Professional Documents

Culture Documents

Compressor Installation Guide 25

Compressor Installation Guide 25

Uploaded by

Ismail AliCopyright:

Available Formats

You might also like

- Unicos URK-700 Keratometer - Service ManualDocument64 pagesUnicos URK-700 Keratometer - Service ManualWilson Cepeda0% (1)

- Module 1 - Learning The Basic Computer ConceptsDocument180 pagesModule 1 - Learning The Basic Computer ConceptsAmir M. Villas87% (15)

- ME-Tut 4Document2 pagesME-Tut 4Shekhar SinghNo ratings yet

- Steam Jet Refrigeration and Vapour Absorption SystemDocument21 pagesSteam Jet Refrigeration and Vapour Absorption SystemmohitNo ratings yet

- Afhx (High Ambient) Mes0446aDocument24 pagesAfhx (High Ambient) Mes0446aEduardo Luis Souza100% (1)

- The Demise of The Primary-Secondary Pumping Paradigm For Chilled Water Plant DesignDocument5 pagesThe Demise of The Primary-Secondary Pumping Paradigm For Chilled Water Plant DesignWayde WillinsNo ratings yet

- Basic of C - Geeky Shows 1Document4 pagesBasic of C - Geeky Shows 1Tavishi Singh100% (3)

- Evaporative Condenser Engineering Manual: Technical ResourcesDocument18 pagesEvaporative Condenser Engineering Manual: Technical ResourcesMohamed IbrahimNo ratings yet

- 3.5 Steam Jet Refrigeration SystemDocument8 pages3.5 Steam Jet Refrigeration SystemShaik mahammad ArifNo ratings yet

- Cooling Circulating Water, Purge Water & Cooling Tower SystemDocument22 pagesCooling Circulating Water, Purge Water & Cooling Tower SystemSCE CCGT3No ratings yet

- Cooling Water and Cooling TowerDocument37 pagesCooling Water and Cooling Towersandip singhNo ratings yet

- Cooling Water System 1Document18 pagesCooling Water System 1anupam01013787No ratings yet

- Boiler Circulation SystemDocument32 pagesBoiler Circulation SystemRitik Dewangan100% (2)

- Liquid Subcooling: The Case For RefrigerantDocument4 pagesLiquid Subcooling: The Case For RefrigeranttaupiqNo ratings yet

- Centrifugal Chiller Heat Transfer Efficiency: Performance Diagnosis Condenser EvaluationDocument2 pagesCentrifugal Chiller Heat Transfer Efficiency: Performance Diagnosis Condenser EvaluationKipper GNo ratings yet

- Steam Jet RefrigerationDocument2 pagesSteam Jet Refrigerationelaizaagudo17No ratings yet

- Fordson Major ManualDocument47 pagesFordson Major ManualHassan GDOURANo ratings yet

- HVAC Chilled Water Distribution SchemesDocument56 pagesHVAC Chilled Water Distribution SchemesJenson Joy100% (5)

- Chapter 4. Steam Jet Refrigeration SystemsDocument14 pagesChapter 4. Steam Jet Refrigeration SystemsMicah SileshiNo ratings yet

- Hot and Cold Water Supply AMGDDocument26 pagesHot and Cold Water Supply AMGDJasleenNo ratings yet

- Engineering Manual Evaporative CondensersDocument16 pagesEngineering Manual Evaporative Condenserstulamst100% (2)

- Thermostatic Expansion Valves - Alco: Operating Principles ProcedureDocument34 pagesThermostatic Expansion Valves - Alco: Operating Principles ProcedureMeher YoussfiNo ratings yet

- Steam Jet Refrigeration SystemDocument9 pagesSteam Jet Refrigeration SystemHenok Ghiday0% (1)

- 83-84 Cooling SystemsDocument2 pages83-84 Cooling SystemsParthivNo ratings yet

- Exh 2100Document18 pagesExh 2100RogerNo ratings yet

- Free Cooling Without Refrigeration ProcessDocument9 pagesFree Cooling Without Refrigeration Processsaif aliNo ratings yet

- Troubleshooting Guide: Start Up ConditionsDocument4 pagesTroubleshooting Guide: Start Up ConditionsShouzab AbbasNo ratings yet

- Locomotive - Cooling Water SystemDocument5 pagesLocomotive - Cooling Water SystemArpan MaheshwariNo ratings yet

- Peter Phelps, Jr. Phelps Engineering Company Laguna Niguel, CaliforniaDocument15 pagesPeter Phelps, Jr. Phelps Engineering Company Laguna Niguel, CaliforniaidigitiNo ratings yet

- Vortex Tube Steam Jet RefrigerationDocument14 pagesVortex Tube Steam Jet RefrigerationDInesh KumarNo ratings yet

- ML-Engine: COMPETENCE 3 - Operation, Surveillance, Performance Assessment and Maintaining Safety of Propulsion Plant and Auxilliary MachineryDocument9 pagesML-Engine: COMPETENCE 3 - Operation, Surveillance, Performance Assessment and Maintaining Safety of Propulsion Plant and Auxilliary Machineryjohn aldrinNo ratings yet

- Cooling Tower Rev4Document19 pagesCooling Tower Rev4Etienne NASALANDINo ratings yet

- Blowdown in Boiler - Boiler Blowdown Calculation Formula & Calculator...Document7 pagesBlowdown in Boiler - Boiler Blowdown Calculation Formula & Calculator...حسين مهديNo ratings yet

- 6.8 Steam Jet Refrigeration System:: Control Valve Steam Nozzle Thermo Compresser EjectorDocument4 pages6.8 Steam Jet Refrigeration System:: Control Valve Steam Nozzle Thermo Compresser EjectorChristian D. AllanaNo ratings yet

- Ijett V4i5p58 PDFDocument4 pagesIjett V4i5p58 PDFAndirazakNo ratings yet

- Pressurized Deaerator Spec PDFDocument9 pagesPressurized Deaerator Spec PDFkosmc123No ratings yet

- CCI Power ApplicationsDocument57 pagesCCI Power Applicationssukanya_ravichandran100% (1)

- M05-008 - HVAC Chilled Water Distribution Schemes - USDocument56 pagesM05-008 - HVAC Chilled Water Distribution Schemes - USmaddy_giftNo ratings yet

- FWGDocument8 pagesFWGSWASTIK MISHRANo ratings yet

- High-Performance Chilled-Water Systems TraneDocument55 pagesHigh-Performance Chilled-Water Systems TraneMoideen TCNo ratings yet

- HXAC 134a MS0454ADocument21 pagesHXAC 134a MS0454AEduardo SouzaNo ratings yet

- Steam GenerationDocument5 pagesSteam GenerationRavi KumarNo ratings yet

- 49.22 2007 ASHRAE Handbook-HVAC Applications (SI) : Swimming Pools/Health Clubs. The Desirable Temperature ForDocument2 pages49.22 2007 ASHRAE Handbook-HVAC Applications (SI) : Swimming Pools/Health Clubs. The Desirable Temperature ForAhmed Mohamed GadoNo ratings yet

- Chiller BasicsDocument38 pagesChiller BasicsGiftson ImmanuelNo ratings yet

- Distilling Plant - Week 8Document35 pagesDistilling Plant - Week 8இராம் பாபுNo ratings yet

- Water Chiller Selection and OptimizationDocument6 pagesWater Chiller Selection and OptimizationsmaluqNo ratings yet

- Altair MixerDocument20 pagesAltair Mixerdwightman13No ratings yet

- Ae MFP 23aDocument2 pagesAe MFP 23aBhagat ShardanandNo ratings yet

- Fresh Water Generator On ShipsDocument11 pagesFresh Water Generator On ShipsGuruNo ratings yet

- District Cooling Plant 1696416191Document11 pagesDistrict Cooling Plant 1696416191mohd rafiq mohd haniNo ratings yet

- Static HeadDocument6 pagesStatic Headvalentinlupascu33No ratings yet

- 2004-07 Care & Maintenance of Water HeatersDocument2 pages2004-07 Care & Maintenance of Water HeatersMike PerryNo ratings yet

- 01.BAC HBii Maintenance of Crossflow TowersDocument32 pages01.BAC HBii Maintenance of Crossflow TowersJehuty88No ratings yet

- Ashrae D 9305 20021125Document7 pagesAshrae D 9305 20021125Gaye KanalNo ratings yet

- The Importance of Proper Level Control of Feedwater HeatersDocument6 pagesThe Importance of Proper Level Control of Feedwater Heatersnirbhay111100% (1)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Refits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5From EverandRefits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5Rating: 3 out of 5 stars3/5 (1)

- Process Engineering: Facts, Fiction and FablesFrom EverandProcess Engineering: Facts, Fiction and FablesRating: 3 out of 5 stars3/5 (2)

- Hot Water Heater Installation and Repair: A Step-by-Step Guide to DIY Installation, Maintenance, and Troubleshooting for Homeowners: Homeowner Plumbing Help, #4From EverandHot Water Heater Installation and Repair: A Step-by-Step Guide to DIY Installation, Maintenance, and Troubleshooting for Homeowners: Homeowner Plumbing Help, #4No ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-15Document1 pageCMMT-AS Manual 2023-11l 8204518g1-15Ismail AliNo ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-23Document1 pageCMMT-AS Manual 2023-11l 8204518g1-23Ismail AliNo ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-19Document1 pageCMMT-AS Manual 2023-11l 8204518g1-19Ismail AliNo ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-13Document1 pageCMMT-AS Manual 2023-11l 8204518g1-13Ismail AliNo ratings yet

- ProductOverview 2023 EN-92Document1 pageProductOverview 2023 EN-92Ismail AliNo ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-21Document1 pageCMMT-AS Manual 2023-11l 8204518g1-21Ismail AliNo ratings yet

- ProductOverview 2023 EN-95Document1 pageProductOverview 2023 EN-95Ismail AliNo ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-14Document1 pageCMMT-AS Manual 2023-11l 8204518g1-14Ismail AliNo ratings yet

- ProductOverview 2023 EN-93Document1 pageProductOverview 2023 EN-93Ismail AliNo ratings yet

- ProductOverview 2023 EN-94Document1 pageProductOverview 2023 EN-94Ismail AliNo ratings yet

- ProductOverview 2023 EN-89Document1 pageProductOverview 2023 EN-89Ismail AliNo ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-11Document1 pageCMMT-AS Manual 2023-11l 8204518g1-11Ismail AliNo ratings yet

- ProductOverview 2023 EN-86Document1 pageProductOverview 2023 EN-86Ismail AliNo ratings yet

- ProductOverview 2023 EN-91Document1 pageProductOverview 2023 EN-91Ismail AliNo ratings yet

- ProductOverview 2023 EN-57Document1 pageProductOverview 2023 EN-57Ismail AliNo ratings yet

- ProductOverview 2023 EN-81Document1 pageProductOverview 2023 EN-81Ismail AliNo ratings yet

- ProductOverview 2023 EN-59Document1 pageProductOverview 2023 EN-59Ismail AliNo ratings yet

- ProductOverview 2023 En-65Document1 pageProductOverview 2023 En-65Ismail AliNo ratings yet

- ProductOverview 2023 EN-55Document1 pageProductOverview 2023 EN-55Ismail AliNo ratings yet

- ProductOverview 2023 EN-88Document1 pageProductOverview 2023 EN-88Ismail AliNo ratings yet

- ProductOverview 2023 EN-12Document1 pageProductOverview 2023 EN-12Ismail AliNo ratings yet

- ProductOverview 2023 EN-45Document1 pageProductOverview 2023 EN-45Ismail AliNo ratings yet

- ProductOverview 2023 EN-46Document1 pageProductOverview 2023 EN-46Ismail AliNo ratings yet

- 5 Steps Before Making An Air Compressor Purchase DecisionDocument40 pages5 Steps Before Making An Air Compressor Purchase DecisionIsmail AliNo ratings yet

- ProductOverview 2023 EN-14Document1 pageProductOverview 2023 EN-14Ismail AliNo ratings yet

- ProductOverview 2023 EN-38Document1 pageProductOverview 2023 EN-38Ismail AliNo ratings yet

- ProductOverview 2023 EN-8Document1 pageProductOverview 2023 EN-8Ismail AliNo ratings yet

- ProductOverview 2023 EN-36Document1 pageProductOverview 2023 EN-36Ismail AliNo ratings yet

- ProductOverview 2023 EN-25Document1 pageProductOverview 2023 EN-25Ismail AliNo ratings yet

- Compressor Installation Guide 3Document1 pageCompressor Installation Guide 3Ismail AliNo ratings yet

- Op AmpsDocument36 pagesOp Ampsisraeljumbo100% (1)

- Gypsum ProductsDocument53 pagesGypsum ProductsKiran KumarNo ratings yet

- Gregory M Sped841 UnitlessonDocument1 pageGregory M Sped841 Unitlessonapi-271896767No ratings yet

- Ap Question Bank With AnswersDocument34 pagesAp Question Bank With AnswersKarthik G BNo ratings yet

- 1-Port Gigabit GPON/EPON Wireless-N ONU Router: Model No: iB-FONG11GWDocument1 page1-Port Gigabit GPON/EPON Wireless-N ONU Router: Model No: iB-FONG11GWFilesNo ratings yet

- DMC RepairDocument155 pagesDMC RepairАndrey100% (1)

- Long Quiz 1-BDocument11 pagesLong Quiz 1-BEthel FajardoNo ratings yet

- Doll & Torkzadeh (1994)Document10 pagesDoll & Torkzadeh (1994)Riyan MardiyantaNo ratings yet

- Chapter #4 Bending Stress: Simple Bending Theory Area of Second Moment Parallel Axes Theorem Deflection of Composite BeamDocument30 pagesChapter #4 Bending Stress: Simple Bending Theory Area of Second Moment Parallel Axes Theorem Deflection of Composite Beamlayiro2No ratings yet

- 08 GRP08a SGCMDocument18 pages08 GRP08a SGCMeurospeed2No ratings yet

- ADC and DACDocument7 pagesADC and DACGhulam MurtazaNo ratings yet

- 9620 Chem Unit 2 - 201705-MSDocument27 pages9620 Chem Unit 2 - 201705-MSNasimNo ratings yet

- Color ModelsDocument14 pagesColor ModelsHarikarthikKumaraveluNo ratings yet

- WEEK 2 Handout Police PhotographyDocument2 pagesWEEK 2 Handout Police Photography3C GADAYAN CONAN A.No ratings yet

- AJAX & PHP Question BankDocument18 pagesAJAX & PHP Question Bankaryansuthar194No ratings yet

- Introducing The HA480: ConfidentialDocument30 pagesIntroducing The HA480: ConfidentialRay PutraNo ratings yet

- 264 - Using Combustion Ion Chromatography To Determine Halogens and Sulfur in Aromatic HydrocarbonsDocument35 pages264 - Using Combustion Ion Chromatography To Determine Halogens and Sulfur in Aromatic HydrocarbonsMiguelNo ratings yet

- Tcs Technical MCQDocument20 pagesTcs Technical MCQrayapati navyasreeNo ratings yet

- August Losch Model of Central Place: Prof. Nizamuddin Khan D/O Geography, AMU, AligarhDocument17 pagesAugust Losch Model of Central Place: Prof. Nizamuddin Khan D/O Geography, AMU, AligarhVishvarajNo ratings yet

- Voice Recognition SystemDocument18 pagesVoice Recognition SystemArun Sharma75% (16)

- Thermoset Vs Thermoplastic CompositesDocument4 pagesThermoset Vs Thermoplastic Compositesairbuk doeingNo ratings yet

- UserManual (EziSERVO PlusR) - Communication Function - Ver6 (Eng)Document124 pagesUserManual (EziSERVO PlusR) - Communication Function - Ver6 (Eng)Rorisvon AlmeidaNo ratings yet

- Document 2137586.1 Mass Allocation PDFDocument28 pagesDocument 2137586.1 Mass Allocation PDFr.n.pradeepNo ratings yet

- Uop ButamerDocument2 pagesUop ButamerCHANADAS0% (1)

- Electolux EFLS617SIW 4.4 Cu. FTDocument32 pagesElectolux EFLS617SIW 4.4 Cu. FTpalkybdNo ratings yet

- Large Data Set Lds-EdexcelDocument146 pagesLarge Data Set Lds-EdexcelhadzNo ratings yet

Compressor Installation Guide 25

Compressor Installation Guide 25

Uploaded by

Ismail AliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compressor Installation Guide 25

Compressor Installation Guide 25

Uploaded by

Ismail AliCopyright:

Available Formats

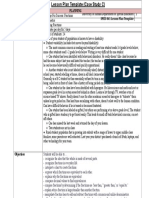

24 Guidelines for cooling water

requirements

Knowing your total cooling water requirement 50% of the water flow should be by-passed

and its allowed temperature increase you can around the compressor and be mixed with the

calculate the heat amount that has cooled away warm compressor water before entering the

in the cooling tower. cooling tower.

t v

D X Q in kcal/second You'll need to balance and adjust the by-passed

water flow in accordance with your actual

t o

where D is increase of cooling water temp. in C compressor running conditions.

v

Q is cooling water flow in litres/second.

You can cool the water in a cooling tower to a

o

Calculate with a cooling water temperature temperature approximately 5 C above the wet

o

increase of 15 C. Should a lower temperature bulb temperature. If you still need better cooling

o

increase than 15 C be required, please contact you will have to make a large increase in the size

your Atlas Copco Engineer for advice. of your cooling tower.

The water pressure in G or Z compressor must Even, in the warmest countries, wet bulb temper-

o

not exceed 5 bar. You must therefore limit the ature seldom exceeds 28 C. This fact makes

o

water pressure drop through the compressor to cooling water temperature of 33 C possible &

o

approximately 2 bar. If you install a cooling 35 C practical.

water pump close to and before the compressor,

the pump must overcome the following You must regularly check you cooling water

resistance: quality. Cooling water should be soft, clean and

free from mineral salts. Your cooling tower must

Compressor 2.0 bar have a chemical dosage system to prevent algae

Static water height 0.3 bar growth, line crustation and corrosion.

Cooling tower nozzle 0.4 bar

Pipes, bends and valves 0.3 bar A cooling tower always uses up a certain amount

Totally 3.0 bar of water. The three main reasons are:

In countries with a temperate climate you can Evaporation Splashing Dilution

o

reduce water temperature by 15 C in a cooling

tower. You can use a simple single-circuit You can work out the water amount lost by

cooling system with this water flow: evaporation with this formula:

Heat quantity kcal/hour water loss in

Pump Compressor Cooling Tower = liters/hour

580

580 is evaporation coefficient for water

In tropical countries with high temperature and Splash losses are negligible

high humidity it is difficult to obtain a better

o

temperature reduction than 10 C in a cooling

You need to add water dilution to avoid

tower. To get this you will need a double-circuit

increased concentration of mineral salts. The

cooling system with two water pumps, a

amount of water to be added is approximately

separate water basin, and individual water

50% of the evaporation without chemical dosage

circuits for tower and compressor. This gives a

at favourable conditions.

sophisticated and efficient solution but

investment needed is high. The alternative is

If you have a chemical dosage system, then your

to use a modified single-circuit system. Your

dilution needs can be reduced to 25% of the

investment costs will be lower. But you must

evaporation.

dimension your cooling tower for a water flow

50% higher than the flow through the

The total water amount you need to add equals

compressor.

evaporation amount plus 25% or 50%.

You might also like

- Unicos URK-700 Keratometer - Service ManualDocument64 pagesUnicos URK-700 Keratometer - Service ManualWilson Cepeda0% (1)

- Module 1 - Learning The Basic Computer ConceptsDocument180 pagesModule 1 - Learning The Basic Computer ConceptsAmir M. Villas87% (15)

- ME-Tut 4Document2 pagesME-Tut 4Shekhar SinghNo ratings yet

- Steam Jet Refrigeration and Vapour Absorption SystemDocument21 pagesSteam Jet Refrigeration and Vapour Absorption SystemmohitNo ratings yet

- Afhx (High Ambient) Mes0446aDocument24 pagesAfhx (High Ambient) Mes0446aEduardo Luis Souza100% (1)

- The Demise of The Primary-Secondary Pumping Paradigm For Chilled Water Plant DesignDocument5 pagesThe Demise of The Primary-Secondary Pumping Paradigm For Chilled Water Plant DesignWayde WillinsNo ratings yet

- Basic of C - Geeky Shows 1Document4 pagesBasic of C - Geeky Shows 1Tavishi Singh100% (3)

- Evaporative Condenser Engineering Manual: Technical ResourcesDocument18 pagesEvaporative Condenser Engineering Manual: Technical ResourcesMohamed IbrahimNo ratings yet

- 3.5 Steam Jet Refrigeration SystemDocument8 pages3.5 Steam Jet Refrigeration SystemShaik mahammad ArifNo ratings yet

- Cooling Circulating Water, Purge Water & Cooling Tower SystemDocument22 pagesCooling Circulating Water, Purge Water & Cooling Tower SystemSCE CCGT3No ratings yet

- Cooling Water and Cooling TowerDocument37 pagesCooling Water and Cooling Towersandip singhNo ratings yet

- Cooling Water System 1Document18 pagesCooling Water System 1anupam01013787No ratings yet

- Boiler Circulation SystemDocument32 pagesBoiler Circulation SystemRitik Dewangan100% (2)

- Liquid Subcooling: The Case For RefrigerantDocument4 pagesLiquid Subcooling: The Case For RefrigeranttaupiqNo ratings yet

- Centrifugal Chiller Heat Transfer Efficiency: Performance Diagnosis Condenser EvaluationDocument2 pagesCentrifugal Chiller Heat Transfer Efficiency: Performance Diagnosis Condenser EvaluationKipper GNo ratings yet

- Steam Jet RefrigerationDocument2 pagesSteam Jet Refrigerationelaizaagudo17No ratings yet

- Fordson Major ManualDocument47 pagesFordson Major ManualHassan GDOURANo ratings yet

- HVAC Chilled Water Distribution SchemesDocument56 pagesHVAC Chilled Water Distribution SchemesJenson Joy100% (5)

- Chapter 4. Steam Jet Refrigeration SystemsDocument14 pagesChapter 4. Steam Jet Refrigeration SystemsMicah SileshiNo ratings yet

- Hot and Cold Water Supply AMGDDocument26 pagesHot and Cold Water Supply AMGDJasleenNo ratings yet

- Engineering Manual Evaporative CondensersDocument16 pagesEngineering Manual Evaporative Condenserstulamst100% (2)

- Thermostatic Expansion Valves - Alco: Operating Principles ProcedureDocument34 pagesThermostatic Expansion Valves - Alco: Operating Principles ProcedureMeher YoussfiNo ratings yet

- Steam Jet Refrigeration SystemDocument9 pagesSteam Jet Refrigeration SystemHenok Ghiday0% (1)

- 83-84 Cooling SystemsDocument2 pages83-84 Cooling SystemsParthivNo ratings yet

- Exh 2100Document18 pagesExh 2100RogerNo ratings yet

- Free Cooling Without Refrigeration ProcessDocument9 pagesFree Cooling Without Refrigeration Processsaif aliNo ratings yet

- Troubleshooting Guide: Start Up ConditionsDocument4 pagesTroubleshooting Guide: Start Up ConditionsShouzab AbbasNo ratings yet

- Locomotive - Cooling Water SystemDocument5 pagesLocomotive - Cooling Water SystemArpan MaheshwariNo ratings yet

- Peter Phelps, Jr. Phelps Engineering Company Laguna Niguel, CaliforniaDocument15 pagesPeter Phelps, Jr. Phelps Engineering Company Laguna Niguel, CaliforniaidigitiNo ratings yet

- Vortex Tube Steam Jet RefrigerationDocument14 pagesVortex Tube Steam Jet RefrigerationDInesh KumarNo ratings yet

- ML-Engine: COMPETENCE 3 - Operation, Surveillance, Performance Assessment and Maintaining Safety of Propulsion Plant and Auxilliary MachineryDocument9 pagesML-Engine: COMPETENCE 3 - Operation, Surveillance, Performance Assessment and Maintaining Safety of Propulsion Plant and Auxilliary Machineryjohn aldrinNo ratings yet

- Cooling Tower Rev4Document19 pagesCooling Tower Rev4Etienne NASALANDINo ratings yet

- Blowdown in Boiler - Boiler Blowdown Calculation Formula & Calculator...Document7 pagesBlowdown in Boiler - Boiler Blowdown Calculation Formula & Calculator...حسين مهديNo ratings yet

- 6.8 Steam Jet Refrigeration System:: Control Valve Steam Nozzle Thermo Compresser EjectorDocument4 pages6.8 Steam Jet Refrigeration System:: Control Valve Steam Nozzle Thermo Compresser EjectorChristian D. AllanaNo ratings yet

- Ijett V4i5p58 PDFDocument4 pagesIjett V4i5p58 PDFAndirazakNo ratings yet

- Pressurized Deaerator Spec PDFDocument9 pagesPressurized Deaerator Spec PDFkosmc123No ratings yet

- CCI Power ApplicationsDocument57 pagesCCI Power Applicationssukanya_ravichandran100% (1)

- M05-008 - HVAC Chilled Water Distribution Schemes - USDocument56 pagesM05-008 - HVAC Chilled Water Distribution Schemes - USmaddy_giftNo ratings yet

- FWGDocument8 pagesFWGSWASTIK MISHRANo ratings yet

- High-Performance Chilled-Water Systems TraneDocument55 pagesHigh-Performance Chilled-Water Systems TraneMoideen TCNo ratings yet

- HXAC 134a MS0454ADocument21 pagesHXAC 134a MS0454AEduardo SouzaNo ratings yet

- Steam GenerationDocument5 pagesSteam GenerationRavi KumarNo ratings yet

- 49.22 2007 ASHRAE Handbook-HVAC Applications (SI) : Swimming Pools/Health Clubs. The Desirable Temperature ForDocument2 pages49.22 2007 ASHRAE Handbook-HVAC Applications (SI) : Swimming Pools/Health Clubs. The Desirable Temperature ForAhmed Mohamed GadoNo ratings yet

- Chiller BasicsDocument38 pagesChiller BasicsGiftson ImmanuelNo ratings yet

- Distilling Plant - Week 8Document35 pagesDistilling Plant - Week 8இராம் பாபுNo ratings yet

- Water Chiller Selection and OptimizationDocument6 pagesWater Chiller Selection and OptimizationsmaluqNo ratings yet

- Altair MixerDocument20 pagesAltair Mixerdwightman13No ratings yet

- Ae MFP 23aDocument2 pagesAe MFP 23aBhagat ShardanandNo ratings yet

- Fresh Water Generator On ShipsDocument11 pagesFresh Water Generator On ShipsGuruNo ratings yet

- District Cooling Plant 1696416191Document11 pagesDistrict Cooling Plant 1696416191mohd rafiq mohd haniNo ratings yet

- Static HeadDocument6 pagesStatic Headvalentinlupascu33No ratings yet

- 2004-07 Care & Maintenance of Water HeatersDocument2 pages2004-07 Care & Maintenance of Water HeatersMike PerryNo ratings yet

- 01.BAC HBii Maintenance of Crossflow TowersDocument32 pages01.BAC HBii Maintenance of Crossflow TowersJehuty88No ratings yet

- Ashrae D 9305 20021125Document7 pagesAshrae D 9305 20021125Gaye KanalNo ratings yet

- The Importance of Proper Level Control of Feedwater HeatersDocument6 pagesThe Importance of Proper Level Control of Feedwater Heatersnirbhay111100% (1)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Refits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5From EverandRefits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5Rating: 3 out of 5 stars3/5 (1)

- Process Engineering: Facts, Fiction and FablesFrom EverandProcess Engineering: Facts, Fiction and FablesRating: 3 out of 5 stars3/5 (2)

- Hot Water Heater Installation and Repair: A Step-by-Step Guide to DIY Installation, Maintenance, and Troubleshooting for Homeowners: Homeowner Plumbing Help, #4From EverandHot Water Heater Installation and Repair: A Step-by-Step Guide to DIY Installation, Maintenance, and Troubleshooting for Homeowners: Homeowner Plumbing Help, #4No ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-15Document1 pageCMMT-AS Manual 2023-11l 8204518g1-15Ismail AliNo ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-23Document1 pageCMMT-AS Manual 2023-11l 8204518g1-23Ismail AliNo ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-19Document1 pageCMMT-AS Manual 2023-11l 8204518g1-19Ismail AliNo ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-13Document1 pageCMMT-AS Manual 2023-11l 8204518g1-13Ismail AliNo ratings yet

- ProductOverview 2023 EN-92Document1 pageProductOverview 2023 EN-92Ismail AliNo ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-21Document1 pageCMMT-AS Manual 2023-11l 8204518g1-21Ismail AliNo ratings yet

- ProductOverview 2023 EN-95Document1 pageProductOverview 2023 EN-95Ismail AliNo ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-14Document1 pageCMMT-AS Manual 2023-11l 8204518g1-14Ismail AliNo ratings yet

- ProductOverview 2023 EN-93Document1 pageProductOverview 2023 EN-93Ismail AliNo ratings yet

- ProductOverview 2023 EN-94Document1 pageProductOverview 2023 EN-94Ismail AliNo ratings yet

- ProductOverview 2023 EN-89Document1 pageProductOverview 2023 EN-89Ismail AliNo ratings yet

- CMMT-AS Manual 2023-11l 8204518g1-11Document1 pageCMMT-AS Manual 2023-11l 8204518g1-11Ismail AliNo ratings yet

- ProductOverview 2023 EN-86Document1 pageProductOverview 2023 EN-86Ismail AliNo ratings yet

- ProductOverview 2023 EN-91Document1 pageProductOverview 2023 EN-91Ismail AliNo ratings yet

- ProductOverview 2023 EN-57Document1 pageProductOverview 2023 EN-57Ismail AliNo ratings yet

- ProductOverview 2023 EN-81Document1 pageProductOverview 2023 EN-81Ismail AliNo ratings yet

- ProductOverview 2023 EN-59Document1 pageProductOverview 2023 EN-59Ismail AliNo ratings yet

- ProductOverview 2023 En-65Document1 pageProductOverview 2023 En-65Ismail AliNo ratings yet

- ProductOverview 2023 EN-55Document1 pageProductOverview 2023 EN-55Ismail AliNo ratings yet

- ProductOverview 2023 EN-88Document1 pageProductOverview 2023 EN-88Ismail AliNo ratings yet

- ProductOverview 2023 EN-12Document1 pageProductOverview 2023 EN-12Ismail AliNo ratings yet

- ProductOverview 2023 EN-45Document1 pageProductOverview 2023 EN-45Ismail AliNo ratings yet

- ProductOverview 2023 EN-46Document1 pageProductOverview 2023 EN-46Ismail AliNo ratings yet

- 5 Steps Before Making An Air Compressor Purchase DecisionDocument40 pages5 Steps Before Making An Air Compressor Purchase DecisionIsmail AliNo ratings yet

- ProductOverview 2023 EN-14Document1 pageProductOverview 2023 EN-14Ismail AliNo ratings yet

- ProductOverview 2023 EN-38Document1 pageProductOverview 2023 EN-38Ismail AliNo ratings yet

- ProductOverview 2023 EN-8Document1 pageProductOverview 2023 EN-8Ismail AliNo ratings yet

- ProductOverview 2023 EN-36Document1 pageProductOverview 2023 EN-36Ismail AliNo ratings yet

- ProductOverview 2023 EN-25Document1 pageProductOverview 2023 EN-25Ismail AliNo ratings yet

- Compressor Installation Guide 3Document1 pageCompressor Installation Guide 3Ismail AliNo ratings yet

- Op AmpsDocument36 pagesOp Ampsisraeljumbo100% (1)

- Gypsum ProductsDocument53 pagesGypsum ProductsKiran KumarNo ratings yet

- Gregory M Sped841 UnitlessonDocument1 pageGregory M Sped841 Unitlessonapi-271896767No ratings yet

- Ap Question Bank With AnswersDocument34 pagesAp Question Bank With AnswersKarthik G BNo ratings yet

- 1-Port Gigabit GPON/EPON Wireless-N ONU Router: Model No: iB-FONG11GWDocument1 page1-Port Gigabit GPON/EPON Wireless-N ONU Router: Model No: iB-FONG11GWFilesNo ratings yet

- DMC RepairDocument155 pagesDMC RepairАndrey100% (1)

- Long Quiz 1-BDocument11 pagesLong Quiz 1-BEthel FajardoNo ratings yet

- Doll & Torkzadeh (1994)Document10 pagesDoll & Torkzadeh (1994)Riyan MardiyantaNo ratings yet

- Chapter #4 Bending Stress: Simple Bending Theory Area of Second Moment Parallel Axes Theorem Deflection of Composite BeamDocument30 pagesChapter #4 Bending Stress: Simple Bending Theory Area of Second Moment Parallel Axes Theorem Deflection of Composite Beamlayiro2No ratings yet

- 08 GRP08a SGCMDocument18 pages08 GRP08a SGCMeurospeed2No ratings yet

- ADC and DACDocument7 pagesADC and DACGhulam MurtazaNo ratings yet

- 9620 Chem Unit 2 - 201705-MSDocument27 pages9620 Chem Unit 2 - 201705-MSNasimNo ratings yet

- Color ModelsDocument14 pagesColor ModelsHarikarthikKumaraveluNo ratings yet

- WEEK 2 Handout Police PhotographyDocument2 pagesWEEK 2 Handout Police Photography3C GADAYAN CONAN A.No ratings yet

- AJAX & PHP Question BankDocument18 pagesAJAX & PHP Question Bankaryansuthar194No ratings yet

- Introducing The HA480: ConfidentialDocument30 pagesIntroducing The HA480: ConfidentialRay PutraNo ratings yet

- 264 - Using Combustion Ion Chromatography To Determine Halogens and Sulfur in Aromatic HydrocarbonsDocument35 pages264 - Using Combustion Ion Chromatography To Determine Halogens and Sulfur in Aromatic HydrocarbonsMiguelNo ratings yet

- Tcs Technical MCQDocument20 pagesTcs Technical MCQrayapati navyasreeNo ratings yet

- August Losch Model of Central Place: Prof. Nizamuddin Khan D/O Geography, AMU, AligarhDocument17 pagesAugust Losch Model of Central Place: Prof. Nizamuddin Khan D/O Geography, AMU, AligarhVishvarajNo ratings yet

- Voice Recognition SystemDocument18 pagesVoice Recognition SystemArun Sharma75% (16)

- Thermoset Vs Thermoplastic CompositesDocument4 pagesThermoset Vs Thermoplastic Compositesairbuk doeingNo ratings yet

- UserManual (EziSERVO PlusR) - Communication Function - Ver6 (Eng)Document124 pagesUserManual (EziSERVO PlusR) - Communication Function - Ver6 (Eng)Rorisvon AlmeidaNo ratings yet

- Document 2137586.1 Mass Allocation PDFDocument28 pagesDocument 2137586.1 Mass Allocation PDFr.n.pradeepNo ratings yet

- Uop ButamerDocument2 pagesUop ButamerCHANADAS0% (1)

- Electolux EFLS617SIW 4.4 Cu. FTDocument32 pagesElectolux EFLS617SIW 4.4 Cu. FTpalkybdNo ratings yet

- Large Data Set Lds-EdexcelDocument146 pagesLarge Data Set Lds-EdexcelhadzNo ratings yet