Professional Documents

Culture Documents

MSS SP-44-1991

MSS SP-44-1991

Uploaded by

abu.qckumyang0 ratings0% found this document useful (0 votes)

8 views27 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

8 views27 pagesMSS SP-44-1991

MSS SP-44-1991

Uploaded by

abu.qckumyangCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 27

NSS SP-44 94 MM S770b4G OSOO7S3 GT Ml

MANUFACTURERS STANDARDIZATION SOCIETY

of the VALVE AND FITTINGS INDUSTRY, INC.

127 Park Street, NE. © Vienna, VA22180-602 © ——*(703)281-6613___ © FAX (703}281-667t

‘Executive Director—Olen Thornton

May 7, 1996

‘70 WHOM I7 MAY CONCERN

Subject: Errata for MSS SP-64-1996, steel Pipeline

"Langes

The subject Standard Practice was announced as a 1996 revised 6P and courtesy

distribution was made to you on April 2, 1996, Please make changes to your copy

as follows

a, Page 3, Table 2, List of zolting spacifications. under Intersiediate

Notes, the references (c) for a453-651 and A453-660 should both be

Listed as references (e). Under NOTES, (hj should ead. . . see aleo

Bote (c). Bolts with drilled... .

D. Page 20, annex c, Refaranced standards snd Applicable Date

1994, code for Pressure Piping, should read 631.1 - B31.

for Pressure Piping.

Ga tots

fen Thornton

Bade. —

= 1996, code

PRESIDENTS: G4 Joly Hen Vag Mare Go» HR Sondre - Grind

ICE | GA 0. # T- orp.

™ TAEASURER EE Lakin- Ane cat ro Boe

Copyright by the Manufacturers Standardization Socky Of The Valve.

“Tue Jan 30 16:13:24 2001

Fittings industry ine

HSS SP-44 9) MM S770bU0 O500S87 337 aN

STANDARD PRACTICE SP-44

196

MSS ~

STEEL PIPELINE FLANGES

Developed und Approved

by the

‘Manufacturers Standardization Society

vy. _of the. i.

aive and Fittings Industry, Inc.

127 Park Seat, NE

Vienna, Virginia 22180

(703) 281-6613

Originally Approved July 1952

Copyrightby the Manufacturers Standardization Sockety OF The Valve And Fittings Industry Inc

“Tue dan 30 16:13:25 2001

NSS SP=44 93 MM S770b40 0500588 OSb mM

mss STANDARD PRACTICE spe

‘An MSS Standard Practice is intended as a basis for common practice by the manufacturer, the user, and

the general public. The existence of an MSS Standard Practice does riot in itself preclude tha manufacture,

Sale, oF use of products not conforming to the Standard Practice. Mandatory conformance is established only

by reference in a code, specification, sales contract or public law, as applicable,

Substantive changes in this 1996 edition are “Dagged™ by

‘parallel bars as shown on the margins of this paragraph. The

specie detai ofthe cnange may be determined by comparing {

‘the material lagged with that in the previous edition,

"Non-toleranced dimensions inthis Standard Practice are nominal, and

lunless otherwise specified, shall be considered “for reference only”,

Any part of this standard may be quoted. Credit lines should read ‘Extracted from MSS SP-44, 1996, with

permission of the publisher, the Menutecturers Standardization Society.’ Reproduction prohibited under

‘copyright convention unfess writen permission (s granted by the Manufacturers Standardization Society ofthe

Valve and Fittings Industry, Ino.

Copyright ©, 1985 by

‘Manufactures Standardization

Val aud Fig industry, Ine.

ve and Fit Indy,

Piet BUSA.

Copnrightby the Manufacturers Standardization Soctety Of The Valve And Fitings Industry Inc

‘Tue dan 30 16:13:27 2001

ASS SP-44 4) WM 5770640 0500589 T92 Ee

MSS STANDARD PRACTICE SPs

FOREWORD

‘The Manufacturers Standardization Society originally developed the Standard Practice in response to the continued

requests for ste! pipe flanges for pipeline use, particularly in sies larger than those covered by ANS! Standard B16.5 on

Stee\ Pipe Flanges and Flanged Fittings. The line pipe is uniquely characterized by high-strength, cold worked, thinall of

‘the carbon stel grade, which necesltates special considerations forthe welding end of the flanges

‘The size and pressure class range was originally NPS 26 through NPS 36 in pressure clases customarily designated in

‘ANS! Standard B16.5 as 300, 400, 600, and 900 fb. The 1970 ecltion deleted the slio-on flanges for lack of demand, and

added a 150 tb, clas and coverage for sizes NPS 12 through NPS 2. Additional coverage was also necesltated by the advent

(of the use of fine pipe of grades having minimum specified yield strength higher than the 82,000 pel maximum contemplated

atthe time of intial development. and therefore sti thinner wal,

In some instances, this advent widened the diferental berween the tense properties ofthe flange steel versus that of

‘he mating pipe set. This, n turn necesttated greater flexibity Inthe selection of hub dimensions, so mat various combina

tons of materia-strength and flange-dimensions could be utlized to supply the flanges. Section 5 on Flange Design was intro-

‘voed at this point, and is one of the key features of this standard, The 1972 edition included the coverage of blind Flanges

in all pressure classes and clarification of text requirements for better understanding and usage under the more diverse

conditions.

‘The 1975 ecition expanded the size range above size NPS 36. The drilling templates for the Clas 160 flanges of the

INPS 38 and larger sizes continued the orevious ohiloscohy of adcoting the drilling temolate of the Class 125 of ANS!

Standard B16.1. However, the driling templates of the Class 300 flanges of the NPS 38 and larger sizes did nat continue

the adoption of the Class 250 of ANSI Standard 816.1 drilling templates, nor did the NPS 38 and larger sizes of Classes 400.

(00, and 900 continue the extrapolation of ANS! B16.6 drilling template; instead, these driling tarolaes were necessarily

esigned more compactly because of the increased loads. White these flanges are designated by the customary ANSI Standard

Cass 150, 300. 400, 600, and 900, their use is almost entirely contined to cross country transmission pipelines at atmot-

pherie temperatures. The flanges have been designed primarily for use at their cold ratings which conform to the ANSI

Standard 816.5 ratings of 100F, and are intended primarily for attachment to relatively thin-wall high strength cold worked

pipe, and high-strength butt welding fittings in pipeline service at temperatures of 460F and lower. Howev

(of other materials are capable of pressure temperature ratings as specified in Paragraph 22.

“The 1680 edition was created to bring the document into claser editorial alignment with ANSI B16.5. However, out of

recognition of the succesful experience of the pipeline Industry, room temperature ratings were extended to 250F. De-ating

above 250F was accelerated such that the 450F ratings ae the same as B16.8, Users are cautioned that whan thasa flanges

‘ate bolted to valves and used at temperatures between 100F and 450F, the rating of the valve will not be a high as the flange,

‘The 1990 tevision of this SP was required to update the reference standards list and delete the metric equivalents.

‘The 1991 revision of this SP wes required to add blind flange machining guidance, flat face requirements and precau

tlonary notes as well as update of referenced standards.

‘The 1996 revision adds a table with permissible imperfections in flange facing finish and clarifies annex A design

criteria, There were several errata, or corrections mace to references to other standards. Dimensional toferances have

been changed where necessary to conform with ASME B16.5 and B16.47,

Copyright by the Manufacturers Standardization Sockty Of The Valve And Fittings Industry Inc

Tubdan 30 4611329 20

WSS SP-44 92 Wm 5270640 OSO0590 704 a

Mss STANDARD PRACTICE spat

PAGE,

5. FLANGE DESIGN........

6 MARKING

1. FACINGS .

8. CODE LIMITATIONS

9. FLANGE BOLTING DIMENSIONS

i0, TOLERANCES .

Moaaaan eee EE

TABLE 1 — TENSILE REQUIREMENTS

2.— LIST OF BOLTING SPECIFICATIONS «20.2...

3 — PRESSURE-TEMPERATURE RATINGS «-

4 — SHEET GASKET DIMENSIONS .

3 — RING.JOINT GASKET DIMENSIONS .

6 — CLASS 150, 285 PSI RAISED FACE...

7 — CLASS 300, 740 PSI RAISED FACE AND RING-TYPE JOINT

8 — CLASS 400, 990 PSI RAISED FACE AND RING-TYPE JOINT

9 — CLASS 600, 1480 PSI RAISED FACE AND RING-TYPE JOINT.

0 — CLASS 900, 2290 PSi RAISED FACE AND RING-TYPE JOINT.

Al — PERMISSIBLE IMPERFECTIONS IN FLANGE FACING FINISH

FIGURE 1 — ACCEPTABLE DESIGNS FOR UNEQUAL WALL THICKNESS

2— RECOMMENDED BEVEL FOR WALL THICKNESS (1) AT END OF FLANGE,

0.88 IN. OR LESS .. trisetesetersesstetsastsses

3.— RECOMMENDED BEVEL FOR WALL THICKNESS (1) AT END OF FLANGE,

GREATER THAN 0388 IN.....-..

ANNEX A— DESIGN CRITERIA

ANNEX B— BLIND FLANGE DESIGN CRITERIA .. seeeeeeene D

ANNEX € — REFERENCED STANDARDS AND APPLICABLE DATES 20

it

(Copyright by the Manufacturers Standardization Society Of The Valve And Fitfings Industry Inc

‘Tubdan 30 461302 201

‘MSS

NSS SP-04 92 mm 5770640 050059) G40 EB

STANDARD PRACTICE, SP44

i. SCOPE

1.] General, — This standard covers pressure-

temperature ratings, materials, dimensions, toler

ances {by reference 10 ASME/ANSI BI6S),

marking and testing. The weiding neck type flanges

shat be forged steel, and the blind flanges may be

made of cither forged ste! or from sto} plates.

4.) Dimensional requirements for sizes NPS 10

and smaller are provided by reference to ASME}

ANS] BI6.5, When such Ranges meet all other

stipnenions of this standard, they shall be con-

sidered as complying therewith.

1.2 References

1.21 Referenced Standards — Standards and

specifications adopted by reference in this standard

are shown in Antex C, for convenience of idemti-

‘ying edition number, date and source of supply.

A flange made in conformance with a prior edi-

tion of referenced standards and in all other

respects conforming to this standard will be com-

sidered 10 be in conformance even though the:

tion reference may be changed in a subsequent revi-

sion of this Standard Practice.

1.2.2 Codes and Regulations — A flange usetl

under the jurisdiction of the ASME Boiler and

Pressure Vessei Code, the ANSI Code for Pressure

Piping, or Governmental Regulations, is subject

10 any Imttatton of that code or regulation, This

includes any maximum temperature limitation for

‘material, or rule governing the use of a material

at a Jow temperature,

2. PRESSURE-TEMPERATURE RATINGS

2.1 General Flanges covered by this standard shal!

‘de designated as one of the following: Class 150,

300, 400, 600 and 900. Ratings in Table 3 are in

U.S. customary units.

2.2 Rating for Other Materials and Temperatures

above 450 F — NPS 26and larger flanges forged of

Copyright by the Manufacturers Standardiz ation Society Of The Valve And Fitfings Industry inc

‘Tue dan 30 16:13:34 2001

steeis covered in ASME/ ANSI BI6.5 whose bores

are no largerthan those which may be calculated for

pipe complying with parallel ASTM pipe speciica-

tions, and which comply with all requirements (ex-

cept dimensions) of American National Standard

BIG. are capable of being utilized at the pressure-

temperature ratings given in that standard,

MATERIALS

3.1 The steel used in the manufacture af these

‘flanges shall be selected by the manufacturer 10

snect the following requirements.

3.1 Allmaterials used for flanges shail be killed

steel

3.1.2 The steet used shall be suitable for field

weldingto other Manges, fittings, or pipe manufac.

tured under ASTM specifications A 105, A 33,

A 106, A 380, A 381, A 694, A 707, or API

Standard SL.

3.1.8 The steel used stall have & maximum car

‘boa content of 0,35 and a carbon equivalent com-

‘puted by the following equation:

ce = c+ Mb, EtMOLV, Meo

that should not exceed 0.489%, based on ladle

analysis. If the carbon equivalent factor exceeds

(0.48%, the acceptance of the flanges shall be based

‘on agreement between purchaser and manufac-

turer

3.1.3.1 The choice and use of alloying elements,

‘combined with the elements within the fimits

prescribed in paragraph 3.1.3 to give the required

‘ensile properties prescribed in paragraphs 3.1.4

shall be made by the flange manufacturer and in-

cluded and reported in the ladle analysis to identi-

fy the type of steel.

3.1.4 The steel used shall have tensile properties

‘conforming tothe requirements preceribed in Table

1 and capable of meeting the requirements of

section 4 and the flange manufacturer's design

‘conditions as given in Annex A.

WSS SP-b4 9] MH S77040 OSO0S92 587 mm

STANDARD PRACTICE

SPA

3.1.4.1 The test specimens may be taken from the

forgings or, at the manufacturers’ option, from

the billets or forging bar entering into the finished

product, provided such test blank has undergone

Telatively the same forming and the equivalent feat

‘weatment as the finished flange. The dimensions

Of the test blank must be such as to adequately

reflect che heat reatment properties of the hub of

the flange. Specimens shall be obtained from the

midwall of the thinnest section of the hub of the

flange or % in, rom the surface of the est biank..

‘The orientation of specimens taken from a lange

shall be longitudinal

3.2 Bolting — Boiting listed in Table 2 shall be

vvsod in flanged joints covered by this standard.

Bolting of other material may be used if permit-

ted by ihe applicable code or governmental regula-

don, Ati bolting materials are subject to the folow-

ing limitations.

3.2.1 High Strength Bolting — Bolting materials

having allowable stresses not fess than those for

ASTM A193 Gr B7 are listed as high strength in

Table 2. These and other materials of comparable

strength may be used in any flanged joint.

3.2.2 Intermediate Strength Bolting — Bolting

materials listed as intermediate strength in Table

2, and other bolting of comparable strength, may

‘be used in any flanged joint, provided the user

verifies their ability to seat the selected gasket and

‘maintain a sealed joint under expected operating

conditions.

3.23 Low Strength Boling — Bolting materials

having not more than 30 ksi specified minimum

‘Yield strength are listed as low strength in Table 2.

These materials and others of comparable strength

‘shall be used only in Class 150 and Class 300 joints,

and only with gaskets described in 3.3.2.

‘TABLE J. TENSILE REQUIREMENTS

YIELD POINT | TENSILE STRENGTH

MIN MIN, [ELONGATION IN 2 IN.

GRADE isi ist MIN. PERCENT

] [6 36" 60 20

Fa 2 «0 20

F46 46 60 20

Fas 48 62 20

F50 50 64 20

F52 32 66 20

F56 56 68 20

F60 60 15 20

Fos 65 7 18

F710 70 80 18

] © Note: except as required in para. 4.2.

(Copyright by the Manufacturers Standardiz ation Society Of The Valve And Fitfings Industry Inc

‘Tue dan 30 16:13:97 2001

WSS SP-uu 9) MM S770640 0500593 433 mM

‘MSS STANDARD PRACTICE SP-44

TABLE 2. LIST OF BOLTING SPECIFICATIONS

ASTM BOLTING MATERIALS

HIGH STRENGTH® | INTERMEDIATE STRENGTH © LOW STRENGTH

SPEC-GR. NOTES SPEC-GR. NOTES SPEC-GR. NOTES:

A193-B7 A193-BS A193-B8 cLi @

4193-516 A193.B6 AI3BEC CLI} (®)

32017 @ | a193-B6x A193-BEM CLI]

AS2OL7A {| A193.37M AissBeT cli] @)

A320-L7B {@) AI93-B8 cL? o ‘AI93-BBA &)

AROLIC {| AlgzBEC CLZ o AI93-BBCA, @

A320-L43 @ AI93-B8M = CL2 oO A193-B8MA @

A354-BC A193-B8T = CL2 a A193-B8TA @

A3S4-BD A320-BS cL2 @ A307-B a)

AS40-B2) A320-B8C = CL2 o A320-B8 CLI @®

AS40-B22 A320-B8F = CL2 o A320-B8C CLI ()

AS40-B23 A320-B8M = CL2 o A320-B8M = CL @®

AS40-B24

A320-B8T = CL? oO A320-B8T = CLI. @

A449 @

A8S3-651 ©

5453-660 ©

General Note:

Boling materials shall not be used beyond temperature limits specified in the governing Code.

NOTES:

(2) These boking materials may be used with all sted materials and gaskets.

(@) These boking materials may be used with all sted materials and gaskets; provided it has been verified

athai a sealed joint can be maintained under rated pressure and temperature.

(© These bolting materials may be used with all listed materials but are limited to Class 150 and Class 300

Joints. See 3.3 for recommended gasket practices.

{@) This ferric material is intended for low temperature service, use A194 Gr. 4 or Gr. 7 muts.

{) This special alloy is intended for high temperature service with austenitic stainless sted,

(This austenitic stainless steel has been carbide solution treated and strain hardened. Use A194 nuts of

corresponding material,

(gh This austenitic stainless material has been carbide solution treated but not strain hardened. Use A194

nuts of corresponding material.

(2) This carbon ste! fastener shall not be used above 400 F or below 20 F,seealsoNNote C. Botts with drilled

or undersized heads shall not be used

@ Acceptable nuts for use with quenched and tempered bolts are A194 Gr, 2 and Gr. 2H. Mechanical

‘property requirements for studs shall be the same as those for bolis.

(Copyright by the Manufacturers Standardization Society Of The Valve And Fitfings Industry Inc

“Tue Jan 30 16:13:29 2001

WSS SP-44 93 MM S770640 OSOOS94 35T am

loading without injurious crushing, and which are

suitable for the service conditions. Particular at-

tention should be given to gasket selection if a

system hydrostatic test will exceed the test pressure

specified in 8.2. Such a test involves the risk of ex-

‘cessive flange distortion,

3.3.2 Gasket dimensions for 1/16 inch sheet asbes-

tos in Tabie 4 are based ona contact area equal to

approximately twice the Dott root area. Class 150

flanged joints should use these exclusively

3.3.3 Ring joint gasket materials shall eonform to

ANSI B16.20 with dimensions as given in Tables,

3.3.4 Sheet and ring joint gaskets for sizes NPS.

40 and smaiier shall conform to ASME) ANSI

BI6.5 dimensions and recommendations.

HEAT TREATMENT

4.1. The P42 and higher grades of flanges of all

pressure classes and the class 400 and higher clases

‘of Grace F36 flanges shall be normalized or quen-

hed and tempered.

4.2 It is recognized that the cooling rate in a

‘quenching operation may be slower in the thicker

section of the flange than in the thinner hub

section. Hence, the increase in yield strength due

Copyrightby the Manufacturers Standardization Sockety OF The Valve And Fittings Indusirying

“Tue Jan 30 16:13:42 2001

MISS STANDARD PRACIICE SP4

sLE 3, PRESSURE-TEMPERATURE RATINGS

MAXIMUM ALLOWABLE NON-SHOCK WORKING PRESSURES

IN POUNDS PER SQUARE INCH (GAGE)

crass | ciass | crass | ciass | CLASS

TEMP. F 150 300 400 600 300

20 to 250 25 40 390 1480 220

300 as ns 955 1430 2145

350 265 60 92s 1380 2070

0 255 665 890 1330 2000

450 us 640 360 1285 1925

3.3 Gasket Material ‘0 the quenching operation may be less inthe ring

section than in the hub section. This factor is ac-

3.3.1 The user is sesponsible for selection of gasket counted for inthe Section on Design in Paragraph

materials which wil withstand the expected bolt 5.3. NPS 38 and larger sizes ofthe 300 and higher

classes of welding neck flanges shall have 42 ksi

‘minimum yield streagth in the ring section,

. FLANGE DESIGN

5.1 Dring Templates

derived as follows:

5.1.1 Class 150 flange drilfing templates are the

same as ASME/ANSI BI6.5 and Class 125 of

ANSI/ ASME Bi6.1.

— Drilling templates are

5.1.2 Sizes 24 and smaller class 300 flanges have

‘drilling templates which are the same as ASME/

ANSI BI6.5 and Class 250 of ANSI) ASME B16.1.

‘Sizes 24 through 36 inclusive have drilling templates

which are interpolations of Class 250 of ANSI)

ASME B16.1 except the diameter of the bolt holes

fre only one-eighth inch larger than bolt diameters,

Larger sizes are designed in accordance with

Appendix 2 of Division 1 of Section VIII of

ASME Boiler and Pressure Vessel Code.

5.1.3 Size 36 and smaller of Classes 400, 600, and

900 flanges have drilling ‘templates which are

extrapolations from ASME/ANSI BI6.5. Larger

sizes are designed in accordance with Appendix 2 |

of Division 1 of Section Vil of ASME Boiler and.

Pressure Vessel Code

Mss

WSS SP-44 91 IM 5770bN0 DSODS5S 2% we

STANDARD PRACTICE

spat

5.2 Flange Ring Design — The outside diameter

‘and flange thickness of sizes NPS 24 and smaller

‘flanges are in accordance with ASME/ ANSIBI6.5.

‘Larger sizes are designed in accordance with Appen-

| ix 2 of Division I of Section VIN of ASME |

Boifer and Pressure Vessel Code and the flange

ing shal have sufficient pressure capacity for the

servive hasod on its strength in the normatized

condition, This capacity shall be substantiated by

‘he Ruks for Bolted Flange Connections, Apper-

dix2 of Division | of the ASME Unfired Pressure

Code Section VIF, with allowable design stresses

a3 given in Annex A of this standard.

5.3 Hub Design

] 53.1 Sizes NPS 24 and smatier, When the |

‘mechanical (minimum yield smength) properties of

all sections of the flanges are equal to or higher

‘than those of the pipe to be matched, the Tub

dimensions may be the same as those of ASME]

ANSI BI6.5. Larger sizes are designed in accord

] ance with Appendix 2 of Section VIII of ASME J

Boiler and Pressure Vessei Code.

1532 tn addition, when the minimum yleld [

strength of the hub portion of any flange or its

representative test specimen is Yess than that

specified forthe pipe to be matched, the minimum

thickness of the hub at the welding end shall be

such that the product ofits thickness times is yield

strength (at welding end) shall at least equal the

product of the specified nominal wall thickness

and minimum specified yield strength of the pipe

tobe matched. Under these conditions, Sizes NPS

2Aand smaller Manges may also have a single taper

hhub and the outside diameter of the hub at the

base may be modified in accordance with ASME |

Section VILI Division 1 Appendix 2 calculations.

1593. When the manufacturer employs this op- |

‘Hon, the flange identification should be a combina-

‘tion of the class of material of the flange and of

‘the pipe for which the flange has been designed.

‘See 6.1.

1534 When the hub thickness at the welding |

ceftd must be greater than the adjoining pipe, the

Joint design shall be as shown in any of the three

sketches in Figure 1.

‘Copyright by the Manufacturers Standardiz ation Society Of The Valve And Fitfings Industry Inc

“Tue dan 30 16:13:44 2001

3.4 Welding Bnd — The welding end shall ben

accordance with Figure 2 for wall thickness (of

{ intended mating pipe) of 0.88 in. and tess. For |

‘thicker walls, refer to Figure 3.

SS Blind Flange

[55 2) The outside diameter and thickness of |

blind Manges shall be as listed in Tables 6, 7, 8,9

and 10. Thicknesses listed are based on material

Ihaving mechanical properties for Grade F36 of

‘Table L. Drilling templates are per Paragraph 5.1.

Thinner flanges of higher strength material may

be furnished in accordance with Annex B rues.

15.5.2 b) Blind Ganges need not be faced in the f

center if, when this center is raised, its diameter is

at least 5 in, smaller chan the nominal pipe size.

“When the center part ls depressed, its diameter

shall not be greater than the gasket TD specified in

Table 4 Tess 2 inches (LID. -2 = max. depression

OD}.

5.46 Dimensional requirements for NPS 10 and

smaller shall bein accordance with ASME/ANST

BI6S.

5.7 Flat Face Flanges — This standard permics

flat face Ranges in all classes, by providing anges

having either the full thicknest or the thickness

with the raised face removed, without reduction

of the presenreterperature ratings mabject to the

following provisions.

5.1 The thickness of Class 150 or 300 flange

from which the raised face has been removed shall

bbe no less than the applicable dimension C of

Tables 6 && 7 minus 0:06 in,

$.7.2 The thickness of a flange of Class 400 or

hhigher from which the raised thee has been re-

‘moved shalt be no lest than the applicable C

dimension of Tables 8, 9 and 1G.

3.73 ‘The flange facing shall conform with sec

tion 7.2 for the full width of seating of the gasket.

5.8 Spot Facing — All flanges shall have bearing

‘surfaces for bolting which shall be parallel to the

flange face within 1 deg. Any back facing or spot

ss

WSS SP-44 93 MM 5770640 OSO0S%b 122 mt

STANDARD PRACTICE

SP

6

facing required to accomplish paratelsm shall

vnot reduce the flange thickness C below the

dimensions given in Tables 6 7, 8, 9 and 10. Any

spot facing or back facing shall be in accordance

with MSS SP-.9,

MARKING

6.1 Flanges shall be marked in accordance with

the rules established in MSS Standard Practice

SP-25, Standard Marking System for Valves, Fit-

tings, Flanges, and Unions. In addition, the let-

ters, “PL” shall precede the grade symiool mar

ing. The grade symbol marked on the Welding

Neck Flange shail designate the grade of material

in the welding end of the hub. When flanges are

‘proctuced under the opxion of Paragraph 3.3.1, the

marking will also include the grade of the material

‘of the pipe which the flange will match. For ex-

ample, a flange having a grade F2 hub designed

10 be used with grade X60 pipe would contain the

marking PL #42/X60 in addition to the marking

specified in MSS SP-25,

6.2 Flanges in sizes NPS 10 and smatfer produced

10 B16.5 dimensions and complying with all other

requirements of this Standard Practice shall be

‘marked in accordance with 6.1.

FACINGS,

7.1. lange Facing Finish — The finish of contact

aces of pipe flanges shall be juciged by visual com-

parison with Ra Standards (see ANSI B46.1) and

not by instruments having stylus tracers and elec-

‘tronicamplification. The finishes required are given.

‘below. Other finishes may be furnished by agres-

ment between user and manulacturer.

ish having from 125 in. to

250 jin. average shall be furnished. The cutting

too! employed shoud have an approximate 0.06

in. or larger radius, and there shoukd be from 44

to 55 grooves per in,

73. Ring Joint — The side wall surface of gasket

_groene shall not exceed 63 microinch roughness

8

2

7.4 Flange Facing Finish Imperfections in the

‘flange facing Tinish shall not exceed the dimen-

sions shown in Table I. Adjacent imperfections

shall be separated by a distance of at least four

times the permissabie radial projection, Protru-

sions above the separations are not allowed.

CODE LIMITATIONS

8.1. A produet used under the jurisdiction of the

ASME Boiler amd Pressure Vessel Code or of the

ANSI Code for Pressure Piping, is subject to any

Tinitation of that code. This includes any manimum

temperature Imitation for a material, or a code

ale governing the use of a material at a low

‘emperature.

8.2 Flange Testing — Flanges are not required

to be hydrostativaly teste, Flanged joints may be

subjected to system hydrostatic tests at pressures

not exceeding 1.5 tines the 100 F rating.

LANGE BOLTING DIMENSIONS

91 Alloy-stel stud-bolts threaded at both ends or

fall length, or bolts with hexagonal heads conform-

ing to American National Standard heavy dimen-

sions (ANSI B18.2.{) may be used and shall have

ruts conforming to American National Standard

heavy dimensions (ANS! B18.2.2).

9.2 Carbon Steel bolts smaller than % in. shall

hhave square heads or heavy hex heads (ANSI

BI8.2.1), and shall have heavy hex nuts (ANSI

‘B18.2.2). Bolts 4 in. and larger shall have equare

Ineads or hex heads (ANSI B18.2.1), and shall have

hhex nuts or heavy hex nuts (ANSI B18.2.2},

9.3 Threads of carbon steel bolts and stud bolts

shall be coarse series, Class 2A (ANSI B1.1), and

nuts shall be coarse series, Class 2B.

9.4 All alloy steel bolting shall be threaded in ac-

cordance with ANSI B1.1. Nominal diameters 1

)_ and smaller shall be of the coarse thread series;

nominal diameters 1 in. and larger shal! be of the

8 thread series. Bolts, studs and stud-holts shall

‘have a Class 2A thread, and nuts shall have a class

2B thread.

Copiright by the Manufacturers Standardiz ation Sockety Of The Valve And Fittings Industry Inc

Tubdan 30 46:1347 20

WSS SP-¥4 4) Mm S770b40 OSO0S97 O64 MM

STANDARD PRACTICE

sP-4

10.

9.5 Bolting to Cast Iron Flanges — Where Class

150 steel flanges are bolted to Class 125 cast iron

flanges or Class 300 steel flanges are bolted to

Cass 250 cast iron flanges, it is recommended that

ow strength bolting be used. Hf intermediate or

high-strength bolting is used, it is recommended

that the mating flanges be flat faced and that full

faced gaskets extending to the OD. of the flange

be used,

TOLERANCES

10.4 Eacings

‘Outside Diameter, 0.06 in. raised face:

Sizes NPS 12 to NPS 24 inclusi

‘Sizes NPS 26 and Larger: 40.08

£0.03 in,

Outside Diameter 0.25 in. raised face:

‘Sizes NPS 12 to NPS 24 inclusive: +£0.02 in.

Sizes NPS 26 and Larger: 30.04 in.

10.2 Flange Thickness

Sizes NPS 18 and Smaller +0.12 in,

rer0

Sizes NPS 20 and larger +0.19 in.

210

10.5 Hub Dimensions Gincluding welding ends

10.3.1 Nominal Outside Diameter of Welding End

of welding neck flanges (Dimension H, in Tables

6,7,8,9 and 10,

Slzes NPS 12 10 NPS 24 in, +0.16 in,

0.03 in,

Sizes NPS 26 and farger 0.24 in.

0.06 in,

10.3.2 Nominal Inside Diameter of Welding Ends

of welding neck flanges (Dimension B in the

referenced Figures).

‘Sizes NPS 12 to 18 inclusive

‘Sizes NPS 20 and larger

10,33 Thickness of Hub — Regardless of toler-

ances specified for dimensions A and B, the

thickness of hub at the welding end shall never be

Jess than 8744 percent of the nominal thickacss of

‘the pipe to which the flange Is to be attached.

10.4 Overall Length through Hub on Welding

Neck Flanges

Sizes NPS 12 to NPS 24 incl, 49,12 in,

-O48in,

‘Sizes NPS 26 and larger £09 in,

40.5 Driling and Facing

10.5.1 Bolt Circle Diameter, +0.06 in,

10.5.2 Center-to-Center of adjacent bolt holes,

£0.03 in.

10,53 Eoceatricity between bolt circle diameter and

‘machined facing diameters.

Sizes NPS 12 to NPS 24, incl. 0.06 in,

Sizes NPS 26 and larger 0.09 in,

these sizrs shall be as specified in ASME/ ANSI

BI6S.

‘The listing of decimal tolerances does not imply

method of measurement,

(Copyright by the Manufacturers Standartiz ation Society Of The Valve And Fittings Industry Inc

“Tue dan 30 16:13:50 2001

WSS SP-u4 54 ER S77ORNO OSODSNG TTS ma

Mss STANDARD PRACTICE srt

@

14° MIN. (1:4)

18° MAK.

NOTES:

GENERAL:

When the minimum specified yield strengths of the sections to be joined are unequal, the deposited weld

etal shall have mechanical properties at least equal to those of the section having the higher strength, and|

the minimum thickness, tp, shall at least equal t times the ratio of minimum specified yield strength of pipe|

and flange, but not to exceed 1.5t.

Neither ty, tp, nor ty +t shall exceed 0.5t

FIGURE i — ACCEPTABLE DESIGNS FOR UNEQUAL WALL THICKNESS"?

(See Paragraph 5.3)

© SUPPLEMENTARY FOOTNOTE: Sec ASME B31 Piping Codes for additional fabrication details.

Copyrightby thé Manufaciurers Standardization Sockety OF The Valve And Fiings Industry lnc

“Tue dan 30 16:13:82 2001

WSS SP-44 9% MM 577040 OSOOSST 93) mm

‘MSS: STANDARD PRACTICE SP-4

e

F 05" + oor

at

ie a

FIGURE 2— BEVEL DETAIL FOR WALL THICKNESS (T) 0.88 OR LESS

NOTE: © Flange sizes 24 and smaller may be furnished with 37-4° bevel at option of manufacturer.

FIGURE 3— BEVEL DETAIL FOR WALL THICKNESS (T) GREATER THAN 0.88

(Copyright by the Manufacturers Standardiz ation Society Of The Valve And Fitfings Industry Inc

“Tue Jan 30 16:13:54 2001

WSS SP-44 4 mM S?70b40 OS00500 483 mm

MSS STANDARD PRACTICE sP.44

‘TABLE 4— SHEET GASKET DIMENSIONS Dimensions in inches

NOM. op. 1, D. GASKET G MIN.

PIPE. | GASKET

SIZE

R® 150 300 400 600 300

\2 15.00 12.75 12.75 _[ iz%s [eas

14 16.25 14,00 14.00, 14.00 14.00

6, 16.50 16.00 16.00 16.00 16.00.

we 21.00 18.00 18.00 18.00 18.00

20 23.00. 20.00 20.00 20.00 20.00

22 25.25 22.00 22.00. 22.00 =

2 27.25 24.00 24.00, 24.00 24.00

26. 29.50. 26.00 37.62 26.62 26.

a 31.50 28.00 29.50 | 28.38 | 28.38

30 337 30.00 31.62 3038 | 3038

32 36.00 32.00 33.13 32.50 32.38

4 38.00 35.62 34.25 34.38

36 40.25 36.00 37.62 36.25 36.38)

38 38.00 38.00 3750, 37.00}

40 40.00 40.00 39.50 39.00;

az Some 8 42.00 42.00 450 41,00}

a4 oDot 44.00 aa. 43.50 43.00

46, Raioed 46.00 46.00 45.50 45.00)

48 heer, 48.00 48.00 47.50 47.00.

$0 pnb 30.00 30.00 49.25 =

32 aie 52.00 52.00 51.25 =

54 S210 $4.00 54.00 53.25 =

56 56.00 55.25 =

38 $8.00 58.00 $728 =

60 60.00 60.00 39.25 =

NOTE: Outside Diameter R may be made to fit the inside diameter of the bolts to act as a locating device

when making a joint in the field, however, in no case should the contact area of the gasket be

increased by changing the diameter of the raised face on the flange.

(Copyright by the Manufacturers Standardiz ation Sockty Of The Valve And Fittings Industry Inc

Tubdan 30 4671355 201

NSS SP-44 52 MM 5770b40 OSOUL0) 337 BS

sP-44

STANDARD PRACTICE

-sdiuey safe, par ‘gg 2218 203 pareydurawioo jou are siaqsUD WHOL Bury

‘O91a AWS 205 ‘Suorsuounp ro4seA 1tHOL-FuuE yo SEOUEL3TOD BUNT IO ¢) “ALON

NOLLVWMOANI TVLNAWA dds

sold], see | ostor | dou | eas. 2901 si80 | Osco] ve

yoru S2E1| 000 [iow | xs 0 | c90T | siwo | Ooo ke | — be

c01W. ost1_[ 0009 | sou_| eas 0 | ev0T |" Ece0 [one

Ont ‘ose T_[ ose te | sou_| s8r0_|~ 860 [osc | Oseee”

TOI Ose | OOF | tou_[ SRFO_|8e60 | Osz0 | “OOS IF

‘Ore Ser | 00s6r | fo¥ | serO_| #fo0 | sco | 00sec

SLU. oor [Ose uaa | erro caso | sev0 osc

— — ig¥_|cee0_| osc] rs 1 000 sz

Ze OO 4¥_|ire0| ge | 00s 0] 000Re

OLY OSEO eu] SEO eer | 000 Te

9% SFO sbe0 [sero 1 o0s 8

For ceo O Soe0 wero |

isu FO soe 0 REPO | ObOST

H ¥ v | sas

ON sury | aur ON dig

un ruoineg | Jo fury vet

Jovian | irra 1K, “WON

006 ssw19 INY ‘OOF OOF SSYT)

‘soYouy ur stOIsuoUNC] SNOISNANTG 19SVD INIOPONTY STAVE

-aetny pun Ur | ppEN Fu 205 6O'O

‘aoqfeus pur “ur g0 NPI at 205 Ut O9}0

smIpey,

Copyright by the Manufacturers Standardization Society Of The Valve And Fitfings Industry Inc

“Tue Jan 30 16:13:57 2001

MSS SP-44 93 MH 5770b40 OSOOLO2 2st me

‘MSS ‘STANDARD PRACTICE spe

TABLE 6 — CLASS 150, 285 PSI AT ATMOSPHERIC TEMPERATURE RAISED FACE"

‘Dimensions in inches

HUB

FLANGE DIMENSIONS DIMEN- DRILLING

SIONS

8 Raised

3| op Thick. | Length | ,OD | No. } Dia Dia. | Face Fillet

2] of of Tare | Ease | of] of of | Dia, | Radius

E | Flange | Flange } Hub | End | po] Bolt | Bolt aan |

oO c Y Hub | Holes! Holes } Circle | A

(MIN) x

12 17.00 | 15.00 | 038}

i 18.75 | 1625_| 0.38

16 21.25 | 18.50_| 0.38

78 BTS [3.00 | 038

x $:00_| 23.00} 0.38,

20, TIS ose

20 2930-[3735_|_038

24 373 {3930 [08 |

36 34.00 31.30] 0.44

28 36.00 |33.75_| 0.44

z 38.50 [36.00 | 0.44

52 20:50} 38.00_} 00

32_| 62 [42.75 1

2 45.25]

36, [aris

36, 49.50

a0) 31.75

40 [sa75

a4 36.00

aa 3825

EC 00.50

ag 62.75]

as “65.007

a or

32 35

nea Noes: "© ating frais ce angi praia ot ht cas shown Table

For matching tlm se Sesion 10. © ies ob spiel by ctor

For machng od dei se Fg 12nd. © serSmsion

(© where cakulated ind thickness iss than the mating welding sec, the thickest

vere ade gta See paragraph fr material equrement

2

Copyrightby the Manufacturers Standardization Sockety OF The Valve And Fittings Industry Ine

“Tue Jan 30 16:14:00 2001

WSS SP-H4 92 MM S770b4D USOOL03 142 wt

MSS STANDARD PRACTICE sP-44

Ene ®

eo =

wo)

RING-TYPE ONT PARED FACE

‘TABLE 7 — CLASS 300, 740 PSI AT ATMOSPHERIC TEMPERATURE RAISED FACE“! AND.

RING-TYPE JOINTS

‘Dimensions in inches

FLANGE DIMENSIONS [HUB DIM] DRILLING FACING DIMENSIONS:

a a ST soe ta |

tes [cow Pasar) a Tar Paar [a ee

| tage ng foam [estat oe | cee le | op Teea no | “mt aia!

Thre tae tapers tas pr Tarr He poe Her ea wr

papa pa [ser] ers | a 0312 | 16500 [ones aei [-038-| 003

asso 225] 225 | s15| 900 [20 | 138 2250 0312 | 1ns00—[oaes | nes [038 | 00

zao0_ 36 ea] aoe PE [2075 asi2 | 21000 [oaes [wee [038 | 003

sao [30 orf poe [aa asis| 3000 [oss [wos | a

33.00 262 es} asas [Pier [avis ‘osse | 35.000 [ose [wai [038 | coe

3600 gar] rer rer ase | FTL 088E oP Oe

Seas a Sart apo [ae soo] 29300 [over [RIS [03H | 06

7s | 338 save [ae [as tr 0300 _| 31800 oe 06,

aca [36 aie aso a oat Bae

i535 | a 0362_| 380 eae oa

ase [40 ser | Sem Oso Oe

$000) 41 Loser | aoase ast oar

O30

‘0

O50

75 — as

espa { ors = e300_| sz00 [= | — O30

apie erp eae fits H a0 | 400 - — | — P= = beef

Genera Noes: [Note (0 Rating or ised fae Manges proiated om the wea shot ghee own Table?

Fr matching trance se Secon 10. (©) Dimension tobe peiied by atom,

Fer welling ead Stl se Figs, 2nd 2 (© See Serion

(© Where caked bind thicoess sth the mating welding nec he thicknesses

sere made equa. See paragraph 55 for materi equremens

(© hb dimension or Size and smaier anges may vay asexpained in paragraph 3.2

13

Copyright by the Manufacturers Standartiz ation Society Of The Valve And Fittings Industry inc

“Tue Jan 30 16:14:02 2001

NSS SP-44 93 MN S770b40 OSO0bO4 025 BH

Mss ‘STANDARD PRACTICE sP44

[Eaceot ||

a

RING-TYPE JOINT ase Pace

TABLE 8 — CLASS 400, 990 PSI AT ATMOSPHERIC TEMPERATURE RAISED FACE® AND.

RING-TYPE JOINTS

Dimensions in inches

EET aon REE Tse pasos

F sate Paw Past [oa [ee TERNGTYPE FONT ats | cro

re | oparlrmtceor Anse | trey, | oocad? [isi [Pant [Pe [EE me ack [Wg [Ra |at ker

lox | Mage Wewnee [owen] thon | Enaist [ice | fom | cick | ‘bo. [be Da [ove Bo | fae

as son | es ios [ras [som | seas [aa | samo [ane esol aus | om

ae Tes Ta [amas [ies Hine [asses Pao) ner] gee [a

750 Ts0_[ 250] aso [sooo Posts [ise [eaea] Res] oan [oes

tee 35 [oT a op as aT oa | oe

ior ass | our [rrasof osse) mo] wae] coe

350 ‘rao rae [ ooo arse [ae [nar oe

395 > Sra Lara Pasar P S00 POL RAP

3 [os [ose | son [oe] aveT oa fae

ay [ow | wa ato von mp ose Pao

wars =o

[Be fosco 3 wr = tom,

Sas [Tar nH ae

[eae pe ae] Er

Genera Nowe: [Notes ©) Ratngfor raed face anges predated on ewe fhe paket showniaTable2,

For matching tolerances se Section 10 ©) Dimensions tobe speed by custome.

For weing end det see Fue |, 8 See Secon 5

(© Whee calculated ing thickness isles tha the mating welding nek, the tikes

were made qual. See paragraph 3. for material equerents

(9 Hp dimension for Sze 4nd sae Danges ay vaya explana inparagaph 5.3.2.

4

(Copyright by the Manufacturers Standardization Society Of The Valve And Fitfings Industry Inc —

“Tue Jan 30 16:14:04 2001

WSS SP-44 43 WH 5770040 OSODLOS Ths mm

MSS STANDARD PRACTICE

P44

bat

+ BNawe af

L

a wNeo—

2G TPLONT ‘Rae FACE

Lene]

RING-TYPE JOINTS,

‘TABLE 9 — CLASS 600, 1480 PSI AT ATMOSPHERIC TEMPERATURE RAISED FACE" AND,

. Dimensions in inches

Bae TEP HE] tana | couse a Kea | Bsr

i Peo] rma ea 2 [| a | be

ees A =

7 sche ser per eet

E Sete Sar per [eae

if es barter tert

a see ear pa eet

¥ teers carter ea

= Sp tance

= at_[ar Seep ere

a rr ar a}

= hee aoe

a ape # te

a a ct

E : —

opener E =

=e 3 o

He = —

Pebesbe = t=

Si—[ aya} tse [eas [ eas separ Se =

Bert ssa se sre pe] sae | eee ir

Se oa

General Notes ‘Notes: @) Rating for raid face anger i predicted onthe wr af hast guns chown in Tale 2

Tormnng ore Scion ©) Dims nb pc yon

Fereling nd es Fee 2a 3 (© sess

(Were cles Win thickness than be mating welding neck the ticket

‘were mae equal. ee paragraph 33 for mater equemens

(©) ub cimension for Size 4and sales fangs may vaya explained in paragraph $32

(Copyright by the Manufacturers Standardization Society Of The Valve And Fitfings Industry Inc

“Tue Jan 30 16:14:06 2001

NSS SP-44 93 MM 5770b40 OSOUbOb 97) mw

STANDARD PRACTICE

MSS

“Ces ude pout sea ws eS aqrME HE YZ AS} BONE GOH)

sua pT YF 3351

screen au BON Hep 3 oH SITE

eee

peg" sg 25 ma pn BAM IO

‘1 ono 98 suo FDR JO

p73 a 6 pean sy ey po fo (9) SION KT

ose | ost. % seo | oe [raw

ost | 0s We ‘oor | eve | srw | oy

ots | tos ve 356 [we | owe | wv

suie | Svs. i crs | are | ost | ty

ssn | sts. © we [see oF.

sete | 5005 7 ost ra

se oF | C08. 4 st9 ca

oo | sew t 059) ca

00% [0559 7 59. te

seve [sot 0 ae, oe

oste | sco w 295 a

ose | osur we oss x

seit [ose we os ra

‘ore | os Ts. %

oot | wou w 00, a

ost | sre w. ost

Seo | 00Tz. [7 see

‘ost | wore 7 we [are

x, a eT

SSE Sr Sar A va [aR | os

me | P| FONVIG TONSIL

‘SNOISKAMIG ONIOVA OuiTTING, ia aon SRoTSNaNIG TORT

soup uTsuOSEANKT —SINIOPIAAL-ONRICNY

avs asive

(@AVAGASIVA AUN LVUTAWAL RAAASONLV LV ISd OCC ‘006 SSV TD — OFT TEVI

6

(Copyrightby the Manufacturers Standardization Sockety OF The Valve And Fittings Industry Inc

“Tue Jan 30 16:14:08 2001

Mss

STANDARD PRACTICE

HSS SP-44 91 MH 5770640 SOOO? 836 aw

| ZABLE PERMISSABLE IMPERFECTIONS IN FLANGE FACING FINISH [

MAXIMUM RADIAL® MAXIMUM DEPTH AND RADIAL

PROJECTION OF IMPERFECTIONS } PROJECTION OF IMPERFECTIONS.

NPS WHICH ARE NO DEEPER THAN WHICH ARE DEEPER THAN

‘THE BOTTOM OF THE ‘THE BOTTOM OF THE

‘SERRATIONS, IN, ‘SERRATIONS, IN.

12-14 ost os

16 038 08

18-24 0.50 025

26-36 030 025

38-48 056 028

50-60 062 o3t

NOTES: © Imperfections less than half the depth of the serrations shall not be cause for rejection,

See paragraph 7.4

© A radial projection s!

be measured by the difference between an inner radius and an

outer radius encompassing the imperfection where the radius is struck from the center

line of the bore.

7

(Copyright by the Manufacturers Standardiz lion Society Of The Valve And Fitfings Industry Inc

“Tue dan 30 16:14"12 2001

WSS SP-Wh 3h ME S77G640 OS00L08 274 mm

SEANDARD PRACTICE

ANNEX A

DESIGN CRITERIA

‘This Annex is an integral part of this Standard Practice which is placed after the main text for convenience.

‘These flanges were designed in accordance with the formula of paragraphs UA 45 - UA 59 (inclusive) of Section

‘VIH Unfired Pressure Vessel, Division 1. (1950ed.) Currently, the equivalent paragraphs are found in Appendix 2

of ASME Section VIII Division 1. This Annex is presented as a description ofthe basis for this Standard, Any

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Loading Facilities For Bulk Road Vehicles: Dep SpecificationDocument45 pagesLoading Facilities For Bulk Road Vehicles: Dep Specificationabu.qckumyangNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Galvacoat Data SheetDocument2 pagesGalvacoat Data Sheetabu.qckumyangNo ratings yet

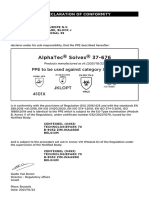

- Alphatec-Solvex-37-676 - Alphatec® Solvex®-37-676 - Eu - 20231109 - Declaration of ConformityDocument3 pagesAlphatec-Solvex-37-676 - Alphatec® Solvex®-37-676 - Eu - 20231109 - Declaration of Conformityabu.qckumyangNo ratings yet

- Alphatec-Solvex-37-676 - Alphatec® Solvex®-37-676 - Uk - 20231109 - Declaration of ConformityDocument1 pageAlphatec-Solvex-37-676 - Alphatec® Solvex®-37-676 - Uk - 20231109 - Declaration of Conformityabu.qckumyangNo ratings yet

- C150 - 91 Thickness Design of Ductile-Iron PipeDocument44 pagesC150 - 91 Thickness Design of Ductile-Iron Pipeabu.qckumyangNo ratings yet

- Aci 305R-99Document20 pagesAci 305R-99abu.qckumyangNo ratings yet

- MSS SP-80-1997Document27 pagesMSS SP-80-1997abu.qckumyangNo ratings yet