDocument1 pagePlant Berkapasitas 1.500 Metrik Ton Per Jam, Stockpile Untuk 120.000 Metrik Ton, PelabuhanueiehjdNo ratings yet

- Emirates Glass Laboratory: Table of ResultsDocument1 pageEmirates Glass Laboratory: Table of ResultsNav JavNo ratings yet

- 2011 AJC Prelim H2 Physics P1Document18 pages2011 AJC Prelim H2 Physics P1Aletheia LaiNo ratings yet

- Bornay AeconDocument2 pagesBornay AeconAlexandre Boullot100% (2)

- TC Panel (GB) (0701)Document2 pagesTC Panel (GB) (0701)Bojan KitanovskiNo ratings yet

- Eche0807 at C1Document6 pagesEche0807 at C1Hema LataNo ratings yet

- Lecture Sheet 1 - Introduction, Coplanar & Non Coplanar ForcesDocument26 pagesLecture Sheet 1 - Introduction, Coplanar & Non Coplanar ForcesNafin AfnanNo ratings yet

- General Physics 1 Module 5Document30 pagesGeneral Physics 1 Module 5RJ ManalangNo ratings yet

- Design DataDocument16 pagesDesign DataSaber Abdel MoreidNo ratings yet

- Course Unit: Bachelor of Science in Mechanical Engineering: Mechanical Engineering Laboratory 1Document5 pagesCourse Unit: Bachelor of Science in Mechanical Engineering: Mechanical Engineering Laboratory 1Sandra Abancio HollmanNo ratings yet