Professional Documents

Culture Documents

001 Influences - On - Measuring - Results

001 Influences - On - Measuring - Results

Uploaded by

Thamizhmani VOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

001 Influences - On - Measuring - Results

001 Influences - On - Measuring - Results

Uploaded by

Thamizhmani VCopyright:

Available Formats

Influences on measuring results

Measuring Machine

Measuring Strategy Machine geometry

Inspection planning Sensors

Sensor Measuring standard

Measuring method Accuracy (MPE) Environment

Filter setting Measuring range Temperature

Outlier elimination Measuring software Temperature gradient

Analysis strategy Error correction (CAA) Temperature drift

Clamping/fixturing strategy Qualification normal Thermal radiation

Alignment strategy Illumination Contamination, dust

Illumination strategy Telecentricity Vibrations

Zoom Sensor limits Humidity

Number of measuring points Hysteresis, dynamics Air draft

Distribution of measuring points ... Light reflections

Probing force ...

Scanning speed

Usage of rotary table

...

Workpiece

ults

Form error

Operator Dimension

re s

Education/training Weight

Use of tools

in g Material

Clamping check

meas u r Linear expansion

Alignment check Surface

EN_60_023_014I Printed in Germany. CZ-IX/2016 © Carl Zeiss Industrielle Messtechnik GmbH

Stylus qualification Brightness/reflection

Measurement planning Part temperature

Avoiding of collisions Inspection Task Part contamination

Stylus assembly Application orientation Elasticity/plasticity

Shaft probing Tolerance orientation Drawing/CAD

Machine monitoring Process and cycle time orientation ...

Care and cleanliness Task-oriented reports

Motivation Volume orientation

... ...

You might also like

- 5 Converting Concentrations To Different UnitsDocument2 pages5 Converting Concentrations To Different UnitsJacob DaughertyNo ratings yet

- Measurement System Analysis: One Day Training ProgramDocument52 pagesMeasurement System Analysis: One Day Training ProgramvishvendanNo ratings yet

- Sap TerminologyDocument17 pagesSap TerminologydesaivaibhavNo ratings yet

- Measurement System AnalysisDocument44 pagesMeasurement System AnalysisMahender Kumar100% (4)

- Measurement Systems Analysis: Champion TrainingDocument45 pagesMeasurement Systems Analysis: Champion TrainingRavindra ErabattiNo ratings yet

- 9097 - Metrology & Quality ControlDocument7 pages9097 - Metrology & Quality ControlAhmed Abu-SinnaNo ratings yet

- CHAP (35) 35 Engr Metrology & InstrumentationDocument4 pagesCHAP (35) 35 Engr Metrology & InstrumentationfarizanNo ratings yet

- Mtrology in AircraftDocument22 pagesMtrology in Aircraftkrishnamurari1962No ratings yet

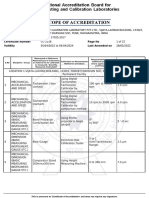

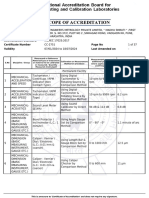

- Scope CC 3131Document6 pagesScope CC 3131Assistant Director KHRINo ratings yet

- Ctwist: Circumferential Tread Wear Imaging SystemDocument2 pagesCtwist: Circumferential Tread Wear Imaging SystemPhilipe WeisheimerNo ratings yet

- Basic Seven ToolsDocument33 pagesBasic Seven ToolsSin TungNo ratings yet

- Scope CC 2660Document12 pagesScope CC 2660rp801113717No ratings yet

- SCS - ScopeDocument22 pagesSCS - ScopeRakesh TrentiyaNo ratings yet

- 6 Appendix 6Document4 pages6 Appendix 6tiaraNo ratings yet

- Fundamentals20Measurement V4Document217 pagesFundamentals20Measurement V4Ana Paola Sandoval SánchezNo ratings yet

- Scope 62852 CC 3229 1687415485Document25 pagesScope 62852 CC 3229 1687415485rp801113717No ratings yet

- CNC Mill Operations Crosswalk V2Document2 pagesCNC Mill Operations Crosswalk V2MFNo ratings yet

- Visual Testing Topical Outline: FundamentalsDocument2 pagesVisual Testing Topical Outline: FundamentalsGaurav ChopraNo ratings yet

- M&M 4TH Tecahnig PlanDocument4 pagesM&M 4TH Tecahnig PlansanjaymehtasupaulNo ratings yet

- Concepts of Metrology: Krishna Murari Senior Faculty, HMADocument22 pagesConcepts of Metrology: Krishna Murari Senior Faculty, HMAkrishnamurari1962No ratings yet

- Analog Outside Micrometer - 130262486 - 25 MM YDocument15 pagesAnalog Outside Micrometer - 130262486 - 25 MM YishraqaliahsanNo ratings yet

- Solutions For Metrology: EV GROUP® - Products MetrologyDocument6 pagesSolutions For Metrology: EV GROUP® - Products MetrologyvinayakpandeyNo ratings yet

- Scope CC 3399Document10 pagesScope CC 3399dheeraj chawlaNo ratings yet

- Scope 92026 CC 3897 1715082517Document13 pagesScope 92026 CC 3897 1715082517mathewsj920No ratings yet

- Hand Out Precision EnggDocument5 pagesHand Out Precision EnggkrishnanNo ratings yet

- Measurement Systems Analysis WebinarDocument37 pagesMeasurement Systems Analysis WebinarOlirvag100% (1)

- 18 Measurement Systems AnalysisDocument118 pages18 Measurement Systems Analysisankit7588No ratings yet

- Precision Equipments (Chennai) Pvt. LTD.: Ultrasonic Examination ReportDocument5 pagesPrecision Equipments (Chennai) Pvt. LTD.: Ultrasonic Examination ReportqaNo ratings yet

- Active IAQ 6209 Calibration CertificateDocument13 pagesActive IAQ 6209 Calibration Certificatehashibpervez.shvenergybdNo ratings yet

- Laboratory NameDocument13 pagesLaboratory NameVikram BillalNo ratings yet

- Mechanical Measurements - 1Document6 pagesMechanical Measurements - 1فضائح لا تصدقNo ratings yet

- Kudle LabDocument22 pagesKudle LabVikasNo ratings yet

- Scope 51970 CC 2403 1684006228Document26 pagesScope 51970 CC 2403 1684006228AcuteNo ratings yet

- Herramientas de EvaluacionDocument3 pagesHerramientas de EvaluacionJavier Gomez LopezNo ratings yet

- Calibration of Simple Vernier Caliper Using Slip Gauge Made by Nano Material IJERTCONV6IS01006Document3 pagesCalibration of Simple Vernier Caliper Using Slip Gauge Made by Nano Material IJERTCONV6IS01006Maya LamichhaneNo ratings yet

- Control Plan H.TDocument1 pageControl Plan H.TABHISHEK PANDEYNo ratings yet

- Se 75 (25.6)Document2 pagesSe 75 (25.6)விஷ்ணு ராஜசெல்வன்No ratings yet

- Measurement Systems Variables: These Are Some of The Variables in A Measurement System. What Others Can You Think Of?Document5 pagesMeasurement Systems Variables: These Are Some of The Variables in A Measurement System. What Others Can You Think Of?Ashish GuptaNo ratings yet

- Scope CC 2751Document37 pagesScope CC 2751Vishal ShindeNo ratings yet

- Kahari MikkoDocument87 pagesKahari MikkoIgor MemonNo ratings yet

- Stage Activity Quality Control: Summary of Sampling ErrorsDocument7 pagesStage Activity Quality Control: Summary of Sampling ErrorsKarol FernandezNo ratings yet

- MCE 476 - Nondestructive Testing Methods: InstructorDocument120 pagesMCE 476 - Nondestructive Testing Methods: InstructorasotjaNo ratings yet

- Msa - MTCS - 2Document18 pagesMsa - MTCS - 2Rajesh SahasrabuddheNo ratings yet

- Mechanical Engineering VI Sem SyllabusDocument25 pagesMechanical Engineering VI Sem Syllabussaurabh1116No ratings yet

- R - 2017 Metrology and Measurement Lab-1Document73 pagesR - 2017 Metrology and Measurement Lab-1Gajendran A MECH KIOTNo ratings yet

- Swep20 Act ScottDocument11 pagesSwep20 Act Scottkorray1No ratings yet

- Machine Vision: Systems Sensors SoftwareDocument20 pagesMachine Vision: Systems Sensors SoftwareLam Nhat QuangNo ratings yet

- Microrep Calibration Laboratory - Capability 2019-1Document10 pagesMicrorep Calibration Laboratory - Capability 2019-1Vikram BillalNo ratings yet

- Scope CC 2331Document5 pagesScope CC 2331snsarangi06No ratings yet

- Standard Qap Rev.00Document2 pagesStandard Qap Rev.00Suraj GuptaNo ratings yet

- CAM2® 2020 FARO Arm Basic Tactile TrainingDocument150 pagesCAM2® 2020 FARO Arm Basic Tactile TrainingKarl SmithNo ratings yet

- AM Für Space Anwedungen - "Leason Learned" Re-Design Sentinel 1 Upper SBA SupportDocument31 pagesAM Für Space Anwedungen - "Leason Learned" Re-Design Sentinel 1 Upper SBA SupportagniflameNo ratings yet

- Full CMC Template CalibrationDocument31 pagesFull CMC Template CalibrationStudent ForeignNo ratings yet

- Scope CC 3287Document28 pagesScope CC 3287rohitprasad7250No ratings yet

- 07 Control PlanDocument5 pages07 Control PlanManoharar RNo ratings yet

- 04 MarTestDocument67 pages04 MarTesttheboogiemanNo ratings yet

- Principles of Mapping With Petrel©Document4 pagesPrinciples of Mapping With Petrel©Hcene HcenNo ratings yet

- TEC-Test Procedure EMF Measurement of Base StationDocument42 pagesTEC-Test Procedure EMF Measurement of Base StationHaresh Jindal100% (1)

- Scope CC 3287Document28 pagesScope CC 3287Indranath MoulickNo ratings yet

- Pipeline Inspection Method Metode Inspeksi Pipa PenyalurDocument35 pagesPipeline Inspection Method Metode Inspeksi Pipa PenyaluradityaromasNo ratings yet

- 007 White Paper TemperatureDocument7 pages007 White Paper TemperatureThamizhmani VNo ratings yet

- Batch20 - Final Project ReportDocument62 pagesBatch20 - Final Project ReportThamizhmani VNo ratings yet

- WCR and Job Card - KaruthapandiDocument17 pagesWCR and Job Card - KaruthapandiThamizhmani VNo ratings yet

- WCR and Job Card - ManinkandanDocument11 pagesWCR and Job Card - ManinkandanThamizhmani VNo ratings yet

- Composite CurvesDocument3 pagesComposite CurvesThamizhmani VNo ratings yet

- Sdote Unit 4 Bejan BookDocument13 pagesSdote Unit 4 Bejan BookThamizhmani VNo ratings yet

- Wa0006.Document1 pageWa0006.Thamizhmani VNo ratings yet

- Skill MatrixDocument5 pagesSkill MatrixThamizhmani VNo ratings yet

- INVITATIONDocument1 pageINVITATIONThamizhmani VNo ratings yet

- Excel For Scientists and Engineers - 2006 - Billo - Appendix 4 Some Equations For Curve FittingDocument13 pagesExcel For Scientists and Engineers - 2006 - Billo - Appendix 4 Some Equations For Curve FittingThamizhmani VNo ratings yet

- First Rank List 2020-21Document14 pagesFirst Rank List 2020-21Thamizhmani VNo ratings yet

- Rubber Bulb Seals: Weather Resistant EPDM-Plain BackDocument5 pagesRubber Bulb Seals: Weather Resistant EPDM-Plain BackRaulNo ratings yet

- IBM® DB2 Universal Database™ Replication Guide and ReferenceDocument789 pagesIBM® DB2 Universal Database™ Replication Guide and ReferenceKuzumichNo ratings yet

- Cos1512 104 2012 1 BDocument11 pagesCos1512 104 2012 1 BLina Slabbert-van Der WaltNo ratings yet

- Kinematic ENGEODocument15 pagesKinematic ENGEOHedi HNo ratings yet

- Hoja de Actividades InglesDocument7 pagesHoja de Actividades InglesArianny Añez SampayoNo ratings yet

- Perimeter of TrianglesDocument2 pagesPerimeter of TrianglesKhaeroni KhaeroniNo ratings yet

- MC 2 Lab Prelim 2Document4 pagesMC 2 Lab Prelim 2Diana Joy Ancheta CldheiNo ratings yet

- Maths Preparation Tracker For All SSC Exams by The PunditsDocument1 pageMaths Preparation Tracker For All SSC Exams by The Punditsanime0001001No ratings yet

- Literature SurveyDocument3 pagesLiterature SurveyEzhilarasiNo ratings yet

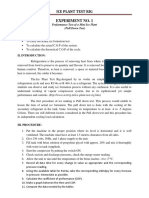

- Ice Plant Test Rig Experiment No. 1: I. ObjectivesDocument9 pagesIce Plant Test Rig Experiment No. 1: I. ObjectivesJacinto DianitoNo ratings yet

- Initial Analysis of PCM Integrated Solar CollectorsDocument5 pagesInitial Analysis of PCM Integrated Solar CollectorsTushar Kant SwainNo ratings yet

- Energies 16 05169Document24 pagesEnergies 16 05169Ali .VNo ratings yet

- To Study The Characteristics of The Hydraulic Jump Developed in Lab Flume.Document6 pagesTo Study The Characteristics of The Hydraulic Jump Developed in Lab Flume.Afzal WaseemNo ratings yet

- Nicole Ezzo Resume 2014Document4 pagesNicole Ezzo Resume 2014api-218916677No ratings yet

- Non Contact Liquid Level SensorDocument5 pagesNon Contact Liquid Level SensorGeorge AquanautNo ratings yet

- Biochemistry I BSC 211: LipidsDocument16 pagesBiochemistry I BSC 211: LipidsKelvin ChipezeniNo ratings yet

- SCILAB Elementary FunctionsDocument25 pagesSCILAB Elementary FunctionsMAnohar KumarNo ratings yet

- Con CurrencyDocument46 pagesCon Currency007wasrNo ratings yet

- String Operations in PythonDocument6 pagesString Operations in PythonShubhraNo ratings yet

- Differential Calculus Module November 2020 FinalDocument2 pagesDifferential Calculus Module November 2020 FinalChristy Mae LabajoNo ratings yet

- Terex Gottwald Model 6 Harbour Crane: A Combination of Power and FunctionalityDocument43 pagesTerex Gottwald Model 6 Harbour Crane: A Combination of Power and Functionalitychelin33100% (1)

- II Pipeline Design Codes and Standards-MSGDocument74 pagesII Pipeline Design Codes and Standards-MSGSanjay Kumar100% (3)

- Inet Manual DRAFTDocument134 pagesInet Manual DRAFTDarlison OsorioNo ratings yet

- Paper Presentation ON: 4 Semester COMPDocument36 pagesPaper Presentation ON: 4 Semester COMPRavinNo ratings yet

- Introduction/Abstract: TeknikgruppenDocument14 pagesIntroduction/Abstract: TeknikgruppenKlaas Krona100% (1)

- Twelve Principles of AnimationDocument5 pagesTwelve Principles of AnimationSanket ShethNo ratings yet

- Ec8681.1 QPDocument4 pagesEc8681.1 QPHdhdhNo ratings yet

- Midterm Exam in General MathematicsDocument3 pagesMidterm Exam in General Mathematicsjoan datuNo ratings yet