Professional Documents

Culture Documents

AA DS006A OiW100

AA DS006A OiW100

Uploaded by

Omar SaaedCopyright:

Available Formats

You might also like

- Rsearch Methods Exam QuestionsDocument82 pagesRsearch Methods Exam Questionsjohn baptesNo ratings yet

- Measurement of Remaining Primary Antioxidant Content in In-Service Industrial Lubricating Oils by Linear Sweep VoltammetryDocument14 pagesMeasurement of Remaining Primary Antioxidant Content in In-Service Industrial Lubricating Oils by Linear Sweep VoltammetryJuan F AlvarezNo ratings yet

- AVEVA E3D Tutorial Equipment Modeling With Practical ExampleDocument8 pagesAVEVA E3D Tutorial Equipment Modeling With Practical ExampleRamon Alejandro Porras Hernandez100% (1)

- Rocol Sapphire® Hi-Power Range 22Document7 pagesRocol Sapphire® Hi-Power Range 22Luz Angela GuerreroNo ratings yet

- Icap 4200 Icp OesDocument4 pagesIcap 4200 Icp Oeslahiru1983No ratings yet

- AN 43158 ICP OES Lubricating Oil ASTM D5185 AN43158 EN PDFDocument4 pagesAN 43158 ICP OES Lubricating Oil ASTM D5185 AN43158 EN PDFwahyubudiutamaNo ratings yet

- Eraspec Oil Article PinDocument3 pagesEraspec Oil Article PinHARVY19No ratings yet

- FT IR SpectrometryDocument4 pagesFT IR SpectrometryHARVY19No ratings yet

- CHIMEC Monthly Report N-01-11 January 2011Document14 pagesCHIMEC Monthly Report N-01-11 January 2011walidlamiriNo ratings yet

- Petrochemical - AN40757Document3 pagesPetrochemical - AN40757MidnightCowb0yNo ratings yet

- NLGI Grease Technical DocumentDocument10 pagesNLGI Grease Technical Documentho-faNo ratings yet

- Application Wear Metals Icp-Oes-5800 5994-1671en Us AgilentDocument9 pagesApplication Wear Metals Icp-Oes-5800 5994-1671en Us Agilentc1nthiacruzNo ratings yet

- L-HG Slideway Hydraulic OilDocument2 pagesL-HG Slideway Hydraulic OilYoong TanNo ratings yet

- Ozhllii!iieri': Electro-MotiveDocument3 pagesOzhllii!iieri': Electro-MotiveVladimir ArsicNo ratings yet

- Fluidcarecenter: The Research and Development Center For Fluid ExpertiseDocument8 pagesFluidcarecenter: The Research and Development Center For Fluid ExpertiseRolando Jara YoungNo ratings yet

- Sinopec Diesel Engine Oil Euro E6 10W 40Document3 pagesSinopec Diesel Engine Oil Euro E6 10W 40pedriscoNo ratings yet

- AN 43158 ICP OES Lubricating Oil ASTM D5185 AN43158 EN PDFDocument3 pagesAN 43158 ICP OES Lubricating Oil ASTM D5185 AN43158 EN PDFmustafaNo ratings yet

- Measuring Hydrocarbon Oil Index PDFDocument4 pagesMeasuring Hydrocarbon Oil Index PDFMukhtiar Ahmed LakhanNo ratings yet

- 44 135950GDE LubricantsDocument32 pages44 135950GDE LubricantsCarlos DiazNo ratings yet

- BroucherDocument6 pagesBroucherFraz AhmadNo ratings yet

- Lubriplate Syn Lube Synthetic Fluid Series: Description Typical Test Data - ApplicationsDocument2 pagesLubriplate Syn Lube Synthetic Fluid Series: Description Typical Test Data - ApplicationsDixo FernandezNo ratings yet

- SpectrOil M SeriesDocument4 pagesSpectrOil M Seriesjohn.rozas.91No ratings yet

- SpectrOil 100 Series DatasheetDocument2 pagesSpectrOil 100 Series DatasheetClydeA.SardoncilloNo ratings yet

- Axios Petro - Oil TraceDocument6 pagesAxios Petro - Oil TracePatricia MedinaNo ratings yet

- 3 Sinopec MTF 75W 90 Fully Synthetic Transmission Gear Oil 201703 PDFDocument2 pages3 Sinopec MTF 75W 90 Fully Synthetic Transmission Gear Oil 201703 PDFindeskeyNo ratings yet

- FanPro Special Tests Brochure IIDocument8 pagesFanPro Special Tests Brochure IIsubrahmanyam.knvNo ratings yet

- Guía de Inspección GDY106-85Document7 pagesGuía de Inspección GDY106-85Adolfo DonairesNo ratings yet

- OA-TO Turbine Oil AnalysisDocument3 pagesOA-TO Turbine Oil AnalysisRizkyNo ratings yet

- Brochure On OIW AnalyzerDocument15 pagesBrochure On OIW AnalyzerBenedict EromoseleNo ratings yet

- PN M150 Oil Analysis Kit enDocument2 pagesPN M150 Oil Analysis Kit enZoe Fii Barbata100% (1)

- Analysis of Edible Oils and Fats: The Seven Most Important Parameters For Quality ControlDocument20 pagesAnalysis of Edible Oils and Fats: The Seven Most Important Parameters For Quality ControlAnonymous IAwTAgNo ratings yet

- Avio 550 Max ICP-OES ASTM D5185 In-Service Oils Application NoteDocument4 pagesAvio 550 Max ICP-OES ASTM D5185 In-Service Oils Application Notec1nthiacruzNo ratings yet

- Sys Master - Pdfs - h1b - Hee - 10468320477214 - COA - DRE C16813600 - ST WB CERT 4368759 1 1 1Document2 pagesSys Master - Pdfs - h1b - Hee - 10468320477214 - COA - DRE C16813600 - ST WB CERT 4368759 1 1 1victoriaaniekan95No ratings yet

- Product Info - 20211123 - New Product - Automatic Na Sensor Regeneration AMI Sodium PDocument1 pageProduct Info - 20211123 - New Product - Automatic Na Sensor Regeneration AMI Sodium PCarmen LopezNo ratings yet

- Iso 7120 en PDFDocument6 pagesIso 7120 en PDFkarlitox123No ratings yet

- Acid Number in Lubricating and Motor Oil: Reliable Determination According To ASTM D664 and IP 177Document2 pagesAcid Number in Lubricating and Motor Oil: Reliable Determination According To ASTM D664 and IP 177udsaigakfsNo ratings yet

- Biodiesel Dari Minyak NabatiDocument17 pagesBiodiesel Dari Minyak NabatiHanderson PanjaitanNo ratings yet

- Paper962833 2837Document6 pagesPaper962833 2837AKOGU J. AKPOCHI J.No ratings yet

- What Is RULER: Oil Analysis For Predictive MaintenanceDocument2 pagesWhat Is RULER: Oil Analysis For Predictive Maintenancemohamed abdelmoniemNo ratings yet

- 27e9f1d3-c2a9-443a-b033-5cecf47738caDocument3 pages27e9f1d3-c2a9-443a-b033-5cecf47738caahmetNo ratings yet

- S - Separators Meet The New Standard For Separation PerformanceDocument4 pagesS - Separators Meet The New Standard For Separation PerformanceninatenaNo ratings yet

- Application News: Analysis of Additive Elements in Lubricating Oil According To ASTM D4951: ICPE-9820Document2 pagesApplication News: Analysis of Additive Elements in Lubricating Oil According To ASTM D4951: ICPE-9820haremNo ratings yet

- Aparat PT Biodiesel METROHMDocument16 pagesAparat PT Biodiesel METROHMCorina StanculescuNo ratings yet

- Oil Analysis Condition MonitoringDocument24 pagesOil Analysis Condition MonitoringMarc Samuel Vromans100% (5)

- Nalfleet Nalcool 2000Document2 pagesNalfleet Nalcool 2000ferdy110276No ratings yet

- TDS - LubInsight XRF Neo - 2022.11.01Document2 pagesTDS - LubInsight XRF Neo - 2022.11.01Daniel CaviedesNo ratings yet

- Material and Equipment Standard: IPS-M-TP-672Document7 pagesMaterial and Equipment Standard: IPS-M-TP-672RezaNo ratings yet

- AppNote 21-DOMINO Water Solubility AlgorithmsDocument4 pagesAppNote 21-DOMINO Water Solubility AlgorithmsMikeNo ratings yet

- Ruler - Technology: Remaining Useful Life Evaluation RoutineDocument6 pagesRuler - Technology: Remaining Useful Life Evaluation RoutineLord Krsnik100% (1)

- 15 PPM Bilge AlarmDocument9 pages15 PPM Bilge AlarmIgnacio SantanaNo ratings yet

- SAPPHIRE Hi-Torque Range - GBDocument2 pagesSAPPHIRE Hi-Torque Range - GBYonish SisoNo ratings yet

- ALS LubeWatch Program OverviewDocument6 pagesALS LubeWatch Program OverviewWahib AlbazNo ratings yet

- 7 - FTIR Analysis of Used Lubricating Oils General ConsiderationDocument4 pages7 - FTIR Analysis of Used Lubricating Oils General ConsiderationJoel CunhaNo ratings yet

- QC3077 Lrac4478Document2 pagesQC3077 Lrac4478Exata MetrologiaNo ratings yet

- J114ADocument2 pagesJ114AIrelena RomeroNo ratings yet

- Ftir Analysis of Used Lubricating OilsDocument4 pagesFtir Analysis of Used Lubricating Oilsjuli_radNo ratings yet

- FT-IR Analysis of Used Lubricating OilsDocument4 pagesFT-IR Analysis of Used Lubricating OilsMeetika GuptaNo ratings yet

- Chevron LubeWatch Brochure - 2018 PDFDocument20 pagesChevron LubeWatch Brochure - 2018 PDFHaitham YoussefNo ratings yet

- 129-138 Passive GuideDocument10 pages129-138 Passive GuideLeonardo bernal vallejo100% (1)

- Dilutor Dinamico 6100Document1 pageDilutor Dinamico 6100jonathan PIANo ratings yet

- Datasheet FluidScan® 1000 SeriesDocument4 pagesDatasheet FluidScan® 1000 SeriesfaisiiNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- 9c2ZFB SpecsDocument1 page9c2ZFB SpecsOmar SaaedNo ratings yet

- Sonde - Accessori ENG 2Document8 pagesSonde - Accessori ENG 2Omar SaaedNo ratings yet

- YSI9300 9500 DatasheetDocument2 pagesYSI9300 9500 DatasheetOmar SaaedNo ratings yet

- Sal000116b - N200Document2 pagesSal000116b - N200Omar SaaedNo ratings yet

- SDS - WC Cod 0.5X 1Document5 pagesSDS - WC Cod 0.5X 1Omar SaaedNo ratings yet

- SDS - KF 0.6X 5MLDocument6 pagesSDS - KF 0.6X 5MLOmar SaaedNo ratings yet

- SDS - Astm P 128 02Document6 pagesSDS - Astm P 128 02Omar SaaedNo ratings yet

- 0023 EN 202008 BitumenDocument16 pages0023 EN 202008 BitumenOmar SaaedNo ratings yet

- SDS - Astm P 126 01Document6 pagesSDS - Astm P 126 01Omar SaaedNo ratings yet

- SwiftScan 1 Apr 2021 8.46 PMDocument2 pagesSwiftScan 1 Apr 2021 8.46 PMOmar SaaedNo ratings yet

- 2020EIE GAS 05 Liquid SamplerDocument4 pages2020EIE GAS 05 Liquid SamplerOmar SaaedNo ratings yet

- Optimisation of Catalyst Distribution in The Catal-2Document9 pagesOptimisation of Catalyst Distribution in The Catal-2Omar SaaedNo ratings yet

- Yearly Profit & Loss Statement Template - TemplateLabDocument3 pagesYearly Profit & Loss Statement Template - TemplateLabOmar SaaedNo ratings yet

- Linseis TGA 1000 Thermogravimetric Analyzers v5Document14 pagesLinseis TGA 1000 Thermogravimetric Analyzers v5Omar SaaedNo ratings yet

- File 2Document14 pagesFile 2Omar SaaedNo ratings yet

- A Model of Naphtha Reforming in A RadialDocument128 pagesA Model of Naphtha Reforming in A RadialOmar SaaedNo ratings yet

- 8# Carbon ResidueDocument1 page8# Carbon ResidueOmar SaaedNo ratings yet

- ExperimentalStudyandSimulationofIraqiHeavyNaphthaCatalyticReformingReactionsUsingPt Ir SN Al2O3andPt Ir Al2O3CatalystsDocument24 pagesExperimentalStudyandSimulationofIraqiHeavyNaphthaCatalyticReformingReactionsUsingPt Ir SN Al2O3andPt Ir Al2O3CatalystsOmar SaaedNo ratings yet

- Sal000118a - N200HDocument2 pagesSal000118a - N200HOmar SaaedNo ratings yet

- Oc0010 Tds enDocument1 pageOc0010 Tds enOmar SaaedNo ratings yet

- Quiz Sle LudecompositionDocument4 pagesQuiz Sle LudecompositionOmar SaaedNo ratings yet

- Ad0092 600Document1 pageAd0092 600Omar SaaedNo ratings yet

- 4# Pour Point - NewLab 300Document2 pages4# Pour Point - NewLab 300Omar SaaedNo ratings yet

- NlxengDocument1 pageNlxengOmar SaaedNo ratings yet

- Omnitek BitU-Visc - Automatic Viscometry System - Technical DatasheetDocument1 pageOmnitek BitU-Visc - Automatic Viscometry System - Technical DatasheetOmar SaaedNo ratings yet

- Sal000040d - T100HDocument2 pagesSal000040d - T100HOmar SaaedNo ratings yet

- Water 10 00906 v3Document18 pagesWater 10 00906 v3Omar SaaedNo ratings yet

- Sal000041g - T100uDocument2 pagesSal000041g - T100uOmar SaaedNo ratings yet

- Ol 900 EngDocument1 pageOl 900 EngOmar SaaedNo ratings yet

- Sodium Acid Pyrophosphate PowderDocument2 pagesSodium Acid Pyrophosphate PowderOmar SaaedNo ratings yet

- Basic Allied Health Statistics and AnalysisDocument289 pagesBasic Allied Health Statistics and AnalysisAlaa Abu AishehNo ratings yet

- Matrix Factorization-1Document5 pagesMatrix Factorization-1Lâm Anh VũNo ratings yet

- FP Medium Voltage Transformer CatalogDocument36 pagesFP Medium Voltage Transformer CatalogCiro LeonNo ratings yet

- 1 Data Sheet - M Series - m030 - MA1-CE 7.25Document2 pages1 Data Sheet - M Series - m030 - MA1-CE 7.25Manickam ThanneermalaiNo ratings yet

- CHE3161 Semester1 2010 Solutions PDFDocument14 pagesCHE3161 Semester1 2010 Solutions PDFkumiristineNo ratings yet

- Lab 1204Document5 pagesLab 1204Yash RajNo ratings yet

- All Units Java HandwrittenDocument195 pagesAll Units Java Handwrittenpankaj patil100% (2)

- Hawe Hydraulics b7700 CanDocument12 pagesHawe Hydraulics b7700 CanIvan D. RiveraNo ratings yet

- Monthly Test (April) - Igcse Maths: Marks %Document6 pagesMonthly Test (April) - Igcse Maths: Marks %Aqilah AbdullahNo ratings yet

- Data Analytics Assignment 1Document11 pagesData Analytics Assignment 1RADHIKA CHANDAKNo ratings yet

- Raoult's LawDocument8 pagesRaoult's LawHARSH DHOLAKIYANo ratings yet

- Flowchart ArduinoDocument4 pagesFlowchart ArduinoSeptian Citra KusumaNo ratings yet

- Determining Sediment Concentration in Water Samples: Standard Test Methods ForDocument6 pagesDetermining Sediment Concentration in Water Samples: Standard Test Methods ForFajar Adi Nugroho100% (1)

- Tariq PHD Thesis 13-08Document168 pagesTariq PHD Thesis 13-08unaialapontNo ratings yet

- Bahir Dar University 1Document7 pagesBahir Dar University 1Anonymous QvkcpUeUcJNo ratings yet

- Is 13630 2 2006 PDFDocument8 pagesIs 13630 2 2006 PDFMazhar DhankotNo ratings yet

- OmniSwitch 6450-24-48 Datasheet enDocument10 pagesOmniSwitch 6450-24-48 Datasheet enrenuNo ratings yet

- Paper 1 SPM 2004Document4 pagesPaper 1 SPM 2004Marsilah Anum MarhamNo ratings yet

- Bentley NevadaDocument4 pagesBentley NevadarenvouzNo ratings yet

- Eigenvalues and Eigenvectors TutorialDocument11 pagesEigenvalues and Eigenvectors TutorialMebeek DagnewNo ratings yet

- ErrorDocument26 pagesErrorShashi WaghNo ratings yet

- Body BiasDocument7 pagesBody BiasSwaroop KumarNo ratings yet

- Recidual Force EquationDocument14 pagesRecidual Force EquationGirish DeshmukhNo ratings yet

- Agenda: o Current Task Group Actions o Overview of API 6D 24 Edition o Future Task Group ActionsDocument29 pagesAgenda: o Current Task Group Actions o Overview of API 6D 24 Edition o Future Task Group ActionsdliyaxNo ratings yet

- Aerospace: Numerical Simulation of The Anti-Icing Performance of Electric Heaters For Icing On The NACA 0012 AirfoilDocument15 pagesAerospace: Numerical Simulation of The Anti-Icing Performance of Electric Heaters For Icing On The NACA 0012 AirfoilNaveen NaviNo ratings yet

- 9 - Introduction To Network LayerDocument28 pages9 - Introduction To Network LayerDjangoNo ratings yet

- Introduction In: Rotating EquipmentDocument57 pagesIntroduction In: Rotating EquipmentAhmed ZNo ratings yet

- Coterminal Angles and Reference AnglesDocument3 pagesCoterminal Angles and Reference AnglesRaycelyn Joy CaburnayNo ratings yet

AA DS006A OiW100

AA DS006A OiW100

Uploaded by

Omar SaaedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AA DS006A OiW100

AA DS006A OiW100

Uploaded by

Omar SaaedCopyright:

Available Formats

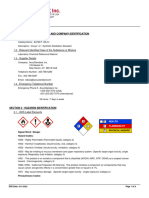

OiW-100 Oil in Water Analyzer

Applied Analytics DS-006A — Revised 07 July 2017

Continuous analysis of total petroleum concentration in water.

As global oil production grows each year, so does the amount of water being released into the environment from refining

and other processes. Continuously monitoring dynamic oil concentrations in effluent water, the OIW-100 is a painless and

economical option for complying with increasingly stringent wastewater regulations. Measuring aromatics’ absorbance from

250 to 320 nm, the OIW-100 accurately correlates total oil concentrations from trace levels to high contamination.

Features

»» Continuously measures total petroleum concentration in a homogenous water stream sample

»» Totally solid state build with no moving parts — modern design for low maintenance

»» Correlates aromatic hydrocarbons’ absorbance to total oil using customer sample for precise calibration

»» Long-lifespan xenon light source (avg. 5 years)

APPLIED

TM

1 DS-006A: Oil in Water Analyzer

A N A L Y T I C S

OiW-100 Oil in Water Analyzer

Applied Analytics DS-006A — Revised 07 July 2017

OiW-100 Internal Components

human machine

interface (HMI)

I/O board

power

supplies

nova II™

spectrophotometer

circuit

breakers

2 DS-006A: Oil in Water Analyzer

OiW-100 Oil in Water Analyzer

Applied Analytics DS-006A — Revised 07 July 2017

Optical Assembly & Principle of Operation

light source

holographic

grating

fiber optic cables

diode array

flow cell

o-ring

collimator

The OiW-100 measurement cycle is instantaneous, but it can be helpful to visualize it in stages:

(1) The white light signal originates in the pulsed Xe lamp that functions as the light source.

(2) The signal travels via fiber optic cable to the flow cell. A collimator narrows the light beam.

(3) The signal travels directly across the flow cell, interacting with the continuously drawn process sample.

(4) The signal exits the flow cell through a collimator, now containing the distinct absorbance imprint of the current

chemical composition of the sample.

(5) The signal travels via fiber optic cable to the nova II.

(6) The signal is dispersed by the holographic grating. Each differentiated wavelength is focused onto a designated

photodiode within the diode array. The nova II provides this rich data to the HMI for real-time visualization of the

absorbance spectrum.

The Oil Measurement

In various industries, complying with environmental regulations often boils down to verifying specified limits for oil content in

effluent water. In order to validate their investments in wastewater processing, refineries and plants require highly accurate

online monitoring of dissolved and un-dissolved hydrocarbon concentrations in runoff water. High oil content in effluent

water also presents a maintenance concern, as it often indicates equipment failure (e.g. leaky heat exchangers) and that the

wastewater is unfit for reuse in the facility.

3 DS-006A: Oil in Water Analyzer

OiW-100 Oil in Water Analyzer

Applied Analytics DS-006A — Revised 07 July 2017

By nature, petroleum is a mixture of many compounds; this complex constitution (including hundreds of unique organic

compounds) makes it impossible to directly measure the concentration of oil in solution. How can we verify that this vague

mixture is below limits in our wastewater?

The answer lies in aromatic hydrocarbons, which, on average, comprise 15% (by weight) of crude oil. These molecules have

strong absorbance features in the 250-320nm wavelength range and can thus be easily detected through UV-VIS (ultraviolet-

visible) spetrophotometry.

The OIW-100 continuously monitors the total aromatics’ concentration in wastewater streams. While conventional

photometric analyzers will only measure absorbance at the 254nm benzene peak--a single value susceptible to cross-

interference and lacking any internal reference for validation--the OIW-100 uses diode array technology to measure the

absorbance spectrum across the full 250-320nm aromatic absorbance range.

The system correlates aromatics’ concentration to total oil in the water. To perfect the correlation, the instrument is calibrated

for the typical composition of oil in the customer’s wastewater (using a process sample).

E

Oil-to-aromatics’ correlation.

D In calibration, aromatics’ absorbance

spectra are correlated to total oil

absorbance

C concentrations using a sample.

A 2 mg/L oil

B B 4 mg/L oil

C 6 mg/L oil

A D 8 mg/L oil

E 10 mg/L oil

230 240 250 260 270 280 290

wavelength (nm)

4 DS-006A: Oil in Water Analyzer

OiW-100 Oil in Water Analyzer

Applied Analytics DS-006A — Revised 07 July 2017

OiW-100 Technical Drawing

5 DS-006A: Oil in Water Analyzer

OiW-100 Oil in Water Analyzer

Applied Analytics DS-006A — Revised 07 July 2017

All performance specifications are subject to the assumption that the sample conditioning system and unit installation are

approved by Applied Analytics. For any other arrangement, please inquire directly with Sales.

Subject to modifications. Specified product characteristics and technical data do not serve as guarantee declarations.

Technical Data

General

Measurement Principle Dispersive UV-Vis absorbance spectrophotometry

Detector nova II™ Spectrophotometer

Data sheet: http://aai.solutions/documents/AA_DS201A_novaII.pdf

Spectral Range 200-800 nm

Light Source Standard: pulsed xenon lamp with average 5 year lifespan

Fiber Optic Cables Standard: 600 μm core 1.8 meter fiber optic cables (qty = 2)

Data sheet: http://aai.solutions/documents/AA_DS206A_FiberOptics.pdf

Sample Medium Homogenous phase liquid

Sample Introduction Standard: stainless steel 316L flow cell with application-dependent path length

Options in data sheet: http://aai.solutions/documents/AA_DS207X_FlowCell_All.pdf

Sample Conditioning Custom design if necessary

Analyzer Calibration If possible, analyzer is calibrated with customer sample; no re-calibration required after

initial calibration; measurement normalized by Auto Zero.

Reading Verification Simple verification with samples and self-check diagnostic

Human Machine Interface Applied Analytics standard HMI: industrial controller with touch-screen LCD display

Data sheet: http://aai.solutions/documents/AA_DS202A_HMI.pdf

User Interface ECLIPSE™ Runtime Software

Data sheet: http://aai.solutions/documents/AA_DS203A_Eclipse.pdf

Data Storage Solid State Drive

Data sheet: http://aai.solutions/documents/AA_DS204A_SSD.pdf

Enclosure Standard: wall-mounted, carbon steel NEMA 4 enclosure

Options in data sheet: http://aai.solutions/documents/AA_DS401X_Enclosures.pdf

Available Certifications Standard: General Purpose

Available Options: ATEX, IECEx, EAC

Please inquire with your sales representative for additional certifications (CSA, FM etc.).

Measuring Parameters

Accuracy @ range 0-20 mg/L: ±2% full scale

Response Time Analyzer response time is 1 to 5 seconds

Zero Drift ±0.1% after 1hr warm-up (measured over 24hrs at constant ambient temp.)

Sensitivity ±0.1% full scale

Noise 0.004 AU at 220 nm

Sample Conditions

Sample Temperature Using flow cell: -20 to 150 °C (-4 to 302 °F)

Sample Pressure (max) Using flow cell: 206 bar (3000 psi)

Ambient Conditions

Analyzer Environment Indoor/Outdoor (no shelter required)

Ambient Temperature Standard: 0 to 35 °C (32 to 95 °F)

With optional temperature control: -20 to 55 °C (-4 to 131 °F)

To avoid radiational heating, use of a sunshade is recommended for systems installed in

direct sunlight.

6 DS-006A: Oil in Water Analyzer

OiW-100 Oil in Water Analyzer

Applied Analytics DS-006A — Revised 07 July 2017

Physical Specifications

Dimensions Analyzer: 24” H x 20” W x 8” D (610mm H x 508mm W x 203mm D)

SCS (if included): custom size

Weight Analyzer: 32 lbs. (15 kg)

SCS (if included): variable depending on custom build

Wetted Materials Standard: K7 glass, Viton, stainless steel 316L

Various custom materials available — please inquire.

Utility Requirements

Electrical Requirements 85 to 264 VAC 47 to 63 Hz

Power Consumption 45 watts

Outputs/Communication

Outputs 1x galvanically isolated 4-20mA analog output per measured analyte

2x digital outputs for fault and SCS control

Optional: Modbus TCP/IP; RS-232; RS-485; Fieldbus; Profibus; HART; more

I/O Electronics Voltage/Current Interface Module (i.e. I/O Board)

Data sheet: http://aai.solutions/documents/AA_DS205A_VCIM.pdf

is a registered trademark of Applied Analytics, Inc. | www.aai.solutions

Headquarters Asia Pacific Sales India Sales

Applied Analytics, Inc. Applied Analytics Asia Pte. Ltd. Applied Analytics (India) Pte. Ltd.

Burlington, MA | sales@aai.solutions Singapore | sales@appliedanalytics.com.sg Mumbai, India | sales@appliedanalytics.in

North America Sales Middle East Sales

Applied Analytics North America, Ltd. Applied Analytics Oil & Gas Operations, L.L.C.

Houston, TX | sales@appliedanalytics.us Abu Dhabi, UAE | sales@appliedanalytics.ae

Europe Sales Brazil Sales

Applied Analytics Europe, AG Applied Analytics do Brasil

Genève, Switzerland | sales@appliedanalytics.eu Rio de Janeiro, Brazil | vendas@aadbl.com.br

© 2017 Applied Analytics, Inc. Products or references stated may be trademarks or registered trademarks of their respective owners. All rights reserved. We

reserve the right to make technical changes or modify this document without prior notice. Regarding purchase orders, agreed-upon details shall prevail.

7 DS-006A: Oil in Water Analyzer

You might also like

- Rsearch Methods Exam QuestionsDocument82 pagesRsearch Methods Exam Questionsjohn baptesNo ratings yet

- Measurement of Remaining Primary Antioxidant Content in In-Service Industrial Lubricating Oils by Linear Sweep VoltammetryDocument14 pagesMeasurement of Remaining Primary Antioxidant Content in In-Service Industrial Lubricating Oils by Linear Sweep VoltammetryJuan F AlvarezNo ratings yet

- AVEVA E3D Tutorial Equipment Modeling With Practical ExampleDocument8 pagesAVEVA E3D Tutorial Equipment Modeling With Practical ExampleRamon Alejandro Porras Hernandez100% (1)

- Rocol Sapphire® Hi-Power Range 22Document7 pagesRocol Sapphire® Hi-Power Range 22Luz Angela GuerreroNo ratings yet

- Icap 4200 Icp OesDocument4 pagesIcap 4200 Icp Oeslahiru1983No ratings yet

- AN 43158 ICP OES Lubricating Oil ASTM D5185 AN43158 EN PDFDocument4 pagesAN 43158 ICP OES Lubricating Oil ASTM D5185 AN43158 EN PDFwahyubudiutamaNo ratings yet

- Eraspec Oil Article PinDocument3 pagesEraspec Oil Article PinHARVY19No ratings yet

- FT IR SpectrometryDocument4 pagesFT IR SpectrometryHARVY19No ratings yet

- CHIMEC Monthly Report N-01-11 January 2011Document14 pagesCHIMEC Monthly Report N-01-11 January 2011walidlamiriNo ratings yet

- Petrochemical - AN40757Document3 pagesPetrochemical - AN40757MidnightCowb0yNo ratings yet

- NLGI Grease Technical DocumentDocument10 pagesNLGI Grease Technical Documentho-faNo ratings yet

- Application Wear Metals Icp-Oes-5800 5994-1671en Us AgilentDocument9 pagesApplication Wear Metals Icp-Oes-5800 5994-1671en Us Agilentc1nthiacruzNo ratings yet

- L-HG Slideway Hydraulic OilDocument2 pagesL-HG Slideway Hydraulic OilYoong TanNo ratings yet

- Ozhllii!iieri': Electro-MotiveDocument3 pagesOzhllii!iieri': Electro-MotiveVladimir ArsicNo ratings yet

- Fluidcarecenter: The Research and Development Center For Fluid ExpertiseDocument8 pagesFluidcarecenter: The Research and Development Center For Fluid ExpertiseRolando Jara YoungNo ratings yet

- Sinopec Diesel Engine Oil Euro E6 10W 40Document3 pagesSinopec Diesel Engine Oil Euro E6 10W 40pedriscoNo ratings yet

- AN 43158 ICP OES Lubricating Oil ASTM D5185 AN43158 EN PDFDocument3 pagesAN 43158 ICP OES Lubricating Oil ASTM D5185 AN43158 EN PDFmustafaNo ratings yet

- Measuring Hydrocarbon Oil Index PDFDocument4 pagesMeasuring Hydrocarbon Oil Index PDFMukhtiar Ahmed LakhanNo ratings yet

- 44 135950GDE LubricantsDocument32 pages44 135950GDE LubricantsCarlos DiazNo ratings yet

- BroucherDocument6 pagesBroucherFraz AhmadNo ratings yet

- Lubriplate Syn Lube Synthetic Fluid Series: Description Typical Test Data - ApplicationsDocument2 pagesLubriplate Syn Lube Synthetic Fluid Series: Description Typical Test Data - ApplicationsDixo FernandezNo ratings yet

- SpectrOil M SeriesDocument4 pagesSpectrOil M Seriesjohn.rozas.91No ratings yet

- SpectrOil 100 Series DatasheetDocument2 pagesSpectrOil 100 Series DatasheetClydeA.SardoncilloNo ratings yet

- Axios Petro - Oil TraceDocument6 pagesAxios Petro - Oil TracePatricia MedinaNo ratings yet

- 3 Sinopec MTF 75W 90 Fully Synthetic Transmission Gear Oil 201703 PDFDocument2 pages3 Sinopec MTF 75W 90 Fully Synthetic Transmission Gear Oil 201703 PDFindeskeyNo ratings yet

- FanPro Special Tests Brochure IIDocument8 pagesFanPro Special Tests Brochure IIsubrahmanyam.knvNo ratings yet

- Guía de Inspección GDY106-85Document7 pagesGuía de Inspección GDY106-85Adolfo DonairesNo ratings yet

- OA-TO Turbine Oil AnalysisDocument3 pagesOA-TO Turbine Oil AnalysisRizkyNo ratings yet

- Brochure On OIW AnalyzerDocument15 pagesBrochure On OIW AnalyzerBenedict EromoseleNo ratings yet

- PN M150 Oil Analysis Kit enDocument2 pagesPN M150 Oil Analysis Kit enZoe Fii Barbata100% (1)

- Analysis of Edible Oils and Fats: The Seven Most Important Parameters For Quality ControlDocument20 pagesAnalysis of Edible Oils and Fats: The Seven Most Important Parameters For Quality ControlAnonymous IAwTAgNo ratings yet

- Avio 550 Max ICP-OES ASTM D5185 In-Service Oils Application NoteDocument4 pagesAvio 550 Max ICP-OES ASTM D5185 In-Service Oils Application Notec1nthiacruzNo ratings yet

- Sys Master - Pdfs - h1b - Hee - 10468320477214 - COA - DRE C16813600 - ST WB CERT 4368759 1 1 1Document2 pagesSys Master - Pdfs - h1b - Hee - 10468320477214 - COA - DRE C16813600 - ST WB CERT 4368759 1 1 1victoriaaniekan95No ratings yet

- Product Info - 20211123 - New Product - Automatic Na Sensor Regeneration AMI Sodium PDocument1 pageProduct Info - 20211123 - New Product - Automatic Na Sensor Regeneration AMI Sodium PCarmen LopezNo ratings yet

- Iso 7120 en PDFDocument6 pagesIso 7120 en PDFkarlitox123No ratings yet

- Acid Number in Lubricating and Motor Oil: Reliable Determination According To ASTM D664 and IP 177Document2 pagesAcid Number in Lubricating and Motor Oil: Reliable Determination According To ASTM D664 and IP 177udsaigakfsNo ratings yet

- Biodiesel Dari Minyak NabatiDocument17 pagesBiodiesel Dari Minyak NabatiHanderson PanjaitanNo ratings yet

- Paper962833 2837Document6 pagesPaper962833 2837AKOGU J. AKPOCHI J.No ratings yet

- What Is RULER: Oil Analysis For Predictive MaintenanceDocument2 pagesWhat Is RULER: Oil Analysis For Predictive Maintenancemohamed abdelmoniemNo ratings yet

- 27e9f1d3-c2a9-443a-b033-5cecf47738caDocument3 pages27e9f1d3-c2a9-443a-b033-5cecf47738caahmetNo ratings yet

- S - Separators Meet The New Standard For Separation PerformanceDocument4 pagesS - Separators Meet The New Standard For Separation PerformanceninatenaNo ratings yet

- Application News: Analysis of Additive Elements in Lubricating Oil According To ASTM D4951: ICPE-9820Document2 pagesApplication News: Analysis of Additive Elements in Lubricating Oil According To ASTM D4951: ICPE-9820haremNo ratings yet

- Aparat PT Biodiesel METROHMDocument16 pagesAparat PT Biodiesel METROHMCorina StanculescuNo ratings yet

- Oil Analysis Condition MonitoringDocument24 pagesOil Analysis Condition MonitoringMarc Samuel Vromans100% (5)

- Nalfleet Nalcool 2000Document2 pagesNalfleet Nalcool 2000ferdy110276No ratings yet

- TDS - LubInsight XRF Neo - 2022.11.01Document2 pagesTDS - LubInsight XRF Neo - 2022.11.01Daniel CaviedesNo ratings yet

- Material and Equipment Standard: IPS-M-TP-672Document7 pagesMaterial and Equipment Standard: IPS-M-TP-672RezaNo ratings yet

- AppNote 21-DOMINO Water Solubility AlgorithmsDocument4 pagesAppNote 21-DOMINO Water Solubility AlgorithmsMikeNo ratings yet

- Ruler - Technology: Remaining Useful Life Evaluation RoutineDocument6 pagesRuler - Technology: Remaining Useful Life Evaluation RoutineLord Krsnik100% (1)

- 15 PPM Bilge AlarmDocument9 pages15 PPM Bilge AlarmIgnacio SantanaNo ratings yet

- SAPPHIRE Hi-Torque Range - GBDocument2 pagesSAPPHIRE Hi-Torque Range - GBYonish SisoNo ratings yet

- ALS LubeWatch Program OverviewDocument6 pagesALS LubeWatch Program OverviewWahib AlbazNo ratings yet

- 7 - FTIR Analysis of Used Lubricating Oils General ConsiderationDocument4 pages7 - FTIR Analysis of Used Lubricating Oils General ConsiderationJoel CunhaNo ratings yet

- QC3077 Lrac4478Document2 pagesQC3077 Lrac4478Exata MetrologiaNo ratings yet

- J114ADocument2 pagesJ114AIrelena RomeroNo ratings yet

- Ftir Analysis of Used Lubricating OilsDocument4 pagesFtir Analysis of Used Lubricating Oilsjuli_radNo ratings yet

- FT-IR Analysis of Used Lubricating OilsDocument4 pagesFT-IR Analysis of Used Lubricating OilsMeetika GuptaNo ratings yet

- Chevron LubeWatch Brochure - 2018 PDFDocument20 pagesChevron LubeWatch Brochure - 2018 PDFHaitham YoussefNo ratings yet

- 129-138 Passive GuideDocument10 pages129-138 Passive GuideLeonardo bernal vallejo100% (1)

- Dilutor Dinamico 6100Document1 pageDilutor Dinamico 6100jonathan PIANo ratings yet

- Datasheet FluidScan® 1000 SeriesDocument4 pagesDatasheet FluidScan® 1000 SeriesfaisiiNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- 9c2ZFB SpecsDocument1 page9c2ZFB SpecsOmar SaaedNo ratings yet

- Sonde - Accessori ENG 2Document8 pagesSonde - Accessori ENG 2Omar SaaedNo ratings yet

- YSI9300 9500 DatasheetDocument2 pagesYSI9300 9500 DatasheetOmar SaaedNo ratings yet

- Sal000116b - N200Document2 pagesSal000116b - N200Omar SaaedNo ratings yet

- SDS - WC Cod 0.5X 1Document5 pagesSDS - WC Cod 0.5X 1Omar SaaedNo ratings yet

- SDS - KF 0.6X 5MLDocument6 pagesSDS - KF 0.6X 5MLOmar SaaedNo ratings yet

- SDS - Astm P 128 02Document6 pagesSDS - Astm P 128 02Omar SaaedNo ratings yet

- 0023 EN 202008 BitumenDocument16 pages0023 EN 202008 BitumenOmar SaaedNo ratings yet

- SDS - Astm P 126 01Document6 pagesSDS - Astm P 126 01Omar SaaedNo ratings yet

- SwiftScan 1 Apr 2021 8.46 PMDocument2 pagesSwiftScan 1 Apr 2021 8.46 PMOmar SaaedNo ratings yet

- 2020EIE GAS 05 Liquid SamplerDocument4 pages2020EIE GAS 05 Liquid SamplerOmar SaaedNo ratings yet

- Optimisation of Catalyst Distribution in The Catal-2Document9 pagesOptimisation of Catalyst Distribution in The Catal-2Omar SaaedNo ratings yet

- Yearly Profit & Loss Statement Template - TemplateLabDocument3 pagesYearly Profit & Loss Statement Template - TemplateLabOmar SaaedNo ratings yet

- Linseis TGA 1000 Thermogravimetric Analyzers v5Document14 pagesLinseis TGA 1000 Thermogravimetric Analyzers v5Omar SaaedNo ratings yet

- File 2Document14 pagesFile 2Omar SaaedNo ratings yet

- A Model of Naphtha Reforming in A RadialDocument128 pagesA Model of Naphtha Reforming in A RadialOmar SaaedNo ratings yet

- 8# Carbon ResidueDocument1 page8# Carbon ResidueOmar SaaedNo ratings yet

- ExperimentalStudyandSimulationofIraqiHeavyNaphthaCatalyticReformingReactionsUsingPt Ir SN Al2O3andPt Ir Al2O3CatalystsDocument24 pagesExperimentalStudyandSimulationofIraqiHeavyNaphthaCatalyticReformingReactionsUsingPt Ir SN Al2O3andPt Ir Al2O3CatalystsOmar SaaedNo ratings yet

- Sal000118a - N200HDocument2 pagesSal000118a - N200HOmar SaaedNo ratings yet

- Oc0010 Tds enDocument1 pageOc0010 Tds enOmar SaaedNo ratings yet

- Quiz Sle LudecompositionDocument4 pagesQuiz Sle LudecompositionOmar SaaedNo ratings yet

- Ad0092 600Document1 pageAd0092 600Omar SaaedNo ratings yet

- 4# Pour Point - NewLab 300Document2 pages4# Pour Point - NewLab 300Omar SaaedNo ratings yet

- NlxengDocument1 pageNlxengOmar SaaedNo ratings yet

- Omnitek BitU-Visc - Automatic Viscometry System - Technical DatasheetDocument1 pageOmnitek BitU-Visc - Automatic Viscometry System - Technical DatasheetOmar SaaedNo ratings yet

- Sal000040d - T100HDocument2 pagesSal000040d - T100HOmar SaaedNo ratings yet

- Water 10 00906 v3Document18 pagesWater 10 00906 v3Omar SaaedNo ratings yet

- Sal000041g - T100uDocument2 pagesSal000041g - T100uOmar SaaedNo ratings yet

- Ol 900 EngDocument1 pageOl 900 EngOmar SaaedNo ratings yet

- Sodium Acid Pyrophosphate PowderDocument2 pagesSodium Acid Pyrophosphate PowderOmar SaaedNo ratings yet

- Basic Allied Health Statistics and AnalysisDocument289 pagesBasic Allied Health Statistics and AnalysisAlaa Abu AishehNo ratings yet

- Matrix Factorization-1Document5 pagesMatrix Factorization-1Lâm Anh VũNo ratings yet

- FP Medium Voltage Transformer CatalogDocument36 pagesFP Medium Voltage Transformer CatalogCiro LeonNo ratings yet

- 1 Data Sheet - M Series - m030 - MA1-CE 7.25Document2 pages1 Data Sheet - M Series - m030 - MA1-CE 7.25Manickam ThanneermalaiNo ratings yet

- CHE3161 Semester1 2010 Solutions PDFDocument14 pagesCHE3161 Semester1 2010 Solutions PDFkumiristineNo ratings yet

- Lab 1204Document5 pagesLab 1204Yash RajNo ratings yet

- All Units Java HandwrittenDocument195 pagesAll Units Java Handwrittenpankaj patil100% (2)

- Hawe Hydraulics b7700 CanDocument12 pagesHawe Hydraulics b7700 CanIvan D. RiveraNo ratings yet

- Monthly Test (April) - Igcse Maths: Marks %Document6 pagesMonthly Test (April) - Igcse Maths: Marks %Aqilah AbdullahNo ratings yet

- Data Analytics Assignment 1Document11 pagesData Analytics Assignment 1RADHIKA CHANDAKNo ratings yet

- Raoult's LawDocument8 pagesRaoult's LawHARSH DHOLAKIYANo ratings yet

- Flowchart ArduinoDocument4 pagesFlowchart ArduinoSeptian Citra KusumaNo ratings yet

- Determining Sediment Concentration in Water Samples: Standard Test Methods ForDocument6 pagesDetermining Sediment Concentration in Water Samples: Standard Test Methods ForFajar Adi Nugroho100% (1)

- Tariq PHD Thesis 13-08Document168 pagesTariq PHD Thesis 13-08unaialapontNo ratings yet

- Bahir Dar University 1Document7 pagesBahir Dar University 1Anonymous QvkcpUeUcJNo ratings yet

- Is 13630 2 2006 PDFDocument8 pagesIs 13630 2 2006 PDFMazhar DhankotNo ratings yet

- OmniSwitch 6450-24-48 Datasheet enDocument10 pagesOmniSwitch 6450-24-48 Datasheet enrenuNo ratings yet

- Paper 1 SPM 2004Document4 pagesPaper 1 SPM 2004Marsilah Anum MarhamNo ratings yet

- Bentley NevadaDocument4 pagesBentley NevadarenvouzNo ratings yet

- Eigenvalues and Eigenvectors TutorialDocument11 pagesEigenvalues and Eigenvectors TutorialMebeek DagnewNo ratings yet

- ErrorDocument26 pagesErrorShashi WaghNo ratings yet

- Body BiasDocument7 pagesBody BiasSwaroop KumarNo ratings yet

- Recidual Force EquationDocument14 pagesRecidual Force EquationGirish DeshmukhNo ratings yet

- Agenda: o Current Task Group Actions o Overview of API 6D 24 Edition o Future Task Group ActionsDocument29 pagesAgenda: o Current Task Group Actions o Overview of API 6D 24 Edition o Future Task Group ActionsdliyaxNo ratings yet

- Aerospace: Numerical Simulation of The Anti-Icing Performance of Electric Heaters For Icing On The NACA 0012 AirfoilDocument15 pagesAerospace: Numerical Simulation of The Anti-Icing Performance of Electric Heaters For Icing On The NACA 0012 AirfoilNaveen NaviNo ratings yet

- 9 - Introduction To Network LayerDocument28 pages9 - Introduction To Network LayerDjangoNo ratings yet

- Introduction In: Rotating EquipmentDocument57 pagesIntroduction In: Rotating EquipmentAhmed ZNo ratings yet

- Coterminal Angles and Reference AnglesDocument3 pagesCoterminal Angles and Reference AnglesRaycelyn Joy CaburnayNo ratings yet