Professional Documents

Culture Documents

Storage Tank G.A UL 142

Storage Tank G.A UL 142

Uploaded by

Abdur RehmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Storage Tank G.A UL 142

Storage Tank G.A UL 142

Uploaded by

Abdur RehmanCopyright:

Available Formats

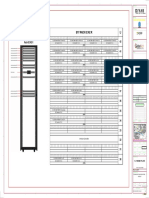

A B C D E F G H I J K

6160 DESIGN DATA

DESIGN CODE ANSI / UL 142, EDITION 2010

6000

EQUIPMENT DIESEL OIL STORAGE TANK

78 LIFTING LUG LIFTING LUG 78

N7 EQUIPMENT TAG NUMBER DT-01

N4 N9 N10 MH1 N8 N5 N1

A 152 300 550 450 600 800 1000 600 400 450 550 300 QUANTITY 1

DESIGN PRESSURE psig ATMOSPHERIC

THK.

8 8

DESIGN TEMPERATURE °C 85

6

1 1A 2 1 3 3A

OPERATING PRESSURE psig -

OPERATING TEMPERATURE °C -

FLUID DIESEL OIL

N3 RADIOGRAPHY SPOT(RT-4)

LS - 3A AT 315.5° JOINT EFFICIENCY 0.85

LS - 1A AT 315.05°

CORROSION ALLOWANCE(int) mm 1.5

LS - 1 AT 45° LS - 3 AT 45° HYDROTEST PRESSURE psig 5

SUPPORT TYPE SADDLE

1075 LS - 2 AT 300°

4 INT. ANGLE 4 MATERIALS

HEAD SPT INT. ANGLE

SHELL A-36

7 HEAD SPT 7

HEAD A-36

INT. RING SPT INT. RING SPT FLANGES A-105

SHELL ID. = n2540

CS - 1

NAME PLATE REINFORCEMENT PADS A-36

CS-2

CS-4

CS-3

NOZZLE NECK A-106 Gr.B Smls. & A-36

INTERNAL / EXTERNAL ATTACHEMENTS SS 304 / A-36

BOLTS / NUTS A-193 Gr.B7 / A-194 Gr.2H

W.L.

W.L.

1064

FITTINGS (INT. & EXT.) A-105 / A-234 WPB

350 MH GASKETS NITRILE NBR

250 SADDLE A-36

EAR LUGS / TAILING LUG A-36

1100

NAME PLATE SS 304

EARTHING LUG SS 304

6 6

GENERAL NOTES:

1.ALL DIMENSIONS ARE IN mm UNLESS OTHERWISE SPECIFIED.

2.ALL FLANGES ARE IN ACCORDANCE WITH ASME B16.5 : 2013.

3.FLANGES BOLT HOLES TO STRADDLE THE PRINCIPLE (MAIN AXIS OF THE VESSEL).

LS - 2A AT 210.05° 4.ALL NOZZLE NECKS (MADE FROM PIPE) SHALL MEET ASME B36.10 : 2018 REQUIREMENTS.

N2

5.ALL THREADED & SOCKET WELD FITTINGS ARE IN ACCORDANCE WITH ASME B16.11 : 2016.

6.ALL BUTT WELDED FITTINGS ARE IN ACCORDANCE WITH ASME B16.9 : 2018.

ERL 7.GASKETS WILL BE SPIRAL WOUND SS 304, GRAPHIT FILLED OR EQUIVALENT AS PER ASME B16.20

: 2017.

1500 1500 8.VESSEL TOLERANCES SHALL BE IN ACCORDANCE WITH ASME SECTION VIII DIV.1 : 2019.

9. WELD SYMBOLS SHALL BE IN ACCORDANCE WITH AWS A2.4, EDITION 2020.

400 600 900 10.BREAK ALL SHARP EDGES, REMOVE ALL BURRS & WELD SPATTERS AND HAVE CLEAN / CLEAR

SLIDING

SADDLE

A

SADDLE

SURFACE BEFORE INSPECTION.

FIXED

N6 N11

5 11.WELDING DETAILS TO BE IN ACCORDANCE WITH ASME SECTION VIII DIV.1 & ASME SECTION IX. 5

1000 4000 1000 12.THE INSIDE EDGE OF ALL NOZZLES SHALL BE ROUNDED OFF BY GRINDING TO PRODUCE

SMOOTH FINISH.

13.ALL REINFORCEMENT PADS TO BE PROVIDED WITH 1 Nos. MAXIMUM DIAMETER 7/16" (11 mm)

ELEVATION VIEW THREADED VENT HOLE

N4 N9 N10 MH-1 N8 N5 N7 N1

LS - 1A LOCATED 180° APART IN THE LOWER PART FOR PNEUMATIC TESTING.THESE HOLES TO BE

° 0°

95 LIFTING LUG FILLED WITH

LS - 3A 44.

315.05° PLASTIC SEALANT OR GREASE AFTER PNEUMATIC TEST.

14.ALL FILLET WELDS SHALL BE CONTINUOUS.

60° N3 15.ALL WELDING SHALL BE DONE BY SMAW, GMAW, GTAW OR SAW PROCESSES TO SUIT.

TAPER 1 : 3 60°

IF REQ'D REFERANCE DRAWING TABLE

OUT SIDE

OUT SIDE Sr. No. DRAWING No. TITLE

LS - 1

1 DT - 02 NOZZLE & ATTACHMENT DETAIL DRAWING

LS - 2 LS - 3

2 DT - 03 MH-1 DETAIL DRAWING

0.5~1.5

4 2~3 300° 45° 4

0.5~1.5

2~3 3 DT - 04 SADDLE DETAIL DRAWING

4 DT - 05 DETAIL DRAWING OF NAME PLATE

TYP.

980

CIRC. & LONG. WELD DETAIL LONG. & CIRC. WELD DETAIL

NAME

FOR EQUAL THICKNESS FOR UN EQUAL THICKNESS PLATE

TYPICAL TYPICAL

270° 90°

3 3

120°

1600 132°

LS - 2A

210.05°

30. N2

05°

180°

THK.

2300

20

2 2

N11 N6

VIEW A-A

NOZZLE DATA

NOZZLE SIZE DN SCHEDULE PROJECTION FROM C.L REPAD OD

QTY. RATING / CLASS TYPE / FACING SERVICE REMARKS

MARK [NPS] / THICK OF SHELL / W.L OF HEAD x THK.

MH1 1 600(24) 10 THk. F.B SEE DWG MANHOLE WITH BLIND YES

N1 1 100(4) 150 SORF 80 / - 150 INLET - YES DRAWN

N2 1 100(4) 150 SORF 80 / - 150 OUTLET - YES Masood 02/01/2024

CHECKED

N3 1 80(3) 150 SORF 80 / - 150 OVER FLOW - YES

AR TITLE

N4 1 100(4) 150 SORF 80 / - 150 RECIRCULATION LINE - YES QA

1 N5 1 50(2) 150 SORF 80 / - 150 VENT - NO GENERAL ARRANGEMENT DRAWING OF 1

N6 1 50(2) 150 SORF 80 / - 150 DRAIN - NO MFG

DIESEL TANK (30 CUM)

N7 1 40(1-1/2) 150 SORF 80 / - 150 LG - NO

ISOMETRIC VIEW N8 1 50(2) 150 SORF 80 / - 150 INSTRUMENT CONNECTION - NO

APPROVED

AR

DIESEL TANK (30 cum) N9 1 25 (1) 150 SORF 80 / - 150 TEMP. GAUGE - NO

SIZE DWG NO REV

N10 1 25 (1) 150 SORF 80 / - 150 HIGH LEVEL ALARM - NO A1 DT-01 A

N11 1 25 (1) 150 SORF 80 / - 150 LOW LEVEL ALARM - NO SCALE

SHEET 1 OF 1

A B C D E F G H I J K

You might also like

- Astm D4603 - IvDocument4 pagesAstm D4603 - IvramNo ratings yet

- Compact Mobility Unit R21Document8 pagesCompact Mobility Unit R21SfvvNo ratings yet

- ManualDocument27 pagesManualAbdur Rehman0% (1)

- Peso Tank Fabrication DWGDocument1 pagePeso Tank Fabrication DWGRishabh VermaNo ratings yet

- HSC01 SM10 Mta01 00001 Ou100017929 R1Document1 pageHSC01 SM10 Mta01 00001 Ou100017929 R1warmaster81No ratings yet

- Door No. Location Description Quantity Opening D - 7 14Th Floor (Sauna) Frameless Glass Door (With Smoke Glass)Document1 pageDoor No. Location Description Quantity Opening D - 7 14Th Floor (Sauna) Frameless Glass Door (With Smoke Glass)Al Noel 歡呼 ThordzNo ratings yet

- Oger International: Al Yamama PalaceDocument1 pageOger International: Al Yamama Palaceahmed sulimanNo ratings yet

- 100 A 32421PE-2 - Layout1Document1 page100 A 32421PE-2 - Layout1Frederique VerhulstNo ratings yet

- R1 Donor Cut Tower: Waste Hexane Drum Item No. D-718Document1 pageR1 Donor Cut Tower: Waste Hexane Drum Item No. D-718NoppolNorasriNo ratings yet

- ABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGDocument1 pageABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGPrabu KumarNo ratings yet

- ABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGDocument1 pageABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGPrabu Kumar100% (1)

- KLD 65 Pdfeed MP 2343 00001 0114 01Document1 pageKLD 65 Pdfeed MP 2343 00001 0114 01chandana kumarNo ratings yet

- 2103A - AYUSH AGRAWAL-Model-2Document1 page2103A - AYUSH AGRAWAL-Model-2Nidhi VermaNo ratings yet

- Chemical Storage Tank GADocument1 pageChemical Storage Tank GAdgmprabhakarNo ratings yet

- Diagrama Eléctrico de Tablero Tornatech GPDDocument8 pagesDiagrama Eléctrico de Tablero Tornatech GPDJorge Calcaneo Martinez100% (1)

- Detail A: Assembly and Detail Shipping Lug Detail 54" Steam Drum FM 120-124 LH BOILERDocument1 pageDetail A: Assembly and Detail Shipping Lug Detail 54" Steam Drum FM 120-124 LH BOILERmorrisonNo ratings yet

- Fw-211-1001-U-06 Ems-A1-20100-Axxx-1001 10160-Ewp-Dau-Ug-000-20101Document1 pageFw-211-1001-U-06 Ems-A1-20100-Axxx-1001 10160-Ewp-Dau-Ug-000-20101BADDY BADDYNo ratings yet

- 008-4th Floor & Roof PlanDocument1 page008-4th Floor & Roof Planmrhtoo119No ratings yet

- S-03710 M54161-1-Rev. 1-As F 8506-Steam Drum AssemblyDocument1 pageS-03710 M54161-1-Rev. 1-As F 8506-Steam Drum Assemblywylie01No ratings yet

- 4020-186-M-029 - 1 Cyanide Stripping Column - General Arrangement 1Document1 page4020-186-M-029 - 1 Cyanide Stripping Column - General Arrangement 1thoriq ikhwanNo ratings yet

- Door No. Location Description Quantity Opening D - 1 Basement 3 To Roofdeck (Typical Service Stair) Fire Rated DoorDocument1 pageDoor No. Location Description Quantity Opening D - 1 Basement 3 To Roofdeck (Typical Service Stair) Fire Rated DoorAl Noel 歡呼 ThordzNo ratings yet

- FL3B-474-P-2634 AsbuiltDocument1 pageFL3B-474-P-2634 AsbuiltAlbet MulyonoNo ratings yet

- Reinforcement Schedule:-: Section C-C T Section D-DDocument1 pageReinforcement Schedule:-: Section C-C T Section D-DyogendraNo ratings yet

- R1 Donor Cut Tower: Hexane Drum Item No. D-755Document1 pageR1 Donor Cut Tower: Hexane Drum Item No. D-755NoppolNorasriNo ratings yet

- Doc38-1 NG - CD - 1355046 - A16-1237589Document2 pagesDoc38-1 NG - CD - 1355046 - A16-1237589etudiant.bouzekri.houdaNo ratings yet

- Fortune BuildersDocument5 pagesFortune Buildersromeo pedranoNo ratings yet

- MH102 - Ground Floor PlanDocument1 pageMH102 - Ground Floor PlankarimNo ratings yet

- Component Detail: Detail of Dished EndDocument1 pageComponent Detail: Detail of Dished EndgobinathNo ratings yet

- Component DetailDocument1 pageComponent DetailgobinathNo ratings yet

- HKN SPD Ar DW 10906 ADocument1 pageHKN SPD Ar DW 10906 AHirushan MenukaNo ratings yet

- SD-9756 Rev 3Document3 pagesSD-9756 Rev 3Amresh KumarNo ratings yet

- Panel - CDocument31 pagesPanel - CAriNo ratings yet

- 2502 ArriboDocument64 pages2502 Arriboerick gonzalezNo ratings yet

- SC7062 11321 11321M Sc7062-Eh0d-Iso-10-11321m-018 00 SP-002Document1 pageSC7062 11321 11321M Sc7062-Eh0d-Iso-10-11321m-018 00 SP-002Hung NguyenNo ratings yet

- R-01 - Ga Reactor Tank 260l - Rev.03-Ga Tank-2Document1 pageR-01 - Ga Reactor Tank 260l - Rev.03-Ga Tank-2syahib muhijarNo ratings yet

- STORAGESDocument1 pageSTORAGESmukul1saxena6364No ratings yet

- Clarifier Tank Layout - 250 CMH PDFDocument1 pageClarifier Tank Layout - 250 CMH PDFepe civil1No ratings yet

- CCB AW and AD Monitoring 04072023Document1 pageCCB AW and AD Monitoring 04072023dayat marzukiNo ratings yet

- Branch For Additional Details and Information. Consult With Diebold Installation/ServiceDocument4 pagesBranch For Additional Details and Information. Consult With Diebold Installation/ServiceDNSXNo ratings yet

- Notes:: Typical Details of Expansion JointDocument1 pageNotes:: Typical Details of Expansion Jointsiddharth yadavNo ratings yet

- 20GHA91BR002Document1 page20GHA91BR002NITHIN MATHEWNo ratings yet

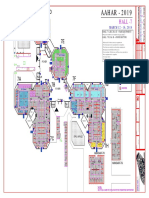

- AAHAR - 2019: Hall - 7Document1 pageAAHAR - 2019: Hall - 7dilipagarwalNo ratings yet

- 240605-TGY-YOGA ROOM SET-30.SignageDocument1 page240605-TGY-YOGA ROOM SET-30.Signagekts.chaunguyenNo ratings yet

- V313 40 (00017967) DecryptDocument15 pagesV313 40 (00017967) DecryptDiego TernavasioNo ratings yet

- Panel - BDocument31 pagesPanel - BAriNo ratings yet

- Baru 2Document3 pagesBaru 2Prima WijayaNo ratings yet

- V313 50 (00017967) DecryptDocument15 pagesV313 50 (00017967) DecryptDiego TernavasioNo ratings yet

- AEGIS 2 General ArrangementDocument1 pageAEGIS 2 General ArrangementMMTMNo ratings yet

- Door No. Location Description Quantity Opening D - 5 Lower Ground To 12Th Floor (Toilets at Retail Area) PVC Flush DoorDocument1 pageDoor No. Location Description Quantity Opening D - 5 Lower Ground To 12Th Floor (Toilets at Retail Area) PVC Flush DoorAl Noel 歡呼 ThordzNo ratings yet

- P&ID 207-R1-ModelDocument1 pageP&ID 207-R1-ModelShahab Z AhmedNo ratings yet

- Portfolio Unni MathewDocument7 pagesPortfolio Unni MathewUnni Mathew VachaparambilNo ratings yet

- A1 Sheet (P-1) SribalajiDocument1 pageA1 Sheet (P-1) Sribalajisribalaji.d2019No ratings yet

- 905.b Elevator DetailsDocument1 page905.b Elevator Details16tiktok treatsNo ratings yet

- V313 60 (00017967) DecryptDocument15 pagesV313 60 (00017967) DecryptDiego TernavasioNo ratings yet

- Door No. Location Description Quantity Opening D - 10A 17Th To 18Th Floor (Bedrooms) Molded Door (Hollow Core)Document1 pageDoor No. Location Description Quantity Opening D - 10A 17Th To 18Th Floor (Bedrooms) Molded Door (Hollow Core)Al Noel 歡呼 ThordzNo ratings yet

- Planos Electricos Del MV 1000Document13 pagesPlanos Electricos Del MV 1000jhon.lunavNo ratings yet

- Vessel Drum Sew DWGDocument2 pagesVessel Drum Sew DWGSANGEETHANo ratings yet

- 07.detail Crossing CableDocument1 page07.detail Crossing CableNovi AntiNo ratings yet

- Door No. Location Description Quantity Opening D - 2 Basement 3 To Roofdeck (Electrical Room) Metal Flush DoorDocument1 pageDoor No. Location Description Quantity Opening D - 2 Basement 3 To Roofdeck (Electrical Room) Metal Flush DoorAl Noel 歡呼 ThordzNo ratings yet

- 125256-22072 LCG3015AJM2 (PL940) (AMNC3i - FS31i-LB) (EXP) Ver1.1Document1,944 pages125256-22072 LCG3015AJM2 (PL940) (AMNC3i - FS31i-LB) (EXP) Ver1.1jturnerNo ratings yet

- 124770-12966 ENSIS3015AJ (EXP) (Ver.1.0)Document1,167 pages124770-12966 ENSIS3015AJ (EXP) (Ver.1.0)AlexNo ratings yet

- d35227 15l Slantpro W EnclosureDocument1 paged35227 15l Slantpro W Enclosure1drydensamuelNo ratings yet

- KU-TWK-00-PI-SPC-0004 - 0 - General Specification - Piping Line Classes and ValvesDocument75 pagesKU-TWK-00-PI-SPC-0004 - 0 - General Specification - Piping Line Classes and ValvesAbdur RehmanNo ratings yet

- Technical QuestionnaireDocument1 pageTechnical QuestionnaireAbdur RehmanNo ratings yet

- Client: Contract: Job / Project TitleDocument5 pagesClient: Contract: Job / Project TitleAbdur RehmanNo ratings yet

- REV Description Date Originated BY Checked BY Approved BY: 01B IFR - Issued For ReviewDocument10 pagesREV Description Date Originated BY Checked BY Approved BY: 01B IFR - Issued For ReviewAbdur RehmanNo ratings yet

- Tank Heat Losses Cal. For Insulated TankDocument24 pagesTank Heat Losses Cal. For Insulated TankAbdur RehmanNo ratings yet

- DN Dat001 001Document4 pagesDN Dat001 001Abdur RehmanNo ratings yet

- Ku-Twk-20-Me-Dts-0006 - Data Sheet For Diesel Tank-5m3 CapacityDocument5 pagesKu-Twk-20-Me-Dts-0006 - Data Sheet For Diesel Tank-5m3 CapacityAbdur RehmanNo ratings yet

- Client: Contract: Job / Project TitleDocument10 pagesClient: Contract: Job / Project TitleAbdur RehmanNo ratings yet

- Client: Contract: Job / Project TitleDocument4 pagesClient: Contract: Job / Project TitleAbdur RehmanNo ratings yet

- MD 502 3DMB Eg PR RPT 0001 - C01Document195 pagesMD 502 3DMB Eg PR RPT 0001 - C01Abdur RehmanNo ratings yet

- PhysicsDocument2 pagesPhysicsAbdur RehmanNo ratings yet

- Stability of A Floating BodyDocument11 pagesStability of A Floating BodyAbdur RehmanNo ratings yet

- Heat Exchanger Lab Report Shell and TubeDocument26 pagesHeat Exchanger Lab Report Shell and TubeAbdur Rehman67% (3)

- Engr. Etizaz Ahsan Noor: Qualification Bsc. Chemical Engineering (Uet Lahore) Subject Specialist: (Matric, FSC Chemistry)Document1 pageEngr. Etizaz Ahsan Noor: Qualification Bsc. Chemical Engineering (Uet Lahore) Subject Specialist: (Matric, FSC Chemistry)Abdur RehmanNo ratings yet

- Amir Ali Shah: Contact InformationDocument3 pagesAmir Ali Shah: Contact InformationAbdur RehmanNo ratings yet

- Measurement and Instrumentation Lab: Experiment # 1Document4 pagesMeasurement and Instrumentation Lab: Experiment # 1Abdur RehmanNo ratings yet

- Structural Evolution of The Jambi Sub-BasinDocument6 pagesStructural Evolution of The Jambi Sub-BasinRustyNo ratings yet

- Condition of EquilibriumDocument15 pagesCondition of EquilibriumwengsungNo ratings yet

- Whole PDFDocument191 pagesWhole PDFMYNAMENo ratings yet

- Ficha Tecnica C400D6Document4 pagesFicha Tecnica C400D6Caro PereraNo ratings yet

- Navision CFRONTDocument146 pagesNavision CFRONTfritz013579No ratings yet

- Final PPT 123Document26 pagesFinal PPT 123Narender KumarNo ratings yet

- Mobile CodesDocument353 pagesMobile CodesManav GuptaNo ratings yet

- Gen Chem Revision 2013 PDFDocument2 pagesGen Chem Revision 2013 PDFPSCNo ratings yet

- First Quarter Science ActivitiesDocument27 pagesFirst Quarter Science ActivitiesMary Rose P. RiveraNo ratings yet

- 'Lvvroyhg Dv$Qdo/Vlv (Ydoxdwlrqlq (Ohfwulf3Rzhu 7Udqviruphuvxvlqj&Rqyhqwlrqdo0Hwkrgv D5HylhzDocument10 pages'Lvvroyhg Dv$Qdo/Vlv (Ydoxdwlrqlq (Ohfwulf3Rzhu 7Udqviruphuvxvlqj&Rqyhqwlrqdo0Hwkrgv D5HylhzSergioCarabettiNo ratings yet

- Life Skills-II (Aptitude) Prtice Sheet-1 (CO1)Document7 pagesLife Skills-II (Aptitude) Prtice Sheet-1 (CO1)Kunal MansukhaniNo ratings yet

- Chastotnii Preobrazovatel Sunfar E300 Manual enDocument17 pagesChastotnii Preobrazovatel Sunfar E300 Manual enTamil SelvanNo ratings yet

- Integration - YongyoonnotesDocument5 pagesIntegration - YongyoonnotesTeak TatteeNo ratings yet

- Answer Key Computer Skills (CT 101) Book ActivitiesDocument10 pagesAnswer Key Computer Skills (CT 101) Book ActivitiesMOKHALLAD GHAWASNo ratings yet

- Gemini Photo Digitizer v.X9 - User ManualDocument65 pagesGemini Photo Digitizer v.X9 - User ManualTraian LucaNo ratings yet

- BoeingDocument9 pagesBoeingnavala_pra0% (1)

- Mitsubishi RV-2AJ Robot ControllerDocument33 pagesMitsubishi RV-2AJ Robot ControllerStoneNo ratings yet

- Engineering Proporties of Komice (Pumice) SoilDocument19 pagesEngineering Proporties of Komice (Pumice) SoilLiyu GudissaNo ratings yet

- Ship Resistance OP ShahDocument85 pagesShip Resistance OP ShahlakshmiNo ratings yet

- Codigos de FallaDocument5 pagesCodigos de FallaLuis Angel Condori MoralesNo ratings yet

- 8.1 Purpose of The Unit: 8 Design of Distillation ColumnDocument16 pages8.1 Purpose of The Unit: 8 Design of Distillation Columnsami ullahNo ratings yet

- Plugin Erect BaziDocument15 pagesPlugin Erect BazirendaoNo ratings yet

- How To Bypass The Windows 11 TPM 2.0 RequirementDocument1 pageHow To Bypass The Windows 11 TPM 2.0 Requirementdaniel100% (1)

- Isometric View: SLA Product Variables Part Id Nominal Size ID OD MFG WT Mass (KG)Document2 pagesIsometric View: SLA Product Variables Part Id Nominal Size ID OD MFG WT Mass (KG)leizel dacuNo ratings yet

- Basic C++ TasksDocument4 pagesBasic C++ TasksGhazanfar AliNo ratings yet

- 14 Item 206 BB Base BoardDocument4 pages14 Item 206 BB Base BoardAlexDorNo ratings yet

- Excel Short KeysDocument2 pagesExcel Short Keysdeepchandsharma100% (14)

- Bridge Barriers in Relation To The Crash Testing Standards: Wasim QADIRDocument8 pagesBridge Barriers in Relation To The Crash Testing Standards: Wasim QADIR정주호No ratings yet