Professional Documents

Culture Documents

Life of A Plastic Bottle Infographic

Life of A Plastic Bottle Infographic

Uploaded by

Thilina KavindaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Life of A Plastic Bottle Infographic

Life of A Plastic Bottle Infographic

Uploaded by

Thilina KavindaCopyright:

Available Formats

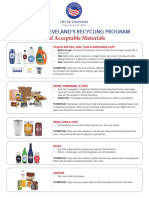

the life cycle of a recycled bottle!

STAGE 1: USED BOTTLE STAGE 2: DIRTY PET FLAKES STAGE 3: CLEAN PET FLAKES

This process begins Used plastic bottles Whether it is with a float-sink

when you place an are shredded with a process or a washing line, the

empty bottle into a machine into tiny pieces, plastic flakes receive continuous

recycling bin. The called flakes. The flakes wash of water and detergent to

bottle is recovered at will be washed to help remove pieces of labels, caps,

a recycling facility and remove glue, paper, sand, germs, or dirt that might have

taken to a a plastic or other contaminants. been found in the dirty flakes.

reclaiming plant.

Plastic #1 is made of polyetheylene terephthalate, aka PETE,

PET, or polyester. It’s known for its strength, durability, barrier

properties, and ability to be formed into various shapes.

Plastic bottles are very recyclable! Recycling a plastic bottle uses

much less energy and natural resouces than making one from new

STAGE 6: NEW BOTTLE (virgin) materials, so remember to put your used bottles in the

recycling bin to help give them new life! STEP 4: RESIN PELLETS

The preform is heated up The clean flakes

again until the plastic is are then melted

soft enough to flow. Then down at a high

pressurized air pushes the

plastic out to the STAGE 5: PREFORM temperature and

formed into resin

edges of the mold, which Using high heat and pellets. At this

forms the plastic into the pressure, the resin pellets point, they could

shape of a bottle. The blow are melted down and be used to make

mold is cooled and it opens injected into a mold to all kinds of

up to release a create the “preform.” useful things.

brand new bottle.

You might also like

- Different Plastic Polymer Types PDFDocument2 pagesDifferent Plastic Polymer Types PDFMuhammad AhamadNo ratings yet

- Ense 015 - HW #2Document2 pagesEnse 015 - HW #2Shekinah AnonuevoNo ratings yet

- Plastic Codes and RecyclingDocument2 pagesPlastic Codes and RecyclingTruck DriverNo ratings yet

- PF TekDocument16 pagesPF Tekskeletor31No ratings yet

- Kawan Guni Recycling Handbook I-Park VersionDocument9 pagesKawan Guni Recycling Handbook I-Park Versionys.thenNo ratings yet

- Spore Study Head Shop Links Seeds Glorious Seeds: Del - Icio.us Digg Reddit Twitter FacebookDocument16 pagesSpore Study Head Shop Links Seeds Glorious Seeds: Del - Icio.us Digg Reddit Twitter FacebookAkkiNo ratings yet

- Plastics and PolymersDocument9 pagesPlastics and PolymersKharylle Ann IglesiasNo ratings yet

- Display Cards 1Document32 pagesDisplay Cards 1Sayyed Paras AliNo ratings yet

- Waste Lesson Plans and Tortola Waste Tour: Slides 1 - 45Document8 pagesWaste Lesson Plans and Tortola Waste Tour: Slides 1 - 45Alle LunagNo ratings yet

- PF BookletDocument24 pagesPF BookletImustaforgotNo ratings yet

- Plastic Waste Management - Selected Solutions and PossibilitiesDocument6 pagesPlastic Waste Management - Selected Solutions and PossibilitiesAnjuNo ratings yet

- How Paper Is Recycled: Adapted FromDocument5 pagesHow Paper Is Recycled: Adapted Fromarlynne97729523No ratings yet

- List of Acceptable Materials: Single Stream Material AcceptabilityDocument3 pagesList of Acceptable Materials: Single Stream Material AcceptabilityWKYC.comNo ratings yet

- Plastic Bottle Manufacturing Process.01Document6 pagesPlastic Bottle Manufacturing Process.01ScribdTranslationsNo ratings yet

- Chemistry of PolymersDocument21 pagesChemistry of PolymersSiya SamriddhiNo ratings yet

- Ichem LabDocument4 pagesIchem LabDiana BunaganNo ratings yet

- Trash Brochere-2Document3 pagesTrash Brochere-2api-357360413No ratings yet

- Preparation in Geotechnical Aspects of Landfill Design: Bicol University College of Engineering Legazpi CityDocument4 pagesPreparation in Geotechnical Aspects of Landfill Design: Bicol University College of Engineering Legazpi CityMa Ella Mae LogronioNo ratings yet

- Day 1Document5 pagesDay 1c5pqcqhznnNo ratings yet

- Mycology LabDocument11 pagesMycology Labnattadeloco100% (1)

- Botellas Pet: Collection SystemsDocument5 pagesBotellas Pet: Collection Systemsalcira socarrasNo ratings yet

- Recyclingfaqs FinalDocument2 pagesRecyclingfaqs Finalbfuodf fndsjbolfkNo ratings yet

- How Long Does It Take Garbage To DecomposeDocument6 pagesHow Long Does It Take Garbage To DecomposeToni IsbandiNo ratings yet

- Investment Proposal: PET Recycling To Bottle To Bottle: 1. Brief Description of ProjectDocument19 pagesInvestment Proposal: PET Recycling To Bottle To Bottle: 1. Brief Description of ProjectFerid HussenNo ratings yet

- Expt. No. 7 Plastics and PolymersDocument8 pagesExpt. No. 7 Plastics and PolymersJan Divrec CaballesNo ratings yet

- Activity 2.1 Kaleidoscope World Materials: For The Body of KaleidoscopeDocument1 pageActivity 2.1 Kaleidoscope World Materials: For The Body of KaleidoscopeMoises Von Rosauro De GraciaNo ratings yet

- A Step-By-Step Guide To Preparing A PF-TEKDocument6 pagesA Step-By-Step Guide To Preparing A PF-TEKesteban5No ratings yet

- Grade 5: First Quarter Grade 5 ScienceDocument20 pagesGrade 5: First Quarter Grade 5 SciencePrecious IdiosoloNo ratings yet

- Ecology ProblemsDocument6 pagesEcology ProblemsKAMSHATNo ratings yet

- REceta Llaveros Plstico Reducir PDFDocument3 pagesREceta Llaveros Plstico Reducir PDFJavier CoyotlNo ratings yet

- PLASTICPeople Classification and Preparation Guide SEP22Document17 pagesPLASTICPeople Classification and Preparation Guide SEP22tuan191184No ratings yet

- Homework AleDocument1 pageHomework AleAlexa Naydi León QuirozNo ratings yet

- Homework AleDocument1 pageHomework AleAlexa Naydi León QuirozNo ratings yet

- The Particulate Nature of MatterDocument5 pagesThe Particulate Nature of MatterStephanie AriasNo ratings yet

- A Demo A Week Makes Science Class The PeakDocument6 pagesA Demo A Week Makes Science Class The PeakPaul SchumannNo ratings yet

- EXAMPLE Information Page of PlasticsDocument1 pageEXAMPLE Information Page of Plasticsmissparish83630No ratings yet

- Recycling and Disposal Guide 2022Document20 pagesRecycling and Disposal Guide 2022ga6ba5No ratings yet

- Learning Activity Sheet in Science Quarter 1Document4 pagesLearning Activity Sheet in Science Quarter 1EDEN GELLANo ratings yet

- Recycle GuideDocument2 pagesRecycle Guidevgk.thinktankNo ratings yet

- PET RecyclingDocument3 pagesPET RecyclingRicardo RuizNo ratings yet

- Earth SciDocument1 pageEarth SciKetaks MooNo ratings yet

- Banana Peels To PaperDocument3 pagesBanana Peels To PaperAshley MNo ratings yet

- PROJECT TATVA FinalDocument19 pagesPROJECT TATVA FinalMuskan MukhiNo ratings yet

- Waste Plactics To Useful Petroleum ProductsDocument6 pagesWaste Plactics To Useful Petroleum ProductsNishant ChoubeyNo ratings yet

- How Long Does It Take Garbage To Decompose?: Plastic WasteDocument2 pagesHow Long Does It Take Garbage To Decompose?: Plastic WasteMuhammad AjiNo ratings yet

- Methods of Recycling PlasticsDocument4 pagesMethods of Recycling PlasticsNaixt CabudzNo ratings yet

- Recycled Chopping BoardDocument13 pagesRecycled Chopping BoardDejan RancicNo ratings yet

- Learning Activity 3 Evidence Recycling CampaignDocument1 pageLearning Activity 3 Evidence Recycling CampaignSonia Andrea Ruiz AlonsoNo ratings yet

- How Paper Is RecycledDocument4 pagesHow Paper Is Recycledsuzehanna87100% (1)

- Teese Directionsprintouts 1Document8 pagesTeese Directionsprintouts 1api-633883722No ratings yet

- G034 Water Sampling OnlineDocument16 pagesG034 Water Sampling Onlinemsvdocumentation29No ratings yet

- Exercise3 SciereportDocument16 pagesExercise3 SciereportNecka AmoloNo ratings yet

- Guia Born 2023 - Led EspDocument47 pagesGuia Born 2023 - Led EspDistribuidorIBoolPedregalDeSantoDomingoNo ratings yet

- Micropropagation at HomeDocument2 pagesMicropropagation at HomeDávid Péter BenkeNo ratings yet

- Common Types of PlasticsDocument8 pagesCommon Types of PlasticsAnis SyuhadaNo ratings yet

- CHEM181NOTES PolymersDocument4 pagesCHEM181NOTES PolymersLara Mae MirabuenoNo ratings yet

- Recycling Opportunities After The Pole ShiftDocument2 pagesRecycling Opportunities After The Pole ShiftZerotheoryNo ratings yet

- Science Around the House: Simple Projects Using Household RecyclablesFrom EverandScience Around the House: Simple Projects Using Household RecyclablesNo ratings yet

- Multiple Choice Questions and Short Answers:: Dps Modern Indian School Doha QatarDocument9 pagesMultiple Choice Questions and Short Answers:: Dps Modern Indian School Doha QatarAfridha Thamzeen A SNo ratings yet

- Soot Formation: Institut Ffir Physikalische Chemic Der Universiti T Gi Ttinoen, 3400 Gbttingen, West German)Document45 pagesSoot Formation: Institut Ffir Physikalische Chemic Der Universiti T Gi Ttinoen, 3400 Gbttingen, West German)MahmoudKamalElshazlyNo ratings yet

- (SiC-En-2013-22) Molding Compounds Adhesion and Influence On Reliability of Plastic Packages For SiC-Based Power MOS DevicesDocument13 pages(SiC-En-2013-22) Molding Compounds Adhesion and Influence On Reliability of Plastic Packages For SiC-Based Power MOS Devicesnuaa_qhhNo ratings yet

- Life Cycle Diagram - Siemens VelaroDocument1 pageLife Cycle Diagram - Siemens VelaroJobin PuthuparampilNo ratings yet

- Liquid Gold and Processes Within Our Bodies: Technology Workshop Craft Home Food Play Outside CostumesDocument6 pagesLiquid Gold and Processes Within Our Bodies: Technology Workshop Craft Home Food Play Outside Costumesx spaceNo ratings yet

- Calculated Moves: Physical Science Week 8 HandoutsDocument2 pagesCalculated Moves: Physical Science Week 8 HandoutsBenj Jamieson DuagNo ratings yet

- Ce-Séries Manual de Operação TK 60980-18-OP Rev 3 04-16Document274 pagesCe-Séries Manual de Operação TK 60980-18-OP Rev 3 04-16Электроника EletroeletrônicaNo ratings yet

- Nitric Acid 60 PR - Safety Data Sheet - EuropeDocument23 pagesNitric Acid 60 PR - Safety Data Sheet - EuropeevinNo ratings yet

- Centre of MassDocument32 pagesCentre of MassR.Yashwanth Raj XBNo ratings yet

- 1.2 Structure of The Earth and Its CompositionDocument20 pages1.2 Structure of The Earth and Its CompositionMa. Chatrina MalanogNo ratings yet

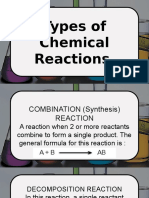

- Types of Chemical ReactionsDocument36 pagesTypes of Chemical ReactionsAira Villarin100% (3)

- Lagrange Equation PDFDocument5 pagesLagrange Equation PDFZyl Elumba-LlantoNo ratings yet

- Determination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and - Butanol in Gasoline by Infrared SpectrosDocument5 pagesDetermination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and - Butanol in Gasoline by Infrared SpectrosBryan PariNo ratings yet

- PVC Manufacturing Technology OverviewDocument31 pagesPVC Manufacturing Technology OverviewMujadid KhawajaNo ratings yet

- Installation and Operation Manual of 110kv TransformerDocument17 pagesInstallation and Operation Manual of 110kv TransformerПавел ПлескацевичNo ratings yet

- Experiment 3 ConclusionDocument2 pagesExperiment 3 ConclusionHamee Gomez100% (1)

- Cycles Multiple ChoiceDocument2 pagesCycles Multiple ChoiceFabriV9No ratings yet

- 99T00069Document4 pages99T00069Hamilton WilliamNo ratings yet

- Class 9 Science Annual Paper 2 Prince Public SchoolDocument3 pagesClass 9 Science Annual Paper 2 Prince Public SchoolSHAURYA VARDHANNo ratings yet

- Brochure Liquid Cylinders DOT 4LDocument8 pagesBrochure Liquid Cylinders DOT 4LShaheer TariqNo ratings yet

- Dimensional Analysis and Model AnalysisDocument43 pagesDimensional Analysis and Model Analysisjohn snowNo ratings yet

- Linde Lectures Munich 1Document39 pagesLinde Lectures Munich 1Flori Rodriguez HernandezNo ratings yet

- Calibrations and StandardizationDocument43 pagesCalibrations and StandardizationWaleed El-azabNo ratings yet

- Hill 1979 Bound Watr in Shaly Sands Its Relation To QV and Other Formation PropertiesDocument17 pagesHill 1979 Bound Watr in Shaly Sands Its Relation To QV and Other Formation PropertiesBurak BulutNo ratings yet

- Bossard VDI 2230 Friction 2021.05Document1 pageBossard VDI 2230 Friction 2021.05gielNo ratings yet

- Rr411801 Electrometallurgy and CorrosionDocument7 pagesRr411801 Electrometallurgy and CorrosionSrinivasa Rao GNo ratings yet

- Class Five Part OneDocument149 pagesClass Five Part Onezhs2qxyz9qNo ratings yet

- Comparison MS CND Cyanide DestructionDocument7 pagesComparison MS CND Cyanide DestructionBrent WoottonNo ratings yet

- Graduation ProjectDocument18 pagesGraduation Projectmohamed moradNo ratings yet

- FluidDocument4 pagesFluidt5qhpc2ck9No ratings yet