Professional Documents

Culture Documents

Risk Management

Risk Management

Uploaded by

ansarmulla711Copyright:

Available Formats

You might also like

- Computed Radiography Procedure (CRT)Document15 pagesComputed Radiography Procedure (CRT)Trung Tinh Ho100% (8)

- Astm D8184 - 18Document7 pagesAstm D8184 - 18mancja100% (3)

- PAUT & TOFD Procedure For EOL, Vadinar PDFDocument40 pagesPAUT & TOFD Procedure For EOL, Vadinar PDFrupam100% (6)

- RT Procedure Rev01EDocument20 pagesRT Procedure Rev01ETrương Ngọc SơnNo ratings yet

- Engineering Spec For Positive Material IdentificationDocument8 pagesEngineering Spec For Positive Material Identificationcancerian86100% (1)

- TM0106 2016 Detection Testing andDocument36 pagesTM0106 2016 Detection Testing andiTuan Khai Truong100% (4)

- RT Asme B31 3 2014Document20 pagesRT Asme B31 3 2014Shanmuga Navaneethan0% (1)

- Industrial Radiography Safety ProcedureDocument22 pagesIndustrial Radiography Safety ProcedureEswaranNo ratings yet

- Magnetic Particle Test Procedure Magnetic Particle Test Procedure MTDocument14 pagesMagnetic Particle Test Procedure Magnetic Particle Test Procedure MTsamer8saif100% (3)

- RT ProcedureDocument33 pagesRT Procedurenathgsurendra100% (2)

- Radiographic Examination Procedure TP-NDT-0001-00Document28 pagesRadiographic Examination Procedure TP-NDT-0001-00wassimwalha2016No ratings yet

- Procedure: R E A (P) LDocument19 pagesProcedure: R E A (P) LPramod GrNo ratings yet

- I-2.52-E Ultrasonic ProcedureDocument35 pagesI-2.52-E Ultrasonic ProcedureMohanadNo ratings yet

- Method of Statement For Current Transformer: Owner/Client Owner'S Engineer ContractorDocument9 pagesMethod of Statement For Current Transformer: Owner/Client Owner'S Engineer ContractorPandrayar MaruthuNo ratings yet

- BIX - RT ProcedureDocument36 pagesBIX - RT ProcedureEduard Abastillas100% (1)

- Method Statement For Testing & Commissioning of Fire Alarm SystemDocument10 pagesMethod Statement For Testing & Commissioning of Fire Alarm Systemanver.yusifNo ratings yet

- Ndt-Opr-003 2.0Document22 pagesNdt-Opr-003 2.0Iwan F Simbolon100% (3)

- Tec SD RS QMS 333 02 Mar 10Document59 pagesTec SD RS QMS 333 02 Mar 10Santhakrishnan AdhinarayananNo ratings yet

- Welding Control ProcedureDocument18 pagesWelding Control ProceduresumitNo ratings yet

- Material Verifications Program - VA21008Document14 pagesMaterial Verifications Program - VA21008alicia sambaiNo ratings yet

- TTA-NDT-PMI-001 Rev.00 PDFDocument8 pagesTTA-NDT-PMI-001 Rev.00 PDFTrịnh Quốc TuyếnNo ratings yet

- B Gas Examination RequirementsDocument25 pagesB Gas Examination RequirementsNnamdi Celestine Nnamdi100% (1)

- Hardness Testing Rev 00Document8 pagesHardness Testing Rev 00muslim100% (1)

- MS-Hazard Materials WorksDocument6 pagesMS-Hazard Materials Worksgafco.phNo ratings yet

- A Sample: Ultrasonic Inspection ProcedureDocument5 pagesA Sample: Ultrasonic Inspection ProcedureMark BrailsfordNo ratings yet

- D8184-18e1-PQ ASTMDocument7 pagesD8184-18e1-PQ ASTMyulfanNo ratings yet

- 10.400.412 General Inspection ProcedureDocument12 pages10.400.412 General Inspection ProcedureedwinsazzzNo ratings yet

- NDT Facility - Magnetic Particle Testing (AC7114 - 2) Checklist - SafetyCultureDocument37 pagesNDT Facility - Magnetic Particle Testing (AC7114 - 2) Checklist - SafetyCulturevalentinNo ratings yet

- Procedure For Magnetic Particle Testing: Ramachal NDT ServicesDocument3 pagesProcedure For Magnetic Particle Testing: Ramachal NDT ServicesAman SarfarazNo ratings yet

- The Selection, Training and Qualification of Nondestructive Assay (NDA) PersonnelDocument3 pagesThe Selection, Training and Qualification of Nondestructive Assay (NDA) Personnelasemamaw damtieNo ratings yet

- OkDocument14 pagesOkresp-ectNo ratings yet

- Petronas Technical Standard (PTS 50.014)Document20 pagesPetronas Technical Standard (PTS 50.014)Kellary Liaw Nyuk Chin100% (2)

- Positive Material Identification (Pmi)Document2 pagesPositive Material Identification (Pmi)MurugadossRajendranNo ratings yet

- Saep 1146Document8 pagesSaep 1146Ronanki RaviNo ratings yet

- 1101 - 1 Procedure For Radiography Rev 1 Dt.19!04!2017 ZORDocument72 pages1101 - 1 Procedure For Radiography Rev 1 Dt.19!04!2017 ZORnathgsurendraNo ratings yet

- CSWIP ISO NDT 11 93 R 8th Edition February 2016Document23 pagesCSWIP ISO NDT 11 93 R 8th Edition February 2016Brandon EricksonNo ratings yet

- MT Chapter-1 APPLICATION, TRAINING & CERTIFICATIONDocument15 pagesMT Chapter-1 APPLICATION, TRAINING & CERTIFICATIONhot boyNo ratings yet

- TUV SUD - MT Procedure Rev.05Document11 pagesTUV SUD - MT Procedure Rev.05HassanNo ratings yet

- NRRC SG 013Document17 pagesNRRC SG 013Ahmed shabanNo ratings yet

- JG-SC-003 NDTDocument10 pagesJG-SC-003 NDTarsil5840No ratings yet

- Visual Examination ProcedureDocument23 pagesVisual Examination ProcedureEdAlmNo ratings yet

- Hydro Test PipingDocument22 pagesHydro Test PipingBernardoNo ratings yet

- 네이버 블로그 - - 글 내용 PrintDocument12 pages네이버 블로그 - - 글 내용 Printoctgdrillstem.inspectionreportsNo ratings yet

- Internship Report On NDT Level 2Document34 pagesInternship Report On NDT Level 2Mohammed SafwanNo ratings yet

- NADCAP Audit Criteria For Nondestructive Testing Facility Magnetic Particle SurveyDocument20 pagesNADCAP Audit Criteria For Nondestructive Testing Facility Magnetic Particle SurveyAnonymous gFcnQ4go100% (1)

- QP-209-18 NDT ProcedureDocument80 pagesQP-209-18 NDT ProcedurewildanmuhammadnajmiNo ratings yet

- Nabl 122 15 PDFDocument14 pagesNabl 122 15 PDFmaheshNo ratings yet

- PMI Report May 2019Document19 pagesPMI Report May 2019RifanjshshNo ratings yet

- Process Piping Guide R2Document12 pagesProcess Piping Guide R2Edson Araga100% (1)

- WZSMS GMB P PR 012 (Non Destructive Test Proc)Document10 pagesWZSMS GMB P PR 012 (Non Destructive Test Proc)azliza msogNo ratings yet

- Ut Tky ProcedureDocument26 pagesUt Tky ProcedureguruNo ratings yet

- RT Film InterpretationDocument33 pagesRT Film InterpretationAdewale JamesNo ratings yet

- Radiographic Examination Procedure As Non Destructive Testing Method in Process PipingDocument9 pagesRadiographic Examination Procedure As Non Destructive Testing Method in Process Pipingdenira k3No ratings yet

- SGS IND NDT Training Consolidated China EN 10Document16 pagesSGS IND NDT Training Consolidated China EN 10mounir bonnoisNo ratings yet

- PMI ProcedureDocument7 pagesPMI ProcedureRoberto Carlos Arana ChumpitazNo ratings yet

- NRRC-SG-08-Application For Authorization of Radiation Dosimetry CalibrationDocument37 pagesNRRC-SG-08-Application For Authorization of Radiation Dosimetry CalibrationESTSS TrainingNo ratings yet

- NDT Sessional 1Document293 pagesNDT Sessional 1Prasen KumarNo ratings yet

- Inspection and Remaining Life Evaluation of Process Plant EquipmentDocument27 pagesInspection and Remaining Life Evaluation of Process Plant Equipmentabisat02100% (2)

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesFrom EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesNo ratings yet

- WPS-PQR Gr. WCBDocument9 pagesWPS-PQR Gr. WCBansarmulla711No ratings yet

- Res Irn Ris-Am-177Document1 pageRes Irn Ris-Am-177ansarmulla711No ratings yet

- WPS-PQR Gr. CF8MDocument9 pagesWPS-PQR Gr. CF8Mansarmulla711No ratings yet

- Training CardDocument9 pagesTraining Cardansarmulla711No ratings yet

- Visual Inspection Reports Format No. SKMF-F - 49Document3 pagesVisual Inspection Reports Format No. SKMF-F - 49ansarmulla711No ratings yet

- ISO Documents List 4Document1 pageISO Documents List 4ansarmulla711No ratings yet

- Supp. Rating FormDocument1 pageSupp. Rating Formansarmulla711No ratings yet

- Ut SKMF-F-38Document1 pageUt SKMF-F-38ansarmulla711No ratings yet

- Fir Ris-Am-116Document1 pageFir Ris-Am-116ansarmulla711No ratings yet

- Irn Ris-Am-158Document1 pageIrn Ris-Am-158ansarmulla711No ratings yet

- Fir Ris-Am-239Document1 pageFir Ris-Am-239ansarmulla711No ratings yet

- Sac26-27 MachanicalDocument5 pagesSac26-27 Machanicalansarmulla711No ratings yet

- Fir Ris-Am-242Document1 pageFir Ris-Am-242ansarmulla711No ratings yet

- Ris Am 128Document1 pageRis Am 128ansarmulla711No ratings yet

- Main Gate Visiter Instructions 1Document1 pageMain Gate Visiter Instructions 1ansarmulla711No ratings yet

- WPS CD3MNDocument8 pagesWPS CD3MNansarmulla711No ratings yet

- Ir# Am-127Document1 pageIr# Am-127ansarmulla711No ratings yet

- LK 40Document3 pagesLK 40ansarmulla711No ratings yet

- Ilovepdf MergedDocument2 pagesIlovepdf Mergedansarmulla711No ratings yet

- Ris Am 128Document1 pageRis Am 128ansarmulla711No ratings yet

- Ilovepdf MergedDocument2 pagesIlovepdf Mergedansarmulla711No ratings yet

- Adapter A4-122 New Doc 02-11-2024 16.02 - 3Document1 pageAdapter A4-122 New Doc 02-11-2024 16.02 - 3ansarmulla711No ratings yet

- Hazard Identification ChecklistDocument2 pagesHazard Identification Checklistansarmulla711No ratings yet

- Ris Am 129Document1 pageRis Am 129ansarmulla711No ratings yet

- Unit 2Document25 pagesUnit 2ansarmulla711No ratings yet

- New Doc 02-14-2024 17.21Document2 pagesNew Doc 02-14-2024 17.21ansarmulla711No ratings yet

Risk Management

Risk Management

Uploaded by

ansarmulla711Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Management

Risk Management

Uploaded by

ansarmulla711Copyright:

Available Formats

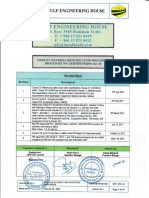

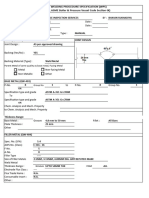

TEST PROCEDURE

MASTER FLOW

CONTROL Issue No./ Date Rev. No./Date

Doc. No. : MFC/TP-001 01/26.12.2023 00/26.12.2023

TITLE Positive Material Identification (PMI)

1.0 Scope

This procedure defines the minimum requirements for performing Positive Material Identification

(PMI) of stainless and alloy materials and welds.

2.0 Definition

Positive Material Identification (PMI) is the verification of materials (also weld materials) by the use

of analytical methods. X-ray fluorescence is the preferred method of PMI, however other methods

such as wet chemical analysis or spectrometry may be applied.

The Purpose of PMI, using mobile instruments is to establish that the correct material type is being

used, and to differentiate between grades of material such as 22% Cr and 25% Cr duplex steels. It

is not intended to be used for accurate chemical analysis or for the verification and confirmation of

material certification reported chemistry. Where an accurate chemical analysis is required, then a

wet test or spectrometry must be specified. These are destructive tests and cannot be used on

production components.

3.0 Qualification of testing personnel

Only suitably experienced personnel shall undertake PMI. There is currently no recognized international

qualification for PMI operators, so operators shall be trained according to equipment manufacturer's

recommendations.

Radiation risks and hazards exist in use of X-ray spectrometry. Local legal requirements related to use X-ray

spectrometer devices for radiation protection as well as the safety measured defined by the manufacturer of the

device have to be known, included in the operator training and followed.

MR PLANT HEAD TECHNICAL DIRECTOR

PREPARED REVIEWED APPROVED

You might also like

- Computed Radiography Procedure (CRT)Document15 pagesComputed Radiography Procedure (CRT)Trung Tinh Ho100% (8)

- Astm D8184 - 18Document7 pagesAstm D8184 - 18mancja100% (3)

- PAUT & TOFD Procedure For EOL, Vadinar PDFDocument40 pagesPAUT & TOFD Procedure For EOL, Vadinar PDFrupam100% (6)

- RT Procedure Rev01EDocument20 pagesRT Procedure Rev01ETrương Ngọc SơnNo ratings yet

- Engineering Spec For Positive Material IdentificationDocument8 pagesEngineering Spec For Positive Material Identificationcancerian86100% (1)

- TM0106 2016 Detection Testing andDocument36 pagesTM0106 2016 Detection Testing andiTuan Khai Truong100% (4)

- RT Asme B31 3 2014Document20 pagesRT Asme B31 3 2014Shanmuga Navaneethan0% (1)

- Industrial Radiography Safety ProcedureDocument22 pagesIndustrial Radiography Safety ProcedureEswaranNo ratings yet

- Magnetic Particle Test Procedure Magnetic Particle Test Procedure MTDocument14 pagesMagnetic Particle Test Procedure Magnetic Particle Test Procedure MTsamer8saif100% (3)

- RT ProcedureDocument33 pagesRT Procedurenathgsurendra100% (2)

- Radiographic Examination Procedure TP-NDT-0001-00Document28 pagesRadiographic Examination Procedure TP-NDT-0001-00wassimwalha2016No ratings yet

- Procedure: R E A (P) LDocument19 pagesProcedure: R E A (P) LPramod GrNo ratings yet

- I-2.52-E Ultrasonic ProcedureDocument35 pagesI-2.52-E Ultrasonic ProcedureMohanadNo ratings yet

- Method of Statement For Current Transformer: Owner/Client Owner'S Engineer ContractorDocument9 pagesMethod of Statement For Current Transformer: Owner/Client Owner'S Engineer ContractorPandrayar MaruthuNo ratings yet

- BIX - RT ProcedureDocument36 pagesBIX - RT ProcedureEduard Abastillas100% (1)

- Method Statement For Testing & Commissioning of Fire Alarm SystemDocument10 pagesMethod Statement For Testing & Commissioning of Fire Alarm Systemanver.yusifNo ratings yet

- Ndt-Opr-003 2.0Document22 pagesNdt-Opr-003 2.0Iwan F Simbolon100% (3)

- Tec SD RS QMS 333 02 Mar 10Document59 pagesTec SD RS QMS 333 02 Mar 10Santhakrishnan AdhinarayananNo ratings yet

- Welding Control ProcedureDocument18 pagesWelding Control ProceduresumitNo ratings yet

- Material Verifications Program - VA21008Document14 pagesMaterial Verifications Program - VA21008alicia sambaiNo ratings yet

- TTA-NDT-PMI-001 Rev.00 PDFDocument8 pagesTTA-NDT-PMI-001 Rev.00 PDFTrịnh Quốc TuyếnNo ratings yet

- B Gas Examination RequirementsDocument25 pagesB Gas Examination RequirementsNnamdi Celestine Nnamdi100% (1)

- Hardness Testing Rev 00Document8 pagesHardness Testing Rev 00muslim100% (1)

- MS-Hazard Materials WorksDocument6 pagesMS-Hazard Materials Worksgafco.phNo ratings yet

- A Sample: Ultrasonic Inspection ProcedureDocument5 pagesA Sample: Ultrasonic Inspection ProcedureMark BrailsfordNo ratings yet

- D8184-18e1-PQ ASTMDocument7 pagesD8184-18e1-PQ ASTMyulfanNo ratings yet

- 10.400.412 General Inspection ProcedureDocument12 pages10.400.412 General Inspection ProcedureedwinsazzzNo ratings yet

- NDT Facility - Magnetic Particle Testing (AC7114 - 2) Checklist - SafetyCultureDocument37 pagesNDT Facility - Magnetic Particle Testing (AC7114 - 2) Checklist - SafetyCulturevalentinNo ratings yet

- Procedure For Magnetic Particle Testing: Ramachal NDT ServicesDocument3 pagesProcedure For Magnetic Particle Testing: Ramachal NDT ServicesAman SarfarazNo ratings yet

- The Selection, Training and Qualification of Nondestructive Assay (NDA) PersonnelDocument3 pagesThe Selection, Training and Qualification of Nondestructive Assay (NDA) Personnelasemamaw damtieNo ratings yet

- OkDocument14 pagesOkresp-ectNo ratings yet

- Petronas Technical Standard (PTS 50.014)Document20 pagesPetronas Technical Standard (PTS 50.014)Kellary Liaw Nyuk Chin100% (2)

- Positive Material Identification (Pmi)Document2 pagesPositive Material Identification (Pmi)MurugadossRajendranNo ratings yet

- Saep 1146Document8 pagesSaep 1146Ronanki RaviNo ratings yet

- 1101 - 1 Procedure For Radiography Rev 1 Dt.19!04!2017 ZORDocument72 pages1101 - 1 Procedure For Radiography Rev 1 Dt.19!04!2017 ZORnathgsurendraNo ratings yet

- CSWIP ISO NDT 11 93 R 8th Edition February 2016Document23 pagesCSWIP ISO NDT 11 93 R 8th Edition February 2016Brandon EricksonNo ratings yet

- MT Chapter-1 APPLICATION, TRAINING & CERTIFICATIONDocument15 pagesMT Chapter-1 APPLICATION, TRAINING & CERTIFICATIONhot boyNo ratings yet

- TUV SUD - MT Procedure Rev.05Document11 pagesTUV SUD - MT Procedure Rev.05HassanNo ratings yet

- NRRC SG 013Document17 pagesNRRC SG 013Ahmed shabanNo ratings yet

- JG-SC-003 NDTDocument10 pagesJG-SC-003 NDTarsil5840No ratings yet

- Visual Examination ProcedureDocument23 pagesVisual Examination ProcedureEdAlmNo ratings yet

- Hydro Test PipingDocument22 pagesHydro Test PipingBernardoNo ratings yet

- 네이버 블로그 - - 글 내용 PrintDocument12 pages네이버 블로그 - - 글 내용 Printoctgdrillstem.inspectionreportsNo ratings yet

- Internship Report On NDT Level 2Document34 pagesInternship Report On NDT Level 2Mohammed SafwanNo ratings yet

- NADCAP Audit Criteria For Nondestructive Testing Facility Magnetic Particle SurveyDocument20 pagesNADCAP Audit Criteria For Nondestructive Testing Facility Magnetic Particle SurveyAnonymous gFcnQ4go100% (1)

- QP-209-18 NDT ProcedureDocument80 pagesQP-209-18 NDT ProcedurewildanmuhammadnajmiNo ratings yet

- Nabl 122 15 PDFDocument14 pagesNabl 122 15 PDFmaheshNo ratings yet

- PMI Report May 2019Document19 pagesPMI Report May 2019RifanjshshNo ratings yet

- Process Piping Guide R2Document12 pagesProcess Piping Guide R2Edson Araga100% (1)

- WZSMS GMB P PR 012 (Non Destructive Test Proc)Document10 pagesWZSMS GMB P PR 012 (Non Destructive Test Proc)azliza msogNo ratings yet

- Ut Tky ProcedureDocument26 pagesUt Tky ProcedureguruNo ratings yet

- RT Film InterpretationDocument33 pagesRT Film InterpretationAdewale JamesNo ratings yet

- Radiographic Examination Procedure As Non Destructive Testing Method in Process PipingDocument9 pagesRadiographic Examination Procedure As Non Destructive Testing Method in Process Pipingdenira k3No ratings yet

- SGS IND NDT Training Consolidated China EN 10Document16 pagesSGS IND NDT Training Consolidated China EN 10mounir bonnoisNo ratings yet

- PMI ProcedureDocument7 pagesPMI ProcedureRoberto Carlos Arana ChumpitazNo ratings yet

- NRRC-SG-08-Application For Authorization of Radiation Dosimetry CalibrationDocument37 pagesNRRC-SG-08-Application For Authorization of Radiation Dosimetry CalibrationESTSS TrainingNo ratings yet

- NDT Sessional 1Document293 pagesNDT Sessional 1Prasen KumarNo ratings yet

- Inspection and Remaining Life Evaluation of Process Plant EquipmentDocument27 pagesInspection and Remaining Life Evaluation of Process Plant Equipmentabisat02100% (2)

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesFrom EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesNo ratings yet

- WPS-PQR Gr. WCBDocument9 pagesWPS-PQR Gr. WCBansarmulla711No ratings yet

- Res Irn Ris-Am-177Document1 pageRes Irn Ris-Am-177ansarmulla711No ratings yet

- WPS-PQR Gr. CF8MDocument9 pagesWPS-PQR Gr. CF8Mansarmulla711No ratings yet

- Training CardDocument9 pagesTraining Cardansarmulla711No ratings yet

- Visual Inspection Reports Format No. SKMF-F - 49Document3 pagesVisual Inspection Reports Format No. SKMF-F - 49ansarmulla711No ratings yet

- ISO Documents List 4Document1 pageISO Documents List 4ansarmulla711No ratings yet

- Supp. Rating FormDocument1 pageSupp. Rating Formansarmulla711No ratings yet

- Ut SKMF-F-38Document1 pageUt SKMF-F-38ansarmulla711No ratings yet

- Fir Ris-Am-116Document1 pageFir Ris-Am-116ansarmulla711No ratings yet

- Irn Ris-Am-158Document1 pageIrn Ris-Am-158ansarmulla711No ratings yet

- Fir Ris-Am-239Document1 pageFir Ris-Am-239ansarmulla711No ratings yet

- Sac26-27 MachanicalDocument5 pagesSac26-27 Machanicalansarmulla711No ratings yet

- Fir Ris-Am-242Document1 pageFir Ris-Am-242ansarmulla711No ratings yet

- Ris Am 128Document1 pageRis Am 128ansarmulla711No ratings yet

- Main Gate Visiter Instructions 1Document1 pageMain Gate Visiter Instructions 1ansarmulla711No ratings yet

- WPS CD3MNDocument8 pagesWPS CD3MNansarmulla711No ratings yet

- Ir# Am-127Document1 pageIr# Am-127ansarmulla711No ratings yet

- LK 40Document3 pagesLK 40ansarmulla711No ratings yet

- Ilovepdf MergedDocument2 pagesIlovepdf Mergedansarmulla711No ratings yet

- Ris Am 128Document1 pageRis Am 128ansarmulla711No ratings yet

- Ilovepdf MergedDocument2 pagesIlovepdf Mergedansarmulla711No ratings yet

- Adapter A4-122 New Doc 02-11-2024 16.02 - 3Document1 pageAdapter A4-122 New Doc 02-11-2024 16.02 - 3ansarmulla711No ratings yet

- Hazard Identification ChecklistDocument2 pagesHazard Identification Checklistansarmulla711No ratings yet

- Ris Am 129Document1 pageRis Am 129ansarmulla711No ratings yet

- Unit 2Document25 pagesUnit 2ansarmulla711No ratings yet

- New Doc 02-14-2024 17.21Document2 pagesNew Doc 02-14-2024 17.21ansarmulla711No ratings yet