Professional Documents

Culture Documents

Cambridge International A Level: Design & Technology 9705/33

Cambridge International A Level: Design & Technology 9705/33

Uploaded by

Maya PopoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cambridge International A Level: Design & Technology 9705/33

Cambridge International A Level: Design & Technology 9705/33

Uploaded by

Maya PopoCopyright:

Available Formats

Cambridge International A Level

DESIGN & TECHNOLOGY 9705/33

Paper 3 October/November 2023

MARK SCHEME

Maximum Mark: 120

Published

This mark scheme is published as an aid to teachers and candidates, to indicate the requirements of the

examination. It shows the basis on which Examiners were instructed to award marks. It does not indicate the

details of the discussions that took place at an Examiners’ meeting before marking began, which would have

considered the acceptability of alternative answers.

Mark schemes should be read in conjunction with the question paper and the Principal Examiner Report for

Teachers.

Cambridge International will not enter into discussions about these mark schemes.

Cambridge International is publishing the mark schemes for the October/November 2023 series for most

Cambridge IGCSE, Cambridge International A and AS Level components, and some Cambridge O Level

components.

This document consists of 16 printed pages.

© UCLES 2023 [Turn over

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Generic Marking Principles

These general marking principles must be applied by all examiners when marking candidate answers. They should be applied alongside the

specific content of the mark scheme or generic level descriptors for a question. Each question paper and mark scheme will also comply with these

marking principles.

GENERIC MARKING PRINCIPLE 1:

Marks must be awarded in line with:

• the specific content of the mark scheme or the generic level descriptors for the question

• the specific skills defined in the mark scheme or in the generic level descriptors for the question

• the standard of response required by a candidate as exemplified by the standardisation scripts.

GENERIC MARKING PRINCIPLE 2:

Marks awarded are always whole marks (not half marks, or other fractions).

GENERIC MARKING PRINCIPLE 3:

Marks must be awarded positively:

• marks are awarded for correct/valid answers, as defined in the mark scheme. However, credit is given for valid answers which go beyond

the scope of the syllabus and mark scheme, referring to your Team Leader as appropriate

• marks are awarded when candidates clearly demonstrate what they know and can do

• marks are not deducted for errors

• marks are not deducted for omissions

• answers should only be judged on the quality of spelling, punctuation and grammar when these features are specifically assessed by the

question as indicated by the mark scheme. The meaning, however, should be unambiguous.

GENERIC MARKING PRINCIPLE 4:

Rules must be applied consistently, e.g. in situations where candidates have not followed instructions or in the application of generic level

descriptors.

© UCLES 2023 Page 2 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

GENERIC MARKING PRINCIPLE 5:

Marks should be awarded using the full range of marks defined in the mark scheme for the question (however; the use of the full mark range may

be limited according to the quality of the candidate responses seen).

GENERIC MARKING PRINCIPLE 6:

Marks awarded are based solely on the requirements as defined in the mark scheme. Marks should not be awarded with grade thresholds or

grade descriptors in mind.

© UCLES 2023 Page 3 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Question Answer Marks Guidance

Section A

Part A – Product Design

1(a) suitable material: 3 Accept any other suitable material or any other reason

appropriate to material choice

– aluminium alloy, stainless steel

– iroko, teak, cedar, pressure treated pine

– HDPE, polypropylene,

– Rattan (palm) synthetic rattan (polyethylene) 1

Reasons, dependant on material :

– looks attractive

– rigid, stable

– long lasting, little maintenance

21

1(b) quality of description: 9 Dependant on material chosen. Does not have to be

- fully detailed all/most stages 4–7 materials selected in part (i) can be a combination of

- some detail, 0–3 materials

quality of sketches up to 2 Solid hardwood top, may need boards joined and glued for

thickness or manufactured board and appropriate finish

Legs turned

Aluminium top with edging and support frame

Legs turned

Must show all key stages of manufacture for full marks

© UCLES 2023 Page 4 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Question Answer Marks Guidance

1(c) explanation could include: 8 Could be

– change in process; – self-assembly arrangement

– change in materials; – cast, whole or parts

– use of jigs, formers, moulds; – injection moulded, blow moulded (parts)

– simplification of design. – costs

– equipment/skills available

quality of explanation:

– logical, structured 4–6 Full details of moulds required for injection moulding or blow

– limited detail, 0–3 moulding

quality of sketches up to 2

Question Answer Marks Guidance

2 examination of issues 20 Discussion could include:

– wide range of relevant issues 4–8 – market demand

– limited range 0–3 – costs involved

– skill demands

quality of explanation – speed of production

– logical, structured 4–8

– limited detail, 0–3 examples / evidence could be

– specific products,

supporting examples / evidence 4 – specific production examples

Full understanding of the range of quantity unit, batch and

mass production systems and reasoning for application

© UCLES 2023 Page 5 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Question Answer Marks Guidance

3(a) description of process 14 Internal and external threading

internal

– fully detailed, all/most stages 3–5 – drill Ø 6.8 20 deep hole

– some detail, 0–2 – apply cutting compound

quality of sketches up to 2 7 – use taper the plug M8 tap

– ensure 900

– .5 rotation anticlockwise to break off chip

external

– secure in vice

– use M8 die in die holder

– apply cutting compound

– ensure 900

– thread to length

comb (finger) joint

– accurately mark out

– cut on inside of waste

line with tenon saw

– remove waste with

coping saw

– chisel to line

– fit and adjust if

required

calendering

– polymer in hopper,

– released to train of

heated rollers to create

a plastic sheet to

desired thickness

– cool

– cut to shape

Accept any other correct variations or methods.

© UCLES 2023 Page 6 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Question Answer Marks Guidance

3(b) Internal and external threading 6 Accept other valid explanations, brief outline points max 3

– difficult to produce any other way

– standard tools used

comb (finger) joint

– joint can be attractive

– strong mechanical strength

– lots of gluing area

calendaring

– even thickness, easily set

– large lengths of sheet produced / cut to width / length

– effective use of material, no wastage

23

© UCLES 2023 Page 7 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Question Answer Marks Guidance

Part B – Practical Technology

4(a) correct monocoque and frame structure 2 8 monocoque – loads are supported by an external skin e.g.

– clear explanation of differences 3–4 egg shell, aircraft fuselage

– explanation of one structure 1–2

– no creditable response 0 frame – built up of parts or members to support loads

quality of sketches up to 2

4(b)(i) quality of explanation 4 Ribs examples

– logical, structured, well communicated 3–4 e.g. food trays,

– limited detail, 1–2 gives stiffness,

– no creditable response 0 rigidity and

stability to

shapes, flat

sheets

4(b)(ii) quality of explanation 4 Braces add strength to

– logical, structured, well communicate 3–4 a joint e.g. wall bracket

– limited detail, 1–2

– no creditable response 0

© UCLES 2023 Page 8 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Question Answer Marks Guidance

4(b)(iii) quality of explanation 4 Gussets examples e.g. roof truss,

– logical, structured, well communicate 3–4 strengthen frames, Gusset plates are

– limited detail, 1–2 used to connect beams and columns

– no creditable response 0 together or to connect truss members,

bolted, screwed or welded.

5(a) See Appendix 1 6 allow 2 marks for calculated correct response

accurate drawing 2

bows notation used 2

correct response 8.7 N 2

5(b) appropriate example 21 6 egg – cycle helmet

quality of explanation honeycomb – doors

– logical, structured, well communicated 3–4 human skeleton – industrial robots

– limited detail, 1–2

– no creditable response 0

© UCLES 2023 Page 9 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Question Answer Marks Guidance

5(c) appropriate graph 2 8 key features

– key features fully explained 5–6

– most features explained not 3–4

– limited detail 1–2

– no creditable response 0

© UCLES 2023 Page 10 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Question Answer Marks Guidance

6 examination of issues 20 Discussion could include:

– wide range of relevant issues 4–8 – repeated accuracy

– limited range 0–3 – speed of production

– training requirements

quality of explanation – equipment costs

– logical, structured 4–8

– limited detail, 0–3 examples / evidence could be

– specific CAM applications,

supporting examples / evidence 4 – specific product examples

© UCLES 2023 Page 11 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Question Answer Marks Guidance

Part C – Graphic Products

7 isometric 1 20

handle 2

collar 2

threaded insert 2

frame 3

blade adjuster 2

slotted pins 2

pin holder 1

correct exploded alignment 2

thick and thin 3

Question Answer Marks Guidance

8 examination of issues 20 Discussion could include:

– wide range of relevant issues 4–8 – security

– limited range 0–3 – focal points, main items

– flow, circulation

quality of explanation – balance of products, images, prices

– logical, structured 4–8 – staff available

– limited detail, 0–3

examples / evidence could be

supporting examples / evidence 4 – specific exhibition features

– specific ways of dealing with security etc

© UCLES 2023 Page 12 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Question Answer Marks Guidance

9 See Appendix 2 20

scale 2

correct projection 2

completed front elevation 5

completed end elevation 3

plan 6

accuracy/line quality 2

© UCLES 2023 Page 13 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Question Answer Marks Guidance

Section B

10, 11 Analysis 80

and 12 Analysis of the given situation/problem. [0–5]

Detailed written specification of the design requirements.

At least five specification points other than those given in the

question [0–5]

Exploration

B Bold sketches and brief notes to show exploration of ideas

for a design solution, with reasons for selection.

range of ideas

annotation related to specification

marketability, [0–5]

innovation [0–5]

evaluation of ideas, [0–5]

selection leading to development [0–5]

communication [0–5]

Development

Bold sketches and notes showing the development,

reasoning and composition of ideas into a single design

proposal. Details of materials, constructional and other

relevant technical details.

Development [0–5]

reasoning [0–5]

materials [0–3]

constructional detail [0–7]

communication [0–5]

Proposed solution

Produce drawing/s of an appropriate kind to show the

complete solution.

proposed solution [0–10]

details/dimensions [0–5]

Evaluation

Written evaluation of the final design solution. [0–5]

© UCLES 2023 Page 14 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Appendix 1 Q5a

© UCLES 2023 Page 15 of 16

9705/33 Cambridge International A Level – Mark Scheme October/November 2023

PUBLISHED

Appendix 2 Q9

© UCLES 2023 Page 16 of 16

You might also like

- Cambridge International A Level: Design & Technology 9705/32Document17 pagesCambridge International A Level: Design & Technology 9705/32Maya PopoNo ratings yet

- 2023 Structural Equivalency Spreadsheet - v1 11Document145 pages2023 Structural Equivalency Spreadsheet - v1 11Prem SinghNo ratings yet

- Bus BodyDocument24 pagesBus BodyHarshdeepsinh Padhiyar100% (1)

- Cambridge International AS & A Level: Design and Technology 9705/32Document16 pagesCambridge International AS & A Level: Design and Technology 9705/32Roshan JhundooNo ratings yet

- Cambridge Assessment International Education: Design and Technology 9705/33 October/November 2019Document16 pagesCambridge Assessment International Education: Design and Technology 9705/33 October/November 2019Farai ThapeloNo ratings yet

- Cambridge IGCSE ™: Design & Technology 0445/12Document10 pagesCambridge IGCSE ™: Design & Technology 0445/12Ali SiddiqNo ratings yet

- Cambridge IGCSE ™: Chemistry 0620/43Document11 pagesCambridge IGCSE ™: Chemistry 0620/43Jahangir KhanNo ratings yet

- Cambridge International AS & A Level: Media Studies 9607/22 May/June 2020Document9 pagesCambridge International AS & A Level: Media Studies 9607/22 May/June 2020Mohamed HNo ratings yet

- Cambridge International AS & A Level: Design & Technology 9705/12Document17 pagesCambridge International AS & A Level: Design & Technology 9705/12Maya PopoNo ratings yet

- 9239 Ext OTG P1 MS BDocument13 pages9239 Ext OTG P1 MS BAlbert MarreddyNo ratings yet

- Cambridge International AS & A Level: Sociology 9699/22Document18 pagesCambridge International AS & A Level: Sociology 9699/22zoyaNo ratings yet

- Cambridge International AS & A Level: Economics 9708/23 October/November 2022Document15 pagesCambridge International AS & A Level: Economics 9708/23 October/November 2022Andrew BadgerNo ratings yet

- Cambridge International AS & A Level: Economics 9708/22Document20 pagesCambridge International AS & A Level: Economics 9708/22rose williamsNo ratings yet

- Cambridge International AS & A Level: EconomicsDocument15 pagesCambridge International AS & A Level: EconomicsAndrew BadgerNo ratings yet

- Cambridge International AS & A Level: Business 9609/13 October/November 2022Document19 pagesCambridge International AS & A Level: Business 9609/13 October/November 2022Sasa DzudzevicNo ratings yet

- Cambridge O Level: Biology 5090/41Document9 pagesCambridge O Level: Biology 5090/41MUHAMMAD SHAZIL AYUBNo ratings yet

- Pass Paper 2Document18 pagesPass Paper 2ttza999No ratings yet

- Cambridge International AS & A Level: Sociology 9699/21Document17 pagesCambridge International AS & A Level: Sociology 9699/21kinggatete2005No ratings yet

- Cambridge International AS & A Level: Business 9609/22Document38 pagesCambridge International AS & A Level: Business 9609/22sadafayub33No ratings yet

- Cambridge International AS & A Level: Economics 9708/22 October/November 2022Document17 pagesCambridge International AS & A Level: Economics 9708/22 October/November 2022kutsofatsoNo ratings yet

- Cambridge International AS & A Level: Design & Technology 9705/11Document17 pagesCambridge International AS & A Level: Design & Technology 9705/11Maya PopoNo ratings yet

- Cambridge International AS & A Level: English Language 9093/13Document13 pagesCambridge International AS & A Level: English Language 9093/13Mihaela Cristina LazarNo ratings yet

- Cambridge International AS & A Level: Psychology 9990/22Document21 pagesCambridge International AS & A Level: Psychology 9990/22rose williamsNo ratings yet

- Cambridge International AS & A Level: Sociology 9699/41Document19 pagesCambridge International AS & A Level: Sociology 9699/41zoyaNo ratings yet

- Cambridge International A Level: Chinese 9715/22Document18 pagesCambridge International A Level: Chinese 9715/22yomamathicccNo ratings yet

- Cambridge International ProjectDocument10 pagesCambridge International ProjectTalha NafeesNo ratings yet

- Cambridge IGCSE ™: First Language EnglishDocument21 pagesCambridge IGCSE ™: First Language EnglishDesy KamajayaNo ratings yet

- Success Groups: Cambridge Physics (0625)Document506 pagesSuccess Groups: Cambridge Physics (0625)Zolfa AlhelaniNo ratings yet

- Urdu P2 MSDocument20 pagesUrdu P2 MSrqb7704No ratings yet

- Cambridge International AS & A Level: Business 9609/32Document24 pagesCambridge International AS & A Level: Business 9609/32sadia asimNo ratings yet

- Cambridge O Level: Commerce 7100/21 October/November 2021Document18 pagesCambridge O Level: Commerce 7100/21 October/November 2021Abu IbrahimNo ratings yet

- Cambridge O Level: Chemistry 5070/42Document7 pagesCambridge O Level: Chemistry 5070/42Maheen BilalNo ratings yet

- Cambridge International AS & A Level: Business 9609/23Document33 pagesCambridge International AS & A Level: Business 9609/23691922029No ratings yet

- Cambridge International A Level: Chinese 9715/21Document18 pagesCambridge International A Level: Chinese 9715/21yomamathicccNo ratings yet

- Cambridge International AS & A Level: Economics 9708/22Document20 pagesCambridge International AS & A Level: Economics 9708/22Ibrahim AbidNo ratings yet

- Cambridge IGCSE ™: Chemistry 0620/43Document11 pagesCambridge IGCSE ™: Chemistry 0620/43Shashwat VignaradjNo ratings yet

- Cambridge O Level: Physics 5054/42Document7 pagesCambridge O Level: Physics 5054/42Lapu LapuNo ratings yet

- Cambridge Assessment International Education: Business Studies 0450/11 October/November 2018Document15 pagesCambridge Assessment International Education: Business Studies 0450/11 October/November 2018Hyacinth ChimundaNo ratings yet

- Cambridge O Level: Computer Science 2210/21Document18 pagesCambridge O Level: Computer Science 2210/21tashi docNo ratings yet

- Cambridge International AS & A Level: Accounting 9706/42Document13 pagesCambridge International AS & A Level: Accounting 9706/42mianhuzaifaalitajNo ratings yet

- Cambridge International AS & A Level: Economics 9708/23Document16 pagesCambridge International AS & A Level: Economics 9708/23Ibrahim AbidNo ratings yet

- Cambridge Assessment International Education: Business 9609/31 October/November 2019Document19 pagesCambridge Assessment International Education: Business 9609/31 October/November 2019Danny DrinkwaterNo ratings yet

- November 2022 (v3) MSDocument13 pagesNovember 2022 (v3) MSjoelfrewuniNo ratings yet

- Cambridge Assessment International Education: Business 9609/11 May/June 2018Document12 pagesCambridge Assessment International Education: Business 9609/11 May/June 2018Dhrisha GadaNo ratings yet

- Cambridge International AS & A Level: English Language 9093/11Document15 pagesCambridge International AS & A Level: English Language 9093/11Sanjana SatishNo ratings yet

- Cambridge International AS & A Level: Biology 9700/42 March 2020Document23 pagesCambridge International AS & A Level: Biology 9700/42 March 2020Y. PurwandariNo ratings yet

- Cambridge International AS & A Level: Psychology 9990/32 May/June 2022Document29 pagesCambridge International AS & A Level: Psychology 9990/32 May/June 2022petop43530No ratings yet

- Cambridge IGCSE™: First Language English 0500/12Document22 pagesCambridge IGCSE™: First Language English 0500/12KayNo ratings yet

- 0680-12 MarkschemeDocument14 pages0680-12 MarkschemeHatice AkcayNo ratings yet

- Cambridge International AS & A Level: Business 9609/42Document19 pagesCambridge International AS & A Level: Business 9609/42sadia asimNo ratings yet

- DT AnswerDocument9 pagesDT Answerkaderrto1986No ratings yet

- Mark Schdeme - 13Document15 pagesMark Schdeme - 13bmensahgms2No ratings yet

- Cambridge International AS & A Level: Business 9609/21Document31 pagesCambridge International AS & A Level: Business 9609/21691922029No ratings yet

- Cambridge International AS & A Level: Physics 9702/43 October/November 2022Document15 pagesCambridge International AS & A Level: Physics 9702/43 October/November 2022hamzaNo ratings yet

- Cambridge International AS & A Level: Design & Technology 9705/13Document16 pagesCambridge International AS & A Level: Design & Technology 9705/13Maya PopoNo ratings yet

- Cambridge International AS & A Level: Sociology 9699/12Document17 pagesCambridge International AS & A Level: Sociology 9699/12Imama WaqasNo ratings yet

- Project CambridgeDocument10 pagesProject Cambridgekaziba stephenNo ratings yet

- Cambridge International AS & A Level: Sociology 9699/13Document16 pagesCambridge International AS & A Level: Sociology 9699/13zoyaNo ratings yet

- Cambridge IGCSE™: Information and Communication Technology 0417/11 October/November 2020Document9 pagesCambridge IGCSE™: Information and Communication Technology 0417/11 October/November 2020osmanfut1No ratings yet

- Cambridge O Level: Travel & Tourism 7096/13 October/November 2022Document12 pagesCambridge O Level: Travel & Tourism 7096/13 October/November 2022ranveergour24No ratings yet

- Get PaperDocument7 pagesGet PaperXabso ShaafiNo ratings yet

- Overview of Aerospace StructuresDocument8 pagesOverview of Aerospace StructuresSameera SrivathsaNo ratings yet

- Monocoque Chassis DesignDocument6 pagesMonocoque Chassis DesignShivam JindalNo ratings yet

- Space Structures: Prof. Alessandro AiroldiDocument46 pagesSpace Structures: Prof. Alessandro Airoldigreenbird02No ratings yet

- Airframe and SystemsDocument104 pagesAirframe and SystemsVivek Baskar50% (2)

- 4.2 Bolt DesignDocument14 pages4.2 Bolt DesignbernabasNo ratings yet

- Mod 8 Aircraft StructureDocument39 pagesMod 8 Aircraft StructureXiaomi ProNo ratings yet

- Atpl 02 Airframes SystemsDocument350 pagesAtpl 02 Airframes Systemsbryanpok100% (1)

- Adama Science and Technology University School of Mechanical Chemical and Materials Engineering Department of Mechanical EngineeringDocument54 pagesAdama Science and Technology University School of Mechanical Chemical and Materials Engineering Department of Mechanical EngineeringShemsudin AhmedteibNo ratings yet

- Factors Affecting The Cost of Airplanes: Presented at The Aircraft Operations Session, Fourth Annual Meeting, 1. Ae. SDocument7 pagesFactors Affecting The Cost of Airplanes: Presented at The Aircraft Operations Session, Fourth Annual Meeting, 1. Ae. SnaveenreddyNo ratings yet

- Koenigsegg EngineeringDocument8 pagesKoenigsegg Engineeringgfdsal878No ratings yet

- Aircraft Structrures II Unit 1 Chapter 3BDocument21 pagesAircraft Structrures II Unit 1 Chapter 3BPragati SinghNo ratings yet

- 2014 FSAE Structural Equivalency Spreadsheet V1.2Document103 pages2014 FSAE Structural Equivalency Spreadsheet V1.2Homer SilvaNo ratings yet

- Chassis: by Naveen KDocument56 pagesChassis: by Naveen KNaveen KandasamyNo ratings yet

- 2017 FSAE ChassisDocument79 pages2017 FSAE Chassiseagles racingNo ratings yet

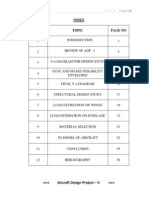

- Index: Aircraft Design Project - IIDocument56 pagesIndex: Aircraft Design Project - IIRohit MunaNo ratings yet

- CIA 2 Part ADocument9 pagesCIA 2 Part Aradhakrishnan100% (1)

- 1 AAM Body-StructuresDocument84 pages1 AAM Body-StructuresKabilan MuthukannanNo ratings yet

- Red Shift Plywood MonocoqueDocument3 pagesRed Shift Plywood Monocoquebimalamarnath100% (1)

- Chap 2 Aeronefs StructureDocument7 pagesChap 2 Aeronefs Structureismain.niniNo ratings yet

- Airframe StructuresDocument23 pagesAirframe StructuresARQUAM WAHAJNo ratings yet

- Using FEA Simulations To Guide Your Monocoque Conception: by Formule ETSDocument31 pagesUsing FEA Simulations To Guide Your Monocoque Conception: by Formule ETSFarzadNo ratings yet

- Monocoque & Semio-MonocoqueDocument2 pagesMonocoque & Semio-MonocoquePRIYA mohadNo ratings yet

- FUSELAGEDocument2 pagesFUSELAGEEster Souza100% (1)

- AircraftDocument202 pagesAircraftJohn Adrian RoceroNo ratings yet

- Geodetic Aircraft StructureDocument14 pagesGeodetic Aircraft Structurezanorak100% (4)

- Sub Module 13.2 Airframe Structures - General ConceptsDocument30 pagesSub Module 13.2 Airframe Structures - General ConceptsteacherNo ratings yet

- Test in English For Maintenance Licenses: Departamento Seguridad OperacionalDocument71 pagesTest in English For Maintenance Licenses: Departamento Seguridad OperacionalAdrianNo ratings yet