Professional Documents

Culture Documents

All Steel Unibody Valve: Bulletin No. 84-00C For Use As Gauge Valve

All Steel Unibody Valve: Bulletin No. 84-00C For Use As Gauge Valve

Uploaded by

baladiroyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

All Steel Unibody Valve: Bulletin No. 84-00C For Use As Gauge Valve

All Steel Unibody Valve: Bulletin No. 84-00C For Use As Gauge Valve

Uploaded by

baladiroyaCopyright:

Available Formats

All Steel Unibody Valve Bulletin No.

84-00C

For use as Gauge Valve

Type V2 & V3

Sizes 1/4" & 3/8" MPT or FPT Globe & Angle

For Ammonia, R22, R507, R134a, R404a

Other Refrigerants and Oils

FEATURES

• ASTM Forged Steel Body

• Design Pressure 450 PSIG (PS), 32 bar

• Fluid Temperature Range -40 deg F to 240 deg F

• Stainless Steel Stem

• Options: Angle or Globe Body, Extended connection

lengths, 3/8" Ferulok Connection (accepts 3/8" OD

tube)

Material Specification

Body: Forged steel, ASTM A105 C 1029 zinc plated

Packing Nut: Steel

Stem: Stainless steel, 1/4" square flats

Stem Packing: Graphite base

Seal Cap: Plastic or Aluminum (V3 only)

Seal Cap O-ring: Neoprene January 2003

Installation, Service and Parts Information

Description

This line of rugged all steel bodied tiny hand valves are The valve is manually closed to prevent venting or to permit

downstream component servicing. When manually opened,

designed to seat tight and permit isolation of small system

the inlet pressure source is equalized to the downstream side.

components. The stainless steel stem has the safety This supports draining, venting, purging or component

feature of being non-removable. The angle bodied valve isolation.

and the globe body, employ the same features. The Safe Operation (See also Bulletin RSB)

optional MPT or FPT connection and variable extended People doing any work on a refrigeration system must be

lengths are provided on both body sizes. See table on qualified and completely familiar with the system and the

page 2. Refrigerating Specialties Division valves involved, or all

Principles of Operation other precautions will be meaningless. This includes

These multiple use small hand valves are normally mounted to reading and understanding pertinent Refrigerating Special-

pipe line components and lead to a gauge or instrument line. ties Division product Bulletins and Safety Bulletin RSB prior

Flow rate are not generally of consideration except where to installation or servicing work.

valve is employed as a drain device or on remote piloted Where cold refrigerant liquid lines are used, it is necessary that

control valves certain precautions be taken to avoid damage that could result

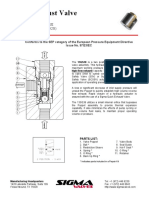

Angle Body from liquid expansion. Temperature increase in a piping

with optional Ferulok Connection section full of solid liquid will cause high pressure due to the

SEAL CAP expanding liquid that can possibly rupture a gasket, pipe or

valve. All hand valves isolating such sections should be

PACKING NUT marked, warning against accidental closing, and must not be

STAINLESS closed until the liquid is removed. Check valves must never be

STEEL STEM installed upstream of solenoid valves, or regulators with

electric shut-off, nor should hand valve upstream of solenoid

valves or downstream of check valves be close until the liquid

O-RING WASHERS has been removed. It is advisable to properly install relief

devices in any section where liquid expansion could take

FERULOK place.

PACKING

NUT

Avoid all piping or control arrangements that might produce

FORGED thermal or pressure shock. For the protection of people and

STEEL BODY products, all refrigerant must be removed from the section to

FERULOK be worked on before a valve, strainer, or other device is

SLEEVE opened or removed. Flanges with ODS connections are not

Fig 1 suitable for ammonia service.

Refrigerating Specialties Division 1

309277

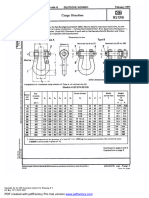

V2 V3

A A

2.75 4.23

2.48

3.76

Unibody Body Inlet Extension Connection

Valve Size Style Connection on Inlet Style Seal Cap

V2 A M 00 N A

Valve Size Style Inlet Extension on Inlet* Connection Seal Cap

V2 1/4" Body A Angle M MPT* 00 None or Female N NPT A Aluminum

V3 3/8" Body G Globe F FPT V2 V3 F Ferulok* (V3 only)

*Globe body with 10 2.50" 13 3.25" P Plastic

13 3.25" 16 4.00" *V2 Angle only

MPT inlet must

have extension. 15 3.75" 20 5.00"

21 5.25" 24 6.00"

26 6.50" 28 7.00"

30 7.50" 32 8.00"

34 8.50"

* Available on MPT inlet only.

Warranty

All Refrigerating Specialties products are warranted against the field; damaged in transit, accidents, misuse, or abuse.

defects in workmanship and materials for a period of one year Products disabled by dirt or other foreign substances will not

from date of shipment from originating factory. This warranty is be considered defective.

in force only when products are properly installed, field The express warranty above constitutes the only warranty of

assembled, maintained, and operated in use and service as Refrigerating Specialties products, and is in lieu of all other

specifically stated in Refrigerating Specialties Catalogs or warranties, expressed or implied, written or oral, including any

Bulletins for normal refrigeration applications, unless other- warranty of merchantability or warranty of fitness for a particu-

wise approved in writing by Refrigerating Specialties Division. lar purpose and in no event is Refrigerating Specialties

Defective products, or parts thereof returned to the factory with responsible for any consequential damages of any nature

transportation charges prepaid and found to be defective by whatsoever. No employee, agent, dealer or other person is

factory inspection will be replaced or repaired at Refrigerating authorized to give any warranties on behalf of Refrigerating

Specialties option, free of charge F.O.B. factory. Warranty Specialties nor to assume for Refrigerating Specialties any

does not cover products that have been altered, or repaired in other liability in connection with any of it products.

Refrigerating Specialties Division 2

You might also like

- ISO TR 10358-1993 ScanDocument54 pagesISO TR 10358-1993 ScanbaladiroyaNo ratings yet

- Va18 Va19Document59 pagesVa18 Va19joymotiNo ratings yet

- Check Valve: Product Bulletin 50-13 CDocument2 pagesCheck Valve: Product Bulletin 50-13 CHuong QuangNo ratings yet

- Avk Gate Valves PDFDocument9 pagesAvk Gate Valves PDFDanielNo ratings yet

- C47 Series IOMDocument8 pagesC47 Series IOMKannan KrisNo ratings yet

- Aventics-R432015593-datasheetDocument10 pagesAventics-R432015593-datasheetantony.ideharaNo ratings yet

- Swing-Flex Check Valve: Operation, Maintenance and Installation ManualDocument8 pagesSwing-Flex Check Valve: Operation, Maintenance and Installation ManualAhmed ShawkyNo ratings yet

- Check Valve - Type CK4ADocument4 pagesCheck Valve - Type CK4AHuong QuangNo ratings yet

- 1 e 456635032Document16 pages1 e 456635032Jaganathan KrishnanNo ratings yet

- Válvula Globo Tipo Placa - Spirax SarcoDocument2 pagesVálvula Globo Tipo Placa - Spirax SarcodgarciabNo ratings yet

- 3.20 On-Off - 27000Document13 pages3.20 On-Off - 27000Cuong TranNo ratings yet

- 52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFDocument7 pages52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFysr3eeNo ratings yet

- Parker Válvula de Segurança Modelos Type HDocument2 pagesParker Válvula de Segurança Modelos Type HFrancisco Javier Leal BrachoNo ratings yet

- Manual Angle Stop Valve EA: Ausgabe: 05/2007Document3 pagesManual Angle Stop Valve EA: Ausgabe: 05/2007Behnam AshouriNo ratings yet

- VSD08M ManualDocument4 pagesVSD08M ManualbnzelectricianshopNo ratings yet

- 08 6.H Pressure VesselDocument32 pages08 6.H Pressure VesselstargaxxxxNo ratings yet

- 50B-4KG1/2050B-4KG1: Pressure Relief ValveDocument2 pages50B-4KG1/2050B-4KG1: Pressure Relief ValveEduardo CastilloNo ratings yet

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- LT Valves Dual Plated Check ValvesDocument20 pagesLT Valves Dual Plated Check ValvesbhaaskarNo ratings yet

- Dv-2 Drain Valve Installation 001Document4 pagesDv-2 Drain Valve Installation 001AriesNo ratings yet

- Arcl Om1 2Document6 pagesArcl Om1 2Farhan FalahNo ratings yet

- ROSOV Manual - L & TDocument122 pagesROSOV Manual - L & TMuneeshNo ratings yet

- Codeline - 80E Series: 8 Inch End Entry Membrane Housing For Ro ApplicationsDocument29 pagesCodeline - 80E Series: 8 Inch End Entry Membrane Housing For Ro ApplicationsCecilia Guerra AburtoNo ratings yet

- Walworth Solid Wedge Slab Gate Valves Carbon Steel and Stainless Steel Class 150 To 900Document30 pagesWalworth Solid Wedge Slab Gate Valves Carbon Steel and Stainless Steel Class 150 To 900Ana LagunesNo ratings yet

- Valves Brochure2019 PDFDocument50 pagesValves Brochure2019 PDFscibduser001No ratings yet

- Flush Bottom Valve Installation-Maintenance-Manual PDFDocument12 pagesFlush Bottom Valve Installation-Maintenance-Manual PDFtuscan23No ratings yet

- Specifications, Applications, Service Instructions & Parts: Sealed Motor Valve & ControllersDocument32 pagesSpecifications, Applications, Service Instructions & Parts: Sealed Motor Valve & ControllersDario MoralesNo ratings yet

- Please Read These Instructions Carefully: GRW/GRL Installation & Operation ManualDocument8 pagesPlease Read These Instructions Carefully: GRW/GRL Installation & Operation ManualCn RomaNo ratings yet

- 900 040 01Document8 pages900 040 01Alessandra FloresfarNo ratings yet

- Warning: Installation, Operating, & Maintenance InstructionsDocument9 pagesWarning: Installation, Operating, & Maintenance InstructionsAnggi SujiwoNo ratings yet

- Flomatic Model 109 NRS Intrucciones de InstalacionDocument3 pagesFlomatic Model 109 NRS Intrucciones de InstalacionJairo Javier Díaz MontenegroNo ratings yet

- Brochure Manifold 2 Valves Rev.00Document12 pagesBrochure Manifold 2 Valves Rev.00ParthibanNo ratings yet

- Om2 8110 0300 13Document66 pagesOm2 8110 0300 13Rizki AnggoroNo ratings yet

- Manual de Instalación de Válvula de BolaDocument4 pagesManual de Instalación de Válvula de BolaCesar GonzalesNo ratings yet

- 3-Way Dual Shut Off ValvesDocument1 page3-Way Dual Shut Off ValvesPete DechaNo ratings yet

- Manuals - G200 Series Back Check Valves Instruction Manual, Fisher-ENDocument4 pagesManuals - G200 Series Back Check Valves Instruction Manual, Fisher-ENrey sarNo ratings yet

- Series "RVT" Relief Valves: Installation and Maintenance InstructionsDocument4 pagesSeries "RVT" Relief Valves: Installation and Maintenance InstructionsFernando Cesar PérezNo ratings yet

- Worcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeDocument16 pagesWorcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeMijin28No ratings yet

- 2 TTB 3Document8 pages2 TTB 3mikecom21No ratings yet

- IBHCVDocument71 pagesIBHCVdvmahiidaNo ratings yet

- Apollo Top Entry Ball Valves Installation, Operation, & Maintenance ManualDocument9 pagesApollo Top Entry Ball Valves Installation, Operation, & Maintenance ManualErcan YilmazNo ratings yet

- Accumulator Block - Hydac - SAFDocument26 pagesAccumulator Block - Hydac - SAFBenAbrahamSamuelNo ratings yet

- Valvula de Control ProporcionalDocument8 pagesValvula de Control ProporcionalAlex ReañoNo ratings yet

- Shut-Off Valve Type SVA-S and SVA-L: Data SheetDocument33 pagesShut-Off Valve Type SVA-S and SVA-L: Data SheetDhouha Ben AbdallahNo ratings yet

- Viking Air Relief ValveDocument2 pagesViking Air Relief ValveSyed AsimNo ratings yet

- FlowserverDocument12 pagesFlowserverCesar Cedano VivarNo ratings yet

- DAN-EX Brochure WebDocument12 pagesDAN-EX Brochure Webzakkyf6455No ratings yet

- Quick Exh Valves 13QS40 - 41 - 80 Rev 0110Document2 pagesQuick Exh Valves 13QS40 - 41 - 80 Rev 0110khaldoun samiNo ratings yet

- Dia-Flo & Pure-Flo Diaphragm Valves Instruction Manual With Dia-Flo ActuatorDocument16 pagesDia-Flo & Pure-Flo Diaphragm Valves Instruction Manual With Dia-Flo Actuatorabdul rehmanNo ratings yet

- Oversized Solenoid Modulator Valve Kit: Aisin AW TF-80/81SCDocument1 pageOversized Solenoid Modulator Valve Kit: Aisin AW TF-80/81SCramon baronaNo ratings yet

- Model 54's 2" Thru 12": Eccentric Check Valves Flo-E-Centric Installation Instructions Flomatic CorporationDocument2 pagesModel 54's 2" Thru 12": Eccentric Check Valves Flo-E-Centric Installation Instructions Flomatic CorporationMASOUDNo ratings yet

- Butterfly Valve User ManualDocument10 pagesButterfly Valve User ManualEduardoAscencioNo ratings yet

- Dorot 68-De - El - MRDocument6 pagesDorot 68-De - El - MRJosé Daniel ArenasNo ratings yet

- Quick Exhaust Valve 13QS38 - 39Document2 pagesQuick Exhaust Valve 13QS38 - 39simplementemoiNo ratings yet

- Gate, Globe and Check Valves: A B C D E F G - F 1 0 - 0 0 6 4 C - 0 2 T YDocument9 pagesGate, Globe and Check Valves: A B C D E F G - F 1 0 - 0 0 6 4 C - 0 2 T Yrawatbs2020No ratings yet

- Bfe API 6a ValvesDocument32 pagesBfe API 6a ValvesAldo P WicaksanaNo ratings yet

- CVS EZ Instruction ManualDocument28 pagesCVS EZ Instruction ManualJohn Harry RamirezNo ratings yet

- 13QS38-39-90 Rev0422Document2 pages13QS38-39-90 Rev0422Murtaza AliNo ratings yet

- I & M Mark V-100 Series: NtroductionDocument16 pagesI & M Mark V-100 Series: Ntroductionwagner machado de moraesNo ratings yet

- AG Gauge Valves AEDocument51 pagesAG Gauge Valves AEbaladiroyaNo ratings yet

- AISI 1213 Carbon Steel Plate, AISI 1213 Sheet, AISI 1213 Flat Bar, AISI 1213 Round Bar, AISI 1213 SuppliersDocument2 pagesAISI 1213 Carbon Steel Plate, AISI 1213 Sheet, AISI 1213 Flat Bar, AISI 1213 Round Bar, AISI 1213 SuppliersbaladiroyaNo ratings yet

- DIN 609 Hex Fit BoltDocument10 pagesDIN 609 Hex Fit BoltbaladiroyaNo ratings yet

- DIN 1662 HexBoltFlngDocument11 pagesDIN 1662 HexBoltFlngbaladiroyaNo ratings yet

- Stainless Steel 316, 316L, 316H Grade Data SheetDocument3 pagesStainless Steel 316, 316L, 316H Grade Data SheetbaladiroyaNo ratings yet

- Astm A487 4 (A)Document1 pageAstm A487 4 (A)baladiroyaNo ratings yet

- Hardness Conversion TableDocument1 pageHardness Conversion TablebaladiroyaNo ratings yet

- DIN 3570 Strap (U-Bolt)Document2 pagesDIN 3570 Strap (U-Bolt)baladiroyaNo ratings yet

- Perimer Red Iron Oxide EpoxyDocument2 pagesPerimer Red Iron Oxide EpoxybaladiroyaNo ratings yet

- Epoxy GlassflakeDocument2 pagesEpoxy GlassflakebaladiroyaNo ratings yet

- DIN 797 Fund BoltDocument1 pageDIN 797 Fund BoltbaladiroyaNo ratings yet

- XPPHCDocument14 pagesXPPHCbaladiroyaNo ratings yet

- DIN 7157 - Fit TolerancesDocument5 pagesDIN 7157 - Fit TolerancesbaladiroyaNo ratings yet

- DIN 82016 Cargo ShacklesDocument3 pagesDIN 82016 Cargo ShacklesbaladiroyaNo ratings yet

- Weld-Overlay - Cladding - Solutions - 2017 - ENDocument36 pagesWeld-Overlay - Cladding - Solutions - 2017 - ENbaladiroyaNo ratings yet

- DIN 3771-1 (O'ring)Document27 pagesDIN 3771-1 (O'ring)baladiroyaNo ratings yet

- Astm E165-NdtDocument20 pagesAstm E165-NdtbaladiroyaNo ratings yet

- Groove DimensionsDocument2 pagesGroove DimensionsbaladiroyaNo ratings yet

- Table-1-ASME-B36.10M-2015-pip ScheduleDocument18 pagesTable-1-ASME-B36.10M-2015-pip SchedulebaladiroyaNo ratings yet

- Terastandard - Bsi Bs Iso 5597 267Document26 pagesTerastandard - Bsi Bs Iso 5597 267baladiroyaNo ratings yet

- National O Ring Catalogue 1Document36 pagesNational O Ring Catalogue 1baladiroyaNo ratings yet

- As568 Standard Size o RingsDocument6 pagesAs568 Standard Size o RingsbaladiroyaNo ratings yet

- Catalog Spring Energized SealsDocument13 pagesCatalog Spring Energized SealsbaladiroyaNo ratings yet

- Augusto 2012Document13 pagesAugusto 2012baladiroyaNo ratings yet

- Exercise - Chemical Reaction EngineeringDocument4 pagesExercise - Chemical Reaction EngineeringJan Mark FongfarNo ratings yet

- MMS - Diagnosis of SCP - 2001-07-31Document94 pagesMMS - Diagnosis of SCP - 2001-07-31Ricardo Hurtado HernándezNo ratings yet

- Laser Principle: Eman Ali AteeqDocument40 pagesLaser Principle: Eman Ali Ateeqmairaj2No ratings yet

- EP 222: Classical Mechanics - Lecture 1: Dipan K. GhoshDocument12 pagesEP 222: Classical Mechanics - Lecture 1: Dipan K. GhoshSiddharth Hari NairNo ratings yet

- Iapmo Ues Er493Document13 pagesIapmo Ues Er493jeffuangNo ratings yet

- 1 s2.0 S0958946506001983 MainDocument8 pages1 s2.0 S0958946506001983 Mainengr.shahidullahkhan123No ratings yet

- Dơnload I M The Great Immortal Hero S Love Interest 1 1st Edition K Klein Full ChapterDocument24 pagesDơnload I M The Great Immortal Hero S Love Interest 1 1st Edition K Klein Full Chapterthouincramp100% (2)

- Introduction To Steel Fiber Reinforced Concrete On Engineering Performance of ConcreteDocument3 pagesIntroduction To Steel Fiber Reinforced Concrete On Engineering Performance of Concreteحسان الحسنNo ratings yet

- Mamography PPT Nov 15 - 2022Document23 pagesMamography PPT Nov 15 - 2022Fouzia NoorNo ratings yet

- 101 - Chem. General ChemistryDocument33 pages101 - Chem. General Chemistrygmgmfn dhdNo ratings yet

- Impact Modifiers Processing Aids Lubricants Microorganism InhibitorsDocument19 pagesImpact Modifiers Processing Aids Lubricants Microorganism InhibitorsSheena GagarinNo ratings yet

- Yankovsky 2014Document29 pagesYankovsky 2014Deepak Kumar SinghNo ratings yet

- Point 1 Point 2 Point 3 Point 4 Point 5Document15 pagesPoint 1 Point 2 Point 3 Point 4 Point 5Annisa Prita MelindaNo ratings yet

- May 21 U5 MSDocument20 pagesMay 21 U5 MSemdyoverdriveNo ratings yet

- 3 Fluid Heat ExchangerDocument19 pages3 Fluid Heat ExchangerAswini RoutNo ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Cox Instruments Flow StraightenersDocument8 pagesCox Instruments Flow StraightenersYasmine ياسمينNo ratings yet

- P-F CURVE: (Potential Failure) : Vibration Analysis, Point Where Failure Starts To OccurDocument1 pageP-F CURVE: (Potential Failure) : Vibration Analysis, Point Where Failure Starts To OccurOscar Marino Campo BonellNo ratings yet

- Grade 2205 DuplexDocument9 pagesGrade 2205 Duplexkresimir.mikoc9765No ratings yet

- SeparatorDocument55 pagesSeparatorOsama HassanNo ratings yet

- Geography 2024 PAPERDocument4 pagesGeography 2024 PAPERunderdawg992No ratings yet

- Msa20111000007 87029177Document5 pagesMsa20111000007 87029177Mario Misael Machado LòpezNo ratings yet

- GTS Academy Free Demo Test PDFDocument10 pagesGTS Academy Free Demo Test PDFHallo KhanNo ratings yet

- VSP White Tiger UCP@A - Report - Aug22Document32 pagesVSP White Tiger UCP@A - Report - Aug22Khoa Nguyen MinhNo ratings yet

- Isododecane and Ldpe ProductionDocument6 pagesIsododecane and Ldpe ProductionjaveddilberNo ratings yet

- Cloud To Cloud (CC) and Intra-Cloud (IC)Document6 pagesCloud To Cloud (CC) and Intra-Cloud (IC)Leo CerenoNo ratings yet

- Definition of Earthquake - UsefulDocument1 pageDefinition of Earthquake - UsefulMJ Dayalo LaxamanaNo ratings yet

- CH 111-2-2023Document71 pagesCH 111-2-2023mirnadeem2021No ratings yet

- The Opportunities of Lithium in Thermal Energy Storage: A State-Of-The-Art ReviewDocument24 pagesThe Opportunities of Lithium in Thermal Energy Storage: A State-Of-The-Art ReviewFrancisco DazaNo ratings yet

- ChemE 146 Worksheet 01 Basics of Process SimulationDocument1 pageChemE 146 Worksheet 01 Basics of Process SimulationJovi LeoNo ratings yet