Professional Documents

Culture Documents

FE2900 - Pressure Losses From Fan Accessories

FE2900 - Pressure Losses From Fan Accessories

Uploaded by

Ahmad NilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FE2900 - Pressure Losses From Fan Accessories

FE2900 - Pressure Losses From Fan Accessories

Uploaded by

Ahmad NilCopyright:

Available Formats

FAN ENGINEERING

Information and Recommendations for the Engineer FE-2900

Pressure Losses from

Fan Accessories

For a fan in a system to perform as rated in a catalog, appurtenance. A screen with a fine mesh will have a

it is necessary for the system to be constructed in such higher value for k than a screen with a loose mesh. The

a way that the airflow pathways into and out of the fan value of k for a fan exhaust or supply hood is typically

are similar to the conditions present during the tests much greater than k for a stack cap, which has straight

performed to develop the fan’s ratings. Usually, this through flow. The value for k for a filtered hood would

means that the fan’s inlet and outlet are free from be even higher.

immediate obstructions and there are no bends in the

ductwork close to the fan. Due to accessory requirements Evasé or Outlet Transitions

or space limitations, this may not be possible. In such These appurtenances change the velocity of the air

cases, the effect of accessories and/or ducting conditions stream by changing the cross sectional area of the

must be taken into account during fan selection to get ductwork. When air stream velocity changes, velocity

the airflow desired. This newsletter will cover the effect pressure is converted to static pressure (or vice-versa).

of accessories/appurtenances added to a fan system. The formula for the losses for changes in area is:

Performance losses are usually represented in units of Loss = -1 x k x dPv

pressure. Performance loss values indicate how much a

fan’s static pressure needs to increase in order to dPv is the change in the air stream velocity pressure and

achieve the same flow at the system’s point of rating k is the efficiency of the transition. The value for dPv is

with the addition of the appurtenance. Typically, the positive when the air stream is slowed down (i.e. the

magnitude of the performance loss is calculated as a cross sectional area of the ductwork is increased) and

function of the velocity pressure at the appurtenance. negative when the velocity is increased. When the loss

is negative (slowing down the air stream), the static

Velocity pressure is proportional to the air stream density pressure generated by the fan with the transition will be

and the square of the air stream velocity. Consider a greater than the static pressure generated without the

system with two locations A & B. If the velocity of the transition. The efficiency of the transition is dependent

air stream at point B is double the velocity at point A, on its design. Long gradual transitions can have

any appurtenance placed into the air stream at point B efficiencies around 85% while short abrupt transitions

will have four times the loss than if the appurtenance is can have efficiencies less than 25%. Since the flow at

placed at point A. Appurtenances placed in the throat the outlet is not uniform, regions of flow velocities well

of a fan’s inlet (where the velocities are usually much in excess of the averages exist. Converting this extra

greater than the ductwork) can have a considerable velocity pressure to static pressure can effectively raise

impact on the fan’s performance. the apparent efficiency to 100%.

Formulae for calculating performance losses may be

available from the fan/accessory manufacturer or the

Variable Inlet Vanes

loss can be estimated using one of many available When 100% open, variable inlet vanes cause a pressure

references (e.g. AMCA Publication 201 — Fans and loss proportional to the velocity pressure. When they are

Systems). not 100% open, the effect of variable inlet vanes on

performance is not so simple to predict. Inlet vanes

Screens, Dampers, Stack Caps and produce a pre-spin in the air stream at the fan’s inlet.

Hoods The spin produced is in the same direction as the fan’s

impeller rotation. This has the effect of lowering the fan’s

These appurtenances place a system resistance on the static pressure (and thus the airflow through the system)

airflow. The function for the magnitude of the as well as the power consumed by the fan. Typically,

performance loss is typically: the effect of variable inlet vanes on fan performance is

Loss = k x Pv = k x (flow rate / flow area)2 x density – interpolated from a series of tests done at various vane

converted to units of pressure. settings. Variable inlet vanes are generally more efficient

than dampers for regulating airflow because they

Pv is the velocity pressure of the air stream at the decrease the power consumed by the fan as well as the

appurtenance and k is a constant value for the given flow.

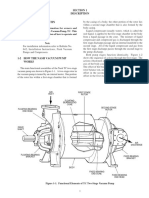

Example of an Accessory Loss Reminders

In the graph below, the solid line represents the fan’s 1) Fan performance is usually published with disclaimers

catalog performance. The dotted line represents the fan’s indicating any appurtenances in the air stream present

performance with some appurtenance added. when the ratings were developed. If the ratings were

developed with a stack cap present, do not correct the

performance for the stack cap. If the ratings were

developed with an evase’, correct the performance if

the evase’ is not used.

2) Losses must be calculated at the same density as

the point of rating.

3) Expanding transitions in the ductwork have a negative

loss (which is a gain). The corrected fan curve after

adding an expanding transition will be above the

uncorrected fan curve. If the selection program does

not allow for correction to an expanding area, the

static pressure entered into the program will be lower

than the desired static pressure. Once corrected, the

result for the addition of the transition (subtracting a

negative loss value) will pass through the desired

point of operation.

4) Failure to account for the effects of appurtenances in

the air stream could require significant changes to

The addition of the appurtenance lowered the airflow achieve the desired airflow.

produced by the fan by about 5% along the system

curve. If the effect of the appurtenance was ignored • Belt driven fans may be able to achieve the

during the fan’s selection process, it would be necessary desired performance by increasing the speed of

to increase the running speed of the fan, get a new the fan. Before selecting/adjusting sheaves, it will

impeller for the fan, or get a new fan to achieve 100% be necessary to check that the impeller, shaft,

of the desired flow. bearings and motor can handle the new speed

and power requirements.

Notice that the intersection of the system curve with the

corrected (dotted) fan curve occurs at about 91% of the • Direct drive fans may be able to achieve the

design static pressure. If the fan selection software used desired performance by using a higher pitch

to make the selection could not automatically correct for impeller (axial fans) or an over width/diameter

the appurtenance, the selection could be made at the impeller design (centrifugal fans). If the direct drive

required flow and at a static pressure 9% higher than fan is attached to an inverter, speeding up the fan

desired. When the resulting performance is corrected for may be possible. Again, it will be necessary to

the appurtenance, the fan curve would pass through the check that the impeller and motor can handle the

desired flow and pressure. requirements.

For example, if the desired fan performance is 10,000 • It may become necessary to select an entirely new

CFM and 10.0 in. w.g., we would have calculated a loss fan to meet the requirements.

of 0.9 in. w.g. for the appurtenance. To select the correct

fan, we would enter 10,000 CFM and 10.9 in. w.g. into

Conclusion

the selection program. When the results of the selection AMCA Publication 201 — Fans and Systems is an excellent

are corrected for the appurtenance, the fan’s corrected reference for fan performance in a system. This

performance curve will pass through 10,000 CFM at 10.0 publication covers such topics as fan ratings, fan laws,

in. w.g. The uncorrected fan curve will show 10.9 in. w.g. fan/system interaction and system effects (the accessories

at the design flow even though only 10.0 in. w.g. will be covered in this newsletter are considered a system

measured in the installed system. effect). Formula and charts are included for estimating

values for losses due to accessories. This publication

also covers losses due to ducting conditions, which are

not covered in this newsletter.

TWIN CITY FAN & BLOWER | WWW.TCF.COM

5959 Trenton Lane N. | Minneapolis, MN 55442 | Phone: 763-551-7600 | Fax: 763-551-7601

©2021 Twin City Fan Companies, Ltd.

You might also like

- Manual Sandvik DP 1500 HydraulicsDocument104 pagesManual Sandvik DP 1500 HydraulicsEmanuel Nicolas VillarruelNo ratings yet

- Introduction to Fly-By-Wire Flight Control SystemsFrom EverandIntroduction to Fly-By-Wire Flight Control SystemsRating: 5 out of 5 stars5/5 (1)

- Application of Measuring Gas Flow in The DowncomerDocument4 pagesApplication of Measuring Gas Flow in The DowncomerAhmad NilNo ratings yet

- AMCA Fan Performance PDFDocument16 pagesAMCA Fan Performance PDFthevellin154No ratings yet

- Rotary Dryer Handbook PDFDocument43 pagesRotary Dryer Handbook PDFAhmad Nil100% (1)

- G2-7 G7L-15 G15L-22 Brendola Leaflet EN 2935086941Document5 pagesG2-7 G7L-15 G15L-22 Brendola Leaflet EN 2935086941Владислав СередаNo ratings yet

- FE 2900 Pressure Losses From Fan AccessoriesDocument2 pagesFE 2900 Pressure Losses From Fan AccessoriesAvery OppegardNo ratings yet

- Duct DesignDocument32 pagesDuct DesignsupportLSMNo ratings yet

- VAV System Air BalancingDocument3 pagesVAV System Air BalancingShoukat Ali ShaikhNo ratings yet

- Fan Calculator (Axial & Centrifugal) - Pressure & Flow - CalQlataDocument10 pagesFan Calculator (Axial & Centrifugal) - Pressure & Flow - CalQlataany oneNo ratings yet

- Basic Fan Engineering NotesDocument5 pagesBasic Fan Engineering NotesrentboyrodriguezNo ratings yet

- System Curve Fan Curve Operating PointDocument45 pagesSystem Curve Fan Curve Operating PointAnonymous I0JAds2SP100% (1)

- Fans Flow ControlDocument5 pagesFans Flow Controlcryovikas1975No ratings yet

- Mod 5-Fan Measurement and TestingDocument227 pagesMod 5-Fan Measurement and Testinglovjnx100% (1)

- Fan Performance EvaluationDocument24 pagesFan Performance EvaluationjohnNo ratings yet

- Fan SelectionDocument61 pagesFan SelectionJugmohunNo ratings yet

- Boiler Draft SystemDocument56 pagesBoiler Draft SystemAmit Chauhan80% (10)

- Engineering Letter: Fanperformance-ThesystemeffectDocument4 pagesEngineering Letter: Fanperformance-ThesystemeffectJuan Pablo ApazaNo ratings yet

- Fan BlowerDocument20 pagesFan BlowerShariq AliNo ratings yet

- Fan and BlowerDocument58 pagesFan and BlowerKAZI SIAMUL ISLAM100% (1)

- Fan Basics: What Is A Fan?Document6 pagesFan Basics: What Is A Fan?Tanuj Singh ChauhanNo ratings yet

- 2.3 ICR Aug 05 - Optimise Fan PerformanceDocument1 page2.3 ICR Aug 05 - Optimise Fan PerformanceKreshnik StratiNo ratings yet

- Ian Coleen Estremera. Activity2 Fans and Blowers - IPEDocument4 pagesIan Coleen Estremera. Activity2 Fans and Blowers - IPEIan EstremeraNo ratings yet

- Fan Engineering Guide - Twin City FansDocument12 pagesFan Engineering Guide - Twin City FansHafiz KamalNo ratings yet

- Haskel Air Amplifier Brochure 7 1 1Document12 pagesHaskel Air Amplifier Brochure 7 1 1Manahil KhalilNo ratings yet

- El 06 PDFDocument2 pagesEl 06 PDFPattyNo ratings yet

- Understanding FanDocument115 pagesUnderstanding Fanpinenamu100% (1)

- Ch4 - PPT - AIR AND WATER DISTRIBUTION PDFDocument50 pagesCh4 - PPT - AIR AND WATER DISTRIBUTION PDFBLa Production100% (1)

- Expanding The Column Overhead System: Instructor: Eng. Ahmed Deyab Fares Mobile: 0127549943Document14 pagesExpanding The Column Overhead System: Instructor: Eng. Ahmed Deyab Fares Mobile: 0127549943TayebASherifNo ratings yet

- High Speed ComDocument11 pagesHigh Speed Comsayansaesue2514No ratings yet

- Fans and Capacity ControlDocument4 pagesFans and Capacity ControlneilratheramNo ratings yet

- Pyro 5. Induced Draft FansDocument7 pagesPyro 5. Induced Draft FanstesfamariamNo ratings yet

- Fan Performance and Fan LawsDocument6 pagesFan Performance and Fan Lawscarlos quirozNo ratings yet

- Fan Basics: What Is A Fan?Document6 pagesFan Basics: What Is A Fan?Rahul JaganNo ratings yet

- Axial Fan PerformanceDocument17 pagesAxial Fan Performancehassan wastiNo ratings yet

- Fans and BlowersDocument3 pagesFans and BlowersLurking RogueNo ratings yet

- CLCH PRC008 enDocument352 pagesCLCH PRC008 enOscar Andrés PavónNo ratings yet

- TheoryDocument14 pagesTheoryRahul TripathiNo ratings yet

- Backward Centrifugal Fans PDFDocument3 pagesBackward Centrifugal Fans PDFudayNo ratings yet

- Fan CurveDocument11 pagesFan CurveMouayad AlaliNo ratings yet

- Tunnel Ventilation SystemDocument12 pagesTunnel Ventilation SystemJaponec Pictures100% (1)

- AirConditioning & Ventilation TCX Methodology Rev# 1.1Document12 pagesAirConditioning & Ventilation TCX Methodology Rev# 1.1Non Etabas GadnatamNo ratings yet

- All You Need To Know About FansDocument10 pagesAll You Need To Know About FansgertibajNo ratings yet

- Haskel Air AaDocument12 pagesHaskel Air AaJorge CastilloNo ratings yet

- CH 07 - Fans & Duct Design - ILDocument38 pagesCH 07 - Fans & Duct Design - ILKamaruz DanialNo ratings yet

- Fan Curves and LawsDocument6 pagesFan Curves and LawsEduardoPomarMakthonNo ratings yet

- Mine VentilationDocument3 pagesMine VentilationAbl EdwrNo ratings yet

- V001t01a071 91 GT 194Document10 pagesV001t01a071 91 GT 194Uzair BukhariNo ratings yet

- Diff Between Blower and FanDocument5 pagesDiff Between Blower and FanKarthikRajuNo ratings yet

- Experiments and CFD Calculations On The Performance of A Non-Reversible Axial FanDocument6 pagesExperiments and CFD Calculations On The Performance of A Non-Reversible Axial FankcpatnaikNo ratings yet

- Explain The Difference Between Fans, Blowers and Compressors?Document2 pagesExplain The Difference Between Fans, Blowers and Compressors?lyheangNo ratings yet

- Fans and BlowersDocument27 pagesFans and BlowersV.BhaskaranNo ratings yet

- Fans and BlowersDocument27 pagesFans and Blowersjkhan_724384No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Introduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsFrom EverandIntroduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsNo ratings yet

- Adaptive Filter: Enhancing Computer Vision Through Adaptive FilteringFrom EverandAdaptive Filter: Enhancing Computer Vision Through Adaptive FilteringNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- FFE - Distribution SystemsDocument8 pagesFFE - Distribution SystemsAhmad NilNo ratings yet

- Overhung V-Belt Fan Problem: Tuan BVDocument6 pagesOverhung V-Belt Fan Problem: Tuan BVAhmad NilNo ratings yet

- Möller SFS - Super Feeding System For Alumina IndustryDocument6 pagesMöller SFS - Super Feeding System For Alumina IndustryAhmad NilNo ratings yet

- Belt Conveyor Design - IdlersDocument10 pagesBelt Conveyor Design - IdlersAhmad NilNo ratings yet

- Rotary Kiln Shell Ovality MeasurementDocument2 pagesRotary Kiln Shell Ovality MeasurementAhmad NilNo ratings yet

- Acoustical Materials Sound Absorbing Materials MDocument5 pagesAcoustical Materials Sound Absorbing Materials MAhmad NilNo ratings yet

- Insider Secrets of Bellows RepairDocument1 pageInsider Secrets of Bellows RepairAhmad NilNo ratings yet

- Micromist Engineered Systems Enhanced Dust Collector Performance Evaporative Gas ConditioningDocument8 pagesMicromist Engineered Systems Enhanced Dust Collector Performance Evaporative Gas ConditioningAhmad NilNo ratings yet

- KalolenyCement CaseStudy2015 PDFDocument2 pagesKalolenyCement CaseStudy2015 PDFAhmad NilNo ratings yet

- How To Chose The Right Air Compressor For Your ApplicationDocument2 pagesHow To Chose The Right Air Compressor For Your ApplicationAhmad NilNo ratings yet

- Kilnscan: Kiln Shell Temperature MonitoringDocument2 pagesKilnscan: Kiln Shell Temperature MonitoringAhmad NilNo ratings yet

- This Preview Is Downloaded From WWW - Sis.se. Buy The Entire Standard Via HTTPS://WWW - Sis.se/std-18341Document11 pagesThis Preview Is Downloaded From WWW - Sis.se. Buy The Entire Standard Via HTTPS://WWW - Sis.se/std-18341Ahmad NilNo ratings yet

- The CFD Simulation of Cyclone Separator Without An PDFDocument11 pagesThe CFD Simulation of Cyclone Separator Without An PDFAhmad NilNo ratings yet

- Kiln Miscellaneous PDFDocument69 pagesKiln Miscellaneous PDFAhmad NilNo ratings yet

- Soniengineeringindustries Price ListDocument1 pageSoniengineeringindustries Price ListMahendra Tyre Works RaigarhNo ratings yet

- Unidirectional Flow Regulator PN10215Document1 pageUnidirectional Flow Regulator PN10215saifurrahman binyulismanNo ratings yet

- AFT NumDocument25 pagesAFT NumChetanPrajapatiNo ratings yet

- Make List SLTD-J-1401-L-6-00003-02Document4 pagesMake List SLTD-J-1401-L-6-00003-02tribhuvan ShankarNo ratings yet

- Wilo Triple Duty Valve / Triple Service Valve: Technical BulletinDocument4 pagesWilo Triple Duty Valve / Triple Service Valve: Technical BulletinilieoniciucNo ratings yet

- Alarm Check Valve PurposeDocument36 pagesAlarm Check Valve PurposeAbdul Majeed KottaNo ratings yet

- Case Study Bonus Project Ahmed ShammaDocument10 pagesCase Study Bonus Project Ahmed ShammaAhmed ShammaNo ratings yet

- Steam Turbine Start UpDocument24 pagesSteam Turbine Start Upmasoodism100% (2)

- Discharge Recirculation and CavitationDocument2 pagesDischarge Recirculation and Cavitationdk4monjure100% (1)

- C in 110 PDFDocument7 pagesC in 110 PDFRezaNo ratings yet

- Mechatronics Module 2Document53 pagesMechatronics Module 2ASWATHY V RNo ratings yet

- LIST of GTDocument5 pagesLIST of GTSonali BanerjeeNo ratings yet

- 2 VAG EKO Plus F4Document3 pages2 VAG EKO Plus F4Baris BoskanNo ratings yet

- Introduction To Hydrogen Piping and Pipeline Systems ASME B313 Vs ASME B3112 PDFDocument4 pagesIntroduction To Hydrogen Piping and Pipeline Systems ASME B313 Vs ASME B3112 PDFYudha Andrie Sasi ZenNo ratings yet

- Hydraulic/Hydrostatic Schematic 864 (S/N 518911354-14999) (S/N 516811037-14999)Document2 pagesHydraulic/Hydrostatic Schematic 864 (S/N 518911354-14999) (S/N 516811037-14999)Ataa AssaadNo ratings yet

- Diagrama Hidráulico 277Document4 pagesDiagrama Hidráulico 277Eduardo SainzNo ratings yet

- Edsg281001 (Sky Air - R410a)Document464 pagesEdsg281001 (Sky Air - R410a)Rizky Riva'i100% (1)

- Liquid Ring Vacuum Pump Construction and WorkingDocument2 pagesLiquid Ring Vacuum Pump Construction and Workingwindgust82No ratings yet

- FMEA - Chris Satria Pramana - 02111540000131Document3 pagesFMEA - Chris Satria Pramana - 02111540000131ChrisNo ratings yet

- Sample Schematic Diagram For Building With Combined Tank SectorDocument1 pageSample Schematic Diagram For Building With Combined Tank SectorSalman MNo ratings yet

- BPS-121064-F.mg Blowing Procedure For Fuel System Pipe R0Document4 pagesBPS-121064-F.mg Blowing Procedure For Fuel System Pipe R0spazzbgtNo ratings yet

- En AIGA 098-17 Ref Guide For Industrial Gas Cyl Valve Outlet Connections Final VerDocument9 pagesEn AIGA 098-17 Ref Guide For Industrial Gas Cyl Valve Outlet Connections Final VerFloyd PriceNo ratings yet

- Valve MoonDocument1 pageValve MoonMisaelNo ratings yet

- Dokumen - Tips - Gpsa 13 Ed Separation PDFDocument48 pagesDokumen - Tips - Gpsa 13 Ed Separation PDFNovi WulansariNo ratings yet

- 1574 03 Vol 2B DS PackageDocument69 pages1574 03 Vol 2B DS PackageZahoor AhmedNo ratings yet

- MAN Turbocharger Programme 2010 PDFDocument32 pagesMAN Turbocharger Programme 2010 PDFblackgateNo ratings yet

- Nozzle Analysis - 0714 SuctionDocument4 pagesNozzle Analysis - 0714 SuctionBilal MustafaNo ratings yet

- Heating and Air Conditioning: Service InformationDocument37 pagesHeating and Air Conditioning: Service InformationJipsonCuevaNo ratings yet