Professional Documents

Culture Documents

Design Recommendations For Thread Forming Screws For Plastics

Design Recommendations For Thread Forming Screws For Plastics

Uploaded by

tk08p884h9gtjvsawqc0 ratings0% found this document useful (0 votes)

10 views1 pageThe document provides recommendations for optimal connections when using Plasfast 30° screws in thermoplastics. It includes a table that lists the recommended pilot hole diameter, outer diameter, and screw-in depth for various thermoplastic materials, with each dimension specified as a ratio relative to the screw diameter. The table provides this technical dimensional data to assist with selecting the proper screw size based on the thermoplastic material grade.

Original Description:

Original Title

Design Recommendations for Thread Forming Screws for Plastics

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides recommendations for optimal connections when using Plasfast 30° screws in thermoplastics. It includes a table that lists the recommended pilot hole diameter, outer diameter, and screw-in depth for various thermoplastic materials, with each dimension specified as a ratio relative to the screw diameter. The table provides this technical dimensional data to assist with selecting the proper screw size based on the thermoplastic material grade.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

10 views1 pageDesign Recommendations For Thread Forming Screws For Plastics

Design Recommendations For Thread Forming Screws For Plastics

Uploaded by

tk08p884h9gtjvsawqcThe document provides recommendations for optimal connections when using Plasfast 30° screws in thermoplastics. It includes a table that lists the recommended pilot hole diameter, outer diameter, and screw-in depth for various thermoplastic materials, with each dimension specified as a ratio relative to the screw diameter. The table provides this technical dimensional data to assist with selecting the proper screw size based on the thermoplastic material grade.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Technical Information

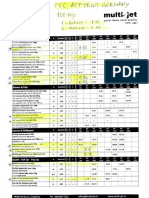

Design recommendation for Plasfast® 30°- Screws

To obtain an optimal connection in thermoplastics we recommend a tube geometry subject to screw diameter and material grade. To assist with the most

important data please refer to the Table 24 shown below.

Recommended pilot hole diameter for Plasfast® 30° - Screws

Material Hole diameter Outer diameter Screw-in depth

dH dA LE

ABS 0,80 x d 2,00 x d 2,00 x d

ABS/PC Blend 0,80 x d 2,00 x d 2,00 x d

ASA 0,78 x d 2,00 x d 2,00 x d

PA 4.6 0,73 x d 1,85 x d 1,80 x d

PA 4.6 GF 30 0,78 x d 1,85 x d 1,80 x d

PA 6 0,75 x d 1,85 x d 1,70 x d

PA 6 GF 30 0,80 x d 2,00 x d 1,90 x d

PA 6.6 0,75 x d 1,85 x d 1,70 x d

PA 6.6 GF 30 0,82 x d 2,00 x d 1,80 x d

PBT 0,75 x d 1,85 x d 1,70 x d

PBT GF 30 0,80 x d 1,80 x d 1,70 x d

PC 0,85 x d 2,50 x d 2,20 x d

PC GF 30 0,85 x d 2,20 x d 2,00 x d

PE LD 0,70 x d 2,00 x d 2,00 x d

PE HD 0,75 x d 1,80 x d 1,80 x d

PET 0,75 x d 1,85 x d 1,70 x d

PET GF30 0,80 x d 1,80 x d 1,70 x d d = Nominal screw diameter

PMMA 0,85 x d 2,00 x d 2,00 x d dA ≥ (2 x d), see Table 24

POM 0,75 x d 1,95 x d 2,00 x d dH = (0,70 bis 0,85 x d), see Table 24

POM GF 30 0,80 x d 1,95 x d 2,00 x d ts = 0,4 x d

h ≥ LE + 1 x d

PP 0,70 x d 2,00 x d 2,00 x d

LE ≥ (2 x d), see Table 24

PP GF 30 0,72 x d 2,00 x d 2,00 x d

s = without set parameter

PP TV 20 0,72 x d 2,00 x d 2,00 x d

dE = 1,05 x d

PPO 0,85 x d 2,50 x d 2,20 x d

PS 0,80 x d 2,00 x d 2,00 x d

PVC (hard) 0,80 x d 2,00 x d 2,00 x d

PEEK 0,85 x d 2,00 x d 2,00 x d

SAN 0,77 x d 2,00 x d 1,90 x d

Technical and dimensional information provided may be subject to change if international standards are amended. All information provided is for reference

purposes only and cannot, therefore, be considered to be legally binding.

You might also like

- Ont SpectoolDocument23 pagesOnt SpectoolSaid AdingniNo ratings yet

- Request For Inspection & Approval - FinalDocument1 pageRequest For Inspection & Approval - FinalmuneerpmhNo ratings yet

- 67697425-Bolt-Design 72Document1 page67697425-Bolt-Design 72pawkomNo ratings yet

- Multi Jet Cenovnik Mart 2020Document2 pagesMulti Jet Cenovnik Mart 2020Nenad AndjelkovicNo ratings yet

- Brosur U Ditch - PT. Titan Precast IndonesiaDocument2 pagesBrosur U Ditch - PT. Titan Precast IndonesiaAdi PriyapurnatamaNo ratings yet

- Air Conditioning Design Mapua University North/Northwest Building, 1 - 4 FloorDocument10 pagesAir Conditioning Design Mapua University North/Northwest Building, 1 - 4 FloorJamiel CatapangNo ratings yet

- Tech Paper Ringfeder Safety Covers Shrink Discs RFN 4061 RFN 4161 en 10 2021Document2 pagesTech Paper Ringfeder Safety Covers Shrink Discs RFN 4061 RFN 4161 en 10 2021pete20r2No ratings yet

- Item 35Document2 pagesItem 35honj enzaliNo ratings yet

- Maxima Demanda Colegio Rev 01Document7 pagesMaxima Demanda Colegio Rev 01Davis EdwardNo ratings yet

- Dmt80480T070 - 32W: 7.0 Inches, 800Xrgbx480, 16.7M Colors, Android LCMDocument3 pagesDmt80480T070 - 32W: 7.0 Inches, 800Xrgbx480, 16.7M Colors, Android LCMDoug AdamsNo ratings yet

- Calculo Electrico MajoDocument1 pageCalculo Electrico MajoRubenNo ratings yet

- Assignment 01Document6 pagesAssignment 01asifNo ratings yet

- (Zybio) Hematology Analyzer Z3Document1 page(Zybio) Hematology Analyzer Z3Tinmb FernandoNo ratings yet

- Seval Kablo Yeni̇ Fi̇yat Li̇stesi̇Document1 pageSeval Kablo Yeni̇ Fi̇yat Li̇stesi̇ZaaaazznananananaNo ratings yet

- Nilai Uts Ipa Genap 2021Document2 pagesNilai Uts Ipa Genap 2021Akhy YudistiraNo ratings yet

- FT GeotextilesDocument2 pagesFT GeotextilesElber Ramiro Olivares BareñoNo ratings yet

- Mercor Trape Desfumare MCR ThermolightDocument8 pagesMercor Trape Desfumare MCR ThermolightAlexandru ConstantinescuNo ratings yet

- Mercor Trape Desfumare MCR ThermolightDocument8 pagesMercor Trape Desfumare MCR ThermolightAlexandru ConstantinescuNo ratings yet

- Pipe Support TemplatesDocument31 pagesPipe Support TemplatesasdfdfNo ratings yet

- JE-Y (ST) Y: BD Si Industry-Electronic Cable According To DIN VDE 0815Document1 pageJE-Y (ST) Y: BD Si Industry-Electronic Cable According To DIN VDE 0815Narendra Reddy BhumaNo ratings yet

- C29-JE-Y (ST) Y BD PDFDocument1 pageC29-JE-Y (ST) Y BD PDFNarendra Reddy BhumaNo ratings yet

- c29 Je y (ST) y BDDocument1 pagec29 Je y (ST) y BDNarendra Reddy BhumaNo ratings yet

- Livro 3Document2 pagesLivro 3Natalia RochaNo ratings yet

- (Zybio) Hematology Analyzer Z50Document1 page(Zybio) Hematology Analyzer Z50Tinmb Fernando0% (1)

- Multiple-Choice Test Shooting Method Ordinary Differential EquationsDocument15 pagesMultiple-Choice Test Shooting Method Ordinary Differential EquationsHanmant OulkarNo ratings yet

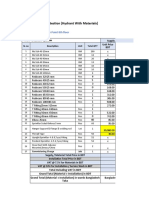

- Budget For Fire Protection (Hydrant With Materials)Document2 pagesBudget For Fire Protection (Hydrant With Materials)Md.Sofiqur RahmanNo ratings yet

- Data Sheet Docol Tube 780 2016-03-31 57 371857150 enDocument9 pagesData Sheet Docol Tube 780 2016-03-31 57 371857150 enJoe TrumpNo ratings yet

- Draft Nilai Tkj-FixDocument11 pagesDraft Nilai Tkj-FixSigit Putra WicaksonoNo ratings yet

- ThicknessDocument53 pagesThicknessRajul MuraliNo ratings yet

- Linear Programming Problems CH19Document4 pagesLinear Programming Problems CH19الف تاتNo ratings yet

- D' Seal / Fluid Seal For Hydraulic ApplicationDocument1 pageD' Seal / Fluid Seal For Hydraulic ApplicationkaryaNo ratings yet

- Appendix BDocument6 pagesAppendix BChirag ThanviNo ratings yet

- 5 Type Curves MatchingDocument52 pages5 Type Curves MatchingIbnu KostNo ratings yet

- 10peep Hole Glass (Drawing)Document1 page10peep Hole Glass (Drawing)btmj2022No ratings yet

- Cuadro de Cargas: Tablero Distrubucion Td-01Document1 pageCuadro de Cargas: Tablero Distrubucion Td-01Miguel Angel Lopez NievesNo ratings yet

- Acoustic Panels PerforatedDocument6 pagesAcoustic Panels Perforatedviktor mickovskiNo ratings yet

- Contec Quiltec-I-Wipes TDSDocument2 pagesContec Quiltec-I-Wipes TDSKarina Rodriguez MattaNo ratings yet

- N° Descripcion Unidad Cantidad PrecioDocument2 pagesN° Descripcion Unidad Cantidad PrecioDaniel MendozaNo ratings yet

- PlastiforteDocument2 pagesPlastiforteDaniel MendozaNo ratings yet

- DENR-FMB - Price Monitoring SystemDocument2 pagesDENR-FMB - Price Monitoring SystemMarien MontecalvoNo ratings yet

- CIREX - Casting Tolerancies VDG P690Document4 pagesCIREX - Casting Tolerancies VDG P690sean jukesNo ratings yet

- PVC Insulated, and PVC Sheathed Cables With Fine-Stranded Copper Conductor YslyDocument5 pagesPVC Insulated, and PVC Sheathed Cables With Fine-Stranded Copper Conductor Yslyfonsek12No ratings yet

- SPK GS SMDocument61 pagesSPK GS SMZammet WolesNo ratings yet

- Sensitivity AnalysisDocument7 pagesSensitivity AnalysisChaitanya100% (1)

- ANALYSISDocument4 pagesANALYSISfrancis sebastian lagamayoNo ratings yet

- Manual Calc. of PressureDocument1 pageManual Calc. of PressureRio PutraNo ratings yet

- n07v K EngDocument1 pagen07v K EngJUANQUIREALNo ratings yet

- Plant FittingsDocument1 pagePlant Fittingsadnanmushtaqpa00416No ratings yet

- Cuadro de Cargas Circuito Capacidad ConductorDocument2 pagesCuadro de Cargas Circuito Capacidad ConductorCarlos CcañaNo ratings yet

- Bill of Materials For Plumbing WorksDocument4 pagesBill of Materials For Plumbing WorksKaren TyNo ratings yet

- Dosh 2nd Edition First Aid KitDocument2 pagesDosh 2nd Edition First Aid Kitscrib madNo ratings yet

- Martini-DataSheet-Absorb 0421 v1Document5 pagesMartini-DataSheet-Absorb 0421 v1lac ngoNo ratings yet

- Calculo de Flete TerrestreDocument3 pagesCalculo de Flete TerrestreRonie Velasque roblesNo ratings yet

- Report StrutsDocument15 pagesReport Strutsfazlin natasyaNo ratings yet

- Isometric ProjectionsDocument8 pagesIsometric Projectionskartik.doye2005No ratings yet

- Cass AassDocument4 pagesCass AassSurya LatifNo ratings yet

- Unicon Bid-W CosttDocument2 pagesUnicon Bid-W CosttGilnert DayananNo ratings yet

- BassBox ProDocument3 pagesBassBox ProWildson FSONo ratings yet

- Tabel de Dimensionare Teava Pentru APA CALDA (Delta T 20 K)Document4 pagesTabel de Dimensionare Teava Pentru APA CALDA (Delta T 20 K)Unleashe12No ratings yet

- Frenzelit - Gasket Characteristics DIN 28090-1 Novatec PREMIUM IIDocument1 pageFrenzelit - Gasket Characteristics DIN 28090-1 Novatec PREMIUM IIRuben PauwelsNo ratings yet

- Aucr2013 PDFDocument21 pagesAucr2013 PDFjenidaniNo ratings yet

- Enable Support For Other File Formats, Such As PDF and XPSDocument2 pagesEnable Support For Other File Formats, Such As PDF and XPSErika KhasanahNo ratings yet

- CRCNetBase RU Library ListDocument309 pagesCRCNetBase RU Library ListHung TranNo ratings yet

- Maintenance & Safety: On-Campus ENGG C242 PB Venkataraman 5. Maintenance ProcessesDocument6 pagesMaintenance & Safety: On-Campus ENGG C242 PB Venkataraman 5. Maintenance ProcessesShafi AsafaliNo ratings yet

- Network PlanningDocument59 pagesNetwork PlanningVignesh ManickamNo ratings yet

- DMR 25 NIL3N-5 6 Feb 2017 PDFDocument4 pagesDMR 25 NIL3N-5 6 Feb 2017 PDFFrambia Rachmat0% (1)

- CMMS2Document80 pagesCMMS2Mahmoud GamalNo ratings yet

- Hse Company ProfileDocument4 pagesHse Company Profileeng_waleed200850% (2)

- Lesson 1 (Fundamentals of DBMS) PDFDocument30 pagesLesson 1 (Fundamentals of DBMS) PDFLingerfaith Mayor MoralesNo ratings yet

- C-Class Operator's ManualDocument398 pagesC-Class Operator's ManualPet UrNo ratings yet

- Role of Information Technology in ProcurementDocument33 pagesRole of Information Technology in ProcurementNEMON MSIGWA71% (7)

- Acetic Acid ProductionDocument3 pagesAcetic Acid ProductionRojan PradhanNo ratings yet

- H28 2aDocument49 pagesH28 2ajwsiglerNo ratings yet

- TAX105 - TAX - 105C-Input Tax 2Document1 pageTAX105 - TAX - 105C-Input Tax 2Mae CarcidoNo ratings yet

- Vocational Training ReportDocument68 pagesVocational Training ReportNamishaAgarwalNo ratings yet

- Software Development Life Cycle - An OverviewDocument15 pagesSoftware Development Life Cycle - An OverviewPratap K J100% (2)

- Sta Clara Power Brouchure Feb 2012Document10 pagesSta Clara Power Brouchure Feb 2012Jess Sibal100% (1)

- SQL Server DBA Interview QuestionsDocument3 pagesSQL Server DBA Interview Questionsjeffa123100% (1)

- Ansal - Oracle Impl DraftDocument43 pagesAnsal - Oracle Impl Draftnitingupta11066No ratings yet

- Manitou CBC Constructiebak - Feyter Forklift ServicesDocument1 pageManitou CBC Constructiebak - Feyter Forklift ServicesJavier Martinez RamirezNo ratings yet

- Fly Ash Building BricksDocument12 pagesFly Ash Building BricksAnonymous g1LSaA100% (1)

- 10 Series CNC OSAI Programming Manual (Rev 18 - 4457k)Document587 pages10 Series CNC OSAI Programming Manual (Rev 18 - 4457k)kwood94xjNo ratings yet

- Final-POM-tham khảoDocument2 pagesFinal-POM-tham khảoNganNo ratings yet

- DQF 126520-1 (Er)Document37 pagesDQF 126520-1 (Er)rob.macgregorNo ratings yet

- 2015 Global State of Information Security SurveyDocument8 pages2015 Global State of Information Security SurveyIDG_WorldNo ratings yet

- Amit Sharma Tata MotorsDocument86 pagesAmit Sharma Tata MotorsSami Zama0% (1)

- NEST - Solar Power Plants - An IntroductionDocument7 pagesNEST - Solar Power Plants - An IntroductionRohit Raj RanganathanNo ratings yet

- EASA Guidance Material For PBNDocument21 pagesEASA Guidance Material For PBNPedro Vitor100% (1)

- What Is Properties in SoapUIDocument19 pagesWhat Is Properties in SoapUISai KrishnaNo ratings yet