Professional Documents

Culture Documents

SATIP-W-011-01 Rev 8

SATIP-W-011-01 Rev 8

Uploaded by

saravananmenmathiCopyright:

Available Formats

You might also like

- Clow Imc08 Im 10Document23 pagesClow Imc08 Im 10Fatima AbboudNo ratings yet

- SATR-W-2006 Rev 6Document1 pageSATR-W-2006 Rev 6Manoj KumarNo ratings yet

- 1 SATIP-E-007-01 Air Cooled HExch - Fin Fan-Rev 01Document2 pages1 SATIP-E-007-01 Air Cooled HExch - Fin Fan-Rev 01Anonymous S9qBDVkyNo ratings yet

- Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument5 pagesSaudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliShahbaz AhmadNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument12 pagesSaudi Aramco Typical Inspection Planspravin231No ratings yet

- Incr - XXXDocument2 pagesIncr - XXXsadik coolsadyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Active Doc ListDocument405 pagesActive Doc Listnadeem UddinNo ratings yet

- Satr W 2013Document8 pagesSatr W 2013Rijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- SAES-M-005 PDF Download - Design and Construction of Fixed Offshore Platforms - PDFYARDocument8 pagesSAES-M-005 PDF Download - Design and Construction of Fixed Offshore Platforms - PDFYARZahidRafiqueNo ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- Engineering Standard: SAES-H-200 30 March 2020 Storage, Handling, and Installation of Coated PipesDocument10 pagesEngineering Standard: SAES-H-200 30 March 2020 Storage, Handling, and Installation of Coated PipesMuhammad AsifNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- 175 011100Document2 pages175 011100Abu Anas M.SalaheldinNo ratings yet

- SAIC L 2031 (Comments)Document2 pagesSAIC L 2031 (Comments)Anton Thomas PunzalanNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- QMIS LBE Rev Mech Final OldDocument683 pagesQMIS LBE Rev Mech Final OldprabakaranNo ratings yet

- 175-Ir171300, (850146), 11.30.2015Document2 pages175-Ir171300, (850146), 11.30.2015Rami ELLOUMINo ratings yet

- CV of QC Piping and NDT Coordinator VigneshPethurajDocument5 pagesCV of QC Piping and NDT Coordinator VigneshPethurajEswari AnandNo ratings yet

- Section Subject: Shaybah CPF Expansion ProjectDocument21 pagesSection Subject: Shaybah CPF Expansion ProjectAdhie Waelacxh100% (1)

- SATR-W-2007 Rev 7Document4 pagesSATR-W-2007 Rev 7QA QCNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- 175-026600 10312016Document2 pages175-026600 10312016Prasanna UmapathyNo ratings yet

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocument1 pageSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387No ratings yet

- 5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFDocument136 pages5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFsumit kumarNo ratings yet

- Saes A 109Document5 pagesSaes A 109SIVANo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- 01 Samss 010Document11 pages01 Samss 010biplabpal2009No ratings yet

- Materials System SpecificationDocument3 pagesMaterials System SpecificationMoustafa BayoumiNo ratings yet

- Ir 175-010000Document2 pagesIr 175-010000Abu Anas M.SalaheldinNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- 175 010700 PDFDocument2 pages175 010700 PDFAbu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument19 pagesSaudi Aramco Inspection ChecklistIrshad IqbalNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 Mechkarthi51289No ratings yet

- Materials System SpecificationDocument7 pagesMaterials System SpecificationFlorante NoblezaNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- SAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpDocument2 pagesSAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpAhdal NoushadNo ratings yet

- Schedule B - Attachment IVDocument29 pagesSchedule B - Attachment IVAbdul Ahad LoneNo ratings yet

- SATR-J - 6802 - Rev 0 PDFDocument3 pagesSATR-J - 6802 - Rev 0 PDFAdel KlkNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18nadeem shaikhNo ratings yet

- SATR-J - 6801 - Rev 0 PDFDocument6 pagesSATR-J - 6801 - Rev 0 PDFAdel KlkNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Arabian Oil Company: Instrument Specification Sheet - Pressure and Differential Pressure GaugesDocument2 pagesSaudi Arabian Oil Company: Instrument Specification Sheet - Pressure and Differential Pressure GaugesMuhammad Shahid0% (1)

- SAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesDocument6 pagesSAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesAhdal NoushadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- GI-0002.600 (Unit Accpetance After T&I Shut DownDocument4 pagesGI-0002.600 (Unit Accpetance After T&I Shut DownSanthoshNo ratings yet

- Saep 125Document9 pagesSaep 125Demac SaudNo ratings yet

- SATIP-P-104-05 Rev 8 Final Above Grade Conduits PDFDocument2 pagesSATIP-P-104-05 Rev 8 Final Above Grade Conduits PDFSabheeh AliNo ratings yet

- Saep 323 PDFDocument8 pagesSaep 323 PDFthanga balanNo ratings yet

- SATR-W-2008 Rev 8 FD-1Document6 pagesSATR-W-2008 Rev 8 FD-1asiqna100% (1)

- Milestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Document4 pagesMilestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Raghad GNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- 01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeDocument4 pages01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeZahidRafiqueNo ratings yet

- Saudi Aramco Engineering Index : A B C D E F G H J L M E Q WDocument3 pagesSaudi Aramco Engineering Index : A B C D E F G H J L M E Q Wkhuram916No ratings yet

- SAER1972Document9 pagesSAER1972zamil2008No ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalpravinNo ratings yet

- SATIP-W-011-01 Note5Document14 pagesSATIP-W-011-01 Note5Deo MNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of Pipelines SATIP-W-012-01 31-Dec-14 MechanicalDocument10 pagesSaudi Aramco Typical Inspection Plan: Welding of Pipelines SATIP-W-012-01 31-Dec-14 Mechanicalpravin0% (1)

- Profit and Loss NewDocument34 pagesProfit and Loss NewPranjal SharmaNo ratings yet

- Schermerhorn Mgmt9 Ch19Document30 pagesSchermerhorn Mgmt9 Ch19api-3738694No ratings yet

- LEC-2010 Value-Stream Mapping The Chemical ProcessesDocument5 pagesLEC-2010 Value-Stream Mapping The Chemical ProcessesMustafa Mert SAMLINo ratings yet

- Jurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover SheetDocument35 pagesJurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover Sheettomj9104No ratings yet

- PQR: Emsb/Pqr-002: Groove Design of Test Coupon Welding Sequence of Test CouponDocument2 pagesPQR: Emsb/Pqr-002: Groove Design of Test Coupon Welding Sequence of Test CouponMohd AshrafNo ratings yet

- Quality SpecificationDocument11 pagesQuality SpecificationHazarish BaharuddinNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- ZIMSEC O Level Commerce 4049q2 Specimen - WXlNTiqA039c1JqDocument4 pagesZIMSEC O Level Commerce 4049q2 Specimen - WXlNTiqA039c1JqMenson100% (7)

- Ragan: Economics: Fifteenth Canadian EditionDocument31 pagesRagan: Economics: Fifteenth Canadian EditionAmn GillNo ratings yet

- Chapter Four International Marketing Product PolicyDocument53 pagesChapter Four International Marketing Product PolicyEyob ZekariyasNo ratings yet

- Ah.. TourDocument1 pageAh.. TourCristchen EsporsadoNo ratings yet

- Paper On HR Scorecard FinalDocument22 pagesPaper On HR Scorecard FinalkkoolkankNo ratings yet

- Psychology and Marketing - 2022 - Shahid - The Role of Sensory Marketing and Brand Experience in Building EmotionalDocument15 pagesPsychology and Marketing - 2022 - Shahid - The Role of Sensory Marketing and Brand Experience in Building EmotionalMichelle VargasNo ratings yet

- Attitude Research of FevicolDocument10 pagesAttitude Research of FevicolShraddha TiwariNo ratings yet

- Javed Akbar Sial (... Resume)Document3 pagesJaved Akbar Sial (... Resume)Anonymous SnHo3YzSpNo ratings yet

- Service Marketing TriangleDocument17 pagesService Marketing TriangleDr.vikas Goya100% (1)

- MPI Report 002 Mast 002 R.1Document1 pageMPI Report 002 Mast 002 R.1John DolanNo ratings yet

- SOP - For - GTAW WeldingDocument3 pagesSOP - For - GTAW WeldingqualityNo ratings yet

- Chapter 02 Test Bank - Static - Version1Document34 pagesChapter 02 Test Bank - Static - Version1Veronica MargotNo ratings yet

- Topic 7 - Cost-Volume-Profit Analysis (Student Version)Document28 pagesTopic 7 - Cost-Volume-Profit Analysis (Student Version)Nur afiqahNo ratings yet

- Marketing Canadian 3rd Edition Grewal Solutions ManualDocument83 pagesMarketing Canadian 3rd Edition Grewal Solutions ManualLobna QassemNo ratings yet

- MGT2034 Operation Management Group AssignmentDocument23 pagesMGT2034 Operation Management Group AssignmentEldon LiewNo ratings yet

- The Road To Digital Success in Pharma - McKinsey & CompanyDocument10 pagesThe Road To Digital Success in Pharma - McKinsey & CompanyharshalNo ratings yet

- What Is Value-Stream Mapping: T O Ta L V A L U E Strea M Trea M S Valu E A L TOTDocument8 pagesWhat Is Value-Stream Mapping: T O Ta L V A L U E Strea M Trea M S Valu E A L TOTNavnath TamhaneNo ratings yet

- TQCSIF-025 - (Audit Plan For Client) PT Sinotrans CSC IndonesiaDocument1 pageTQCSIF-025 - (Audit Plan For Client) PT Sinotrans CSC IndonesiaFerris FerrisNo ratings yet

- Soroush Soleymani: EducationDocument3 pagesSoroush Soleymani: EducationNews GetNo ratings yet

- E Commerce Analytics IIDocument5 pagesE Commerce Analytics IItrupti deoreNo ratings yet

- Quality ChainDocument2 pagesQuality ChainA KumarNo ratings yet

- MF MCQ 2Document33 pagesMF MCQ 2Aniruddha AmnerkarNo ratings yet

SATIP-W-011-01 Rev 8

SATIP-W-011-01 Rev 8

Uploaded by

saravananmenmathiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SATIP-W-011-01 Rev 8

SATIP-W-011-01 Rev 8

Uploaded by

saravananmenmathiCopyright:

Available Formats

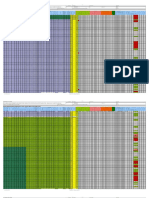

SAUDI ARAMCO ID/PID FORM REV 8 - 30-June-14 Rev 8 COS 06/30/2014

SAUDI ARAMCO TYPICAL INSPECTION PLAN SATIP No. APPROVED DATE DISCIPLINE:

Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MECHANICAL

PROJECT TITLE: WBS/BI/JO/NO. CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ITEM QUALITY QUALITY ASSIGNMENTS

PROJECT PHASE TASK / ACTIVITY REMARKS

NO. PROCEDURE RECORD SAUDI

CNTRCTR

ARAMCO

1.0 DOCUMENT REVIEW

1.1 Review WPS, PQR (New, Existing) SAIC-W-2001 SAIC-W-2001 RH RH

SAIC-W-2035 SAIC-W-2035

Welder/Welding Operator Certs Review Use SATR-W-2003

1.2 RH R

and Issuance of JCC

Weld Repair Procedure and WPS to be

1.3 SAIC-W-2002 SAIC-W-2002 RH RH

used including specific instructions

Procedure for Weld ID, Traceability,

1.4 Tracking & Status Reporting (SAEP- SAIC-W-2008 SAIC-W-2008 RH RH Requirements of SAEP-1160 Sect 6 are incorporated.

1160*)

Post Weld Heat Treatment (PWHT)

1.5 SAIC-W-2003 SAIC-W-2003 RH RH

Procedure & Equipment Package

Weld Hardness Testing Procedure &

1.6 SAIC-W-2012 SAIC-W-2012 RH RH

Proposed M&TE Equipment Records

Gap Control Procedure & Inspection of SAIC-W-2037 SAIC-W-2037

1.7 RH RH

Welded Socket & Threaded Joints

Positive Material Identification Procedure

1.8 SAIC-L-2004 SAIC-L-2004 RH RH

(Alloy Verification)

Refer to respective SATIP for NDE. (SATIP-NDE-UT-01,

1.9 Non-Destructive Testing Procedure See Remarks See Remarks

LPT-01 MPT-01, RT-01)

Procedure for Control of Welding

1.10 SAIC-W-2009 SAIC-W-2009 RH RH

Consumables

Welding Overlays & Clad Materials*

1.11 See Remarks See Remarks Refer to SATIP-W-014-01(*Rare application)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID FORM REV 8 - 30-June-14 Rev 8 COS 06/30/2014

SAUDI ARAMCO TYPICAL INSPECTION PLAN SATIP No. APPROVED DATE DISCIPLINE:

Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MECHANICAL

PROJECT TITLE: WBS/BI/JO/NO. CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ITEM QUALITY QUALITY ASSIGNMENTS

PROJECT PHASE TASK / ACTIVITY REMARKS

NO. PROCEDURE RECORD SAUDI

CNTRCTR

ARAMCO

1.12 Welding Strip Linings* (As Required) See Remarks See Remarks Refer to SATIP-W-015-01 (*Rare application)

Welding Special* Corrosion-Resistant

1.13 Materials (As Required) See Remarks See Remarks Refer to SATIP- W-016-01 (*Rare application)

2.0 MATERIAL RECEIVING

Receiving Inspection & Verification of

SA shall verify and inspect first delivered batch of

Welding Consumable Controls in Place SAIC-W-2010

2.1 SAIC-W-2010 H W consumables & check for compliance to approved control

(Properties, type, source, segregation, SATR-W-2009

procedures with random checks thereafter

storage, Issue, Handling, etc.)

SAIC-W-2011 First Calibration witnessed, Random witnessing by SA

2.2 Verify Welding Equipment Calibration SAIC-W-2011 H W

SATR-W-2011 thereafter.

Verify Positive Material Identification of SAIC-L-2010

Refer to Note 1 General Notes for SA Inspection

2.3 Low Alloy, Stainless Steel, Nickel & SAIC-L-2010 SATR-L-2012 H W

responsibility.

Copper Based Materials (As Required) SATR-L-2013

3.0 INSTALLATION

3.1 Welding Overlays & Clad Materials See Remarks See Remarks See SATIP-W-014-01 (As Required)

3.2 Welding Strip Linings See Remarks See Remarks See SATIP-W-015-01, etc. (As required)

3.3 Welding Special* Corr-Resistant Mat'ls See Remarks See Remarks See SATIP-W-016-01 (As Required)

Welding Consumable Control (Storage, SAIC-W-2032

3.4 SAIC-W-2032 H W Refer to Note 1 (General)

Handling, Issue & Conditioning) SATR-W-2010

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID FORM REV 8 - 30-June-14 Rev 8 COS 06/30/2014

SAUDI ARAMCO TYPICAL INSPECTION PLAN SATIP No. APPROVED DATE DISCIPLINE:

Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MECHANICAL

PROJECT TITLE: WBS/BI/JO/NO. CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ITEM QUALITY QUALITY ASSIGNMENTS

PROJECT PHASE TASK / ACTIVITY REMARKS

NO. PROCEDURE RECORD SAUDI

CNTRCTR

ARAMCO

S Aramco's responsibilities varies as follows:

SAIC-W-2033 a) "W" -for build-up thickness not exceeding 1/3 of the

3.5 Buttering or Weld Build-Up of Joints SAIC-W-2033 SATR-W-2006 H W/H metal thickness or 10mm whichever is less.

b) "H" - for build-up thickness exceeding the above and

requiring CSD's approval.

S. Aramco's responsibilities varies as follows:

a) "W" - for Welding on normal services at normal

W/H

Pre-Welding & Weld Joint Fit-Up SAIC-W-2005 conditions, refer to Note 1 of the General Notes.

3.6 SAIC-W-2005 H See

Inspection SATR-W-2006 b) "H" - for critical welds, i.e..; Tie-Ins, buttering, Hot

remarks

Taps, NDE-In-Lieu of Hydro & others as determined by

project requirements.

S. Aramco's responsibilities varies as follows:

a) "S" - Generally is a surveillance activity for Saudi

S/W Aramco, except in welding of stainless steel piping and

SAIC-W-2006

3.7 In-Process Weld Inspection SAIC-W-2006 W See piping in low temp service.

SATR-W-2007

Remarks b) "W" - S. Aramco inspects and verifies Heat Input at

random or on routine basis for low temp service and for

stainless steel welding.

Inspect Welds for Socket Joints and Seal

3.8 SAIC-W-2037 SAIC-W-2037 H W

Welded Thread Jts. - Gap Control

SAIC-W-2007

3.9 Post-Welding Visual Inspection SAIC-W-2007 H W

SATR-W-2007

Repair of Weld Joints or Base Metal by

3.10 SAIC-W-2013 SAIC-W-2013 W S

Welding (Prior to Weld Acceptance)

Selection of Weld Joints for NDE*

SAIC-W-2015 SA Participates in selection Process daily.

3.11 (Follow NDE Process Control SAIC-W-2015 H W

Proc.)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID FORM REV 8 - 30-June-14 Rev 8 COS 06/30/2014

SAUDI ARAMCO TYPICAL INSPECTION PLAN SATIP No. APPROVED DATE DISCIPLINE:

Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MECHANICAL

PROJECT TITLE: WBS/BI/JO/NO. CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ITEM QUALITY QUALITY ASSIGNMENTS

PROJECT PHASE TASK / ACTIVITY REMARKS

NO. PROCEDURE RECORD SAUDI

CNTRCTR

ARAMCO

Verify NDE Method Application and *Refer to the respective NDE SATIP

3.12 Evaluation, Documentation & Reporting of See Remarks See Remarks W / RH* W / R* (SATIP-NDE-UT-01, LPT-01, MPT-01, RT-01,

Results* etc.):

Database Reporting (per SAEP-1160)

a) Production Weld Status,

SAIC-W-2016

b) Welder & Project Repair Rate

SATR-W-2013, Data tracking system(s) shall be maintained & kept

3.13 c) Welder's Individual Repair Rate SAIC-W-2016 H R

SATR-W-2018, current & available for SA review at all times.

d) NDE & backlog of welds &

SATR-W-2019

status e) Special

Process* status per weld

SAIC-W-2004

3.14 Post Weld Heat Treatment Inspection SAIC-W-2004 H W&R Refer to Note 1 of the General Notes

SATR-W-2005

Verification of Hardness Testing SAIC-W-2014

3.15 SAIC-W-2014 H W&R Refer to Note 1 of the General Notes

Application and Results SATR-W-2012

Positive Material Identification (PMI) of SAIC-L-2010

3.16 Deposited Weld for alloyed materials SAIC-L-2010 SATR-A-2012 H W&R Refer to Note 1 of the General Notes

within the scope of SAES-A-206. SATR-A-2013

Modification or Re-Work After Weld SAIC-W-2036 SAIC-W-2036

3.17 H H

Acceptance (Use with SAIC-W-2013)

4.0 PRE-COMMISSIONING

Final Welding Insp & Documentation a) Refer to SATIP for Pressure Testing.

4.1 (Database Report, Welding Summary/ SATR-W-2008 H R b) Verify SAEP-1160 Database Requirements are

Record & Weld Map) per SAEP-1160 complied.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID FORM REV 8 - 30-June-14 Rev 8 COS 06/30/2014

SAUDI ARAMCO TYPICAL INSPECTION PLAN SATIP No. APPROVED DATE DISCIPLINE:

Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MECHANICAL

PROJECT TITLE: WBS/BI/JO/NO. CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ITEM QUALITY QUALITY ASSIGNMENTS

PROJECT PHASE TASK / ACTIVITY REMARKS

NO. PROCEDURE RECORD SAUDI

CNTRCTR

ARAMCO

GENERAL NOTES

The first three incidents of each Inspection or testing activity listed as "W' require 100 % participation by Saudi Aramco Site Inspection Personnel. After this period, Saudi Aramco Inspection may adjust the

1

levels of Saudi Aramco participation based upon the Contractor’s performance.

2 Surveillance: QA/QC organization to monitor work in progress without notice from Construction Organization

Witness: QA/QC organization shall be notified of the timing of Inspection or test in advance. However, the inspection or test shall be performed as scheduled if the QA/QC

3

organization representative is not present.

Hold: QA/QC organization shall be notified of the timing of inspection or test in advance. Inspection or test shall not be carried out without the QA/QC organization

4

representative in attendance.

5 If the Main Contractor delegates the assigned responsibility to the Subcontractor, then the Main Contractor will have the same degree of responsibility as assigned to Saudi Aramco.

LEGEND

H Hold Point for QC Inspection/ Test R Review of Documents

W Witness Inspection/Test RH Review and Approval of Documents

S Surveillance I 100% Contractor Inspection

Saudi Aramco: Company General Use

DISCIPLINE:

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

REMARKS

Use SATR-W-2003

Requirements of SAEP-1160 Sect 6 are incorporated.

Refer to respective SATIP for NDE. (SATIP-NDE-UT-01,

LPT-01 MPT-01, RT-01)

Refer to SATIP-W-014-01(*Rare application)

Saudi Aramco: Company General Use

DISCIPLINE:

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

REMARKS

Refer to SATIP-W-015-01 (*Rare application)

Refer to SATIP- W-016-01 (*Rare application)

SA shall verify and inspect first delivered batch of

consumables & check for compliance to approved control

procedures with random checks thereafter

First Calibration witnessed, Random witnessing by SA

thereafter.

Refer to Note 1 General Notes for SA Inspection

responsibility.

See SATIP-W-014-01 (As Required)

See SATIP-W-015-01, etc. (As required)

See SATIP-W-016-01 (As Required)

Refer to Note 1 (General)

Saudi Aramco: Company General Use

DISCIPLINE:

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

REMARKS

S Aramco's responsibilities varies as follows:

a) "W" -for build-up thickness not exceeding 1/3 of the

metal thickness or 10mm whichever is less.

b) "H" - for build-up thickness exceeding the above and

requiring CSD's approval.

S. Aramco's responsibilities varies as follows:

a) "W" - for Welding on normal services at normal

conditions, refer to Note 1 of the General Notes.

b) "H" - for critical welds, i.e..; Tie-Ins, buttering, Hot

Taps, NDE-In-Lieu of Hydro & others as determined by

project requirements.

S. Aramco's responsibilities varies as follows:

a) "S" - Generally is a surveillance activity for Saudi

Aramco, except in welding of stainless steel piping and

piping in low temp service.

b) "W" - S. Aramco inspects and verifies Heat Input at

random or on routine basis for low temp service and for

stainless steel welding.

SA Participates in selection Process daily.

Saudi Aramco: Company General Use

DISCIPLINE:

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

REMARKS

*Refer to the respective NDE SATIP

(SATIP-NDE-UT-01, LPT-01, MPT-01, RT-01,

etc.):

Data tracking system(s) shall be maintained & kept

current & available for SA review at all times.

Refer to Note 1 of the General Notes

Refer to Note 1 of the General Notes

Refer to Note 1 of the General Notes

a) Refer to SATIP for Pressure Testing.

b) Verify SAEP-1160 Database Requirements are

complied.

Saudi Aramco: Company General Use

DISCIPLINE:

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

REMARKS

GENERAL NOTES

participation by Saudi Aramco Site Inspection Personnel. After this period, Saudi Aramco Inspection may adjust the

truction Organization

dvance. However, the inspection or test shall be performed as scheduled if the QA/QC

dvance. Inspection or test shall not be carried out without the QA/QC organization

e Main Contractor will have the same degree of responsibility as assigned to Saudi Aramco.

LEGEND

Review of Documents

Review and Approval of Documents

100% Contractor Inspection

Saudi Aramco: Company General Use

You might also like

- Clow Imc08 Im 10Document23 pagesClow Imc08 Im 10Fatima AbboudNo ratings yet

- SATR-W-2006 Rev 6Document1 pageSATR-W-2006 Rev 6Manoj KumarNo ratings yet

- 1 SATIP-E-007-01 Air Cooled HExch - Fin Fan-Rev 01Document2 pages1 SATIP-E-007-01 Air Cooled HExch - Fin Fan-Rev 01Anonymous S9qBDVkyNo ratings yet

- Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument5 pagesSaudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliShahbaz AhmadNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument12 pagesSaudi Aramco Typical Inspection Planspravin231No ratings yet

- Incr - XXXDocument2 pagesIncr - XXXsadik coolsadyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Active Doc ListDocument405 pagesActive Doc Listnadeem UddinNo ratings yet

- Satr W 2013Document8 pagesSatr W 2013Rijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- SAES-M-005 PDF Download - Design and Construction of Fixed Offshore Platforms - PDFYARDocument8 pagesSAES-M-005 PDF Download - Design and Construction of Fixed Offshore Platforms - PDFYARZahidRafiqueNo ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- Engineering Standard: SAES-H-200 30 March 2020 Storage, Handling, and Installation of Coated PipesDocument10 pagesEngineering Standard: SAES-H-200 30 March 2020 Storage, Handling, and Installation of Coated PipesMuhammad AsifNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- 175 011100Document2 pages175 011100Abu Anas M.SalaheldinNo ratings yet

- SAIC L 2031 (Comments)Document2 pagesSAIC L 2031 (Comments)Anton Thomas PunzalanNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- QMIS LBE Rev Mech Final OldDocument683 pagesQMIS LBE Rev Mech Final OldprabakaranNo ratings yet

- 175-Ir171300, (850146), 11.30.2015Document2 pages175-Ir171300, (850146), 11.30.2015Rami ELLOUMINo ratings yet

- CV of QC Piping and NDT Coordinator VigneshPethurajDocument5 pagesCV of QC Piping and NDT Coordinator VigneshPethurajEswari AnandNo ratings yet

- Section Subject: Shaybah CPF Expansion ProjectDocument21 pagesSection Subject: Shaybah CPF Expansion ProjectAdhie Waelacxh100% (1)

- SATR-W-2007 Rev 7Document4 pagesSATR-W-2007 Rev 7QA QCNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- 175-026600 10312016Document2 pages175-026600 10312016Prasanna UmapathyNo ratings yet

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocument1 pageSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387No ratings yet

- 5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFDocument136 pages5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFsumit kumarNo ratings yet

- Saes A 109Document5 pagesSaes A 109SIVANo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- 01 Samss 010Document11 pages01 Samss 010biplabpal2009No ratings yet

- Materials System SpecificationDocument3 pagesMaterials System SpecificationMoustafa BayoumiNo ratings yet

- Ir 175-010000Document2 pagesIr 175-010000Abu Anas M.SalaheldinNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- 175 010700 PDFDocument2 pages175 010700 PDFAbu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument19 pagesSaudi Aramco Inspection ChecklistIrshad IqbalNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 Mechkarthi51289No ratings yet

- Materials System SpecificationDocument7 pagesMaterials System SpecificationFlorante NoblezaNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- SAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpDocument2 pagesSAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpAhdal NoushadNo ratings yet

- Schedule B - Attachment IVDocument29 pagesSchedule B - Attachment IVAbdul Ahad LoneNo ratings yet

- SATR-J - 6802 - Rev 0 PDFDocument3 pagesSATR-J - 6802 - Rev 0 PDFAdel KlkNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18nadeem shaikhNo ratings yet

- SATR-J - 6801 - Rev 0 PDFDocument6 pagesSATR-J - 6801 - Rev 0 PDFAdel KlkNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Arabian Oil Company: Instrument Specification Sheet - Pressure and Differential Pressure GaugesDocument2 pagesSaudi Arabian Oil Company: Instrument Specification Sheet - Pressure and Differential Pressure GaugesMuhammad Shahid0% (1)

- SAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesDocument6 pagesSAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesAhdal NoushadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- GI-0002.600 (Unit Accpetance After T&I Shut DownDocument4 pagesGI-0002.600 (Unit Accpetance After T&I Shut DownSanthoshNo ratings yet

- Saep 125Document9 pagesSaep 125Demac SaudNo ratings yet

- SATIP-P-104-05 Rev 8 Final Above Grade Conduits PDFDocument2 pagesSATIP-P-104-05 Rev 8 Final Above Grade Conduits PDFSabheeh AliNo ratings yet

- Saep 323 PDFDocument8 pagesSaep 323 PDFthanga balanNo ratings yet

- SATR-W-2008 Rev 8 FD-1Document6 pagesSATR-W-2008 Rev 8 FD-1asiqna100% (1)

- Milestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Document4 pagesMilestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Raghad GNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- 01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeDocument4 pages01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeZahidRafiqueNo ratings yet

- Saudi Aramco Engineering Index : A B C D E F G H J L M E Q WDocument3 pagesSaudi Aramco Engineering Index : A B C D E F G H J L M E Q Wkhuram916No ratings yet

- SAER1972Document9 pagesSAER1972zamil2008No ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalpravinNo ratings yet

- SATIP-W-011-01 Note5Document14 pagesSATIP-W-011-01 Note5Deo MNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of Pipelines SATIP-W-012-01 31-Dec-14 MechanicalDocument10 pagesSaudi Aramco Typical Inspection Plan: Welding of Pipelines SATIP-W-012-01 31-Dec-14 Mechanicalpravin0% (1)

- Profit and Loss NewDocument34 pagesProfit and Loss NewPranjal SharmaNo ratings yet

- Schermerhorn Mgmt9 Ch19Document30 pagesSchermerhorn Mgmt9 Ch19api-3738694No ratings yet

- LEC-2010 Value-Stream Mapping The Chemical ProcessesDocument5 pagesLEC-2010 Value-Stream Mapping The Chemical ProcessesMustafa Mert SAMLINo ratings yet

- Jurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover SheetDocument35 pagesJurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover Sheettomj9104No ratings yet

- PQR: Emsb/Pqr-002: Groove Design of Test Coupon Welding Sequence of Test CouponDocument2 pagesPQR: Emsb/Pqr-002: Groove Design of Test Coupon Welding Sequence of Test CouponMohd AshrafNo ratings yet

- Quality SpecificationDocument11 pagesQuality SpecificationHazarish BaharuddinNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- ZIMSEC O Level Commerce 4049q2 Specimen - WXlNTiqA039c1JqDocument4 pagesZIMSEC O Level Commerce 4049q2 Specimen - WXlNTiqA039c1JqMenson100% (7)

- Ragan: Economics: Fifteenth Canadian EditionDocument31 pagesRagan: Economics: Fifteenth Canadian EditionAmn GillNo ratings yet

- Chapter Four International Marketing Product PolicyDocument53 pagesChapter Four International Marketing Product PolicyEyob ZekariyasNo ratings yet

- Ah.. TourDocument1 pageAh.. TourCristchen EsporsadoNo ratings yet

- Paper On HR Scorecard FinalDocument22 pagesPaper On HR Scorecard FinalkkoolkankNo ratings yet

- Psychology and Marketing - 2022 - Shahid - The Role of Sensory Marketing and Brand Experience in Building EmotionalDocument15 pagesPsychology and Marketing - 2022 - Shahid - The Role of Sensory Marketing and Brand Experience in Building EmotionalMichelle VargasNo ratings yet

- Attitude Research of FevicolDocument10 pagesAttitude Research of FevicolShraddha TiwariNo ratings yet

- Javed Akbar Sial (... Resume)Document3 pagesJaved Akbar Sial (... Resume)Anonymous SnHo3YzSpNo ratings yet

- Service Marketing TriangleDocument17 pagesService Marketing TriangleDr.vikas Goya100% (1)

- MPI Report 002 Mast 002 R.1Document1 pageMPI Report 002 Mast 002 R.1John DolanNo ratings yet

- SOP - For - GTAW WeldingDocument3 pagesSOP - For - GTAW WeldingqualityNo ratings yet

- Chapter 02 Test Bank - Static - Version1Document34 pagesChapter 02 Test Bank - Static - Version1Veronica MargotNo ratings yet

- Topic 7 - Cost-Volume-Profit Analysis (Student Version)Document28 pagesTopic 7 - Cost-Volume-Profit Analysis (Student Version)Nur afiqahNo ratings yet

- Marketing Canadian 3rd Edition Grewal Solutions ManualDocument83 pagesMarketing Canadian 3rd Edition Grewal Solutions ManualLobna QassemNo ratings yet

- MGT2034 Operation Management Group AssignmentDocument23 pagesMGT2034 Operation Management Group AssignmentEldon LiewNo ratings yet

- The Road To Digital Success in Pharma - McKinsey & CompanyDocument10 pagesThe Road To Digital Success in Pharma - McKinsey & CompanyharshalNo ratings yet

- What Is Value-Stream Mapping: T O Ta L V A L U E Strea M Trea M S Valu E A L TOTDocument8 pagesWhat Is Value-Stream Mapping: T O Ta L V A L U E Strea M Trea M S Valu E A L TOTNavnath TamhaneNo ratings yet

- TQCSIF-025 - (Audit Plan For Client) PT Sinotrans CSC IndonesiaDocument1 pageTQCSIF-025 - (Audit Plan For Client) PT Sinotrans CSC IndonesiaFerris FerrisNo ratings yet

- Soroush Soleymani: EducationDocument3 pagesSoroush Soleymani: EducationNews GetNo ratings yet

- E Commerce Analytics IIDocument5 pagesE Commerce Analytics IItrupti deoreNo ratings yet

- Quality ChainDocument2 pagesQuality ChainA KumarNo ratings yet

- MF MCQ 2Document33 pagesMF MCQ 2Aniruddha AmnerkarNo ratings yet