Professional Documents

Culture Documents

6WG Failure Codes

6WG Failure Codes

Uploaded by

Servi PadCopyright:

Available Formats

You might also like

- 4gr-Fse Engine Control System - Terminals of EcmDocument12 pages4gr-Fse Engine Control System - Terminals of EcmImtiaz Imtiaz Ali83% (6)

- ZF Fault Codes LatestDocument38 pagesZF Fault Codes LatestDragan90% (20)

- AW4 ManualDocument112 pagesAW4 ManualFurRelKT100% (4)

- ZF - Error Code ListDocument56 pagesZF - Error Code ListHenrique88% (17)

- Acronyms TOYOTA PDFDocument5 pagesAcronyms TOYOTA PDFAlex Molina100% (3)

- ZD30 Diagnostic ModeDocument18 pagesZD30 Diagnostic ModeRafael Zuñiga100% (1)

- Transmission Error Codes - CargadorasDocument36 pagesTransmission Error Codes - CargadorasTeresa Marina Peralta80% (5)

- ProEFI Pro128 BMW E46 M3 Pinout SheetDocument2 pagesProEFI Pro128 BMW E46 M3 Pinout SheetHugoCar77100% (1)

- 3512b-Main Elect WiringDocument8 pages3512b-Main Elect WiringHany Atwa100% (7)

- A750E and A750F Automatic Transmission: DescriptionDocument41 pagesA750E and A750F Automatic Transmission: DescriptionIzabela Mądzelewska100% (4)

- Automatic Transmission PDFDocument51 pagesAutomatic Transmission PDFwanaw100% (3)

- ZF Fault Codes LatestDocument38 pagesZF Fault Codes LatestParc Elyes100% (7)

- 3512 Diag - Engine - 1243-06 - SisDocument8 pages3512 Diag - Engine - 1243-06 - Sisshashank715No ratings yet

- Audi A4 A5 Q5 B8 ABS MVB Measuring Value Blocks PDFDocument10 pagesAudi A4 A5 Q5 B8 ABS MVB Measuring Value Blocks PDFMohammed MochrifNo ratings yet

- Helicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsFrom EverandHelicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsRating: 5 out of 5 stars5/5 (1)

- AB60E Transmission OperationDocument1 pageAB60E Transmission OperationЙордан ВасилевNo ratings yet

- ZF - Description of The Fault CodesDocument53 pagesZF - Description of The Fault Codescesar100% (1)

- ZF EST 37 Fault CodesDocument51 pagesZF EST 37 Fault CodesPeetNo ratings yet

- Description of The Fault Codes For ERGO-Control EST37: ZF FRIEDRICHSHAFEN AktiengesellschaftDocument57 pagesDescription of The Fault Codes For ERGO-Control EST37: ZF FRIEDRICHSHAFEN AktiengesellschaftmorusNo ratings yet

- FC 942 Fault CodeDocument42 pagesFC 942 Fault CodeJasmin KahrimanovićNo ratings yet

- td1403 03 PDFDocument42 pagestd1403 03 PDFcoulibalyoumarNo ratings yet

- Error Code ListDocument3 pagesError Code Listميلاد النعيريNo ratings yet

- ZF Wg110 Transmission Fault CodesDocument25 pagesZF Wg110 Transmission Fault Codesnamduong368100% (9)

- 12 Trans Error CodeDocument26 pages12 Trans Error CodeAnangtri Wahyudi100% (1)

- A320 Procedures SIMPLE v1.24Document9 pagesA320 Procedures SIMPLE v1.24BrittzNo ratings yet

- Error Code ZF 422zxDocument56 pagesError Code ZF 422zxAdenilson FagundesNo ratings yet

- Description of The Fault Codes For ERGO-Control EST37: ZF FRIEDRICHSHAFEN AktiengesellschaftDocument53 pagesDescription of The Fault Codes For ERGO-Control EST37: ZF FRIEDRICHSHAFEN Aktiengesellschafthellel faouziNo ratings yet

- Error Code List Ergopower-Est37/A: ZF Passau GMBHDocument56 pagesError Code List Ergopower-Est37/A: ZF Passau GMBHTogu Marnaek SiagianNo ratings yet

- Error Code Transmisi LW 800 KDocument53 pagesError Code Transmisi LW 800 KsobirinNo ratings yet

- DTC P0135 Oxyge (A/F) Sensor Heater Circuit (Bank 1 Sensor 1)Document3 pagesDTC P0135 Oxyge (A/F) Sensor Heater Circuit (Bank 1 Sensor 1)Erln Lima100% (1)

- Airbus h145 Checklists - h145 ChecklistsDocument3 pagesAirbus h145 Checklists - h145 ChecklistshelloNo ratings yet

- MAN FFR Onboard Computer Fault Codes ListDocument7 pagesMAN FFR Onboard Computer Fault Codes Listhanif khan100% (3)

- MAN FFR Onboard Computer Fault Codes ListDocument7 pagesMAN FFR Onboard Computer Fault Codes ListOroszi Gábor100% (1)

- ECU Pin-Out 90-93 MTDocument1 pageECU Pin-Out 90-93 MTAkis AlmasidisNo ratings yet

- Mercedes-Motor ControllDocument9 pagesMercedes-Motor ControllKris BoNo ratings yet

- A320 Abnormal NotesDocument12 pagesA320 Abnormal NotesCheck Singh100% (1)

- Error Screen: 4 - Instruments/ControlsDocument12 pagesError Screen: 4 - Instruments/ControlsDaniel Henrique PiovesaniNo ratings yet

- A320 Abnormal Notes: Last UpdatedDocument13 pagesA320 Abnormal Notes: Last UpdatedDevdatt SondeNo ratings yet

- Terminals of Ecm: E3 E4 E5 E6Document5 pagesTerminals of Ecm: E3 E4 E5 E6suraj100% (2)

- 1328 754 507 PTBR Iveco PDF FallosDocument163 pages1328 754 507 PTBR Iveco PDF Falloslisandro100% (1)

- CodesDocument3 pagesCodesإطار كيسيNo ratings yet

- ECM/PCM Input and Output TestsDocument2 pagesECM/PCM Input and Output TestsDhami NongNo ratings yet

- Avanza RelayDocument4 pagesAvanza RelayLeonardNo ratings yet

- Mazda Cx5 Workshop Manual96Document1 pageMazda Cx5 Workshop Manual96Negrin44No ratings yet

- Fault Code - Elektra & Superia HW InverterDocument9 pagesFault Code - Elektra & Superia HW Invertersomnath serviceNo ratings yet

- Fehlercodetabelle WA150-320Document2 pagesFehlercodetabelle WA150-320João MariaNo ratings yet

- ECOS ComponentsDocument29 pagesECOS ComponentsHerikb2No ratings yet

- 4852a - Pro128 1993-1995 Toyota MR2 TurboDocument2 pages4852a - Pro128 1993-1995 Toyota MR2 TurboAlexey MishurovskyNo ratings yet

- 01 MDocument2 pages01 MGuilherme ZoboliNo ratings yet

- Application Note AN-VG7-001v101EN Encoder Check and Pole Tuning Procedure For PMSM in Lift ApplicationsDocument4 pagesApplication Note AN-VG7-001v101EN Encoder Check and Pole Tuning Procedure For PMSM in Lift ApplicationshassanNo ratings yet

- F2500TF BOperatingInstructionDocument10 pagesF2500TF BOperatingInstructionmarcoNo ratings yet

- Toytoa Wire DiagramDocument8 pagesToytoa Wire Diagramspybot1331100% (1)

- GLine Pump MS Setup W VT5041 (Rexroth 3X BFB A11-152) HPN 5577580Document12 pagesGLine Pump MS Setup W VT5041 (Rexroth 3X BFB A11-152) HPN 5577580Алексей ЧаусовNo ratings yet

- 350 T 02 GbexpDocument1 page350 T 02 GbexpIonut GrozaNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- High Efficiency RF and Microwave Solid State Power AmplifiersFrom EverandHigh Efficiency RF and Microwave Solid State Power AmplifiersRating: 3 out of 5 stars3/5 (2)

- Fujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandFujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- Fujifilm X-T4: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandFujifilm X-T4: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Electronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesNo ratings yet

- Audi Takes CVT From 15th Century To 21st Century: Tech BriefsDocument3 pagesAudi Takes CVT From 15th Century To 21st Century: Tech BriefskarthikozyNo ratings yet

- Fluid CouplingDocument7 pagesFluid CouplingBalu SukumarNo ratings yet

- U340 441E DescriptionDocument25 pagesU340 441E Descriptionjo_cfo257388% (17)

- GearsDocument16 pagesGearsabdulrahmanhagag1No ratings yet

- Zeroshift atDocument8 pagesZeroshift atItalo AdottiNo ratings yet

- ZF As Tronic Schematic EDocument2 pagesZF As Tronic Schematic ESaša Oljača78% (18)

- ME 374 Equations and TablesfinalDocument29 pagesME 374 Equations and TablesfinalKlinsmannJanujajJurgenNo ratings yet

- TORQUE CONVERTER 4) TURBINE SHAFT AND STATOR D135A-1 S - N 10001-UP Komatsu Part CatalogDocument1 pageTORQUE CONVERTER 4) TURBINE SHAFT AND STATOR D135A-1 S - N 10001-UP Komatsu Part CatalogBluish FlameNo ratings yet

- Direct Shift Gearbox 0d9 EngDocument141 pagesDirect Shift Gearbox 0d9 EngeliotroyanoNo ratings yet

- Automatic Transaxle Assy (U34#E Series) : OverhaulDocument46 pagesAutomatic Transaxle Assy (U34#E Series) : Overhaulvipper king2012No ratings yet

- Gearbox PPT (Repaired)Document11 pagesGearbox PPT (Repaired)Siddharth BalekarNo ratings yet

- 91 Zf3 Zf5hp19 Inc FlaDocument14 pages91 Zf3 Zf5hp19 Inc FlaJohn Eduard Sierra VelandiaNo ratings yet

- Topic 3 Gears and ShaftsDocument27 pagesTopic 3 Gears and ShaftsSaiful AnuarNo ratings yet

- Tabla de Equivalencia de Aceites Lubricantes para Cárter Línea AutomotrizDocument3 pagesTabla de Equivalencia de Aceites Lubricantes para Cárter Línea AutomotrizRaul TarquiniNo ratings yet

- Hpi Intructions #A205 RS4 2 Speed TransmissionDocument1 pageHpi Intructions #A205 RS4 2 Speed TransmissionelvuelodelcondorNo ratings yet

- What Is A Gearbox? (Transmission) - Types, Parts, Function & DiagramDocument14 pagesWhat Is A Gearbox? (Transmission) - Types, Parts, Function & DiagramTisha GaikwadNo ratings yet

- 4 F 27 eDocument122 pages4 F 27 eApple MiseryNo ratings yet

- 43 A Aisin Warner AWTF60 SNDocument6 pages43 A Aisin Warner AWTF60 SNmeyyiti01No ratings yet

- ZF4HP24: Please Quote The Full Transmission Code When Ordering PartsDocument4 pagesZF4HP24: Please Quote The Full Transmission Code When Ordering PartsDenis KonovalovNo ratings yet

- 8287 9084 ActDocument9 pages8287 9084 ActossoskiNo ratings yet

- 440-T4 / 4T60E / 4T65E 440-T4 / 4T60E / 4T65E: FWD 4 Speed FWD 4 SpeedDocument1 page440-T4 / 4T60E / 4T65E 440-T4 / 4T60E / 4T65E: FWD 4 Speed FWD 4 SpeedCheryl BishopNo ratings yet

- CPM Parts Catalog 6-20-13Document60 pagesCPM Parts Catalog 6-20-13Adrian MotocNo ratings yet

- Western Star - PowertrainDocument20 pagesWestern Star - PowertrainRobert Orosco B.No ratings yet

- DCT-Dual Clutch TransmissionDocument16 pagesDCT-Dual Clutch TransmissionVinod Kumar100% (3)

- Performance Catalog 010616 ReDocument17 pagesPerformance Catalog 010616 Rerobertoperez525100% (1)

- Flange CouplingDocument27 pagesFlange Couplingrajdrkl100% (1)

- BMW GS6-17BG-5Document7 pagesBMW GS6-17BG-5Jordy PerezNo ratings yet

6WG Failure Codes

6WG Failure Codes

Uploaded by

Servi PadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6WG Failure Codes

6WG Failure Codes

Uploaded by

Servi PadCopyright:

Available Formats

ZF FRIEDRICHSHAFEN Aktiengesellschaft

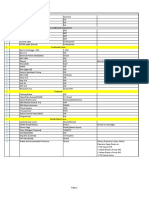

Benennung: fault codes Nr.: DIN Seite 1

Zusatzbenennung: description of fault codes for Ergo control A4 von 53

Diese technische Unterlage darf weder kopiert 03-05-13 Schwarz

noch dritten Personen ohne unsere Erlaubnis 22

mitgeteilt werden. Index Nr. Datum Name Film

K3 ZFN 904 ÄNDERUNGEN

Erstellt: Geprüft: Freigegeben :

Name: Burkhart Sieger Burkhart

Abteilung: AC-ET1 TE-AB AC-ET1

Datum: 2005-01-31 03-10-01 05-01-31

Description

of the

fault codes

for

ERGO-Control EST37

document created for customer "6WG mit CAN J1939" jjjj-04-tt

ZF Friedrichshafen AG 05-01-31

Faultcodes ERGO-Control EST37A

Index of changes:

date index comment software version

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 2 von 37

ZF Friedrichshafen AG 05-01-31

Faultcodes ERGO-Control EST37A

1 Introduction

1.1 Abbreviations

o.c. open circuit

s.c. short circuit

OP-Mode operating mode

TCU transmission control unit

EEC electronic engine controller

PTO power take off

1.2 ZF - Display:

If a fault is detected, the display shows a spanner symbol (g) for a fault. The display shows the fault

code, if the gear selector is on neutral position.

If more than one fault is detected, each fault code is shown for about 1 second.

left right

h f e d character character

S

T

O

P

a b c g

(special symbols a-h)

1.3 Display during operation

Symbol meaning remarks

1F, 1R actual gear and direction

2F, 2R left digit shows actual gear

3F, 3R right digit shows actual direction

4F

5F

6F

LF, LR limp home gear

F or R, no gear Clutch Cutoff

F or R flashing direction F or R selected while turbine CAUTION gear will engage if turbine speed drops

speed is too high

NN not neutral, waiting for neutral after to engage a gear, first move shift selector to neutral

power up or a severe fault position and again to F or R position

** oil temperature too low, no gear warm up engine / transmission

available

*N oil temperature low, only one gear warm up engine / transmission

available

1 bar (special manual mode 1st gear

symbol)

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 3 von 37

ZF Friedrichshafen AG 05-01-31

Faultcodes ERGO-Control EST37A

2 bars manual mode 2nd gear

3 bars manual mode 3rd gear

4 bars manual mode 4th gear and also 5th and 6th

gear in 6WG

4 bars and 2 automatic mode

arrows

Bars flashing 6 WG: converter lockup clutch open difference of engine and turbine speed above a certain

limit and lockup clutch not activated

4 WG: Downshift mode activ

Spanner at least one fault activ select neutral to get fault code displayed

Fault code see faultcode list

WS warning sump temperature changes between actual gear/direction while driving, in

neutral only displayed if no fault is detected (spanner)

WR warning retarder temperature changes between actual gear/direction while driving, in

neutral only displayed if no fault is detected (spanner)

WT warning torque converter temperature changes between actual gear/direction while driving, in

neutral only displayed if no fault is detected (spanner)

WE warning high engine speed changes between actual gear/direction while driving, in

neutral only displayed if no fault is detected (spanner)

WV warning high output speed (velocity) changes between actual gear/direction while driving, in

neutral only displayed if no fault is detected (spanner)

WL warning high transmission input torque changes between actual gear/direction while driving, in

(load) neutral only displayed if no fault is detected (spanner)

PN direction F or R selected while parking transmission in neutral until parking brake is released

brake engaged CAUTION: vehicle starts to move after release of

parking brake

EE flashing no communication with display checked wiring from TCU to display

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 4 von 37

ZF Friedrichshafen AG 05-01-31

Faultcodes ERGO-Control EST37A

1.4 Display during AEB-Mode

symbol meaning remarks

PL AEB - Starter is plugged at the

diagnostic plug

ST AEB-Starter-button is pressed

K1..K4,KV,KR calibrating clutch K1..K4, KV or KR

resp.

_ and Kx wait for start, initialization of clutch Kx,

x: 1, 2, 3, 4, V, R

≡ and Kx fast fill time determination of clutch Kx

= and Kx compensating pressure determination of

clutch Kx

OK calibration for all clutches finished Transmissions stays in neutral, you have to restart the

TCU (ignition off/on) after removing AEB-Starter

STOP AEB canceled (activation stopped) Transmissions stays in neutral, you have to restart the

TCU (ignition off/on)

STOP and Kx AEB stopped, clutch Kx can't be Transmissions stays in neutral, you have to restart the

calibrated TCU (ignition off/on)

Spanner and Kx Kx couldn't be calibrated, AEB finished Transmissions stays in neutral, you have to restart the

TCU (ignition off/on)

∆E engine speed too low,

Ö raise engine speed

∇E engine speed too high,

Ö lower engine speed

∆T transmission oil temperature too low,

Ö heat up transmission

∇T transmission oil temperature too high

Ö cool down transmission

FT transmission temperature not in defined Transmissions stays in neutral, you have to restart the

range during calibration TCU (ignition off/on)

FB operating mode not NORMAL or Transmissions stays in neutral, you have to restart the

transmission temperature sensor TCU (ignition off/on)

defective or storing of Calibrated values

to EEPROM-has failed.

FO Outputspeed_not_zero Transmissions stays in neutral, you have to restart the

TCU (ignition off/on)

FN Shift lever not in Neutral position Transmissions stays in neutral, you have to restart the

TCU (ignition off/on)

FP Parkbrake_not_applied Transmissions stays in neutral, you have to restart the

TCU (ignition off/on)

STOP AEB - Starter was used incorrect or is Transmissions stays in neutral, you have to restart the

defective. Wrong device or wrong cable TCU (ignition off/on)

used

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 5 von 37

ZF Friedrichshafen AG 05-01-31

Faultcodes ERGO-Control EST37A

1.5 Display during Inchpedal Calibration

symbol meaning remarks

push down the pedal slowly until

IP ⇓ endposition is reached and hold this

position

Release the pedal slowly until

IP ⇑ endposition is reached

A problem occurred, release the pedal If the expected enposition could not be reached, release

IP ⇑ flashing slowly until endposition is reached the pedal and try again

OK Finished inchpedal calibration

successful

FN and Stop Shift lever not in Neutral position Calibration is aborted

FS and Stop sensor supply voltage AU1 is out of Calibration is aborted

the specified range

FO and Stop Outputspeed is not zero Calibration is aborted

SL and Stop sensor voltage below specified Calibration is aborted

rangel

SU and Stop sensor voltage above specified Calibration is aborted

rangel

IL and Stop sensor position for released pedal Calibration is aborted

out of specified range

IU and Stop sensor position for pressed pedal out Calibration is aborted

of specified range

TO and Stop time-out calibration, pedal not moved Calibration is aborted

after calibration start

DL and Stop angle between pedalpositions Calibration is aborted

released and pressed to small

DU and Stop angle between pedalpositions Calibration is aborted

released and pressed to big

FI and Stop sensor signal 1 and 2 don't match Calibration is aborted

together

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 6 von 37

ZF Friedrichshafen AG 05-01-31

Faultcodes ERGO-Control EST37A

2 definition of operating modes

NORMAL:

There's no failure detected in the transmission-system or the failure has no or slight effects on

transmission control. TCU will work without or in special cases with little limitations. (see following

table)

SUBSTITUTE CLUTCH CONTROL:

TCU can't change the gears or the direction under the control of the normal clutch modulation. TCU

uses the substitute strategy for clutch control. All modulations are only time controlled. (Comparable

with EST 25)

LIMP-HOME:

The detected failure in the system has strong limitations to transmission control. TCU can engage

only one gear in each direction. In some cases only one direction will be possible.

TCU will shift the transmission into neutral at the first occurrence of the failure. First, the operator

must shift the gear selector into neutral position.

If output speed is less than a threshold for neutral to gear and the operator shifts the gear selector into

forward or reverse, the TCU will select the limp-home gear .

If output speed is less than a threshold for reversal speed and TCU has changed into the limp-home

gear and the operator selects a shuttle shift, TCU will shift immediately into the limp-home gear of the

selected direction.

If output speed is greater than the threshold, TCU will shift the transmission into neutral. The operator

has to slow down the vehicle and must shift the gear selector into neutral position.

TRANSMISSION-SHUTDOWN:

TCU has detected a severe failure that disables control of the transmission.

TCU will shut off the solenoid valves for the clutches and also the common power supply (VPS1).

Transmission shifts to Neutral. The park brake will operate normally, also the other functions which

use ADM 1 to ADM 8.

The operator has to slow down the vehicle. The transmission will stay in neutral.

TCU-SHUTDOWN:

TCU has detected a severe failure that disables control of system.

TCU will shut off all solenoid valves and also both common power supplies (VPS1, VPS2). The park

brake will engage, also all functions are disabled which use ADM 1 to ADM 8.

The transmission will stay in neutral.

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 7 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

3 table of fault codes

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

11 5000 12 LOGICAL ERROR AT GEAR RANGE SIGNAL TCU shifts transmission to neutral • check the cables from TCU to shift lever failure cannot be detected in

TCU detected a wrong signal combination OP-Mode: transmission shutdown • check signal combinations of shift lever systems with DW2/DW3 shift

for the gear range positions for gear range lever

• cable from shift lever to TCU is fault is taken back if TCU

broken detects a valid signal for the

• cable is defective and is contacted to position

battery voltage or vehicle ground

• shift lever is defective

12 5010 12 LOGICAL ERROR AT DIRECTION SELECT TCU shifts transmission to neutral • check the cables from TCU to shift lever fault is taken back if TCU

SIGNAL OP-Mode: transmission shutdown • check signal combinations of shift lever detects a valid signal for the

TCU detected a wrong signal combination positions F-N-R direction at the shift lever

for the direction

• cable from shift lever to TCU is

broken

• cable is defective and is contacted to

battery voltage or vehicle ground

• shift lever is defective

13 5020 12 LOGICAL ERROR AT ENGINE DERATING after selecting neutral, TCU • check engine derating device This fault is reset after power

DEVICE changes to OP-Mode limp home up of TCU

TCU detected no reaction of engine while

derating device activ

15 5040 12 LOGICAL ERROR AT DIRECTION SELECT TCU shifts transmission to neutral • check the cables from TCU to shift lever fault is taken back if TCU

SIGNAL 2. SHIFT LEVER if selector activ 2 detects a valid neutral signal

TCU detected a wrong signal combination OP-Mode: transmission shutdown • check signal combinations of shift lever for the direction at the shift

for the direction if selector activ positions F-N-R lever

• cable from shift lever 2 to TCU is

broken

• cable is defective and is contacted to

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 8 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

battery voltage or vehicle ground

• shift lever is defective

16 5050 12 LOGICAL ERROR AT AXLE CONNECTION OP-Mode: normal • check the cables from TCU to feedback

feedback axle connection measured by axle connection switch

TCU and output signal axle connection • check signals of the feedback axle

don't fit connection switch

• axle can’t be connected or

disconnected due to mechanical

problem

• one of the cables from feedback axle

connection -switch to TCU is broken

25 5110 3 S.C. TO BATTERY VOLTAGE OR O.C. AT no reaction, • check the cable from TCU to the sensor

TRANSMISSION SUMP TEMPERATURE SENSOR TCU uses default temperature • check the connectors

INPUT OP-Mode: normal • check the temperature sensor

the measured voltage is too high:

• cable is defective and is contacted to

battery voltage

• cable has no connection to TCU

• temperature sensor has an internal

defect

• connector pin is contacted to battery

voltage or is broken

26 5110 4 S.C. TO GROUND AT TRANSMISSION SUMP no reaction, • check the cable from TCU to the sensor

TEMPERATURE SENSOR INPUT TCU uses default temperature • check the connectors

the measured voltage is too low: OP-Mode: normal • check the temperature sensor

• cable is defective and is contacted to

vehicle ground

• temperature sensor has an internal

defect

• connector pin is contacted to vehicle

ground

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 9 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

27 5120 3 S.C. TO BATTERY VOLTAGE OR O.C. AT no reaction, • check the cable from TCU to the sensor

RETARDER / TORQUECONVERTER TCU uses default temperature • check the connectors

TEMPERATURE SENSOR INPUT OP-Mode: normal • check the temperature sensor

the measured voltage is too high:

• cable is defective and is contacted to

battery voltage

• cable has no connection to TCU

• temperature sensor has an internal

defect

• connector pin is contacted to battery

voltage or is broken

28 5120 4 S.C. TO GROUND AT RETARDER / no reaction, • check the cable from TCU to the sensor

TORQUECONVERTER TEMPERATURE SENSOR TCU uses default temperature • check the connectors

INPUT OP-Mode: normal • check the temperature sensor

the measured voltage is too low:

• cable is defective and is contacted to

vehicle ground

• temperature sensor has an internal

defect

• connector pin is contacted to vehicle

ground

29 5130 3 S.C. TO BATTERY VOLTAGE OR O.C. AT TCU uses default value • check the cable from TCU to the sensor

PARKING BRAKE SENSOR INPUT OP-Mode: normal • check the connectors

the measured voltage is too high: • check the parking brake sensor

• cable is defective and is contacted to

battery voltage

• cable has no connection to TCU

• sensor has an internal defect

• connector pin is contacted to battery

voltage or is broken

2A 5130 4 S.C. TO GROUND PARKING BRAKE SENSOR TCU uses default value • check the cable from TCU to the sensor

INPUT OP-Mode: normal • check the connectors

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 10 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

the measured voltage is too low: • check the parking brake sensor

• cable is defective and is contacted to

vehicle ground

• sensor has an internal defect

• connector pin is contacted to vehicle

ground

2B 5313 12 INCHSENSOR-SIGNAL MISMATCH During inching mode: TCU shifts • check the cable from TCU to the sensor

the measured voltage from CCO and CCO2 to neutral • check the connectors

signal don’t match: While not inching: no change • check sensor

• cable is defective OP-Mode: normal

• sensor has an internal defect

2C 5135 3 S.C. TO BATTERY VOLTAGE OR O.C. AT DLM TCU uses default value • check the cable from TCU to the sensor

TRACTION ADJUST DASHBOARD DEVICE OP-Mode: normal • check the connectors

INPUT • check the DLM Traction Adjust

the measured voltage is too high: dashboard device

• cable is defective and is contacted to

battery voltage

• cable has no connection to TCU

• sensor has an internal defect

• connector pin is contacted to battery

voltage or is broken

2D 5135 4 S.C. TO GROUND DLM TRACTION ADJUST TCU uses default value • check the cable from TCU to the sensor

DASHBOARD DEVICE INPUT OP-Mode: normal • check the connectors

the measured voltage is too low: • check the DLM Traction Adjust

• cable is defective and is contacted to dashboard device

vehicle ground

• sensor has an internal defect

• connector pin is contacted to vehicle

ground

2E 5137 3 S.C. TO BATTERY VOLTAGE OR O.C. AT DLM TCU uses default value • check the cable from TCU to the sensor

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 11 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

STEERING ANGLE SENSOR INPUT OP-Mode: normal • check the connectors

the measured voltage is too high: • check the DLM STEERING ANGLE

• cable is defective and is contacted to SENSOR

battery voltage

• cable has no connection to TCU

• sensor has an internal defect

• connector pin is contacted to battery

voltage or is broken

2F 5137 4 S.C. TO GROUND DLM STEERING ANGLE TCU uses default value • check the cable from TCU to the sensor

SENSOR INPUT OP-Mode: normal • check the connectors

the measured voltage is too low: • check the DLM STEERING ANGLE

• cable is defective and is contacted to SENSOR

vehicle ground

• sensor has an internal defect

• connector pin is contacted to vehicle

ground

31 5140 3 S.C. TO BATTERY VOLTAGE OR O.C. AT OP-Mode: substitute clutch • check the cable from TCU to the sensor

ENGINE SPEED INPUT control • check the connectors

TCU measures a voltage higher than 7.00 V • check the speed sensor

at speed input pin

• cable is defective and is contacted to

battery voltage

• cable has no connection to TCU

• speed sensor has an internal defect

• connector pin is contacted to battery

voltage or has no contact

32 5140 4 S.C. TO GROUND AT ENGINE SPEED INPUT OP-Mode: substitute clutch • check the cable from TCU to the sensor

TCU measures a voltage less than 0.45V at control • check the connectors

speed input pin • check the speed sensor

• cable / connector is defective and is

contacted to vehicle ground

• speed sensor has an internal defect

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 12 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

33 5140 12 LOGICAL ERROR AT ENGINE SPEED INPUT OP-Mode: substitute clutch • check the cable from TCU to the sensor This fault is reset after power

TCU measures a engine speed over a control • check the connectors up of TCU

threshold and the next moment the • check the speed sensor

measured speed is zero • check the sensor gap

• cable / connector is defective and has

bad contact

• speed sensor has an internal defect

• sensor gap has the wrong size

34 5150 3 S.C. TO BATTERY VOLTAGE OR O.C. AT OP-Mode: substitute clutch • check the cable from TCU to the sensor

TURBINE SPEED INPUT control • check the connectors

TCU measures a voltage higher than 7.00 V if a failure is existing at output • check the speed sensor

at speed input pin speed,

• cable is defective and is contacted to TCU shifts to neutral

battery voltage OP-Mode: limp home

• cable has no connection to TCU

• speed sensor has an internal defect

• connector pin is contacted to battery

voltage or has no contact

35 5150 4 S.C. TO GROUND AT TURBINE SPEED INPUT OP-Mode: substitute clutch • check the cable from TCU to the sensor

TCU measures a voltage less than 0.45V at control • check the connectors

speed input pin if a failure is existing at output • check the speed sensor

• cable / connector is defective and is speed,

contacted to vehicle ground TCU shifts to neutral

• speed sensor has an internal defect OP-Mode: limp home

36 5150 12 LOGICAL ERROR AT TURBINE SPEED INPUT OP-Mode: substitute clutch • check the cable from TCU to the sensor This fault is reset after power

TCU measures a turbine speed over a control • check the connectors up of TCU

threshold and at the next moment the if a failure is existing at output • check the speed sensor

measured speed is zero speed, • check the sensor gap

• cable / connector is defective and has TCU shifts to neutral

bad contact OP-Mode: limp home

• speed sensor has an internal defect

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 13 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

• sensor gap has the wrong size

37 5160 3 S.C. TO BATTERY VOLTAGE OR O.C. AT OP-Mode: substitute clutch • check the cable from TCU to the sensor

INTERNAL SPEED INPUT control • check the connectors

TCU measures a voltage higher than 7.00 V • check the speed sensor

at speed input pin

• cable is defective and is contacted to

battery voltage

• cable has no connection to TCU

• speed sensor has an internal defect

• connector pin is contacted to battery

voltage or has no contact

38 5160 4 S.C. TO GROUND AT INTERNAL SPEED INPUT OP-Mode: substitute clutch • check the cable from TCU to the sensor

TCU measures a voltage less than 0.45V at control • check the connectors

speed input pin • check the speed sensor

• cable / connector is defective and is

contacted to vehicle ground

• speed sensor has an internal defect

39 5160 12 LOGICAL ERROR AT INTERNAL SPEED INPUT OP-Mode: substitute clutch • check the cable from TCU to the sensor This fault is reset after power

TCU measures a internal speed over a control • check the connectors up of TCU

threshold and at the next moment the • check the speed sensor

measured speed is zero • check the sensor gap

• cable / connector is defective and has

bad contact

• speed sensor has an internal defect

• sensor gap has the wrong size

3A 5170 3 S.C. TO BATTERY VOLTAGE OR O.C. AT special mode for gear selection • check the cable from TCU to the sensor

OUTPUT SPEED INPUT OP-Mode: substitute clutch • check the connectors

TCU measures a voltage higher than 12.5 V control • check the speed sensor

at speed input pin if a failure is existing at turbine

• cable is defective and is contacted to speed,

battery voltage TCU shifts to neutral

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 14 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

• cable has no connection to TCU OP-Mode: limp home

• speed sensor has an internal defect

• connector pin is contacted to battery

voltage or has no contact

3B 5170 4 S.C. TO GROUND AT OUTPUT SPEED INPUT special mode for gear selection • check the cable from TCU to the sensor

TCU measures a voltage less than 1.00V at OP-Mode: substitute clutch • check the connectors

speed input pin control • check the speed sensor

• cable / connector is defective and is if a failure is existing at turbine

contacted to vehicle ground speed,

• speed sensor has an internal defect TCU shifts to neutral

OP-Mode: limp home

3C 5170 12 LOGICAL ERROR AT OUTPUT SPEED INPUT special mode for gear selection • check the cable from TCU to the sensor This fault is reset after power

TCU measures a output speed over a OP-Mode: substitute clutch • check the connectors up of TCU

threshold and at the next moment the control • check the speed sensor

measured speed is zero if a failure is existing at turbine • check the sensor gap

• cable / connector is defective and has speed,

bad contact TCU shifts to neutral

• speed sensor has an internal defect OP-Mode: limp home

• sensor gap has the wrong size

3E 5180 2 OUTPUT SPEED ZERO DOESN’T FIT TO OTHER special mode for gear selection • check the sensor signal of output speed This fault is reset after power

SPEED SIGNALS OP-Mode: substitute clutch sensor up of TCU

if transmission is not neutral and the control • check the sensor gap of output speed

shifting has finished, if a failure is existing at turbine sensor

TCU measures outputspeed zero and speed, • check the cable from TCU to the sensor

turbine speed or internal speed not equal to TCU shifts to neutral

zero. OP-Mode: limp home

• speed sensor has an internal defect

• sensor gap has the wrong size

56 5280 9 ENGINE CONF TIMEOUT OP-Mode: substitute clutch • check engine controller

Timeout of CAN-message ENGINE CONF control • check wire of CAN-Bus

from engine controller • check cable to engine controller

• interference on CAN-Bus

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 15 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

• CAN wire/connector is broken

• CAN wire/connector is defective and

has contact to vehicle ground or

battery voltage

57 5290 9 EEC1 TIMEOUT OP-Mode: substitute clutch • check EEC controller

Timeout of CAN-message EEC1 from EEC control • check wire of CAN-Bus

controller • check cable to EEC controller

• interference on CAN-Bus

• CAN wire/connector is broken

• CAN wire/connector is defective and

has contact to vehicle ground or

battery voltage

58 5300 9 EEC3 TIMEOUT OP-Mode: substitute clutch • check EEC controller

Timeout of CAN-message EEC3 from EEC control • check wire of CAN-Bus

controller • check cable to EEC controller

• interference on CAN-Bus

• CAN wire/connector is broken

• CAN wire/connector is defective an

has contact to vehicle ground or

battery voltage

65 5430 2 ENGINGE TORQUE SIGNAL OP-Mode:substitute clutch • check engine controller

CAN signal for engine torque is defective control • check wire of CAN-Bus

• engine controller is defective • check cable to engine controller

• interference on CAN-Bus

69 5440 2 REFERENCE ENGINE TORQUE SIGNAL OP-Mode:substitute clutch • check engine controller

CAN signal for reference of engine torque control • check wire of CAN-Bus

is defective • check cable to engine controller

• engine controller is defective

• interference on CAN-Bus

6A 5450 2 ACTUAL ENGINE TORQUE SIGNAL OP-Mode:substitute clutch • check engine controller

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 16 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

CAN signal for actual engine torque is control • check wire of CAN-Bus

defective • check cable to engine controller

• engine controller is defective

• interference on CAN-Bus

6B 5460 2 NOM FRICTION TORQUE SIGNAL OP-Mode:substitute clutch • check engine controller

CAN signal for nominal friction torque is control • check wire of CAN-Bus

defective • check cable to engine controller

• engine controller is defective

• interference on CAN-Bus

6E 5470 2 EEC2 TIMEOUT no reaction, • check EEC controller

Timeout of CAN-message EEC2 from EEC TCU uses default signal • check wire of CAN-Bus

controller accelerator pedal in idle position • check cable to EEC controller

• interference on CAN-Bus OP-Mode: normal

• CAN wire/connector is broken

• CAN wire/connector is defective and

has contact to vehicle ground or

battery voltage

1)

71 5480 3 S.C. TO BATTERY VOLTAGE AT CLUTCH K1 TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from TCU to the

is out of limit, the voltage at K1 valve is if failure at another clutch is gearbox

too high. pending • check the regulator resistance 1)

• cable / connector is defective and has TCU shifts to neutral • check internal wire harness of the

contact to battery voltage OP-Mode: TCU shutdown gearbox

• regulator has an internal defect

1)

72 5480 4 S.C. TO GROUND AT CLUTCH K1 TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit, the voltage at K1 valve is if failure at another clutch is TCU

too low. pending • check the regulator resistance 1)

• cable / connector is defective and has TCU shifts to neutral • check internal wire harness of the

contact to vehicle ground OP-Mode: TCU shutdown gearbox

• cable / connector is defective and has

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 17 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

contact to another regulator output of

the TCU

• regulator has an internal defect

1)

73 5480 5 O.C. AT CLUTCH K1 TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit. if failure at another clutch is TCU

• cable / connector is defective and has pending • check the regulator resistance 1)

no contact to TCU TCU shifts to neutral • check internal wire harness of the

• regulator has an internal defect OP-Mode: TCU shutdown gearbox

1)

74 5490 3 S.C. TO BATTERY VOLTAGE AT CLUTCH K2 TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit, the voltage at K2 valve is if failure at another clutch is TCU

too high. pending • check the regulator resistance 1)

• cable / connector is defective and has TCU shifts to neutral • check internal wire harness of the

contact to battery voltage OP-Mode: TCU shutdown gearbox

• regulator has an internal defect

1)

75 5490 4 S.C. TO GROUND AT CLUTCH K2 TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit, the voltage at K2 valve is if failure at another clutch is TCU

too low. pending • check the regulator resistance 1)

• cable / connector is defective and has TCU shifts to neutral • check internal wire harness of the

contact to vehicle ground OP-Mode: TCU shutdown gearbox

• cable / connector is defective and has

contact to another regulator output of

the TCU

• regulator has an internal defect

1)

76 5490 5 O.C. AT CLUTCH K2 TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit. if failure at another clutch is TCU

• cable / connector is defective and has pending • check the regulator resistance 1)

no contact to TCU TCU shifts to neutral • check internal wire harness of the

OP-Mode: TCU shutdown

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 18 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

• regulator has an internal defect gearbox

1)

77 5500 3 S.C. TO BATTERY VOLTAGE AT CLUTCH K3 TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit, the voltage at K3 valve is if failure at another clutch is TCU

too high. pending • check the regulator resistance 1)

• cable / connector is defective and has TCU shifts to neutral • check internal wire harness of the

contact to battery voltage OP-Mode: TCU shutdown gearbox

• regulator has an internal defect

1)

78 5500 4 S.C. TO GROUND AT CLUTCH K3 TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit, the voltage at K3 valve is if failure at another clutch is TCU

too low. pending • check the regulator resistance 1)

• cable / connector is defective and has TCU shifts to neutral • check internal wire harness of the

contact to vehicle ground OP-Mode: TCU shutdown gearbox

• cable / connector is defective and has

contact to another regulator output of

the TCU

• regulator has an internal defect

1)

79 5500 5 O.C. AT CLUTCH K3 TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit. if failure at another clutch is TCU

• cable / connector is defective and has pending • check the regulator resistance 1)

no contact to TCU TCU shifts to neutral • check internal wire harness of the

• regulator has an internal defect OP-Mode: TCU shutdown gearbox

1)

81 5510 3 S.C. TO BATTERY VOLTAGE AT CLUTCH K4 TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit, the voltage at K4 valve is if failure at another clutch is TCU

too high. pending • check the regulator resistance 1)

• cable / connector is defective and has TCU shifts to neutral • check internal wire harness of the

contact to battery voltage OP-Mode: TCU shutdown gearbox

• regulator has an internal defect

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 19 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

1)

82 5510 4 S.C. TO GROUND AT CLUTCH K4 TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit, the voltage at K4 valve is if failure at another clutch is TCU

too low. pending • check the regulator resistance 1)

• cable / connector is defective and has TCU shifts to neutral • check internal wire harness of the

contact to vehicle ground OP-Mode: TCU shutdown gearbox

• cable / connector is defective and has

contact to another regulator output of

the TCU

• regulator has an internal defect

1)

83 5510 5 O.C. AT CLUTCH K4 TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit. if failure at another clutch is TCU

• cable / connector is defective and has pending • check the regulator resistance 1)

no contact to TCU TCU shifts to neutral • check internal wire harness of the

• regulator has an internal defect OP-Mode: TCU shutdown gearbox

1)

84 5520 3 S.C. TO BATTERY VOLTAGE AT CLUTCH KV TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit, the voltage at KV valve is if failure at another clutch is TCU

too high. pending • check the regulator resistance 1)

• cable / connector is defective and has TCU shifts to neutral • check internal wire harness of the

contact to battery voltage OP-Mode: TCU shutdown gearbox

• regulator has an internal defect

1)

85 5520 4 S.C. TO GROUND AT CLUTCH KV TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit, the voltage at KV valve is if failure at another clutch is TCU

too low. pending • check the regulator resistance 1)

• cable / connector is defective and has TCU shifts to neutral • check internal wire harness of the

contact to vehicle ground OP-Mode: TCU shutdown gearbox

• cable / connector is defective and has

contact to another regulator output of

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 20 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

the TCU

• regulator has an internal defect

1)

86 5520 5 O.C. AT CLUTCH KV TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit. if failure at another clutch is TCU

• cable / connector is defective and has pending • check the regulator resistance 1)

no contact to TCU TCU shifts to neutral • check internal wire harness of the

• regulator has an internal defect OP-Mode: TCU shutdown gearbox

1)

87 5530 3 S.C. TO BATTERY VOLTAGE AT CLUTCH KR TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit, the voltage at KR valve is if failure at another clutch is TCU

too high. pending • check the regulator resistance 1)

• cable / connector is defective and has TCU shifts to neutral • check internal wire harness of the

contact to battery voltage OP-Mode: TCU shutdown gearbox

• regulator has an internal defect

1)

88 5530 4 S.C. TO GROUND AT CLUTCH KR TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit, the voltage at KR valve is if failure at another clutch is TCU

too low. pending • check the regulator resistance 1)

• cable / connector is defective and has TCU shifts to neutral • check internal wire harness of the

contact to vehicle ground OP-Mode: TCU shutdown gearbox

• cable / connector is defective and has

contact to another regulator output of

the TCU

• regulator has an internal defect

1)

89 5530 5 O.C. AT CLUTCH KR TCU shifts to neutral • check the cable from TCU to the gearbox see chapter 4

the measured resistance value of the valve OP-Mode: limp home • check the connectors from gearbox to

is out of limit. if failure at another clutch is TCU

• cable / connector is defective and has pending • check the regulator resistance 1)

no contact to TCU TCU shifts to neutral • check internal wire harness of the

• regulator has an internal defect OP-Mode: TCU shutdown gearbox

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 21 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

1)

8A 5535 4 S.C. TO GROUND AT DLM TRANSVERSAL output will be on until TCU • check the cable from TCU to the valve see chapter 4

OUTPUT power down even if fault • check the connectors

TCU detected a wrong voltage at the output vanishes (loose connection) • check the resistance of valve

pin, that looks like a s.c. to vehicle ground OP-Mode: normal

• cable is defective and is contacted to

vehicle ground

• device has an internal defect

• connector pin is contacted to vehicle

ground

1)

8B 5535 3 S.C. TO BATTERY VOLTAGE AT DLM no reaction • check the cable from TCU to the valve see chapter 4

TRANSVERSAL OUTPUT OP-Mode: normal • check the connectors

TCU detected a wrong voltage at the output • check the resistance of valve

pin, that looks like a s.c. to battery voltage

• cable is defective and is contacted to

battery voltage

• device has an internal defect

• connector pin is contacted to battery

voltage

1)

8E 5536 3 S.C. TO BATTERY VOLTAGE AT DLM no reaction • check the cable from TCU to the device see chapter 4

INDICATOR LAMP OUTPUT OP-Mode: normal • check the connectors

TCU detected a wrong voltage at the output • check the resistance of device

pin, that looks like a s.c. to battery voltage

• cable is defective and is contacted to

battery voltage

• device has an internal defect

• connector pin is contacted to battery

voltage

1)

8F 5536 5 O.C. DLM INDICATOR LAMP OUTPUT no reaction • check the cable from TCU to the device see chapter 4

OP-Mode: normal • check the connectors

TCU detected a wrong voltage at the output • check the resistance of device

pin, that looks like a o.c. for this output pin

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 22 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

• cable is defective and has no

connection to TCU

• device has an internal defect

• connector has no connection to TCU

1)

93 5560 5 O.C. AT RELAY REVERSE WARNING ALARM no reaction • check the cable from TCU to the backup see chapter 4

TCU detected a wrong voltage at the output OP-Mode: normal alarm device

pin, that looks like a o.c. for this output pin • check the connectors from backup alarm

• cable is defective and has no device to TCU

connection to TCU • check the resistance 1) of backup alarm

• backup alarm device has an internal device

defect

• connector has no connection to TCU

1)

94 5570 4 S.C. TO GROUND AT RELAY STARTER no reaction • check the cable from TCU to the starter see chapter 4

INTERLOCK OP-Mode: normal interlock relay

TCU detected a wrong voltage at the output • check the connectors from starter

pin, that looks like a s.c. to vehicle ground interlock relay to TCU

• cable is defective and is contacted to • check the resistance 1) of starter interlock

vehicle ground relay

• starter interlock relay has an internal

defect

• connector pin is contacted to vehicle

ground

1)

95 5570 3 S.C. TO BATTERY VOLTAGE AT RELAY no reaction • check the cable from TCU to the starter see chapter 4

STARTER INTERLOCK OP-Mode: normal interlock relay

TCU detected a wrong voltage at the output • check the connectors from starter

pin, that looks like a s.c. to battery voltage interlock relay to TCU

• cable is defective and is contacted to • check the resistance 1) of starter interlock

battery voltage relay

• starter interlock relay has an internal

defect

• connector pin is contacted to battery

voltage

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 23 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

1)

96 5570 5 O.C. AT RELAY STARTER INTERLOCK no reaction • check the cable from TCU to the starter see chapter 4

TCU detected a wrong voltage at the output OP-Mode: normal interlock relay

pin, that looks like a o.c. for this output pin • check the connectors from starter

• cable is defective and has no interlock relay to TCU

connection to TCU • check the resistance 1) of starter interlock

• starter interlock relay has an internal relay

defect

• connector has no connection to TCU

1)

9A 5590 4 S.C. TO GROUND AT CONVERTER LOCK UP no reaction • check the cable from TCU to the see chapter 4

CLUTCH SOLENOID OP-mode: normal converter clutch solenoid

TCU detected a wrong voltage at the output • check the connectors from converter

pin, that looks like a s.c. to vehicle ground clutch solenoid to TCU

• cable is defective and is contacted to • check the resistance 1) of converter clutch

vehicle ground solenoid

• converter clutch solenoid has an

internal defect

• connector pin is contacted to vehicle

ground

1)

9B 5590 3 O.C. AT CONVERTER LOCK UP CLUTCH converter clutch always open, • check the cable from TCU to the see chapter 4

SOLENOID retarder not available converter clutch solenoid

TCU detected a wrong voltage at the output OP-mode: normal • check the connectors from converter

pin, that looks like a o.c. for this output pin clutch solenoid to TCU

• cable is defective and has no • check the resistance 1) of converter clutch

connection to TCU solenoid

• converter clutch solenoid has an

internal defect

• connector has no connection to TCU

1)

9C 5590 5 S.C. TO BATTERY VOLTAGE AT CONVERTER no reaction • check the cable from TCU to the see chapter 4

LOCK UP CLUTCH SOLENOID OP-mode: normal converter clutch solenoid

TCU detected a wrong voltage at the output • check the connectors from converter

pin, that looks like a s.c. to battery voltage clutch solenoid to TCU

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 24 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

• cable is defective and is contacted to • check the resistance 1) of converter clutch

battery voltage solenoid

• converter clutch solenoid has an

internal defect

• connector pin is contacted to battery

voltage

1)

9D 5600 4 S.C. TO GROUND AT RETARDER SOLENOID no reaction • check the cable from TCU to the retarder see chapter 4

TCU detected a wrong voltage at the output OP-mode: normal solenoid

pin, that looks like a s.c. to vehicle ground • check the connectors from retarder

• cable is defective and is contacted to solenoid to TCU

vehicle ground • check the resistance 1) of retarder

• retarder solenoid has an internal solenoid

defect

• connector pin is contacted to vehicle

ground

1)

9E 5600 3 O.C. AT RETARDER SOLENOID no reaction • check the cable from TCU to the retarder see chapter 4

TCU detected a wrong voltage at the output OP-mode: normal solenoid

pin, that looks like a o.c. for this output pin • check the connectors from retarder

• cable is defective and has no solenoid to TCU

connection to TCU • check the resistance 1) of retarder

• retarder solenoid has an internal solenoid

defect

• connector has no connection to TCU

1)

9F 5600 5 S.C. TO BATTERY VOLTAGE AT RETARDER no reaction • check the cable from TCU to the retarder see chapter 4

SOLENOID OP-mode: normal solenoid

TCU detected a wrong voltage at the output • check the connectors from retarder

pin, that looks like a s.c. to battery voltage solenoid to TCU

• cable is defective and is contacted to • check the resistance 1) of retarder

battery voltage solenoid

• retarder solenoid has an internal

defect

• connector pin is contacted to battery

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 25 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

voltage

1)

A1 5610 4 S.C. TO GROUND AT DIFFLOCK OR AXLE no reaction • check the cable from TCU to the difflock see chapter 4

CONNECTION SOLENOID OP-mode: normal solenoid

TCU detected a wrong voltage at the output • check the connectors from difflock

pin, that looks like a s.c. to vehicle ground solenoid to TCU

• cable is defective and is contacted to • check the resistance 1) of difflock

vehicle ground solenoid

• difflock solenoid has an internal

defect

• connector pin is contacted to vehicle

ground

1)

A2 5610 3 S.C. TO BATTERY VOLTAGE AT DIFFLOCK OR no reaction • check the cable from TCU to the difflock see chapter 4

AXLE CONNECTION SOLENOID OP-mode: normal solenoid

TCU detected a wrong voltage at the output • check the connectors from difflock

pin, that looks like a s.c. to battery voltage solenoid to TCU

• cable is defective and is contacted to • check the resistance 1) of difflock

battery voltage solenoid

• difflock solenoid has an internal

defect

• connector pin is contacted to battery

voltage

1)

A3 5610 5 O.C. AT DIFFLOCK OR AXLE CONNECTION no reaction • check the cable from TCU to the difflock see chapter 4

SOLENOID OP-mode: normal solenoid

TCU detected a wrong voltage at the output • check the connectors from difflock

pin, that looks like a o.c. for this output pin solenoid to TCU

• cable is defective and has no • check the resistance 1) of difflock

connection to TCU solenoid

• difflock solenoid has an internal

defect

• connector has no connection to TCU

1)

A4 5620 4 S.C. TO GROUND AT WARNING SIGNAL no reaction • check the cable from TCU to the warning see chapter 4

OUTPUT OP-mode: normal

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 26 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

TCU detected a wrong voltage at the output device

pin, that looks like a s.c. to vehicle ground • check the connectors from warning

• cable is defective and is contacted to device to TCU

vehicle ground • check the resistance 1) of warning device

• warning device has an internal defect

• connector pin is contacted to vehicle

ground

1)

A5 5620 5 O.C. AT WARNING SIGNAL OUTPUT no reaction • check the cable from TCU to the warning see chapter 4

TCU detected a wrong voltage at the output OP-mode: normal device

pin, that looks like a o.c. for this output pin • check the connectors from warning

• cable is defective and has no device to TCU

connection to TCU • check the resistance 1) of warning device

• warning device has an internal defect

• connector has no connection to TCU

1)

A6 5620 3 S.C. TO BATTERY VOLTAGE AT WARNING no reaction • check the cable from TCU to the warning see chapter 4

SIGNAL OUTPUT OP-mode: normal device

TCU detected a wrong voltage at the output • check the connectors from warning

pin, that looks like a s.c. to battery voltage device to TCU

• cable is defective and is contacted to • check the resistance 1) of warning device

battery voltage

• warning device has an internal defect

• connector pin is contacted to battery

voltage

B1 5660 2 SLIPPAGE AT CLUTCH K1 TCU shifts to neutral • check pressure at clutch K1

TCU calculates a differential speed at OP-Mode: limp home • check main pressure in the system

closed clutch K1. If this calculated value is if failure at another clutch is • check sensor gap at internal speed sensor

out of range, TCU interprets this as pending • check sensor gap at output speed sensor

slipping clutch. TCU shifts to neutral • check signal at internal speed sensor

• low pressure at clutch K1 OP-Mode: TCU shutdown

• check signal at output speed sensor

• low main pressure • replace clutch

• wrong signal at internal speed sensor

• wrong signal at output speed sensor

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 27 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

• wrong size of the sensor gap

• clutch is defective

B2 5665 2 SLIPPAGE AT CLUTCH K2 TCU shifts to neutral • check pressure at clutch K2

TCU calculates a differential speed at OP-Mode: limp home • check main pressure in the system

closed clutch K2. If this calculated value is if failure at another clutch is • check sensor gap at internal speed sensor

out of range, TCU interprets this as pending • check sensor gap at output speed sensor

slipping clutch. TCU shifts to neutral • check signal at internal speed sensor

• low pressure at clutch K2 OP-Mode: TCU shutdown

• check signal at output speed sensor

• low main pressure

• replace clutch

• wrong signal at internal speed sensor

• wrong signal at output speed sensor

• wrong size of the sensor gap

• clutch is defective

B3 5670 2 SLIPPAGE AT CLUTCH K3 TCU shifts to neutral • check pressure at clutch K3

TCU calculates a differential speed at OP-Mode: limp home • check main pressure in the system

closed clutch K3. If this calculated value is if failure at another clutch is • check sensor gap at internal speed sensor

out of range, TCU interprets this as pending • check sensor gap at output speed sensor

slipping clutch. TCU shifts to neutral • check signal at internal speed sensor

• low pressure at clutch K3 OP-Mode: TCU shutdown

• check signal at output speed sensor

• low main pressure • replace clutch

• wrong signal at internal speed sensor

• wrong signal at output speed sensor

• wrong size of the sensor gap

• clutch is defective

B4 5675 2 SLIPPAGE AT CLUTCH K4 TCU shifts to neutral • check pressure at clutch K4

TCU calculated a difference speed at TCU OP-Mode: limp home • check main pressure in the system

calculates a differential speed at closed if failure at another clutch is • check sensor gap at internal speed sensor

clutch K4. If this calculated value is out of pending • check sensor gap at turbine speed sensor

range, TCU interprets this as slipping TCU shifts to neutral • check signal at internal speed sensor

clutch. OP-Mode: TCU shutdown

• check signal at turbine speed sensor

• low pressure at clutch K4

• replace clutch

• low main pressure

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 28 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

• wrong signal at internal speed sensor

• wrong signal at turbine speed sensor

• wrong size of the sensor gap

• clutch is defective

B5 5680 2 SLIPPAGE AT CLUTCH KV TCU shifts to neutral • check pressure at clutch KV

TCU calculates a differential speed at OP-Mode: limp home • check main pressure in the system

closed clutch KV. If this calculated value if failure at another clutch is • check sensor gap at internal speed sensor

is out of range, TCU interprets this as pending • check sensor gap at turbine speed sensor

slipping clutch. TCU shifts to neutral • check signal at internal speed sensor

• low pressure at clutch KV OP-Mode: TCU shutdown

• check signal at turbine speed sensor

• low main pressure • replace clutch

• wrong signal at internal speed sensor

• wrong signal at turbine speed sensor

• wrong size of the sensor gap

• clutch is defective

B6 5685 2 SLIPPAGE AT CLUTCH KR TCU shifts to neutral • check pressure at clutch KR

TCU calculates a differential speed at OP-Mode: limp home • check main pressure in the system

closed clutch KR. If this calculated value if failure at another clutch is • check sensor gap at internal speed sensor

is out of range, TCU interprets this as pending • check sensor gap at turbine speed sensor

slipping clutch. TCU shifts to neutral • check signal at internal speed sensor

• low pressure at clutch KR OP-Mode: TCU shutdown

• check signal at turbine speed sensor

• low main pressure • replace clutch

• wrong signal at internal speed sensor

• wrong signal at turbine speed sensor

• wrong size of the sensor gap

• clutch is defective

B7 5700 0 OVERTEMP SUMP no reaction • cool down machine

TCU measured a temperature in the oil OP-Mode: normal • check oil level

sump that is over the allowed threshold. • check temperature sensor

B8 5710 0 OVERTEMP RETARDER TCU disables retarder • cool down machine

TCU measured a temperature in the OP-Mode: normal • check oil level

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 29 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

retarder oil that is over the allowed • check temperature sensor

threshold.

B9 5720 0 OVERSPEED ENGINE retarder applies if configured -

OP-Mode: normal

BA 5730 0 DIFFERENTIAL PRESSURE OIL FILTER no reaction • check oil filter

TCU measured a voltage at differential OP-Mode: normal • check wiring from TCU to differential

pressure switch out of the allowed range pressure switch

• oil filter is polluted • check differential pressure switch

• cable/connector is broken or (measure resitance)

cable/connector is contacted to

battery voltage or vehicle ground

• differential pressure switch is

defective

BB 5740 2 SLIPPAGE AT CONVERTER LOCKUP CLUTCH • check pressure at converter lockup clutch

TCU calculates a differential speed at • check main pressure in the system

closed converter lockup clutch. If this • check sensor gap at engine speed sensor

calculated value is out of range, TCU • check sensor gap at turbine speed sensor

interprets this as slipping clutch. • check signal at engine speed sensor

• low pressure at converter lockup • check signal at turbine speed sensor

clutch

• replace clutch

• low main pressure

• wrong signal at engine speed sensor

• wrong signal at turbine speed sensor

• wrong size of the sensor gap

• clutch is defective

BC 5745 15 OVERSPEED OUTPUT No reaction

TCU messures an transmission output OP-Mode: normal

speed above the defined threshold

1)

BD 5750 4 S.C. TO GROUND AT ENGINE BRKAE no reaction • check the cable from TCU to the engine see chapter 4

SOLENOID OP-mode: normal brake solenoid

TCU detected a wrong voltage at the output • check the connectors from engine brake

pin, that looks like a s.c. to vehicle ground solenoid to TCU

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 30 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

• cable is defective and is contacted to • check the resistance 1) of engine brake

vehicle ground solenoid

• engine brake solenoid has an internal

defect

• connector pin is contacted to vehicle

ground

1)

BE 5750 3 S.C. TO BATTERY VOLTAGE AT ENGINE no reaction • check the cable from TCU to the engine see chapter 4

BRAKE OP-mode: normal brake solenoid

TCU detected a wrong voltage at the output • check the connectors from engine brake

pin, that looks like a s.c. to battery voltage solenoid to TCU

• cable is defective and is contacted to • check the resistance 1) of engine brake

battery voltage solenoid

• engine brake solenoid has an internal

defect

• connector pin is contacted to battery

voltage

1)

BF 5750 5 O.C. AT ENGINE BRAKE no reaction • check the cable from TCU to the engine see chapter 4

TCU detected a wrong voltage at the output OP-mode: normal brake solenoid

pin, that looks like a o.c. for this output pin • check the connectors from engine brake

• cable is defective and has no solenoid to TCU

connection to TCU • check the resistance 1) of engine brake

• engine brake solenoid has an internal solenoid

defect

• connector has no connection to TCU

C2 5755 15 TRANSMISSION INPUT TORQUE OVERLOAD programmable :No reaction or

TCU calculates an transmission output shift to neutral

torque above the defined threshold OP-Mode: normal

C4 5770 4 S.C. TO GROUND AT JOYSTICK STATUS no reaction • check the cable from TCU to joystick

INDICATOR OP-Mode: normal status indicator

TCU detected a wrong voltage at the output • check the connectors from joystick status

pin, that looks like a s.c. to vehicle ground indicator to TCU

• cable is defective and is contacted to • check the resistance 1) of joystick status

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 31 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

vehicle ground indicator

• joystick status indicator has an

internal defect

• connector pin is contacted to vehicle

ground

C5 5770 3 S.C. TO BATTERY VOLTAGE AT JOYSTICK no reaction • check the cable from TCU to joystick

STATUS INDICATOR OP-Mode: normal status indicator

TCU detected a wrong voltage at the output • check the connectors from joystick status

pin, that looks like a s.c. to battery voltage indicator to TCU

• cable is defective and is contacted to • check the resistance 1) of joystick status

battery voltage indicator

• joystick status indicator has an

internal defect

• connector pin is contacted to battery

voltage

C6 5770 5 O.C. AT JOYSTICK STATUS INDICATOR no reaction • check the cable from TCU to joystick

TCU detected a wrong voltage at the output OP-Mode: normal status indicator

pin, that looks like a o.c. for this output pin • check the connectors from joystick status

• cable is defective and has no indicator to TCU

connection to TCU • check the resistance 1) of joystick status

• joystick status indicator has an indicator

internal defect

• connector has no connection to TCU

CA 5790 9 ENGINE_RETARDER CONFIG_TIMEOUT OP-Mode: substitute clutch • check EEC controller

Timeout of CAN-message control • check wire of CAN-Bus

ENGINE_RETARDER CONFIG from EEC • check cable to EEC controller

controller

• interference on CAN-Bus

• CAN wire/connector is broken

• CAN wire/connector is defective an

has contact to vehicle ground or

battery voltage

TE-AB C:\WINDOWS\TEMP\6WG_CANJ19391.DOC Seite 32 von 37

ZF Friedrichshafen AG

description of fault codes for ERGO-Control 97-09-18

Fault SPN FMI MEANING OF THE FAULT CODE reaction of the TCU possible steps to repair remarks

Code possible reason for fault detection

(hex)

CB 5800 9 ERC1 TIMEOUT OP-Mode: substitute clutch • check EEC controller

Timeout of CAN-message ERC1 from EEC control • check wire of CAN-Bus

controller • check cable to EEC controller

• interference on CAN-Bus