Professional Documents

Culture Documents

VIFT TECA 2022 002815 DAS I 0001 - 01 - Instruments Data Sheets

VIFT TECA 2022 002815 DAS I 0001 - 01 - Instruments Data Sheets

Uploaded by

polrequenamartosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VIFT TECA 2022 002815 DAS I 0001 - 01 - Instruments Data Sheets

VIFT TECA 2022 002815 DAS I 0001 - 01 - Instruments Data Sheets

Uploaded by

polrequenamartosCopyright:

Available Formats

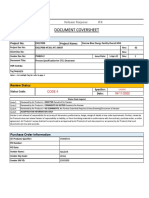

Instruments Data Sheets

A118.I.H.001

VIFT-TECA-2022-002815-DAS-I-0001

Derek Firmado digitalmente por Derek Jose Luis 2023.08.01 Firmado digitalmente por Derek

Gongora

Derek Gongora Gongora

Gongora Flores 17:03:09 +02'00'

Fecha: 2023.08.01 17:02:35

+02'00' Fecha: 2023.08.01 17:03:47 +02'00'

01 01/08/2023 IFA - Issue for Approval DG JLF DG

Rev. Date Description Edited Checked Approved

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

Sheet Rev TAG Service Type

3 01 OGW.TH0201-TE03 Burner Safety Temperature Temp. Sensor Type K (Double)

4 01 OGW.TE0201-TT01 Main inlet Flue Gas Temperature Temperature Transmitter

5 01 OGW.TH0201-TT01 Combustion Chamber (1) Temperature Temperature Transmitter

6 01 OGW.TH0201-TT02 Combustion Chamber (2) Temperature Temperature Transmitter

9 01 OGW.TT-0501 Heat Exchanger Outlet Temperature Temperature Transmitter

12 01 OGW.TT-0601 Bag Filter Flue gas Outlet Temperature Temperature Transmitter

14 01 OGW.TT-0603 Scrubber Flue gas Outlet Temperature Temperature Transmitter

15 01 OGW.PT-0210 Flue gas inlet Pressure (OGW.CL010) Pressure Transmitter

16 01 OGW.PT-0220 Flue gas inlet Pressure (OGW.CL020) Pressure Transmitter

17 01 OGW.PT-0230 Flue gas inlet Pressure (OGW.CL030) Pressure Transmitter

18 01 OGW.PT-0240 Flue gas inlet Pressure (OGW.CL040) Pressure Transmitter

19 01 OGW.TH0201- PT01 Thermal oxidizer Pressure Pressure Transmitter

19 01 OGW.PDT-0250 Bag filter inlet/outlet differential pressure Differential pressure transmitter

Document in first review. Only instruments in the scope of TECAM outside of package units are included. Pending updating with information on the suppliers'

instruments.

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 2 of 15

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

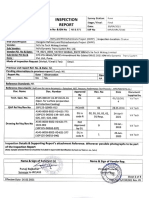

GENERAL

1 5 LINE DN -

INSTRUMENT TYPE Temp. Sensor Type K (Double)

2 6 LINE / EQUIPMENT MATERIAL AISI316L

3 TAG OGW.TH0201-TE03 7 AMBIENT TEMPERATURE 0 + 35ºC indoor

4 SERVICE Burner Safety Temperature 8 AMBIENT HUMIDITY 0.60 to 1

PROCESS DATA

9 FLUID Process air 16 CORROSIVE Yes

10 STATE Gas 17 TOXIC Yes

11 TEMPERATURE (MIN / MAX) ºC 0 850 18 RELEVANT COMPONENTS N2: 1502,44 kg/hO2: 344,00 kg/hCO2: 139,28

12 DESIGN TEMPERATURE (MIN / MAX) ºC -20 1000 19 kg/hAr: 130,22 kg/hDust (H.M.): 0,005

kg/hDust (Minerals); 0,007 kg/hDust (Carbon):

13 PRESSURE (MIN/MAX) mbar g -20 0 20

1,10 kg/hSO2: 20,00 kg/hBaP (C20H12): 0,00

14 DESIGN PRESSURE (MIN/MAX) mbar g -50 50 21 kg/hEPA16 (C10H8): 0,004 kg/hH2O: 424,21

kg/hCO: 0,00 kg/h

15 22

SENSOR AND HEAD

23 SENSOR TYPE Type K (Double) 29 SENSOR LENGTH / EXTENSION [mm] (*) 700

24 ACCURACY / NORM Class 1 IEC 60751 30 PROTECTION COVER DIAMETER [mm] 8

25 AMBIENT PROTECTION IP65 31 PROTECTION COVER MATERIAL Inconel 600

26 HOUSING MATERIAL Suitable for outdoors 32 SENSOR INSULATION MgO

27 ELECTRICAL CONNECTION M20x1,5 33 PROCESS CONNECTION NPT1/2"-M (AISI 316)

28 34 FITTING (PROCESS CON. TO SENSOR) Fixed fitting

THERMOWELL

35 CONSTRUCTION TYPE Threaded 39 INSTRUMENT CONNECTION NPT1/2"-F (AISI 316)

36 MATERIAL Inconel 600 40 PROCESS CONNECTION NPT1"-M(AISI 316)

37 41 INSERTION [mm] 600

38 42 EXTENSION [mm] 100

OPTIONS CERTIFICATION

43 INTEGRATED DISPLAY No 47 SIL -

44 NAME PLATE Yes, AISI 316 / SS wire Attached 48 ATEX No

45 49 CALIBRATION TEST REPORT Yes

46 50 MATERIALS 2,1

NOTES

51 (*) If Sliding Fitting is used for process conection (34), Sensor Length is measured from the header to the end of the sensor.

52 If Fixed Fitting for process connection (34) is used, Sensor Length is from the fitting to the end of the sensor. Length from fitting to header is referred as 'EXTENSION'

53 Include one (1) spare for this position

54

55

56

57

58

59 MANUFACTURER TBD

60 MODEL TBD

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 3 of 15

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

GENERAL

1 5 LINE DN DN300

INSTRUMENT TYPE Temperature Transmitter

2 6 LINE / EQUIPMENT MATERIAL Stainless steel

3 TAG OGW.TE0201-TT01 7 AMBIENT TEMPERATURE 0 + 35ºC indoor

4 SERVICE Main inlet Flue Gas Temperature 8 AMBIENT HUMIDITY 0.60 to 1

PROCESS DATA

9 FLUID Process air 16 CORROSIVE Yes

10 STATE Gas 17 TOXIC Yes

11 TEMPERATURE ºC 0 300 18 RELEVANT COMPONENTS N2: 1502,44 kg/hO2: 344,00 kg/hCO2: 139,28

12 DESIGN TEMPERATURE (MIN / MAX) ºC -20 400 19 kg/hAr: 130,22 kg/hDust (H.M.): 0,005

kg/hDust (Minerals); 0,007 kg/hDust (Carbon):

13 PRESSURE (MIN/MAX) mbar g -20 0 20

1,10 kg/hSO2: 20,00 kg/hBaP (C20H12): 0,00

14 DESIGN PRESSURE (MIN/MAX) mbar g -50 50 21 kg/hEPA16 (C10H8): 0,004 kg/hH2O: 424,21

kg/hCO: 0,00 kg/h

15 22

TRANSMITTER

23 POWER SUPPLY 24Vdc over loop 26 ACCURACY 1,00%

24 OUTPUT SIGNAL 4-20mA passive 27 MOUNTING Head-mounted

25 CALIBRATION RANGE (MIN / MAX) ºC -50 400 28 ELECTRICAL CONNECTION M20x1,5

SENSOR AND HEAD

29 SENSOR TYPE RTD (PT-100) 34 SENSOR LENGTH / EXTENSION [mm] (*) 300

30 ACCURACY / NORM Class 2 IEC 60751 35 PROTECTION COVER DIAMETER [mm] 8

31 AMBIENT PROTECTION IP65 36 PROTECTION COVER MATERIAL Aisi 316

32 HOUSING MATERIAL Suitable for outdoors 37 INSULATION MgO

33 PROCESS CONNECTION NPT1/2"-M (AISI 316) 38 FITTING (PROCESS CON. TO SENSOR) Fixed fitting

THERMOWELL

39 CONSTRUCTION TYPE Threaded 43 INSTRUMENT CONNECTION NPT1/2"-F (AISI 316)

40 MATERIAL Inconel 600 44 PROCESS CONNECTION NPT1"-M(AISI 316)

41 45 INSERTION [mm] 200

42 46 EXTENSION [mm] 100

OPTIONS CERTIFICATION

47 INTEGRATED DISPLAY No 51 SIL -

48 NAME PLATE Yes, AISI 316 / SS wire Attached 52 ATEX No

49 53 CALIBRATION TEST REPORT Yes

50 54 MATERIALS 2.1

NOTES

55 (*) If Sliding Fitting is used for process conection (38), Sensor Length is measured from the header to the end of the sensor.

56 If Fixed Fitting for process connection (38) is used, Sensor Length is from the fitting to the end of the sensor. Length from fitting to header is referred as 'EXTENSION'

57 Include one (1) spare for this position

58

59

60

61

62

63 TRANSMITTER TBD TBD

MANUFACTURER(S) / MODEL(S)

64 TEMPERATURE SENSOR TBD TBD

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 4 of 15

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

GENERAL

1 5 LINE DN -

INSTRUMENT TYPE Temperature Transmitter

2 6 LINE / EQUIPMENT MATERIAL AISI316L

3 TAG OGW.TH0201-TT01 7 AMBIENT TEMPERATURE 0 + 35ºC indoor

4 SERVICE Combustion Chamber (1) Temperature 8 AMBIENT HUMIDITY 0.60 to 1

PROCESS DATA

9 FLUID Process air 16 CORROSIVE Yes

10 STATE Gas 17 TOXIC Yes

11 TEMPERATURE ºC 0 850 18 RELEVANT COMPONENTS N2: 1502,44 kg/hO2: 344,00 kg/hCO2: 139,28

12 DESIGN TEMPERATURE (MIN / MAX) ºC -20 1000 19 kg/hAr: 130,22 kg/hDust (H.M.): 0,005

kg/hDust (Minerals); 0,007 kg/hDust (Carbon):

13 PRESSURE (MIN/MAX) mbar g -20 0 20

1,10 kg/hSO2: 20,00 kg/hBaP (C20H12): 0,00

14 DESIGN PRESSURE (MIN/MAX) mbar g -50 50 21 kg/hEPA16 (C10H8): 0,004 kg/hH2O: 424,21

kg/hCO: 0,00 kg/h

15 22

TRANSMITTER

23 POWER SUPPLY 24Vdc over loop 26 ACCURACY 1,00%

24 OUTPUT SIGNAL 4-20mA passive 27 MOUNTING Head-mounted

25 CALIBRATION RANGE (MIN / MAX) ºC -50 1000 28 ELECTRICAL CONNECTION -

SENSOR AND HEAD

29 SENSOR TYPE Type K 34 SENSOR LENGTH / EXTENSION [mm] (*) 700

30 ACCURACY / NORM Class 2 IEC 60751 35 PROTECTION COVER DIAMETER [mm] 8

31 AMBIENT PROTECTION IP65 36 PROTECTION COVER MATERIAL Inconel 600

32 HOUSING MATERIAL Suitable for outdoors 37 INSULATION MgO

33 PROCESS CONNECTION NPT1/2"-M (AISI 316) 38 FITTING (PROCESS CON. TO SENSOR) Fixed fitting

THERMOWELL

39 CONSTRUCTION TYPE Threaded 43 INSTRUMENT CONNECTION NPT1/2"-F (AISI 316)

40 MATERIAL Inconel 600 44 PROCESS CONNECTION NPT1"-M(AISI 316)

41 45 INSERTION [mm] 600

42 46 EXTENSION [mm] 100

OPTIONS CERTIFICATION

47 INTEGRATED DISPLAY No 51 SIL -

48 NAME PLATE Yes, AISI 316 / SS wire Attached 52 ATEX No

49 53 CALIBRATION TEST REPORT Yes

50 54 MATERIALS 2.1

NOTES

55 (*) If Sliding Fitting is used for process conection (38), Sensor Length is measured from the header to the end of the sensor.

56 If Fixed Fitting for process connection (38) is used, Sensor Length is from the fitting to the end of the sensor. Length from fitting to header is referred as 'EXTENSION'

57 Include one (1) spare for this position

58

59

60

61

62

63 TRANSMITTER TBD TBD

MANUFACTURER(S) / MODEL(S)

64 TEMPERATURE SENSOR TBD TBD

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 5 of 15

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

GENERAL

1 5 LINE DN -

INSTRUMENT TYPE Temperature Transmitter

2 6 LINE / EQUIPMENT MATERIAL AISI316L

3 TAG OGW.TH0201-TT02 7 AMBIENT TEMPERATURE 0 + 35ºC indoor

4 SERVICE Combustion Chamber (2) Temperature 8 AMBIENT HUMIDITY 0.60 to 1

PROCESS DATA

9 FLUID Process air 16 CORROSIVE Yes

10 STATE Gas 17 TOXIC Yes

11 TEMPERATURE ºC 0 850 18 RELEVANT COMPONENTS N2: 1502,44 kg/hO2: 344,00 kg/hCO2: 139,28

12 DESIGN TEMPERATURE (MIN / MAX) ºC -20 1000 19 kg/hAr: 130,22 kg/hDust (H.M.): 0,005

kg/hDust (Minerals); 0,007 kg/hDust (Carbon):

13 PRESSURE (MIN/MAX) mbar g -20 0 20

1,10 kg/hSO2: 20,00 kg/hBaP (C20H12): 0,00

14 DESIGN PRESSURE (MIN/MAX) mbar g -50 50 21 kg/hEPA16 (C10H8): 0,004 kg/hH2O: 424,21

kg/hCO: 0,00 kg/h

15 22

TRANSMITTER

23 POWER SUPPLY 24Vdc over loop 26 ACCURACY 1,00%

24 OUTPUT SIGNAL 4-20mA passive 27 MOUNTING Head-mounted

25 CALIBRATION RANGE (MIN / MAX) ºC -50 1000 28 ELECTRICAL CONNECTION -

SENSOR AND HEAD

29 SENSOR TYPE Type K 34 SENSOR LENGTH / EXTENSION [mm] (*) 700

30 ACCURACY / NORM Class 2 IEC 60751 35 PROTECTION COVER DIAMETER [mm] 8

31 AMBIENT PROTECTION IP65 36 PROTECTION COVER MATERIAL Inconel 600

32 HOUSING MATERIAL Suitable for outdoors 37 INSULATION MgO

33 PROCESS CONNECTION NPT1/2"-M (AISI 316) 38 FITTING (PROCESS CON. TO SENSOR) Fixed fitting

THERMOWELL

39 CONSTRUCTION TYPE Threaded 43 INSTRUMENT CONNECTION NPT1/2"-F (AISI 316)

40 MATERIAL Inconel 600 44 PROCESS CONNECTION NPT1"-M(AISI 316)

41 45 INSERTION [mm] 600

42 46 EXTENSION [mm] 100

OPTIONS CERTIFICATION

47 INTEGRATED DISPLAY No 51 SIL -

48 NAME PLATE Yes, AISI 316 / SS wire Attached 52 ATEX No

49 53 CALIBRATION TEST REPORT Yes

50 54 MATERIALS 2.1

NOTES

55 (*) If Sliding Fitting is used for process conection (38), Sensor Length is measured from the header to the end of the sensor.

56 If Fixed Fitting for process connection (38) is used, Sensor Length is from the fitting to the end of the sensor. Length from fitting to header is referred as 'EXTENSION'

57

58

59

60

61

62

63 TRANSMITTER TBD TBD

MANUFACTURER(S) / MODEL(S)

64 TEMPERATURE SENSOR TBD TBD

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 6 of 15

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

GENERAL

1 5 LINE DN DN300

INSTRUMENT TYPE Temperature Transmitter

2 6 LINE / EQUIPMENT MATERIAL Stainless Steel

3 TAG OGW.TT-0501 7 AMBIENT TEMPERATURE 0 + 35ºC indoor

4 SERVICE Heat Exchanger Outlet Temperature 8 AMBIENT HUMIDITY 0.60 to 1

PROCESS DATA

9 FLUID Process air 16 CORROSIVE Yes

10 STATE Gas 17 TOXIC Yes

11 TEMPERATURE ºC 0 200 18 RELEVANT COMPONENTS N2: 2504,33 kg/hO2: 365,04 kg/hCO2:

12 DESIGN TEMPERATURE (MIN / MAX) ºC 0 250 19 335,90kg/hAr: 130,23 kg/hDust (H.M.): 0,005

kg/hDust (Minerals); 0,007 kg/hDust (Carbon):

13 PRESSURE (MIN/MAX) mbar g -80 0 20

0,26 kg/hSO2: 20,00 kg/hBaP (C20H12): 0,00

14 DESIGN PRESSURE (MIN/MAX) mbar g -80 20 21

kg/hEPA16 (C10H8): 0,00 kg/hH2O:

600,76kg/hCO: 0,00 kg/h

15 22

TRANSMITTER

23 POWER SUPPLY 24Vdc over loop 26 ACCURACY 1,00%

24 OUTPUT SIGNAL 4-20mA passive 27 MOUNTING Head-mounted

25 CALIBRATION RANGE (MIN / MAX) ºC -50 400 28 ELECTRICAL CONNECTION -

SENSOR AND HEAD

29 SENSOR TYPE RTD (PT-100) 34 SENSOR LENGTH / EXTENSION [mm] (*) 400

30 ACCURACY / NORM Class 2 IEC 60751 35 PROTECTION COVER DIAMETER [mm] 8

31 AMBIENT PROTECTION IP65 36 PROTECTION COVER MATERIAL AISI 316

32 HOUSING MATERIAL Suitable for outdoors 37 INSULATION MgO

33 PROCESS CONNECTION NPT1/2"-M (AISI 316) 38 FITTING (PROCESS CON. TO SENSOR) Fixed fitting

THERMOWELL

39 CONSTRUCTION TYPE Threaded 43 INSTRUMENT CONNECTION NPT1/2"-F (AISI 316)

40 MATERIAL AISI 316 44 PROCESS CONNECTION NPT1"-M(AISI 316)

41 45 INSERTION [mm] 300

42 46 EXTENSION [mm] 100

OPTIONS CERTIFICATION

47 INTEGRATED DISPLAY No 51 SIL -

48 NAME PLATE Yes, AISI 316 / SS wire Attached 52 ATEX No

49 53 CALIBRATION TEST REPORT Yes

50 54 MATERIALS 2.1

NOTES

55 (*) If Sliding Fitting is used for process conection (38), Sensor Length is measured from the header to the end of the sensor.

56 If Fixed Fitting for process connection (38) is used, Sensor Length is from the fitting to the end of the sensor. Length from fitting to header is referred as 'EXTENSION'

57

58

59

60

61

62

63 TRANSMITTER TBD TBD

MANUFACTURER(S) / MODEL(S)

64 TEMPERATURE SENSOR TBD TBD

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 7 of 15

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

GENERAL

1 5 LINE DN DN300

INSTRUMENT TYPE Temperature Transmitter

2 6 LINE / EQUIPMENT MATERIAL Stainless Steel

3 TAG OGW.TT-0601 7 AMBIENT TEMPERATURE 0 + 35ºC indoor

4 SERVICE Bag Filter Flue gas Outlet Temperature 8 AMBIENT HUMIDITY 0.60 to 1

PROCESS DATA

9 FLUID Process air 16 CORROSIVE Yes

10 STATE Gas 17 TOXIC Yes

11 TEMPERATURE ºC 0 200 18 RELEVANT COMPONENTS N2: 2504,33 kg/hO2: 365,04 kg/hCO2:

12 DESIGN TEMPERATURE (MIN / MAX) ºC 0 250 19 335,90kg/hAr: 130,23 kg/hDust (H.M.): 0,00

kg/hDust (Minerals); 0,00 kg/hDust (Carbon):

13 PRESSURE (MIN/MAX) mbar g -80 0 20

0,00 kg/hSO2: 20,00 kg/hBaP (C20H12): 0,00

14 DESIGN PRESSURE (MIN/MAX) mbar g -80 20 21 kg/hEPA16 (C10H8): 0,00 kg/hH2O:

600,76kg/hCO: 0,00 kg/h

15 22

TRANSMITTER

23 POWER SUPPLY 24Vdc over loop 26 ACCURACY 1,00%

24 OUTPUT SIGNAL 4-20mA passive 27 MOUNTING Head-mounted

25 CALIBRATION RANGE (MIN / MAX) ºC -50 400 28 ELECTRICAL CONNECTION -

SENSOR AND HEAD

29 SENSOR TYPE RTD (PT-100) 34 SENSOR LENGTH / EXTENSION [mm] (*) 400

30 ACCURACY / NORM Class 2 IEC 60751 35 PROTECTION COVER DIAMETER [mm] 8

31 AMBIENT PROTECTION IP65 36 PROTECTION COVER MATERIAL AISI 316

32 HOUSING MATERIAL Suitable for outdoors 37 INSULATION MgO

33 PROCESS CONNECTION NPT1/2"-M (AISI 316) 38 FITTING (PROCESS CON. TO SENSOR) Fixed fitting

THERMOWELL

39 CONSTRUCTION TYPE Threaded 43 INSTRUMENT CONNECTION NPT1/2"-F (AISI 316)

40 MATERIAL AISI 316 44 PROCESS CONNECTION NPT1"-M(AISI 316)

41 45 INSERTION [mm] 300

42 46 EXTENSION [mm] 100

OPTIONS CERTIFICATION

47 INTEGRATED DISPLAY No 51 SIL -

48 NAME PLATE Yes, AISI 316 / SS wire Attached 52 ATEX No

49 53 CALIBRATION TEST REPORT Yes

50 54 MATERIALS 2.1

NOTES

55 (*) If Sliding Fitting is used for process conection (38), Sensor Length is measured from the header to the end of the sensor.

56 If Fixed Fitting for process connection (38) is used, Sensor Length is from the fitting to the end of the sensor. Length from fitting to header is referred as 'EXTENSION'

57

58

59

60

61

62

63 TRANSMITTER TBD TBD

MANUFACTURER(S) / MODEL(S)

64 TEMPERATURE SENSOR TBD TBD

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 8 of 15

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

GENERAL

1 5 LINE DN DN300

INSTRUMENT TYPE Temperature Transmitter

2 6 LINE / EQUIPMENT MATERIAL Stainless Steel

3 TAG OGW.TT-0603 7 AMBIENT TEMPERATURE 0 + 35ºC indoor

4 SERVICE Scrubber Flue gas Outlet Temperature 8 AMBIENT HUMIDITY 0.60 to 1

PROCESS DATA

9 FLUID Process air 16 CORROSIVE Yes

10 STATE Gas 17 TOXIC Yes

11 TEMPERATURE (MIN / MAX) ºC 0 80 18 RELEVANT COMPONENTS N2: 2504,33 kg/hO2: 365,04 kg/hCO2:

12 DESIGN TEMPERATURE (MIN / MAX) ºC 0 250 19 335,90kg/hAr: 130,23 kg/hDust (H.M.):

0,00kg/hDust (Minerals); 0,00 kg/hDust

13 PRESSURE (MIN / MAX) ºC -80 0 20

(Carbon): 0,00 kg/hSO2: 0,16 kg/hBaP

14 DESIGN PRESSURE mbar g -80 20 21 (C20H12): 0,00 kg/hEPA16 (C10H8): 0,00

kg/hH2O: 600,76kg/hCO: 0,00 kg/h

15 22

TRANSMITTER

23 POWER SUPPLY 24Vdc over loop 26 ACCURACY 1,00%

24 OUTPUT SIGNAL 4-20mA passive 27 MOUNTING Head-mounted

25 CALIBRATION RANGE (MIN / MAX) ºC -50 200 28 ELECTRICAL CONNECTION -

SENSOR AND HEAD

29 SENSOR TYPE RTD (PT-100) 34 SENSOR LENGTH / EXTENSION [mm] (*) 400

30 ACCURACY / NORM Class 2 IEC 60751 35 PROTECTION COVER DIAMETER [mm] 8

31 AMBIENT PROTECTION IP65 36 PROTECTION COVER MATERIAL AISI 316

32 HOUSING MATERIAL Suitable for outdoors 37 INSULATION MgO

33 PROCESS CONNECTION NPT1/2"-M (AISI 316) 38 FITTING (PROCESS CON. TO SENSOR) Fixed fitting

THERMOWELL

39 CONSTRUCTION TYPE Threaded 43 INSTRUMENT CONNECTION NPT1/2"-F (AISI 316)

40 MATERIAL AISI 316 44 PROCESS CONNECTION NPT1"-M(AISI 316)

41 45 INSERTION [mm] 300

42 46 EXTENSION [mm] 100

OPTIONS CERTIFICATION

47 INTEGRATED DISPLAY No 51 SIL -

48 NAME PLATE Yes, AISI 316 / SS wire Attached 52 ATEX No

49 53 CALIBRATION TEST REPORT Yes

50 54 MATERIALS 2.1

NOTES

55 (*) If Sliding Fitting is used for process conection (38), Sensor Length is measured from the header to the end of the sensor.

56 If Fixed Fitting for process connection (38) is used, Sensor Length is from the fitting to the end of the sensor. Length from fitting to header is referred as 'EXTENSION'

57

58

59

60

61

62

63 TRANSMITTER TBD TBD

MANUFACTURER(S) / MODEL(S)

64 TEMPERATURE SENSOR TBD TBD

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 9 of 15

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

GENERAL

1 INSTRUMENT TYPE Pressure Transmitter 5 LINE DN DN200

2 TAG OGW.PT-0210 6 LINE / EQUIPMENT MATERIAL Stainless Steel

3 7 AMBIENT TEMPERATURE 0 + 35ºC indoor

SERVICE CL0010 Process air Inlet Pressure

4 8 AMBIENT HUMIDITY 0.60 to 1

PROCESS DATA

9 PRESSURE (MIN / MAX) mbar g -20 0 16 FLUID Process Air

10 DESIGN PRESSURE (MIN / MAX) mbar g -30 30 17 STATE Gas

11 TEMPERATURE ºC 300 18 CORROSIVE / TOXIC Yes Yes

12 DESIGN TEMPERATURE (MIN / MAX) ºC 0 350 19 RELEVANT COMPONENTS N2: 1502,44 kg/hO2: 344,00 kg/hCO2: 139,28

13 20 kg/hAr: 130,22 kg/hDust (H.M.): 0,005

kg/hDust (Minerals); 0,007 kg/hDust (Carbon):

14 21

1,10 kg/hSO2: 20,00 kg/hBaP (C20H12): 0,00

kg/hEPA16 (C10H8): 0,004 kg/hH2O: 424,21

15 22 kg/hCO: 0,00 kg/h

TRANSMITTER SENSOR AND PROCESS CONNECTION

21 POWER SUPPLY 24Vdc over loop 29 SENSOR-TRANSMITTER ASSEMBLY Compact

22 OUTPUT SIGNAL 4-20mA passive 30 MANIFOLD TYPE (valves) Yes (3 valves)

23 INSTRUMENT RANGE (MIN / MAX) mbar g By Supplier By Supplier 31 PROCESS CONNECTION 1/2"NPT-F

24 CALIBRATION RANGE (MIN / MAX) mbar g -50 50 32 SUPPORT Included

25 ACCURACY 0,10% of span 33 WETTED PARTS MATERIAL AISI316L

26 HOUSING MATERIAL Aluminium epoxy coated 34 DIAPHRAGM SEAL No

27 AMBIENT PROTECTION IP65 35 CAPILARY / LENGTH -

28 ELECTRICAL CONNECTION M20x1.5 36

OPTIONS CERTIFICATION

36 INTEGRATED DISPLAY No 40 SIL -

37 NAME PLATE Yes, AISI 316 / SS wire Attached 41 ATEX No

38 42 CALIBRATION TEST REPORT Yes, calibration certificates

39 43 MATERIALS Yes, 3.1 certificates

NOTES

44 Include one spare transmitter for this position

45 The instrument will be remotely mounted due to the high temperature of the air in the line through 1/2 tubing.

46 If it is considered necessary to use additional elements, they must be offered

47 MANUFACTURER TBD

48 MODEL TBD

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 10 of 15

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

GENERAL

1 INSTRUMENT TYPE Pressure Transmitter 5 LINE DN DN200

2 TAG OGW.PT-0220 6 LINE / EQUIPMENT MATERIAL Stainless Steel

3 7 AMBIENT TEMPERATURE 0 + 35ºC indoor

SERVICE CL0020 Process air Inlet Pressure

4 8 AMBIENT HUMIDITY 0.60 to 1

PROCESS DATA

9 PRESSURE (MIN / MAX) mbar g -20 0 16 FLUID Process Air

10 DESIGN PRESSURE (MIN / MAX) mbar g -30 30 17 STATE Gas

11 TEMPERATURE ºC 300 18 CORROSIVE / TOXIC Yes Yes

12 DESIGN TEMPERATURE (MIN / MAX) ºC 0 350 19 RELEVANT COMPONENTS N2: 1502,44 kg/hO2: 344,00 kg/hCO2: 139,28

13 20 kg/hAr: 130,22 kg/hDust (H.M.): 0,005

kg/hDust (Minerals); 0,007 kg/hDust (Carbon):

14 21

1,10 kg/hSO2: 20,00 kg/hBaP (C20H12): 0,00

kg/hEPA16 (C10H8): 0,004 kg/hH2O: 424,21

15 22 kg/hCO: 0,00 kg/h

TRANSMITTER SENSOR AND PROCESS CONNECTION

21 POWER SUPPLY 24Vdc over loop 29 SENSOR-TRANSMITTER ASSEMBLY Compact

22 OUTPUT SIGNAL 4-20mA passive 30 MANIFOLD TYPE (valves) Yes (3 valves)

23 INSTRUMENT RANGE (MIN / MAX) mbar g By Supplier By Supplier 31 PROCESS CONNECTION 1/2"NPT-F

24 CALIBRATION RANGE (MIN / MAX) mbar g -50 50 32 SUPPORT Included

25 ACCURACY 0,10% of span 33 WETTED PARTS MATERIAL AISI316L

26 HOUSING MATERIAL Aluminium epoxy coated 34 DIAPHRAGM SEAL No

27 AMBIENT PROTECTION IP65 35 CAPILARY / LENGTH -

28 ELECTRICAL CONNECTION M20x1.5 36

OPTIONS CERTIFICATION

36 INTEGRATED DISPLAY No 40 SIL -

37 NAME PLATE Yes, AISI 316 / SS wire Attached 41 ATEX No

38 42 CALIBRATION TEST REPORT Yes, calibration certificates

39 43 MATERIALS Yes, 3.1 certificates

NOTES

44 The instrument will be remotely mounted due to the high temperature of the air in the line through 1/2 tubing.

45 If it is considered necessary to use additional elements, they must be offered

46 MANUFACTURER TBD

47 MODEL TBD

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 11 of 15

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

GENERAL

1 INSTRUMENT TYPE Pressure Transmitter 5 LINE DN DN200

2 TAG OGW.PT-0230 6 LINE / EQUIPMENT MATERIAL Stainless Steel

3 7 AMBIENT TEMPERATURE 0 + 35ºC indoor

SERVICE CL0030 Process air Inlet Pressure

4 8 AMBIENT HUMIDITY 0.60 to 1

PROCESS DATA

9 PRESSURE (MIN / MAX) mbar g -20 0 16 FLUID Process Air

10 DESIGN PRESSURE (MIN / MAX) mbar g -30 30 17 STATE Gas

11 TEMPERATURE ºC 300 18 CORROSIVE / TOXIC Yes Yes

12 DESIGN TEMPERATURE (MIN / MAX) ºC 0 350 19 RELEVANT COMPONENTS N2: 1502,44 kg/hO2: 344,00 kg/hCO2: 139,28

13 20 kg/hAr: 130,22 kg/hDust (H.M.): 0,005

kg/hDust (Minerals); 0,007 kg/hDust (Carbon):

14 21

1,10 kg/hSO2: 20,00 kg/hBaP (C20H12): 0,00

kg/hEPA16 (C10H8): 0,004 kg/hH2O: 424,21

15 22 kg/hCO: 0,00 kg/h

TRANSMITTER SENSOR AND PROCESS CONNECTION

21 POWER SUPPLY 24Vdc over loop 29 SENSOR-TRANSMITTER ASSEMBLY Compact

22 OUTPUT SIGNAL 4-20mA passive 30 MANIFOLD TYPE (valves) Yes (3 valves)

23 INSTRUMENT RANGE (MIN / MAX) mbar g By Supplier By Supplier 31 PROCESS CONNECTION 1/2"NPT-F

24 CALIBRATION RANGE (MIN / MAX) mbar g -50 50 32 SUPPORT Included

25 ACCURACY 0,10% of span 33 WETTED PARTS MATERIAL AISI316L

26 HOUSING MATERIAL Aluminium epoxy coated 34 DIAPHRAGM SEAL No

27 AMBIENT PROTECTION IP65 35 CAPILARY / LENGTH -

28 ELECTRICAL CONNECTION M20x1.5 36

OPTIONS CERTIFICATION

36 INTEGRATED DISPLAY No 40 SIL -

37 NAME PLATE Yes, AISI 316 / SS wire Attached 41 ATEX No

38 42 CALIBRATION TEST REPORT Yes, calibration certificates

39 43 MATERIALS Yes, 3.1 certificates

NOTES

44 The instrument will be remotely mounted due to the high temperature of the air in the line through 1/2 tubing.

45 If it is considered necessary to use additional elements, they must be offered

46 MANUFACTURER TBD

47 MODEL TBD

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 12 of 15

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

GENERAL

1 INSTRUMENT TYPE Pressure Transmitter 5 LINE DN DN200

2 TAG OGW.PT-0240 6 LINE / EQUIPMENT MATERIAL Stainless Steel

3 7 AMBIENT TEMPERATURE 0 + 35ºC indoor

SERVICE CL0040 Process air Inlet Pressure

4 8 AMBIENT HUMIDITY 0.60 to 1

PROCESS DATA

9 PRESSURE (MIN / MAX) mbar g -20 0 16 FLUID Process Air

10 DESIGN PRESSURE (MIN / MAX) mbar g -30 30 17 STATE Gas

11 TEMPERATURE ºC 300 18 CORROSIVE / TOXIC Yes Yes

12 DESIGN TEMPERATURE (MIN / MAX) ºC 0 350 19 RELEVANT COMPONENTS N2: 1502,44 kg/hO2: 344,00 kg/hCO2: 139,28

13 20 kg/hAr: 130,22 kg/hDust (H.M.): 0,005

kg/hDust (Minerals); 0,007 kg/hDust (Carbon):

14 21

1,10 kg/hSO2: 20,00 kg/hBaP (C20H12): 0,00

kg/hEPA16 (C10H8): 0,004 kg/hH2O: 424,21

15 22 kg/hCO: 0,00 kg/h

TRANSMITTER SENSOR AND PROCESS CONNECTION

21 POWER SUPPLY 24Vdc over loop 29 SENSOR-TRANSMITTER ASSEMBLY Compact

22 OUTPUT SIGNAL 4-20mA passive 30 MANIFOLD TYPE (valves) Yes (3 valves)

23 INSTRUMENT RANGE (MIN / MAX) mbar g By Supplier By Supplier 31 PROCESS CONNECTION 1/2"NPT-F

24 CALIBRATION RANGE (MIN / MAX) mbar g -50 50 32 SUPPORT Included

25 ACCURACY 0,10% of span 33 WETTED PARTS MATERIAL AISI316L

26 HOUSING MATERIAL Aluminium epoxy coated 34 DIAPHRAGM SEAL No

27 AMBIENT PROTECTION IP65 35 CAPILARY / LENGTH -

28 ELECTRICAL CONNECTION M20x1.5 36

OPTIONS CERTIFICATION

36 INTEGRATED DISPLAY No 40 SIL -

37 NAME PLATE Yes, AISI 316 / SS wire Attached 41 ATEX No

38 42 CALIBRATION TEST REPORT Yes, calibration certificates

39 43 MATERIALS Yes, 3.1 certificates

NOTES

44 The instrument will be remotely mounted due to the high temperature of the air in the line through 1/2 tubing.

45 If it is considered necessary to use additional elements, they must be offered

46 MANUFACTURER TBD

47 MODEL TBD

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 13 of 15

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

GENERAL

1 INSTRUMENT TYPE Pressure Transmitter 5 LINE DN -

2 TAG OGW.TH0201-PT01 6 LINE / EQUIPMENT MATERIAL AISI316L

3 7 AMBIENT TEMPERATURE 0 + 35ºC indoor

SERVICE TO Pressure

4 8 AMBIENT HUMIDITY 0.60 to 1

PROCESS DATA

9 PRESSURE (MIN / MAX) mbar g -20 0 16 FLUID Process Air

10 DESIGN PRESSURE (MIN / MAX) mbar g -30 30 17 STATE Gas

11 TEMPERATURE (MIN / MAX) ºC 300 850 18 CORROSIVE / TOXIC Yes Yes

12 DESIGN TEMPERATURE (MIN / MAX) ºC 0 1000 19 RELEVANT COMPONENTS N2: 1502,44 kg/hO2: 344,00 kg/hCO2: 139,28

13 20 kg/hAr: 130,22 kg/hDust (H.M.): 0,005

kg/hDust (Minerals); 0,007 kg/hDust (Carbon):

14 21

1,10 kg/hSO2: 20,00 kg/hBaP (C20H12): 0,00

kg/hEPA16 (C10H8): 0,004 kg/hH2O: 424,21

15 22 kg/hCO: 0,00 kg/h

TRANSMITTER SENSOR AND PROCESS CONNECTION

21 POWER SUPPLY 24Vdc over loop 29 SENSOR-TRANSMITTER ASSEMBLY Compact

22 OUTPUT SIGNAL 4-20mA passive 30 MANIFOLD TYPE (valves) Yes (3 valves)

23 INSTRUMENT RANGE (MIN / MAX) mbar g By Supplier By Supplier 31 PROCESS CONNECTION 1/2"NPT-F

24 CALIBRATION RANGE (MIN / MAX) mbar g -50 50 32 SUPPORT Included

25 ACCURACY 0,10% of span 33 WETTED PARTS MATERIAL AISI316L

26 HOUSING MATERIAL Aluminium epoxy coated 34 DIAPHRAGM SEAL No

27 AMBIENT PROTECTION IP65 35 CAPILARY / LENGTH -

28 ELECTRICAL CONNECTION M20x1.5 36

OPTIONS CERTIFICATION

36 INTEGRATED DISPLAY No 40 SIL -

37 NAME PLATE No 41 ATEX No

38 42 CALIBRATION TEST REPORT Yes, calibration certificates

39 43 MATERIALS Yes, 3.1 certificates

NOTES

44 The instrument will be remotely mounted due to the high temperature of the air in the line through 1/2 tubing.

45 If it is considered necessary to use additional elements, they must be offered

46 MANUFACTURER TBD

47 MODEL TBD

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 14 of 15

Client Project Number

REEL A118

Project Document Number

VIANODE FAST TRACK A118.I.H.001

Document Title Revision

Instruments Data Sheets 01

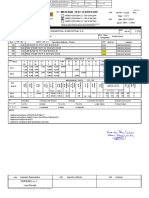

GENERAL

1 INSTRUMENT TYPE Differential Pressure Transmitter 5 LINE DN DN300

2 TAG OGW. PDT-0250 6 LINE / EQUIPMENT MATERIAL Stainless Steel

3 7 AMBIENT TEMPERATURE 0 + 35ºC indoor

SERVICE Bag filter Inlet/Outlet Differential Pressure

4 8 AMBIENT HUMIDITY 0.60 to 1

PROCESS DATA

9 PRESSURE (MIN / MAX) mbar g -58 0 16 FLUID Process Air

10 DESIGN PRESSURE (MIN / MAX) mbar g -80 30 17 STATE Gas

11 TEMPERATURE ºC 200 18 CORROSIVE / TOXIC Yes Yes

12 DESIGN TEMPERATURE (MIN / MAX) ºC 0 250 19 RELEVANT COMPONENTS N2: 2504,33 kg/hO2: 365,04 kg/hCO2:

13 20 335,90kg/hAr: 130,23 kg/hDust (H.M.): 0,005

kg/hDust (Minerals); 0,007 kg/hDust (Carbon):

14 21

0,26 kg/hSO2: 20,00 kg/hBaP (C20H12): 0,00

kg/hEPA16 (C10H8): 0,00 kg/hH2O:

15 22 600,76kg/hCO: 0,00 kg/h

TRANSMITTER HP SIDE PROCESS CONNECTION

21 POWER SUPPLY 24Vdc over loop 30 PROCESS CONNECTION 1/2" NPT-F

22 OUTPUT SIGNAL 4-20mA passive 31 WETTED PARTS MATERIAL AISI316L

23 INSTRUMENT RANGE (MIN / MAX) mbar By Supplier By Supplier 32 DIAPHRAGM SEAL No

24 CALIBRATION RANGE (MIN / MAX) mbar -100 100 33 CAPILARY / LENGTH -

25 ACCURACY 0,10% of cal. span LP SIDE PROCESS CONNECTION

26 HOUSING MATERIAL Aluminium epoxy coated 34 PROCESS CONNECTION 1/2" NPT-F

27 ELECTRICAL CONNECTION M20x1.5 35 WETTED PARTS MATERIAL AISI316L

28 HOUSING AMBIENT PROTECTION IP65 36 DIAPHRAGM SEAL - No

29 MANIFOLD TYPE (valves) No 37 CAPILARY / LENGTH -

OPTIONS CERTIFICATION

38 INTEGRATED DISPLAY No 44 SIL -

39 NAME PLATE No 45 ATEX No

40 SENSOR-TRANSMITTER ASSEMBLY Compact 46 CALIBRATION TEST REPORT Yes, calibration certificates

41 MANIFOLD TYPE (valves) Yes (5 valves) 47 MATERIALS Yes, 3.1 certificates

42 PROCESS CONNECTION 1/2" NPT-F 48

43 SUPPORT Included 49

NOTES

50 Include one spare transmitter for this position

51 The instrument will be remotely mounted due to the high temperature of the air in the line through 1/2 tubing.

52 If it is considered necessary to use additional elements, they must be offered

53 MANUFACTURER TBD

54 MODEL TBD

A118.I.H.001 Rev01 Instruments Data Sheets.xlsx 15 of 15

You might also like

- Paper 42Document12 pagesPaper 42nqrswf9nx9No ratings yet

- User Manual NovDocument578 pagesUser Manual Novgennaro100% (2)

- SL 001 (Rev 57)Document37 pagesSL 001 (Rev 57)Kiran Babu KandulaNo ratings yet

- Service Manual NovAA 800 enDocument90 pagesService Manual NovAA 800 enAnalista de Servicio50% (4)

- Appendix B - Descriptions of The 230 Space GroupsDocument36 pagesAppendix B - Descriptions of The 230 Space GroupsQiang Sun100% (1)

- C711 PDS2Document5 pagesC711 PDS2Jitendra ChaudhariNo ratings yet

- Method of Statement - Equipment Installation: BP West Nile Delta Gas Development ProjectDocument9 pagesMethod of Statement - Equipment Installation: BP West Nile Delta Gas Development ProjectHaggag AbouelkhairNo ratings yet

- SDS-01-M-01 Heavy Fuel Oil HeaterDocument2 pagesSDS-01-M-01 Heavy Fuel Oil HeaterAJAY1381No ratings yet

- Datasheet Evaporative Gas Cooler - R1Document4 pagesDatasheet Evaporative Gas Cooler - R1AyahKenzieNo ratings yet

- DQR Pj. - Motor Operated Valves (Gate)Document2 pagesDQR Pj. - Motor Operated Valves (Gate)Usman ArifNo ratings yet

- Epcm Services For Installation of "Indresid " Demonstration Plant at PanipatDocument19 pagesEpcm Services For Installation of "Indresid " Demonstration Plant at Panipatrutuja100% (2)

- Appendix 3 Documents & Drawings SupplyDocument9 pagesAppendix 3 Documents & Drawings SupplyPaul KIMNo ratings yet

- P40.10830-I-001 - Instrument Index r0 - 26 April 2022Document5 pagesP40.10830-I-001 - Instrument Index r0 - 26 April 2022SyazaNo ratings yet

- Xxp40.10830-I-001 - Instrument Index r0 - 26 April 2022Document5 pagesXxp40.10830-I-001 - Instrument Index r0 - 26 April 2022SyazaNo ratings yet

- Wash Column - E1172-U81-PS-DS-101408 - B PDFDocument13 pagesWash Column - E1172-U81-PS-DS-101408 - B PDFrutujaNo ratings yet

- Compressor Hamworthy HP (Gold Star)Document348 pagesCompressor Hamworthy HP (Gold Star)Spider 02250% (2)

- Gom STP Ins Pid 01013 1Document30 pagesGom STP Ins Pid 01013 1Nikhil PatilNo ratings yet

- Epl 1617 PDFDocument461 pagesEpl 1617 PDFetuk2100% (1)

- IRS For AgitatorDocument3 pagesIRS For AgitatorMonaNo ratings yet

- F2815 50005716-100 X0 MRB Rotary Table NL0133994Document221 pagesF2815 50005716-100 X0 MRB Rotary Table NL0133994Muhammad UsmanNo ratings yet

- Manual VFD Bomba para Lodos NovDocument1,440 pagesManual VFD Bomba para Lodos Novkiko20000No ratings yet

- MPFMDocument5 pagesMPFMmusaveerNo ratings yet

- P01696-1004-4 - 03 As Built Bill of MaterialsDocument15 pagesP01696-1004-4 - 03 As Built Bill of MaterialsMahmoud GaberNo ratings yet

- BP West Nile Delta Gas Development Project: QA/QC Weekly Report (From 27 / 01 /2018 To 01 / 02 / 2018)Document6 pagesBP West Nile Delta Gas Development Project: QA/QC Weekly Report (From 27 / 01 /2018 To 01 / 02 / 2018)Haggag AbouelkhairNo ratings yet

- Method of Statement - Grounding and Lightning AG: BP West Nile Delta Gas Development ProjectDocument7 pagesMethod of Statement - Grounding and Lightning AG: BP West Nile Delta Gas Development ProjectHaggag AbouelkhairNo ratings yet

- Flange 24 InchDocument2 pagesFlange 24 InchreniNo ratings yet

- Pro16-Fr01 - Rev.0c - Snap-Shot ReportDocument54 pagesPro16-Fr01 - Rev.0c - Snap-Shot ReportManuelNo ratings yet

- Krohne Oil & Gas: Customer Review CodeDocument8 pagesKrohne Oil & Gas: Customer Review CodeIbad Alam100% (1)

- 2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaDocument28 pages2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaHiltonNo ratings yet

- Gas Detector InstallationDocument11 pagesGas Detector InstallationOmar TocmoNo ratings yet

- 710 R 001A - B (Methanol Reactors)Document5 pages710 R 001A - B (Methanol Reactors)idilfitriNo ratings yet

- TGP-JE-GTPT-250-EQ-DAT-00105 - 001 - HY - Data Sheet For Air Cooled Heat ExchangerDocument5 pagesTGP-JE-GTPT-250-EQ-DAT-00105 - 001 - HY - Data Sheet For Air Cooled Heat ExchangerRami KsidaNo ratings yet

- Installation, Operation and Maintenance Manual For Smoke Detection Equipment (Vesda System)Document85 pagesInstallation, Operation and Maintenance Manual For Smoke Detection Equipment (Vesda System)enge.aqeelNo ratings yet

- VF006-IN-ILD-0002 - Instrument Loop Drawing - Rev.0Document197 pagesVF006-IN-ILD-0002 - Instrument Loop Drawing - Rev.0Phạm Tấn PhướcNo ratings yet

- Insulation (Hot & Cold) : Engineering Standard Specification FORDocument25 pagesInsulation (Hot & Cold) : Engineering Standard Specification FORHamid MansouriNo ratings yet

- Io ListDocument4 pagesIo ListsswahyudiNo ratings yet

- Service Bulletin Atr72: Transmittal Sheet Revision No. 08Document23 pagesService Bulletin Atr72: Transmittal Sheet Revision No. 08Pradeep K sNo ratings yet

- Crci-M98-34-M204-Da: R47-FV - 0282aDocument6 pagesCrci-M98-34-M204-Da: R47-FV - 0282arajindo1No ratings yet

- ONSHORE TO RISER-FYP-NG01011278-ESTA1-LA-4306-00001-001 Pipeline Material Take Off R02Document17 pagesONSHORE TO RISER-FYP-NG01011278-ESTA1-LA-4306-00001-001 Pipeline Material Take Off R02margaret aideNo ratings yet

- 25509-100-V1B-EKL0-00966 - Substation Building Structural Design BasisDocument15 pages25509-100-V1B-EKL0-00966 - Substation Building Structural Design BasisAnonymous FHkX0ANo ratings yet

- PPL NPL FOSL EGB PWIS INS DSH 009 - C01 - DatasheDocument2 pagesPPL NPL FOSL EGB PWIS INS DSH 009 - C01 - DatashesegunNo ratings yet

- Pre-Commissioning Check Sheet: ElectricalDocument1 pagePre-Commissioning Check Sheet: ElectricalJITHIN KRISHNAN MNo ratings yet

- RCCE-TSN Book-Of-DataDocument25 pagesRCCE-TSN Book-Of-DataIRELECNo ratings yet

- (M107 - Mec.18) PBTMZ7537200 - Tzp00fl1205500aplv001 - 00 - Utility Valve ListDocument8 pages(M107 - Mec.18) PBTMZ7537200 - Tzp00fl1205500aplv001 - 00 - Utility Valve ListrezaNo ratings yet

- 8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9501-00001 - 00Document3 pages8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9501-00001 - 00Rami KsidaNo ratings yet

- FIR - 013-DT - 09.04.2024 (PO No 741004898)Document6 pagesFIR - 013-DT - 09.04.2024 (PO No 741004898)rotobalancerNo ratings yet

- R - ITP - EARTHING RESISTOR - T4344466RevO - F001Document15 pagesR - ITP - EARTHING RESISTOR - T4344466RevO - F001Hareesh NaiduNo ratings yet

- A-4 Calibration Check ReportDocument2 pagesA-4 Calibration Check ReportheikelNo ratings yet

- A10083395 Piping Service IndexDocument2 pagesA10083395 Piping Service IndexPIERRONNo ratings yet

- Aml-78-4800117039-Zv-G01-00002-0000 - V-781012 AbcDocument237 pagesAml-78-4800117039-Zv-G01-00002-0000 - V-781012 AbcrahulNo ratings yet

- 1087 t3082p1-p4 SPLDocument1 page1087 t3082p1-p4 SPLAgnaldo JulioNo ratings yet

- Vendor Documents AND Delivery Schedule FOR XXXXXDocument3 pagesVendor Documents AND Delivery Schedule FOR XXXXXPinak ProjectsNo ratings yet

- Technical Databook Manual ShellDocument3 pagesTechnical Databook Manual Shellstonzedd2No ratings yet

- E13. Sample Inspection Release Certificate IRCDocument2 pagesE13. Sample Inspection Release Certificate IRCMohamedNo ratings yet

- 112T2395 D Device Summary AlarmDocument236 pages112T2395 D Device Summary AlarmJavier Cruz VargasNo ratings yet

- KG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.ADocument5 pagesKG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.Asumit kumarNo ratings yet

- A0-EnG-N-SL-001 Rev 4-Status List For Technical Standards DocumentsDocument67 pagesA0-EnG-N-SL-001 Rev 4-Status List For Technical Standards DocumentsJaseel ValiyaparambilNo ratings yet

- Part SVN89C enDocument8 pagesPart SVN89C enm7hs2g2qhmNo ratings yet

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)From EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Rating: 4 out of 5 stars4/5 (2)

- Power Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryFrom EverandPower Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryNo ratings yet

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- 5-Every 6000 Miles or 6 Months - Whichever Comes FirstDocument1 page5-Every 6000 Miles or 6 Months - Whichever Comes FirstpolrequenamartosNo ratings yet

- 2-Maintenance ScheduleDocument3 pages2-Maintenance SchedulepolrequenamartosNo ratings yet

- Shad 10082Document4 pagesShad 10082polrequenamartosNo ratings yet

- AdditionDocument13 pagesAdditionpolrequenamartosNo ratings yet

- TP LcoDocument1 pageTP LcopolrequenamartosNo ratings yet

- Servlets in JavaDocument26 pagesServlets in JavaPratik GandhiNo ratings yet

- The Secret of The Tesla Coils (Goran Marjanovic)Document17 pagesThe Secret of The Tesla Coils (Goran Marjanovic)THE NIKOLA TESLA INSTITUTE75% (12)

- L e A D 6th Grade Science FinalDocument60 pagesL e A D 6th Grade Science Finalapi-260611241No ratings yet

- Robotics Project Review-1: Title:-Autonomous Car SimulationDocument8 pagesRobotics Project Review-1: Title:-Autonomous Car SimulationPrayNo ratings yet

- Function Arguments and Keyword ArgumentsDocument13 pagesFunction Arguments and Keyword ArgumentsNoble PrinceNo ratings yet

- Counter DotDocument5 pagesCounter DotZulkarnainNo ratings yet

- Backing Up and Restoring HDFS MetadataDocument4 pagesBacking Up and Restoring HDFS MetadataPankaj SharmaNo ratings yet

- MICSDocument6 pagesMICSmaheshwari011No ratings yet

- June 2014 MS - Unit 4 Edexcel Chemistry A-Level PDFDocument34 pagesJune 2014 MS - Unit 4 Edexcel Chemistry A-Level PDFMaria KolokasiNo ratings yet

- MiFlash Result@2021719Document2 pagesMiFlash Result@2021719Kehidupan Dalam JendelaNo ratings yet

- AABC Test Balance Proc PDFDocument189 pagesAABC Test Balance Proc PDFemrahNo ratings yet

- Caiib Exam Syllabus 2021Document4 pagesCaiib Exam Syllabus 2021senthil kumar nNo ratings yet

- JavascriptDocument56 pagesJavascriptJenny Sison-Wilson100% (2)

- Balancing Techniques in OrleansDocument21 pagesBalancing Techniques in OrleansqweqweqweqweqweqweNo ratings yet

- Unacademy Micro RT 27 06 21 With Answer & Solution Main FinalDocument33 pagesUnacademy Micro RT 27 06 21 With Answer & Solution Main FinalVibhas SharmaNo ratings yet

- Simtec Silicone PartsDocument70 pagesSimtec Silicone Partssa_arunkumarNo ratings yet

- Wind TurbineDocument65 pagesWind TurbineAnkit KumarNo ratings yet

- Load Distribution Flow Chart For Bridge DesignDocument1 pageLoad Distribution Flow Chart For Bridge DesignBunkun15No ratings yet

- Copper Cycle Report SP16Document12 pagesCopper Cycle Report SP16BirobaNo ratings yet

- Filtre AerDocument2 pagesFiltre AerSilviu AlexandruNo ratings yet

- Be Summer 2023Document2 pagesBe Summer 2023Abc 194748No ratings yet

- INV 4835E DatasheetDocument3 pagesINV 4835E DatasheetEsteban RamirezNo ratings yet

- EAJB 015A CAB CopelandDocument7 pagesEAJB 015A CAB CopelandNelson LayaNo ratings yet

- Cambridge IGCSE™: Information & Communication Technology 0417/02 October/November 2021Document17 pagesCambridge IGCSE™: Information & Communication Technology 0417/02 October/November 2021EffNo ratings yet

- SQL Cheat Sheet For Data Scientists by Tomi Mester 2019 PDFDocument12 pagesSQL Cheat Sheet For Data Scientists by Tomi Mester 2019 PDFVishal Shah100% (1)

- ASIC Interview Questions 1Document5 pagesASIC Interview Questions 1ramNo ratings yet

- Defects in MaterialDocument15 pagesDefects in MaterialSumit Kumar JhaNo ratings yet