Professional Documents

Culture Documents

2022 QR NRCA-PRC-07-F Variable Speed Compressor Controls

2022 QR NRCA-PRC-07-F Variable Speed Compressor Controls

Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2022 QR NRCA-PRC-07-F Variable Speed Compressor Controls

2022 QR NRCA-PRC-07-F Variable Speed Compressor Controls

Copyright:

Available Formats

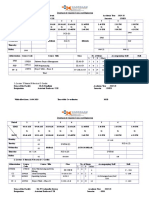

INSTALLER and INSPECTOR QUICK-REFERENCE:

2022 NRCA-PRC-07-F

Variable Speed Compressor Controls

Purpose and Scope of the Test

The test ensures that the applicable compressors control compressor speed in

response to the refrigeration load per the Energy Code.

Test trigger

Newly Constructed Refrigerated Warehouses: Applies to functional testing and

verification of compressor variable speed controls.

Compressor variable speed controls are required on any new refrigeration systems.

Exceptions:

• Systems serving a refrigerated warehouse with less than 3,000 square feet of

combined area.

• New open-drive screw compressors with more than one dedicated

compressor per suction group.

• New open-drive screw compressors on a refrigeration system for which more

than 20 percent of the total design refrigeration load is for quick chilling or

freezing or process refrigeration cooling for other than a refrigerated space.

Relevant Energy Code References and Required Compliance Documents

Title 24, Part 6 of the California Building Code, Building Energy Efficiency Standards

(Energy Code) sections 120.6(a)5; NA7.10.4; NRCC-PRC-E Table F.

Who Can Perform the Test

There are no restrictions. The test is typically performed by the startup technician

responsible for programming the setpoints in the control system.

Required Tools

To perform the test, it will be necessary to override the normal operation of the

controls. The control system for the compressor must be complete, including:

• Variable speed drive on all applicable screw compressors.

• Controls to control the compressor motor speed.

Estimated Time to Complete Test

Construction Inspection: 1 hours (for one condenser)

Functional testing: 2 hours (for one condenser)

2022 NRCA-PRC-07-F Quick Reference Page 1

INSTALLER and INSPECTOR QUICK-REFERENCE:

2022 NRCA-PRC-07-F

Variable Speed Compressor Controls

Potential Issues and Cautions

Adequate Cooling Load. The system cooling load must be sufficiently high for the

test, but the compressor should be not operating at fully capacity. Artificially

increase the load by decreasing the zone setpoint or decrease the load by increasing

the zone setpoint or turning off evaporators as needed to perform the Functional

Testing.

Coordinate test procedures with the refrigeration or controls contractor, or the

facility supervisor since they may be needed to assist with the manipulation of the

control system.

Inspection Enforcement

• All applicable single open-drive screw compressors dedicated to a suction

group have variable speed control.

• All pressure and temperature sensors have been calibrated and read

accurately.

• All sensor readings used by the compressor controller convert or calculate to

the correct conversion units at the controller (e.g., saturated suction pressure

reading is correctly converted to appropriate saturated suction temperature

(SST)).

• All compressor motor speed controls are operational and connected to

compressor motors.

• All speed controls are in “auto” mode.

• Compressor panel control readings for “RPMs,” “percent speed,” “kW,” and

“amps” match the readings from the controller or other control systems.

• Compressor nameplate data is correctly entered into the PLC or other control

system, to the extent required for proper control (e.g., minimum speed).

• Records showing calibration was performed, what offsets or control system

calibration values were used, and documentation of the instrumentation used

for calibration.

Acceptance Criteria

• Compressor speed decreases with decrease in load, and the slide valve (or

other unloading means) are held at 100 percent capacity until the

compressor speed reaches the minimum allowable setpoint.

• With an increase in load, the compressor slide valve (or other unloading

means) should load to 100 percent capacity, and then the compressor speed

should start in increase.

2022 NRCA-PRC-07-F Quick Reference Page 2

You might also like

- Popular Music - Topics, Trends & Trajectories (PDFDrive)Document297 pagesPopular Music - Topics, Trends & Trajectories (PDFDrive)Vuong Huu VinhNo ratings yet

- (Analytical Chemistry Series) Hanrahan, Grady-Environmental Chemometrics - Principles and Modern Applications-CRC Press (2008)Document316 pages(Analytical Chemistry Series) Hanrahan, Grady-Environmental Chemometrics - Principles and Modern Applications-CRC Press (2008)Yahsé Rojas ChallaNo ratings yet

- PerformanceTest Updated9octDocument38 pagesPerformanceTest Updated9octHossein100% (1)

- Standard Field Performance Testing Philosophy: GE Power SystemsDocument6 pagesStandard Field Performance Testing Philosophy: GE Power SystemsMohammed Elarbed100% (1)

- Chap01 - A Career in Process ControlDocument44 pagesChap01 - A Career in Process ControlKeith MaddenNo ratings yet

- Automation of Reciprocating Gas Engine Compressor Packages UsingDocument7 pagesAutomation of Reciprocating Gas Engine Compressor Packages UsingGnanaSekar0% (1)

- AutoCAD IntroductionDocument139 pagesAutoCAD IntroductionEngr Mayer KhanNo ratings yet

- Processcontrol 170515171334Document13 pagesProcesscontrol 170515171334Coral Del Mar100% (1)

- Resetting Setpoints Using Trim & Respond LogicDocument9 pagesResetting Setpoints Using Trim & Respond LogicTejaswinee DarureNo ratings yet

- Datta Meghe College of Engineering, AiroliDocument39 pagesDatta Meghe College of Engineering, AiroliMayuri patilNo ratings yet

- Using Master Controls To Improve The Performance and Efficiency of Industrial Air Compressors - 10142014-tcm9-606986Document7 pagesUsing Master Controls To Improve The Performance and Efficiency of Industrial Air Compressors - 10142014-tcm9-606986Anonymous 1XHScfCINo ratings yet

- ASHRAE Guideline 36-2018: High-Performance Sequences of Operation For HVAC SystemsDocument66 pagesASHRAE Guideline 36-2018: High-Performance Sequences of Operation For HVAC SystemsAouina Chokri100% (1)

- Ia&c Unit - IiiDocument23 pagesIa&c Unit - IiiPradhunya KambleNo ratings yet

- Surge Control: Compressor Surge and MeasurementDocument4 pagesSurge Control: Compressor Surge and Measurementmtrj59100% (1)

- Surge ProtectedDocument42 pagesSurge ProtectedRaul Roque Yujra100% (3)

- DDC System Commissioning Acceptance Procedure: Example Project/Building DescriptionDocument21 pagesDDC System Commissioning Acceptance Procedure: Example Project/Building DescriptionAbdul Mohid SheikhNo ratings yet

- Introduction To Surge ControlDocument6 pagesIntroduction To Surge Controlnote222100% (1)

- Sizing Remi PlantDocument91 pagesSizing Remi PlantgiromadNo ratings yet

- Chiller Testing Procedure Rev 3Document11 pagesChiller Testing Procedure Rev 3Ali AimranNo ratings yet

- Test Procedure:: Functional Testing Guidance Large Packaged HVAC SystemsDocument9 pagesTest Procedure:: Functional Testing Guidance Large Packaged HVAC SystemsLê Nho ĐánNo ratings yet

- Surge Warning SystemDocument19 pagesSurge Warning SystemKajal PrajapatiNo ratings yet

- 17 Womack PresentationMEDIDA DEL GASDocument23 pages17 Womack PresentationMEDIDA DEL GASluk673No ratings yet

- Anti Surge ControlDocument15 pagesAnti Surge Controlella arunNo ratings yet

- Turbomachinery Control System Design Objectives ArticleDocument6 pagesTurbomachinery Control System Design Objectives ArticleChucho CarreroNo ratings yet

- Manitoba RequirementDocument15 pagesManitoba RequirementRASHEED YUSUFNo ratings yet

- Chiller Testing Procedure Rev 1Document15 pagesChiller Testing Procedure Rev 1Ali AimranNo ratings yet

- AgemDocument19 pagesAgemmurjass85No ratings yet

- Reliability Test For The CCPPDocument3 pagesReliability Test For The CCPPRakesh MishraNo ratings yet

- Adaptive ControlDocument30 pagesAdaptive ControlGanesh67% (3)

- Combined Cycle Power Plant OperationDocument21 pagesCombined Cycle Power Plant OperationEgit Bobyarta100% (6)

- RevampingDocument2 pagesRevampingKhalid Latif NiemaNo ratings yet

- 12/23/2021 /conversion/tmp/activity - Task - Scratch/566319865Document5 pages12/23/2021 /conversion/tmp/activity - Task - Scratch/566319865tristan guarinoNo ratings yet

- Control & InstrumentationDocument80 pagesControl & InstrumentationDeep SYNo ratings yet

- Pipeline Pressure Control and Overpressure Protection SummaryDocument3 pagesPipeline Pressure Control and Overpressure Protection Summaryhoangvubui4632No ratings yet

- Sample HVAC ControlsDocument26 pagesSample HVAC Controlsenlightened1718No ratings yet

- Process Control BoilerDocument70 pagesProcess Control BoilerSteve WanNo ratings yet

- Field Testing of CompressorsDocument12 pagesField Testing of CompressorsmishraenggNo ratings yet

- 11 Methodology Guidebook Adjusting Fan SpeedDocument8 pages11 Methodology Guidebook Adjusting Fan Speeddar77456312No ratings yet

- 15 Combined Cycle Power Plant OperationDocument21 pages15 Combined Cycle Power Plant OperationParmeshwar Nath Tripathi100% (4)

- Calibration Procedure - Pressure Test Transducers For API Specification 6A ApplicationsDocument5 pagesCalibration Procedure - Pressure Test Transducers For API Specification 6A Applicationsvinsensius rasaNo ratings yet

- Installation and Commissioning: Centrifugal PumpsDocument3 pagesInstallation and Commissioning: Centrifugal PumpsKu KemaNo ratings yet

- Allison - Technical Documents 157 - Cooling Test - UpdateDocument29 pagesAllison - Technical Documents 157 - Cooling Test - Updateangie michell paccini rodriguezNo ratings yet

- Chapter-8 Turbine and Governor TestingDocument10 pagesChapter-8 Turbine and Governor Testingafru2000No ratings yet

- Chemical and Bio-Process Control: James B. Riggs M. Nazmul KarimDocument44 pagesChemical and Bio-Process Control: James B. Riggs M. Nazmul KarimRiani ZipNo ratings yet

- An Introduction To Energy EfficientDocument27 pagesAn Introduction To Energy Efficientabdelbasset khelilNo ratings yet

- Load Ramp RateDocument8 pagesLoad Ramp Ratevivek1280No ratings yet

- Troubleshooting Actions: Section 7 Troubleshooting and SimulationDocument17 pagesTroubleshooting Actions: Section 7 Troubleshooting and SimulationRishiNo ratings yet

- Model Reference Adaptive ControlDocument57 pagesModel Reference Adaptive ControlmervebayrakNo ratings yet

- Commissioning ChartDocument21 pagesCommissioning ChartSarif IslamNo ratings yet

- Sp9907-A - Chiller Statup ProceduresDocument4 pagesSp9907-A - Chiller Statup ProceduresEmerson Penaforte100% (1)

- Gas Turbine Control Application (GTCA) Functionality and CapabilitiesDocument2 pagesGas Turbine Control Application (GTCA) Functionality and CapabilitiesEliyanto E BudiartoNo ratings yet

- B7.2KENNEDYKILTECHIDEA Presentation Miami June 2013smallDocument30 pagesB7.2KENNEDYKILTECHIDEA Presentation Miami June 2013smallSMBEAUTYNo ratings yet

- Generator Operation PMIDocument30 pagesGenerator Operation PMIrohit_0123100% (3)

- Air Handling Unit Assessment Guidelines: Saving Energy in Commercial BuildingsDocument3 pagesAir Handling Unit Assessment Guidelines: Saving Energy in Commercial BuildingsQazertNo ratings yet

- Control Loop Hardware and TroubleshootingDocument51 pagesControl Loop Hardware and Troubleshootingrosita61100% (1)

- Designing Controls for the Process Industries 1st Seames Solution Manual download pdf full chapterDocument18 pagesDesigning Controls for the Process Industries 1st Seames Solution Manual download pdf full chapterdostonrobalo100% (7)

- CompressorDocument17 pagesCompressorLipika GayenNo ratings yet

- 1815 16 PDFDocument17 pages1815 16 PDFsiamak001No ratings yet

- PB310 S3 Plus Fuel ControllerDocument2 pagesPB310 S3 Plus Fuel ControllerZuñiga AntonioNo ratings yet

- M/E No - C-12, M/E Name: Engine Governo R Test Stand Fo R Woodward Governo RDocument3 pagesM/E No - C-12, M/E Name: Engine Governo R Test Stand Fo R Woodward Governo Ramir barekatiNo ratings yet

- CMX Puesta en Marcha y Trouble ShootingDocument15 pagesCMX Puesta en Marcha y Trouble ShootingMauricio Ariel H. OrellanaNo ratings yet

- York - Capacity Modulation Comparison White PaperDocument4 pagesYork - Capacity Modulation Comparison White PaperIEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPNo ratings yet

- Fuzzy Control With Feedforward Compensator of Superheat in A Variable Speed Refrigeration SystemDocument11 pagesFuzzy Control With Feedforward Compensator of Superheat in A Variable Speed Refrigeration SystemIEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPNo ratings yet

- Modeling and Analysis of A VariableDocument13 pagesModeling and Analysis of A VariableIEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPNo ratings yet

- Solar Water HeatersDocument7 pagesSolar Water HeatersIEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPNo ratings yet

- DDC Control of An Air HandlerDocument10 pagesDDC Control of An Air HandlerIEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPNo ratings yet

- HVACR Tech Tip - Everything You Want To Know About SuperheatDocument6 pagesHVACR Tech Tip - Everything You Want To Know About SuperheatIEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPNo ratings yet

- VX600 All-in-One Controller Specifications-V1.2.1-1Document10 pagesVX600 All-in-One Controller Specifications-V1.2.1-1IEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPNo ratings yet

- Dual Inverter Technogy in RefrigerationDocument7 pagesDual Inverter Technogy in RefrigerationIEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPNo ratings yet

- Xtr116 (IC T o 4 - 20ma)Document17 pagesXtr116 (IC T o 4 - 20ma)IEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPNo ratings yet

- QR Codes For Marketing - A Unique Way To Bridge Offline and Online MediaDocument4 pagesQR Codes For Marketing - A Unique Way To Bridge Offline and Online MediaRon DinNo ratings yet

- Principles and Guidelines in Software UsDocument4 pagesPrinciples and Guidelines in Software Ustrinhtrungkien003No ratings yet

- MATLAB Code of The ProjectDocument4 pagesMATLAB Code of The Projectasefash misganaw100% (1)

- Probit ModelDocument5 pagesProbit ModelNidhi KaushikNo ratings yet

- Francesco Falaschi CV English VersionDocument3 pagesFrancesco Falaschi CV English VersionFrancesco FalaschiNo ratings yet

- First Year Handling Staff Individual Time Table CSEDocument4 pagesFirst Year Handling Staff Individual Time Table CSEkirubaNo ratings yet

- Lecture 9Document8 pagesLecture 9Gordian HerbertNo ratings yet

- PL Mugen 19 Feb 2024 (5 Sheet)Document42 pagesPL Mugen 19 Feb 2024 (5 Sheet)kreatifmandiriintegrasiNo ratings yet

- Movs PDFDocument3 pagesMovs PDFMarceloNo ratings yet

- White Paper A Guide To Going Mobile Only With Samsung DeX 08 2020Document17 pagesWhite Paper A Guide To Going Mobile Only With Samsung DeX 08 2020Peanut BubbaNo ratings yet

- Coin BaseDocument29 pagesCoin BaseSandoval almeida67% (3)

- Last Minute Revision For IP Exam - Societal ImpactsDocument4 pagesLast Minute Revision For IP Exam - Societal ImpactsWhiteNo ratings yet

- InequalitiesDocument4 pagesInequalitiesCHONG JOLYNN SSCNo ratings yet

- Human Factors in Aircraft MaintenanceDocument11 pagesHuman Factors in Aircraft MaintenanceHermawan WawanNo ratings yet

- Dynamic Facility Layout Problem With Hybrid Genetic AlgorithmDocument6 pagesDynamic Facility Layout Problem With Hybrid Genetic AlgorithmRipon Kazi Shah NawazNo ratings yet

- Docu68889 VMAX All Flash Security Configuration GuideDocument120 pagesDocu68889 VMAX All Flash Security Configuration GuideamirbahramNo ratings yet

- IP CCTV System Design GuideDocument50 pagesIP CCTV System Design Guidemujeeb.alam4100% (6)

- Apex 150-Feb2016 PDFDocument4 pagesApex 150-Feb2016 PDFMona UpretiNo ratings yet

- A Guide To Programming in JavaDocument408 pagesA Guide To Programming in JavaDennis Park67% (3)

- Multivariate Statistics: Factor AnalysisDocument4 pagesMultivariate Statistics: Factor Analysisveerashah85No ratings yet

- Microsoft Word - 01 SBST1303 CP PDFDocument222 pagesMicrosoft Word - 01 SBST1303 CP PDFashaNo ratings yet

- GENE150 User ManualDocument13 pagesGENE150 User Manualmustafi28No ratings yet

- 66 - DeMello and Cocordia PaperDocument14 pages66 - DeMello and Cocordia PaperAhmed Salam100% (1)

- Tigertech Rhemos Prenatal RuralDocument6 pagesTigertech Rhemos Prenatal RuraljayramdeepakNo ratings yet

- Vergilius, Aeneid (Eneida) 6 Commentary - Norden, E. (1916) - Leipzig-BerlinDocument506 pagesVergilius, Aeneid (Eneida) 6 Commentary - Norden, E. (1916) - Leipzig-BerlinPatroclo M.No ratings yet

- Requirements FullDocument6 pagesRequirements FullAnthony FloydNo ratings yet

- Assignment Cloud Storage IMD113Document24 pagesAssignment Cloud Storage IMD113Umul Fatimah HazmanNo ratings yet