Professional Documents

Culture Documents

Saic A 1016

Saic A 1016

Uploaded by

Ansar Ali VemmullyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic A 1016

Saic A 1016

Uploaded by

Ansar Ali VemmullyCopyright:

Available Formats

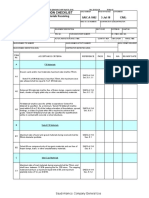

SAUDI ARAMCO ID/PIEU-15-July-2018-REV. 2018.05.00(Standards Cutoff - May 31,2018) Rev.2018.05.

00 31-May-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

HDPE Liner Placement and Seaming Inspection SAIC-A-1016 15-Jul-18 Civil-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Liner Placement

The subgrade should be smooth and free of all rocks, sharp stones,

A1 Method Statement

sticks, roots, sharp objects, or debris of any kind

Liner materials can be deployed by several methods. Ensure that

A2 whichever method is used does not damage the liner, and that the Method Statement

material is not folded, creased of crimped during deployment.

Deployment of liner shall be started first from the floor section. Floor

A3 Method Statement

section HDPE panels of required sizes shall be cut & prepared ready.

Deployment should not be attempted during periods of high wind, in the

A4 precence of excessive moisture or when ambient conditions prohibit Method Statement

successful welding operations

Vertical section panels and floor section panels are jointed by extrusion

A5 Method Statement

welding, with a min.clearance distance 300 mm from the vertical surface.

Liner placement shall not be done during any precipitation, in the

A6 Method Statement

presence of excessive moisture (e.g., fog, rain, dew).

B Seaming Inspection

Joint shall be prepared and executed in accordance with lining

B1 Method Statement

manufacturer's instructions.

Before making field joints, all wrinkles shall be removed from the surfaces

B2 Method Statement

to be joined.

B3 Joining surfaces shall be clean and dry. Method Statement

Cleaning solvents may not be used unless the product is approved by the

B4 Method Statement

liner manufacturer.

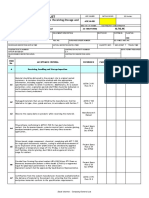

Field pints shall be lapped between 100 and 150 mm or as per

B4 Method Statement

manufacturer recommendation.

Wherever feasible, joining of surfaces shall use a wedge weld, with a void

B5 Method Statement

for air pressure testing and remaining by extrusion weld.

As the installation progresses all seams should be assigned an

B6 identification number and operators name should be recorded in the daily Method Statement

reports.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-15-July-2018-REV. 2018.05.00(Standards Cutoff - May 31,2018) Rev.2018.05.00 31-May-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

HDPE Liner Placement and Seaming Inspection SAIC-A-1016 15-Jul-18 CIVIL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

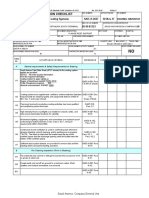

C Patching and Repairing

C1 Patching - Used to repair large holes, tears and sample cut locations. Method Statement

All patches shall extend at least three inches (3") or as per manufacturer

C2 recommendation beyond the edges of the defect and all corners of Method Statement

patches shall be rounded.

C3 Grinding and welding is used to repair section of extruded fillet seams. Method Statement

Spot welding or seaming is used to repair small tears, pinholes or other

C4 Method Statement

minor localized flaws.

C5 Capping is used to repair lengths of extrusion or fusion welded seams. Method Statement

C6 Extrude overlap runs along the length of fusion welded seams. Method Statement

Removal of suspected seam and replace with a strip of new material

C7 Method Statement

seamed into place.

REMARKS:

REFERENCE DOCUMENTS:

1- SAES-A-104 -- Wastewater Treatment, Reuse and Disposal, 25 July 2017

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Sample Structural Investigation ReportDocument16 pagesSample Structural Investigation Reportmr. one100% (1)

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saic A 1016Document2 pagesSaic A 1016karthi51289No ratings yet

- Saic A 1016Document2 pagesSaic A 1016Nickath BanuNo ratings yet

- SAIC-A-1016 Rev 8 HDPE Liner Placement and Seaming Inspection FinalDocument2 pagesSAIC-A-1016 Rev 8 HDPE Liner Placement and Seaming Inspection FinalGOSP3 QC MechanicalNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saic H 1004Document4 pagesSaic H 1004NASIR SYEDNo ratings yet

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechDocument3 pagesSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominNo ratings yet

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- A A A A A A: Saudi Aramco Inspection ChecklistDocument2 pagesA A A A A A: Saudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- SAIC-E-2009 Intrnal Cleanliness Insp of HEDocument2 pagesSAIC-E-2009 Intrnal Cleanliness Insp of HEAnonymous S9qBDVkyNo ratings yet

- Saic H 2014Document2 pagesSaic H 2014Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistAbdul Hannan100% (1)

- Saic H 2015Document4 pagesSaic H 2015jerinNo ratings yet

- Satr M 1063Document3 pagesSatr M 1063jerin100% (1)

- Saic H 1003Document4 pagesSaic H 1003NASIR SYEDNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document8 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- Saic H 2060Document11 pagesSaic H 2060jerinNo ratings yet

- SAIC-H-2032 Rev 7Document4 pagesSAIC-H-2032 Rev 7Satheesh Rama SamyNo ratings yet

- Saic M 1034Document3 pagesSaic M 1034Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document2 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saic LPT 2006Document12 pagesSaic LPT 2006jerinNo ratings yet

- SAIC-H-1002 Rev 7 (Final)Document2 pagesSAIC-H-1002 Rev 7 (Final)ryann mananquilNo ratings yet

- Saic B 1004Document2 pagesSaic B 1004jerinNo ratings yet

- Concrete RepairDocument7 pagesConcrete Repair69badbutchNo ratings yet

- SACIC-S-4098 Rev - Fit Layer Laminate of RTRGRE, GRV, and GRP PipingDocument2 pagesSACIC-S-4098 Rev - Fit Layer Laminate of RTRGRE, GRV, and GRP PipingShohrab JiNo ratings yet

- Saudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistNickath BanuNo ratings yet

- Architectural Painting Works Ins ChecklistDocument2 pagesArchitectural Painting Works Ins Checklistmunna100% (1)

- Saic A 1006Document1 pageSaic A 1006Niel TanedoNo ratings yet

- Saic W 2036Document2 pagesSaic W 2036Basheer VadakkethilNo ratings yet

- SAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionDocument2 pagesSAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionzuknesedriNo ratings yet

- Saic M 1012Document2 pagesSaic M 1012Hussain Nasser Al- NowiesserNo ratings yet

- Satr H 1003Document2 pagesSatr H 1003Thouseef MaNo ratings yet

- SATIP-H-002-01 Rev 7Document4 pagesSATIP-H-002-01 Rev 7Satheesh Rama SamyNo ratings yet

- Satr H 1003Document2 pagesSatr H 1003DipuNo ratings yet

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- Saic N 2026Document3 pagesSaic N 2026jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic LPT 2004Document13 pagesSaic LPT 2004jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiNo ratings yet

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocument1 pageSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387No ratings yet

- Saic A 1002Document2 pagesSaic A 1002karthi51289No ratings yet

- Saic H 2011Document2 pagesSaic H 2011Ansar Ali VemmullyNo ratings yet

- Saic H 1003Document2 pagesSaic H 1003Hussain Nasser Al- NowiesserNo ratings yet

- Saic-M-1018 Rev 7 (Final)Document3 pagesSaic-M-1018 Rev 7 (Final)Satheesh Rama SamyNo ratings yet

- SAIC-H-2007 Rev 7Document5 pagesSAIC-H-2007 Rev 7isslam elhoussanyNo ratings yet

- Afic M 001Document2 pagesAfic M 001Basir AhmadNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 Mechkarthi51289No ratings yet

- Saic H 2002Document3 pagesSaic H 2002NASIR SYEDNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001ansar aliNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic A 1001Document3 pagesSaic A 1001QCI MYOUSIFNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanNo ratings yet

- Saic A 1006Document1 pageSaic A 1006munibbarcaNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 1-Nov-09 CivilDocument1 pageSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saic-H-2027Document3 pagesSaic-H-2027momin0% (1)

- Saudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 30-Apr-13 MechDocument4 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Saic A 1013Document2 pagesSaic A 1013Ansar Ali VemmullyNo ratings yet

- Satip e 007 01Document10 pagesSatip e 007 01Ansar Ali VemmullyNo ratings yet

- Satip D 109 01Document12 pagesSatip D 109 01Ansar Ali VemmullyNo ratings yet

- Satip e 004 01Document10 pagesSatip e 004 01Ansar Ali VemmullyNo ratings yet

- Saic A 1015Document1 pageSaic A 1015Ansar Ali VemmullyNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Ansar Ali VemmullyNo ratings yet

- Saic H 2010Document1 pageSaic H 2010Ansar Ali VemmullyNo ratings yet

- Saic A 1004Document3 pagesSaic A 1004Ansar Ali VemmullyNo ratings yet

- Saic Q 1017Document1 pageSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- Saic P 3314Document2 pagesSaic P 3314Ansar Ali VemmullyNo ratings yet

- ASTM E164-13 Standard Practice For Contact Ultrasonic Testing of WeldmentsDocument24 pagesASTM E164-13 Standard Practice For Contact Ultrasonic Testing of WeldmentsFernandoi100% (1)

- Junior Project Manager Transportation - GeoconsultDocument1 pageJunior Project Manager Transportation - GeoconsultJorge RodriguezNo ratings yet

- Standard Test Procedures PDFDocument391 pagesStandard Test Procedures PDFferdinanad100% (1)

- Sheet Metal Forming BrochureDocument2 pagesSheet Metal Forming BrochureEldori1988No ratings yet

- F-6000 Tapered Joint InstallationDocument78 pagesF-6000 Tapered Joint InstallationDavid Luna MolinaNo ratings yet

- Os 12699 16 - Igbt ConverterDocument4 pagesOs 12699 16 - Igbt ConverterkasiiiiiNo ratings yet

- Why Projects FailDocument18 pagesWhy Projects FailGursimran SinghNo ratings yet

- LOD Spec 2016 Part I 2016-10-19 PDFDocument207 pagesLOD Spec 2016 Part I 2016-10-19 PDFzakariazulkifli92No ratings yet

- Facts: Volvo Buses. When Productivity CountsDocument2 pagesFacts: Volvo Buses. When Productivity CountsPhilippine Bus Enthusiasts SocietyNo ratings yet

- Annexure II UNOPS Health Safety PlanDocument8 pagesAnnexure II UNOPS Health Safety PlanBojan Bijelic100% (1)

- Design Thickness of Cold Formed Members and Sheeting: Continued From p32Document1 pageDesign Thickness of Cold Formed Members and Sheeting: Continued From p32Jianhua WuNo ratings yet

- Cutting Data - Greenwood Tools LTDDocument3 pagesCutting Data - Greenwood Tools LTDJayakrishnaNo ratings yet

- Financial Statement Analysis PDFDocument31 pagesFinancial Statement Analysis PDFkeshaw0% (1)

- Kay Bouvet Engineering Pvt. LTD Central Inspection: Academy of Welding & Consultancy ServicesDocument7 pagesKay Bouvet Engineering Pvt. LTD Central Inspection: Academy of Welding & Consultancy ServicessatnamNo ratings yet

- FRP VesselsDocument4 pagesFRP VesselsKAMIL SHAIKHNo ratings yet

- Homework # 1:: CPM PertDocument2 pagesHomework # 1:: CPM PertShivpreet SharmaNo ratings yet

- ANG en Construction Business 23022006Document94 pagesANG en Construction Business 23022006Cris NeculaNo ratings yet

- Indian Low Medium Voltage Switch Gear Markets FinalDocument17 pagesIndian Low Medium Voltage Switch Gear Markets FinalpraveenramkrishNo ratings yet

- 《Advanced Manufacturing Technology》Experimental ReportDocument11 pages《Advanced Manufacturing Technology》Experimental ReportFarhan mahmud RashikNo ratings yet

- Delay AnalysisDocument40 pagesDelay AnalysisNuha Mansour100% (12)

- Multi Trade PrefabricationDocument6 pagesMulti Trade PrefabricationPaul KwongNo ratings yet

- PeopleSoft Campus Solutions CS 9.2 Release NotesDocument8 pagesPeopleSoft Campus Solutions CS 9.2 Release NotesAkash Kumar Shandilya100% (1)

- NA To Sls en 1991-1-1Document12 pagesNA To Sls en 1991-1-1Shan Sandaruwan AbeywardeneNo ratings yet

- Project FailureDocument12 pagesProject Failurebronco7211100% (1)

- Internal OHS Audit MethodologyDocument8 pagesInternal OHS Audit MethodologyZakari Ibrahim EbijeNo ratings yet

- CMJU-Common Fee Structure (W.e.f. 01 March, 2012) : Sl. No. Course University Fee (Per Year)Document3 pagesCMJU-Common Fee Structure (W.e.f. 01 March, 2012) : Sl. No. Course University Fee (Per Year)souvik5000No ratings yet

- Oracle DB - Machine V2 DatasheetDocument6 pagesOracle DB - Machine V2 Datasheetrichard.linton9586No ratings yet

- TC Case Study End To End Managed Solutions v1.1Document4 pagesTC Case Study End To End Managed Solutions v1.1Chirag ShahNo ratings yet