Professional Documents

Culture Documents

767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07

767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07

Uploaded by

samyghallabOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07

767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07

Uploaded by

samyghallabCopyright:

Available Formats

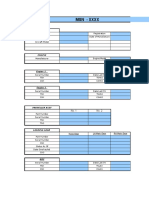

B767 48 HOUR SERVICE CHECK (Elapsed Time) (GE Powered A/C)

NOTE: For ETOPS flights this check must be accomplished by ETOPS authorised person

Aircraft Operator: TUI-NL Registration

AMP: BAL/BOE/6/TFL Date

Station

Form Revision Date: 10th February 2017 Performed IAW AMM Revision

ITEM

TASK DESCRIPTION MECH / INSP

NO.

1. ETOPS Check Left IDG oil level IAW AMM 12-13-03 and service as necessary (MPD 24-001-00)

2. ETOPS Check Right IDG oil level IAW AMM 12-13-03 and service as necessary (MPD 24-001-00)

ETOPS Check L Integrated Drive Generator (IDG) Scavenge Filter Pressure Differential Indicator

3.

IAW AMM 24-11-02 (MPD 24-001-02)

ETOPS Check R Integrated Drive Generator (IDG) Scavenge Filter Pressure Differential Indicator

4.

IAW AMM 24-11-02 (MPD 24-001-02)

Visually check the tail skid low pressure pop-up indicator. If the indicator is extended and shows a

5. red outside diameter, then the shock strut needs to be serviced per AMM 12-15-05/301.

(MPD 32-040-00)

ETOPS Operationally check the Hydraulic Motor Generator (HMG) IAW AMM 24-25-00 or Ops

6. Manual Part B – Supplementary Procedures – Electrical, Hydraulic Generator Test.

Note: Applicable to Airplanes with HMG. (MPD 24-013-00)

Carry out Standby Power Operational long test IAW AMM 24-33-00 page block 600. This task

7. satisfies the requirements of Certification Maintenance Requirement 24-33-00-6A.

(MPD 24-010-00, 24-010-02)

Check passenger service units, passenger seats and seat belts for obvious defects and cleanliness

8. and lifejackets in stowage IAW AMM 25-05-03. Check child and spare life jackets in stowages. (MPD

25-003-00)

Inspect toilet compartments :

ITEMS INSPECTION REQUIREMENTS

All Waste Receptacles Check no damage or distortion & correctly stowed.

All waste receptacle enclosure access doors & Check for proper operation, correct spring and sealing, correct

disposal doors & all self-closing entry flaps. fitment & latching, for containment of possible fire.

Check for wear & condition.

Check sealing strips for security & condition.

9. Check all debris removed & receptacle is clean.

Ashtrays inside & outside compartment. Check ashtrays are fitted & secured.

Placards “NO SMOKING” Check placards are fitted to each side of each lavatory door.

“NO CIGARETTE DISPOSAL” Check placards for clarity & security.

Toilet floor covering. Check for security, condition & no spillage.

Fire extinguisher bottle. Check Eutectic solder intact, security of attachment.

Check fire extinguisher temp indicator intact.

Note: Inspection in accordance with this form ensures compliance with FAA AD 74-08-09. (MPD 25-

006-00)

FORM No: 767-05-20-04/TFL – Issue 07 - Page 1 of 3

B767 48 HOUR SERVICE CHECK (Elapsed Time) (GE Powered A/C)

NOTE: For ETOPS flights this check must be accomplished by ETOPS authorised person

Visually check the Fwd/Aft & Bulk Cargo Compartment Lining to verify integrity of compartment

10.

sealing and fire suppression nozzles are free from obstruction.

11. Check emergency exits are secure.

12. Carry out a physical inspection of infant life valise for seal/tag attachment.

Operationally check AFOLTS IAW AMM task 26-10-00-716-019.

13.

NOTE: Certification Maintenance Requirement 26-10-00-6A. (MPD 26-015-00)

14. Carry out a self-test of the lavatory smoke detector system IAW AMM 26-13-00.

Squib Test Eng, APU, Cargo and Emergency Escape (If Installed) on squib test control panel IAW

15.

AMM 26-21-04. (MPD 26-021-02)

Perform a readout of all EICAS Maintenance Messages by pressing the ECS/MSG display select

16. switch. IAW AMM 31-41-00, p.b.201.

NOTE: Certification Maintenance Requirement 31-41-00-2A. (MPD 31-007-00).

Perform Operational check of CVR IAW AMM 23-71-00.

17.

Ref ED Decision 2015/021/R

Clean the exposed chrome surface on the inner cylinder of the left main landing gear with a cloth

18.

soaked with shock strut fluid.

Clean the exposed chrome surface on the inner cylinder of the right main landing gear with a cloth

19.

soaked with shock strut fluid.

Clean the exposed chrome surface on the inner cylinder of the nose gear with a cloth soaked with

20.

shock strut fluid.

21. Clean the rod end seal area of the nose gear retract actuator with isopropyl alcohol.

1. Visually inspect Left Main Gear Brakes, with parking brake set, for wear, leaks, security and

condition IAW AMM 32-41-08. (MPD 32-024-00).

22.

2. Visually inspect Right Main Gear Brakes, with parking brake set, for wear, leaks, security and

condition IAW AMM 32-41-08. (MPD 32-024-00).

Perform tyre pressure check IAW AMM 12-15-03 and ensure tyre pressures are within the

following limits: (MPD 32-029-02, 32-030-00)

MAIN MAX: 215 PSI NOSE MAX: 177 PSI

MIN : 210 PSI MIN : 172 PSI

23.

If tyre pressure is found outside limits, rectify per AMM 12-15-03.

NOTES: 1. FAA AD-87-08-09: INFLATE TYRES WITH DRY NITROGEN ONLY.

2. Tyre pressures were found using the applicable tyre part number and Pressure Limit

Charts in AMM 12-15-03 and the MAX TAX WEIGHT in AFM.

3. Inflation pressures shown are cold loaded pressures.

4. Tyres on the same axle must be inflated to the same pressure.

FORM No: 767-05-20-04/TFL – Issue 07 - Page 2 of 3

B767 48 HOUR SERVICE CHECK (Elapsed Time) (GE Powered A/C)

NOTE: For ETOPS flights this check must be accomplished by ETOPS authorised person

24. Check all navigation, wing position, wing/body and anti-collision lights for operation and condition.

Check emergency lights, exit lights and floor proximity lighting for operation, condition and security

25.

IAW AMM 33-51-00.

Check crew oxygen pressure on EICAS, ensure above 1000 psi. Raise ADD if pressure is below

26.

1000 psi.

27. Visually inspect the condition of the bulk cargo door seals and installation.

28. Visually inspect the condition of the lower lobe forward and aft cargo door seals and installation.

29. Check door girt bar areas for cleanliness.

General Visual – External Inspection: Entry and Galley Service Doors IAW AMM 52-05-03. (As

30. viewed from ground)

(MPD 52-414-00)

Functionally test the flight deck door security lock as follows:

NOTE: Applicable to aircraft incorporating SB 767-25-0325 or 767-25-0327 or 767-25-0332

1. With the Flight deck door open, set Flight Deck Access System (FDAS) switch, on the door

chime module to NORM, ensure keypad red LED is on.

2. Key in 123 ENT, on the keypad, and ensure that a continuous tone is heard, red keypad LED

goes out and amber LED illuminates.

3. Ensure “AUTO-UNLK” light on the P5 panel is on.

4. Select DENY on the P5 panel and release, ensure “AUTO-UNLK” light goes off, and that the

31. amber LED on the keypad goes off, and the red LED comes on.

5. Enter flight deck, close the door, ensure it cannot be pushed open, ensure that no further tones

are heard for one minute.

6. Select “UNLCKED” ensure a click is heard from the door solenoid, release the door switch.

7. Rotate door handle and open the door, key in 123 ENT and ensure that the following sequence

occurs: a continuous tone is heard for 30 seconds with flashing “AUTO-UNLK” light. After tone,

ensure door solenoid energises for 5 seconds and green keypad LED is on. After 5 seconds

green LED goes out and solenoid relaxes.

8. Set Chime module FDAS switch to off, ensure lock fail light (P5) comes on.

ETOPS For the planned flight/series of flights; Review Aircraft Status Sheets for RVSM and repair

32. interval compliance. Ensure adequate hours/cycles/calendar time remains on all Out of Phase

inspections.

33. Ensure the Aircraft Techlog reflects the “OPEN ADD” items per latest AMOS “ADD-Report”.

Ensure that all cabin safety and MEL related deferred defect categories A, B, C and D are

34.

transferred to the AFL.

35. Certify 48 hour Service Check in the Technical Log.

……END……

FORM No: 767-05-20-04/TFL – Issue 07 - Page 3 of 3

You might also like

- 7000XR Full Flight Simulator: Instructor User GuideDocument378 pages7000XR Full Flight Simulator: Instructor User Guidetubbykaka100% (1)

- Airbus ISI IN-SERVICE RELIABILITY DATA REPORTINGDocument26 pagesAirbus ISI IN-SERVICE RELIABILITY DATA REPORTINGandrinjoNo ratings yet

- Tcaa FeesDocument7 pagesTcaa FeesSPACELINK AERO SERVICESNo ratings yet

- ETOPS Maintenance, Planning and StoresDocument69 pagesETOPS Maintenance, Planning and StoresEduardo RuizNo ratings yet

- Foca Gm/Info: Ground Operations Manual (GOM)Document7 pagesFoca Gm/Info: Ground Operations Manual (GOM)Dav DegoevNo ratings yet

- Pre-Flight / Transit Check: AIRBUS A320-214 & A320-232 Maintenance Check ListDocument5 pagesPre-Flight / Transit Check: AIRBUS A320-214 & A320-232 Maintenance Check ListLandy FebriansyahNo ratings yet

- CRJ Pre - After Flight ChecklistDocument4 pagesCRJ Pre - After Flight ChecklistCHIMONo ratings yet

- King Air 350i ChecklistDocument3 pagesKing Air 350i ChecklistEnmanuel Peña HaddadNo ratings yet

- DC9/MD80 PWJT8 Maintenance Practice Training Manual B1 or B1/B2 LEVELDocument32 pagesDC9/MD80 PWJT8 Maintenance Practice Training Manual B1 or B1/B2 LEVELBRAIYAM ALEXANDER MORENO VARGAS100% (1)

- Bengaluru To Varanasi BLR 17:45 VNS 20:15: Paytm Order ID: 3199688279Document2 pagesBengaluru To Varanasi BLR 17:45 VNS 20:15: Paytm Order ID: 3199688279sujeet_hatNo ratings yet

- Airbus Carbon BrakesDocument10 pagesAirbus Carbon Brakesmicrocera100% (3)

- 767-05-20-02 B767 PRE FLIGHT CHECK Iss 22Document2 pages767-05-20-02 B767 PRE FLIGHT CHECK Iss 22samyghallabNo ratings yet

- 767-05-20-08-TFL B767 125 HOUR SERVICE CHECK (FLIGHT HOURS) TFL (Iss 07)Document2 pages767-05-20-08-TFL B767 125 HOUR SERVICE CHECK (FLIGHT HOURS) TFL (Iss 07)samyghallabNo ratings yet

- Transit Pre Flight Task Card AirbusDocument8 pagesTransit Pre Flight Task Card AirbusAbhijeet ChinchaneNo ratings yet

- Ruge CF6Document168 pagesRuge CF6Daniel LopezNo ratings yet

- 767-1501-Part B - Kit ListDocument3 pages767-1501-Part B - Kit ListsamyghallabNo ratings yet

- 14 31-41 EicasDocument26 pages14 31-41 EicasAndres Aldunate QuezadaNo ratings yet

- FD RT 4 - Basic Performance HandbookDocument51 pagesFD RT 4 - Basic Performance Handbooksidsharma31No ratings yet

- 90-02-15 FaaDocument2 pages90-02-15 FaaJoan MontesNo ratings yet

- infoETOPS PDFDocument4 pagesinfoETOPS PDFhaider551No ratings yet

- Facom Catalogue Aircraft Maintenace Tools 2014 enDocument60 pagesFacom Catalogue Aircraft Maintenace Tools 2014 enKrassin Petrov0% (1)

- Ito-Ip Rnav AppDocument277 pagesIto-Ip Rnav AppaleNo ratings yet

- 767F Product Card 09Document4 pages767F Product Card 09Kishor KituNo ratings yet

- B777 CB ListDocument9 pagesB777 CB ListfiratakinkouNo ratings yet

- MP B737-800 Rev10 Approved 16 August 2021Document1,064 pagesMP B737-800 Rev10 Approved 16 August 2021renzo tonetNo ratings yet

- CTC 504A AnswerbookDocument79 pagesCTC 504A AnswerbookErichCastrejónRodriguezNo ratings yet

- Mel Boeing 767 PDFDocument818 pagesMel Boeing 767 PDFEddy JhetNo ratings yet

- SB 174080-35-04 - Rev 000 - B E AErospaceDocument8 pagesSB 174080-35-04 - Rev 000 - B E AErospacehf8wdg8mmmNo ratings yet

- Fleet Strategy: Investor Day 2007 Frankfurt, January 25, 2007Document29 pagesFleet Strategy: Investor Day 2007 Frankfurt, January 25, 2007cengiz072428951No ratings yet

- Ata 21 TrsonDocument160 pagesAta 21 TrsonTam Ho100% (1)

- VA Rolls RoyceDocument11 pagesVA Rolls RoyceViệt Vớ VẩnNo ratings yet

- Company Procedure Checpoint MNSDocument7 pagesCompany Procedure Checpoint MNSمحمد هافيزيNo ratings yet

- 71-00-00-710-006-B - Minimum Idle CheckDocument6 pages71-00-00-710-006-B - Minimum Idle CheckEder LucianoNo ratings yet

- AC - 20-97B - CHG - 1 - Aircraft Tire Maintenance and Operarional PracticesDocument12 pagesAC - 20-97B - CHG - 1 - Aircraft Tire Maintenance and Operarional PracticesUjang SetiawanNo ratings yet

- Module 5: Digital Techniques and Electronic Instrument SystemsDocument81 pagesModule 5: Digital Techniques and Electronic Instrument SystemsNaseer AbdaljabarNo ratings yet

- Aircraft CheckDocument14 pagesAircraft CheckJesús Márquez TrejoNo ratings yet

- Modul 31 LehrgangDocument1,278 pagesModul 31 LehrgangLuiz FerrazNo ratings yet

- CDL 319Document666 pagesCDL 319Jan kopáčekNo ratings yet

- SAFA Course A - B - CDocument257 pagesSAFA Course A - B - CamroushararaNo ratings yet

- SV PSPMDocument330 pagesSV PSPMCfs CaerosceneNo ratings yet

- Als Part 1 Variation 7.2Document5 pagesAls Part 1 Variation 7.2mnoorebsNo ratings yet

- Fast27 PDFDocument32 pagesFast27 PDFsudarshan111990No ratings yet

- Boeing 767 Reading LightsDocument1 pageBoeing 767 Reading Lightsjuanf490No ratings yet

- Service Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional InformationDocument11 pagesService Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional Informationa_sharafiehNo ratings yet

- ATA33 Lights: B737-600/700/800/900 (CFM56)Document201 pagesATA33 Lights: B737-600/700/800/900 (CFM56)d xhNo ratings yet

- RegulationDocument440 pagesRegulationHend GhanemNo ratings yet

- 757 RB211 TR Ops TS JobAidDocument22 pages757 RB211 TR Ops TS JobAidprzytul2007No ratings yet

- Eshaghbeigi Haghi/Mohammad MR (Adt) 14dec Arn AmsDocument3 pagesEshaghbeigi Haghi/Mohammad MR (Adt) 14dec Arn AmsAli ShahnaNo ratings yet

- Ata25 AirbusDocument308 pagesAta25 AirbusOliver BarrientosNo ratings yet

- Spurious "CAB PR EXCESS RESIDUAL PR" Due To Residual Pressure Switch 14WNDocument6 pagesSpurious "CAB PR EXCESS RESIDUAL PR" Due To Residual Pressure Switch 14WNHarryNo ratings yet

- UsjsjsDocument8 pagesUsjsjsKirito SeiyaNo ratings yet

- 8 Repair BasicsDocument66 pages8 Repair BasicsedvynwillisturbanosNo ratings yet

- 747 400 61Document4 pages747 400 61almraNo ratings yet

- Ee6900 Fms 07 DatabasesDocument56 pagesEe6900 Fms 07 Databasesforumid2697100% (1)

- KLSMMDocument15 pagesKLSMMSudheesh Sudhakaran Nair100% (1)

- Ea 767 31-002 Eicas Upgrade Ops6 PDFDocument5 pagesEa 767 31-002 Eicas Upgrade Ops6 PDFjuanf490No ratings yet

- The Economics of Using Repaired & Serviceable Parts in Engine MaintenanceDocument8 pagesThe Economics of Using Repaired & Serviceable Parts in Engine MaintenanceAsier EulateNo ratings yet

- 74 L3 Oct07 XDocument20 pages74 L3 Oct07 XJimmy HaddadNo ratings yet

- Single Aisle Technical Training Manual RAMP & TRANSIT COURSE - M03 (CFM 56) (Level 2&3) Equipment/FurnishingsDocument60 pagesSingle Aisle Technical Training Manual RAMP & TRANSIT COURSE - M03 (CFM 56) (Level 2&3) Equipment/Furnishingsmarshall100% (1)

- VAA Maintenance 1 - Examination - Ktra TH C HànhDocument11 pagesVAA Maintenance 1 - Examination - Ktra TH C HànhMinh Ngọc LêNo ratings yet

- A321 Fixed EFB - Laptop Install.Document9 pagesA321 Fixed EFB - Laptop Install.Russ HoweNo ratings yet

- B-777 Rev 23Document353 pagesB-777 Rev 23red wolffishNo ratings yet

- Ejamf Fundamentals: Gas Turbine Engine/Air Inlet 15.03Document40 pagesEjamf Fundamentals: Gas Turbine Engine/Air Inlet 15.03w.b tdungNo ratings yet

- Air Conditioning ATA 21: Student Learning ObjectivesDocument115 pagesAir Conditioning ATA 21: Student Learning ObjectivesBelisario Sergio Llacchas rodasNo ratings yet

- AHM560 ATR-45 46Y KrasAvia 1.4 28.06.2023Document31 pagesAHM560 ATR-45 46Y KrasAvia 1.4 28.06.2023LuckyTigerNo ratings yet

- Druck PTX1400Document4 pagesDruck PTX1400samyghallabNo ratings yet

- Druck Dpi261Document5 pagesDruck Dpi261samyghallabNo ratings yet

- M85049 38 9W Amphenol 1158036Document12 pagesM85049 38 9W Amphenol 1158036samyghallabNo ratings yet

- RadiallDocument67 pagesRadiallsamyghallabNo ratings yet

- Arinc 600 SeriesDocument48 pagesArinc 600 SeriessamyghallabNo ratings yet

- BKAD 17augDocument19 pagesBKAD 17augsamyghallabNo ratings yet

- 767-1501-Part B - Kit ListDocument3 pages767-1501-Part B - Kit ListsamyghallabNo ratings yet

- 737-05-20-04-JT - 48 HRS Iss 01 Rev 02Document3 pages737-05-20-04-JT - 48 HRS Iss 01 Rev 02samyghallabNo ratings yet

- 757-05-20-07.iss2. POST MAINTENANCE CHECK FORMDocument2 pages757-05-20-07.iss2. POST MAINTENANCE CHECK FORMsamyghallabNo ratings yet

- 737-35-21-04 Iss 4Document2 pages737-35-21-04 Iss 4samyghallabNo ratings yet

- 767-05-20-07 POST MAINTENANCE CHECK FORM - Iss3Document2 pages767-05-20-07 POST MAINTENANCE CHECK FORM - Iss3samyghallabNo ratings yet

- 767-05-20-08-TFL B767 125 HOUR SERVICE CHECK (FLIGHT HOURS) TFL (Iss 07)Document2 pages767-05-20-08-TFL B767 125 HOUR SERVICE CHECK (FLIGHT HOURS) TFL (Iss 07)samyghallabNo ratings yet

- 737-05-20-02-NG - PRE FLIGHT Iss 13Document2 pages737-05-20-02-NG - PRE FLIGHT Iss 13samyghallabNo ratings yet

- 131-9B Discrepancy SheetDocument2 pages131-9B Discrepancy SheetsamyghallabNo ratings yet

- Case Study 39 Airbus vs. Boeing: Prepared byDocument13 pagesCase Study 39 Airbus vs. Boeing: Prepared byShakir EbrahimiNo ratings yet

- WASP Newsletter 01/01/67Document12 pagesWASP Newsletter 01/01/67CAP History LibraryNo ratings yet

- IATA Training CatalogDocument56 pagesIATA Training CatalogIbaad AhmedNo ratings yet

- Nigeria - CARS-Part-21Document95 pagesNigeria - CARS-Part-21Olusola OgunyemiNo ratings yet

- 11 - Power Plant - Identification Cfm56-3Document8 pages11 - Power Plant - Identification Cfm56-3Diego Alex Gomez PerezNo ratings yet

- Be 200 Pilot's Training Manual JLPDocument372 pagesBe 200 Pilot's Training Manual JLPAviacion Jlp100% (1)

- UFMC 2.8 User Manual PDFDocument173 pagesUFMC 2.8 User Manual PDFDario CastiglianoNo ratings yet

- C400 PohDocument161 pagesC400 PohMichael TenenbaumNo ratings yet

- FAA Order 8150 1D PDFDocument64 pagesFAA Order 8150 1D PDFdanoNo ratings yet

- 4040 26BDocument39 pages4040 26BSergio RomeroNo ratings yet

- Hindustan Aeronautics LimitedDocument9 pagesHindustan Aeronautics LimitedIshaan SoodNo ratings yet

- Anshum Kundra Pgp20101042 Kingfisher AirlinesDocument6 pagesAnshum Kundra Pgp20101042 Kingfisher AirlinesSwarnima JaiswalNo ratings yet

- Case Study 1 HFDocument7 pagesCase Study 1 HFAdib Naufal NasrullahNo ratings yet

- Advisory Circular: U.S. Department of TransportationDocument56 pagesAdvisory Circular: U.S. Department of TransportationOfelia Umpire RuizNo ratings yet

- AS321 GroundDocument25 pagesAS321 GroundEdgar ChavezNo ratings yet

- Adventure Awaits...... : MauleDocument10 pagesAdventure Awaits...... : MauleCarlos Calls MXNo ratings yet

- A Review of Morphing WingDocument7 pagesA Review of Morphing WingSuresh KumarsskNo ratings yet

- F-35 Program Lightning II Fast FactsDocument2 pagesF-35 Program Lightning II Fast FactsOlivier SNo ratings yet

- Airbus A319 A320 A321 Flight Crew Operating Manual FCOM VOL 3Document1,670 pagesAirbus A319 A320 A321 Flight Crew Operating Manual FCOM VOL 3Swapnil kapadia75% (4)

- ADS-B For Dummies-1090ES v04Document25 pagesADS-B For Dummies-1090ES v04justfrens80% (5)

- Storm Shadow DsDocument2 pagesStorm Shadow Dswildfire142100% (1)

- Baseline Geometry CFD ValidationDocument6 pagesBaseline Geometry CFD ValidationKarthikeya SrivathsavNo ratings yet

- Ground Effect - Alex WuDocument16 pagesGround Effect - Alex WuAmirAli MohebbiNo ratings yet