Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

5 viewsMechanical Engineering

Mechanical Engineering

Uploaded by

Marico River Conservation AssociationThis document outlines the modules and course content for an apprenticeship program in fitting and turning. The modules cover topics such as career opportunities, health and safety, engineering drawings, materials, tools and equipment, lifting concepts, screw threads, welding and cutting, and maintenance. Some of the specific course codes address subjects like drawing instruments, dimensioning methods, material properties, hand and power tools, rigging safety, thread calculations, and welding defects. The document provides a breakdown of the percentage of time spent on each module and the credits earned.

Copyright:

© All Rights Reserved

You might also like

- CASE 440, 440CT Series 3 Skid Steer Loader Service Repair Manual PDFDocument29 pagesCASE 440, 440CT Series 3 Skid Steer Loader Service Repair Manual PDFjkmmmm20% (5)

- Cat Forklift t40d t50d Service ManualDocument27 pagesCat Forklift t40d t50d Service Manualalexhughes210188sxi96% (52)

- Cat Forklift V40e V50e Schematic Service ManualDocument15 pagesCat Forklift V40e V50e Schematic Service Manualethanmann190786ikm98% (94)

- Cat Forklift v50d Schematic Service ManualDocument27 pagesCat Forklift v50d Schematic Service Manualashleymcneil190382yko99% (125)

- Cat Forklift Dp70 Service ManualDocument27 pagesCat Forklift Dp70 Service Manualsamanthamoyer170885csp100% (84)

- Reuse and Salvage GuidelinesDocument89 pagesReuse and Salvage Guidelinesmeceng86% (7)

- Cat Forklift Gp30 Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift Gp30 Schematic Service Operation Maintenance Manualfrankstewart270488qny99% (84)

- Case 430 Series 3 Skid Steer PDFDocument1,724 pagesCase 430 Series 3 Skid Steer PDFAny Rayli100% (3)

- SM PC300-350 LC 8Document1,025 pagesSM PC300-350 LC 8Cesar Ego-Aguirre Calderon93% (45)

- Case 440 440ct Series 3 Skid Steer Loader Service Repair ManualpdfDocument58 pagesCase 440 440ct Series 3 Skid Steer Loader Service Repair Manualpdfsebastian velasquezNo ratings yet

- Supersack Winch LC2A030DDocument79 pagesSupersack Winch LC2A030DMohamed AliNo ratings yet

- Catalogo Case 420Document1,840 pagesCatalogo Case 420Fabio100% (2)

- Crude Pump Installation Manual - SULZER PDFDocument992 pagesCrude Pump Installation Manual - SULZER PDFnobelr100% (4)

- Yanmar Diesel EngineDocument240 pagesYanmar Diesel Engineaveselov8887% (23)

- Catalogo Mcbee Cummins KT, QSK 2019Document64 pagesCatalogo Mcbee Cummins KT, QSK 2019Alexis Sanchez100% (1)

- CAT Excavator 330L 9ML ManualsDocument9 pagesCAT Excavator 330L 9ML ManualsCristhian Cardenas88% (8)

- Reading: Healthy Lifestyle Role For All Society'Document4 pagesReading: Healthy Lifestyle Role For All Society'Tore CusimanoNo ratings yet

- HV Turbo Aeration Compressor Service: EngineeringDocument3 pagesHV Turbo Aeration Compressor Service: EngineeringCornel NasturasNo ratings yet

- Impact of Porn On Youth 9Document4 pagesImpact of Porn On Youth 9terminolohiyaNo ratings yet

- 966H Wheel LoadersDocument54 pages966H Wheel Loadersjorge.quiquijana14No ratings yet

- Standard Bills of Materials: MetersDocument48 pagesStandard Bills of Materials: MetersgusmilexaNo ratings yet

- BFL Spinning ScheduleDocument3 pagesBFL Spinning ScheduleBADRI VENKATESHNo ratings yet

- Cat Forklift Gp40 Service Operation Maintenance ManualDocument25 pagesCat Forklift Gp40 Service Operation Maintenance Manualfrankstewart270488qny100% (87)

- 3000 Series Class Literature ListDocument5 pages3000 Series Class Literature ListNova KurniawanNo ratings yet

- Structural Fabrication SpecificationDocument18 pagesStructural Fabrication Specificationravirawat15No ratings yet

- List of Gear StandardDocument7 pagesList of Gear StandardManoj SinghNo ratings yet

- Gears Standards-1Document10 pagesGears Standards-1maheshmbelgavi100% (1)

- Final Year Project - (Mechanical) IEEE 2016-17 Project ListDocument10 pagesFinal Year Project - (Mechanical) IEEE 2016-17 Project ListSPECTRUM SOLUTIONSNo ratings yet

- S-000-1134-004 B 0020 20140625Document12 pagesS-000-1134-004 B 0020 20140625Faris Rosi100% (1)

- Helical Coil SpringDocument36 pagesHelical Coil SpringmailbkraoNo ratings yet

- Cat Forklift Vc60d Service ManualDocument27 pagesCat Forklift Vc60d Service Manualethanmann190786ikm99% (92)

- Cat Forklift Tc60d Schematic Service ManualDocument27 pagesCat Forklift Tc60d Schematic Service Manualchristineferguson190889rtw100% (125)

- H360 LaDocument3 pagesH360 LaAnderson SantosNo ratings yet

- 2013-m100k Int'l SparesDocument3 pages2013-m100k Int'l SparesabdulNo ratings yet

- Treadmill 93T-04 - THH100000 - PARTS LISTDocument19 pagesTreadmill 93T-04 - THH100000 - PARTS LISTpowerliftermiloNo ratings yet

- OPSS 2414 Nov08Document13 pagesOPSS 2414 Nov08Muhammad UmarNo ratings yet

- Engineer's Training Manual-2023Document16 pagesEngineer's Training Manual-2023Jagannath EpeeliNo ratings yet

- Lista Normas EngranajesDocument5 pagesLista Normas EngranajesCarlosQuelartNo ratings yet

- 4065 MDR Phase I - 191001-PaaDocument70 pages4065 MDR Phase I - 191001-PaaPrima AdhiyasaNo ratings yet

- Canalis KTA en Catalogue BD 27 03 2007Document214 pagesCanalis KTA en Catalogue BD 27 03 2007Gabriel Alexis Malagon CarvajalNo ratings yet

- 1U-5482 Pressure Adapter GroupDocument3 pages1U-5482 Pressure Adapter Groupvictor.cipriani0% (1)

- OEM Manuals Service Related Product LogDocument657 pagesOEM Manuals Service Related Product Logmatthew.polenNo ratings yet

- Normas Da AGMA - AtualizadaDocument2 pagesNormas Da AGMA - Atualizadaprofjohnalencar100% (1)

- Turbine Blade MachiningDocument36 pagesTurbine Blade Machiningyh1.yuNo ratings yet

- Shop PC300 8Document989 pagesShop PC300 8MaiChiVu100% (7)

- KoneMontgomery - 47-54 RefacionDocument8 pagesKoneMontgomery - 47-54 RefacionAlex GonzalezNo ratings yet

- Scule HidrauliceDocument34 pagesScule HidraulicelucianbordeutNo ratings yet

- Knuth Milling Machine VHF 3Document5 pagesKnuth Milling Machine VHF 3martin_jaitmanNo ratings yet

- Laurus As Built BOP Part Numbers - UnlockedDocument166 pagesLaurus As Built BOP Part Numbers - UnlockedEstuardo OlanNo ratings yet

- CATDocument21 pagesCATCendit thomas BarusNo ratings yet

- Normas Da AGMA AtualizadaDocument2 pagesNormas Da AGMA AtualizadaSERGIO ALMEIDA BOCCHINo ratings yet

- Ccs Prop ThicknessDocument21 pagesCcs Prop ThicknessAndreas ArapakopoulosNo ratings yet

- APT Special Offers WebDocument8 pagesAPT Special Offers Webjim_m_smithNo ratings yet

- NewDocument47 pagesNewPrufenAmin100% (1)

- LG933Document297 pagesLG933Li Eric0% (1)

- ISM-IsX Wiring Repair KitDocument1 pageISM-IsX Wiring Repair KitHolly ThompsonNo ratings yet

- Xl4000 Series AlkDocument19 pagesXl4000 Series AlkJesant17No ratings yet

- Parts Manual: Customer Support ServicesDocument21 pagesParts Manual: Customer Support ServicespowerliftermiloNo ratings yet

- TBA 3 POMPA - 4-04-13 Rev.1Document14 pagesTBA 3 POMPA - 4-04-13 Rev.1Pratama Trendy LeoNo ratings yet

- Specification For Manufacture Erection and Acceptance of Gate Hoists in Hydraulic and Hydroelectric ProjectsDocument40 pagesSpecification For Manufacture Erection and Acceptance of Gate Hoists in Hydraulic and Hydroelectric Projectssaliyarumesh2292No ratings yet

- Parts Catalog Cummins (500KVA), KTA19 G4 - ESN 41289367 - CPL 4153Document144 pagesParts Catalog Cummins (500KVA), KTA19 G4 - ESN 41289367 - CPL 4153Ari100% (2)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Engineering Graphics & Design P1 Nov 2022 AfrDocument8 pagesEngineering Graphics & Design P1 Nov 2022 AfrMarico River Conservation AssociationNo ratings yet

- Engineering Graphics & Design P1 Nov 2022 MG EngDocument8 pagesEngineering Graphics & Design P1 Nov 2022 MG EngMarico River Conservation AssociationNo ratings yet

- Distance Learning PolicyDocument8 pagesDistance Learning PolicyMarico River Conservation AssociationNo ratings yet

- ED610619Document9 pagesED610619Marico River Conservation AssociationNo ratings yet

- Electricity GridsDocument130 pagesElectricity GridsMarico River Conservation AssociationNo ratings yet

- Engineering Fabrication - Boiler MakingDocument10 pagesEngineering Fabrication - Boiler MakingMarico River Conservation AssociationNo ratings yet

- New Repair and Expansion of Existing HWLC Systems Programe RulesDocument12 pagesNew Repair and Expansion of Existing HWLC Systems Programe RulesMarico River Conservation AssociationNo ratings yet

- Handbook For Teaching and LearningDocument65 pagesHandbook For Teaching and LearningMarico River Conservation AssociationNo ratings yet

- MEMO 04 OF 2015 - CONDUCT OF THE 2015 NC (V) L2-4 SUPPLEMENTARY EXAMINATIONS (All Documents)Document53 pagesMEMO 04 OF 2015 - CONDUCT OF THE 2015 NC (V) L2-4 SUPPLEMENTARY EXAMINATIONS (All Documents)Marico River Conservation AssociationNo ratings yet

- First Principle Thinking - Psychology and The Philosophy of Creativity 2023.V21Document37 pagesFirst Principle Thinking - Psychology and The Philosophy of Creativity 2023.V21Marico River Conservation AssociationNo ratings yet

- Automotive Repair and MaintenanceDocument19 pagesAutomotive Repair and MaintenanceMarico River Conservation AssociationNo ratings yet

- Communication SkillsDocument44 pagesCommunication SkillsMarico River Conservation AssociationNo ratings yet

- Formative Assessment For Students With Disabilities PDFDocument34 pagesFormative Assessment For Students With Disabilities PDFMarico River Conservation AssociationNo ratings yet

- Remedial Teaching StrategiesDocument12 pagesRemedial Teaching StrategiesMarico River Conservation AssociationNo ratings yet

- Learners With Learning DisabilitiesDocument3 pagesLearners With Learning DisabilitiesMarico River Conservation AssociationNo ratings yet

- BilcoDocument16 pagesBilcoruloNo ratings yet

- Exercise 1. You Have Been Given A Form Which Shows The Details of Technical Jobs Carried OutDocument2 pagesExercise 1. You Have Been Given A Form Which Shows The Details of Technical Jobs Carried OutNgo Gia Huy (K15 HCM)No ratings yet

- Basic Facts About ESOPs2Document20 pagesBasic Facts About ESOPs2Quant TradingNo ratings yet

- Annex 3 - 5-Revised EMFDocument3 pagesAnnex 3 - 5-Revised EMFVholts Villa VitugNo ratings yet

- Code of Sports EthicsDocument4 pagesCode of Sports EthicsRadu MiclausNo ratings yet

- Ctu (Zuuu) PDFDocument45 pagesCtu (Zuuu) PDFchang woo yunNo ratings yet

- Roach PreviewDocument14 pagesRoach PreviewDomênico GayNo ratings yet

- Last Six Months Current AffairsDocument102 pagesLast Six Months Current Affairschoudharysiya8580409398No ratings yet

- Pathfit 2Document18 pagesPathfit 2Pam LlanetaNo ratings yet

- 2-BP-3.5K-5K 220v ManualDocument42 pages2-BP-3.5K-5K 220v ManualEcosenseTechnologies GreenenergyNo ratings yet

- Evelyn Glennie (Responses) PDFDocument8 pagesEvelyn Glennie (Responses) PDFRohit JhambNo ratings yet

- Master Circular 16 Compassionate GroundDocument13 pagesMaster Circular 16 Compassionate GroundSHANMUGA VADIVEL SUNDARARAJANNo ratings yet

- Activity 1: Measuring The Volume of Irregularly Shaped ObjectsDocument4 pagesActivity 1: Measuring The Volume of Irregularly Shaped ObjectsBamPanggatNo ratings yet

- Chapter 2 Lesson 21 Animals That Live On LandDocument17 pagesChapter 2 Lesson 21 Animals That Live On LandRoxan S. Pumphrey0% (1)

- 1A Innledning - EPS - Flyer - 2 - Jan - VaslestadDocument4 pages1A Innledning - EPS - Flyer - 2 - Jan - VaslestadNCS40 Trương Quốc BảoNo ratings yet

- 7B ReportDocument12 pages7B ReportRowena A. TomalabcadNo ratings yet

- Essay C DraftDocument7 pagesEssay C Draftapi-242837115No ratings yet

- Activated Carbon From BambooDocument19 pagesActivated Carbon From BambooErik WeeksNo ratings yet

- PC3SH21YFZBFDocument15 pagesPC3SH21YFZBFkrimoNo ratings yet

- The Nest Is Empty - The Hindu Folio On AgingDocument6 pagesThe Nest Is Empty - The Hindu Folio On AgingebooksufiNo ratings yet

- Zoology Mammals (Rabbit)Document3 pagesZoology Mammals (Rabbit)PerrieNo ratings yet

- Copper (RJ-45) SFP: Technical SpecificationsDocument1 pageCopper (RJ-45) SFP: Technical SpecificationsDanielLopezNo ratings yet

- 2022 Tucson Plug in Hybrid Emergency Response Quick Reference GuideDocument2 pages2022 Tucson Plug in Hybrid Emergency Response Quick Reference GuideForum PompieriiNo ratings yet

- Women EmpowermentDocument7 pagesWomen EmpowermentJessica Glenn100% (1)

- D154-85 (2009) Standard Guide For Testing VarnishesDocument4 pagesD154-85 (2009) Standard Guide For Testing VarnishesRonny100% (1)

- Prospect Dispersion Protocol PDFDocument10 pagesProspect Dispersion Protocol PDFsasikala38No ratings yet

- Beyond The Five Stages of Grief - Class 6 DocumentDocument2 pagesBeyond The Five Stages of Grief - Class 6 DocumentoksanaNo ratings yet

Mechanical Engineering

Mechanical Engineering

Uploaded by

Marico River Conservation Association0 ratings0% found this document useful (0 votes)

5 views9 pagesThis document outlines the modules and course content for an apprenticeship program in fitting and turning. The modules cover topics such as career opportunities, health and safety, engineering drawings, materials, tools and equipment, lifting concepts, screw threads, welding and cutting, and maintenance. Some of the specific course codes address subjects like drawing instruments, dimensioning methods, material properties, hand and power tools, rigging safety, thread calculations, and welding defects. The document provides a breakdown of the percentage of time spent on each module and the credits earned.

Original Description:

Fitting and Turning Concepts and Terminolgy

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the modules and course content for an apprenticeship program in fitting and turning. The modules cover topics such as career opportunities, health and safety, engineering drawings, materials, tools and equipment, lifting concepts, screw threads, welding and cutting, and maintenance. Some of the specific course codes address subjects like drawing instruments, dimensioning methods, material properties, hand and power tools, rigging safety, thread calculations, and welding defects. The document provides a breakdown of the percentage of time spent on each module and the credits earned.

Copyright:

© All Rights Reserved

0 ratings0% found this document useful (0 votes)

5 views9 pagesMechanical Engineering

Mechanical Engineering

Uploaded by

Marico River Conservation AssociationThis document outlines the modules and course content for an apprenticeship program in fitting and turning. The modules cover topics such as career opportunities, health and safety, engineering drawings, materials, tools and equipment, lifting concepts, screw threads, welding and cutting, and maintenance. Some of the specific course codes address subjects like drawing instruments, dimensioning methods, material properties, hand and power tools, rigging safety, thread calculations, and welding defects. The document provides a breakdown of the percentage of time spent on each module and the credits earned.

Copyright:

© All Rights Reserved

You are on page 1of 9

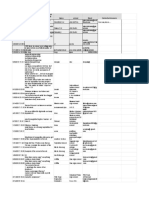

167 KM-01-KT01 Introduction to the Fitting and Turning Trade (5%)/ 32 Credits

169 KT0101 Career opportunities for a qualified fitter and turner

170 KT0102 Occupational profile of a fitter and turner

171 KT0103 Legislation related to apprentices in the fitting and turning trade

181 KM-01-KT02 Workplace health, safety and environmental protection (20%)/32 Credits

183 KT0201 General overview of occupational health and safety legislation

184 KT0202 General workshop safety rules

185 KT0204 Safety symbols and coding

186 KT0205 Types of personal protective equipment

187 KT0206 Hazard identification and risk assessment principles

188 KT0207 Fundamentals of securing worksites

189 KT0208 Environmental protection and pollution concepts

201 KM-01-KT03 Engineering drawings (10%)/32 credits

203 KT0301 Freehand drawing

204 KT0302 Code of practice for engineering drawing (symbols and abbreviations)

205 KT0303 Drawing instruments and equipment

206 KT0304 Dimensioning Methods

207 KT0305 Isometric Drawings

208 KT0306 Assembly and detailed drawings

222 KM-01-KT04 Engineering materials (10%)/32 Credits

224 KT0401 Basic metallurgy and heat concepts

225 KT0402 Properties of base metals, alloys and synthetic materials

226 KT0403 Non-ferrous metals and ferrous materials

227 KT0404 Metal specifications and testing

239 KM-01-KT05 Engineering tools and equipment (15%)/32 credits

241 KT0501 Hand tools to hold, assemble or disassemble components

242 KT0502 Hand-held cutting tools (saws, blades, files, scrapers, chisels, taps and dies, hand reamers,

243 KT0503 Hand-held power tools (angle grinder, drills, drill bits and reamers)

244 KT0504 Measurement tools and equipment (basic measurement tools, precision measuring tools, angu

245 KT0505 Marking-off tools and equipment (punches, scribers, combination sets, protractors, callipers (

263 KM-01-KT06 Basic lifting concepts (8%)/32 Credits

265 KT0601 Rigging (slings, block and tackle, chain block, steel ropes)

266 KT0602 Rigging concepts

267 KT0603 Loads selection and limitations

268 KT0604 Safety precautions

280 KM-01-KT07 Types and applications of screw threads

282 KT0701 Terminology related to screw threads ( pitch, root diameter, nominal diameter, lead, flank, i

283 KT0702 Screw threads (v-thread, acme, and square threads)

284 KT0703 Application of screw threads

285 KT0704 Thread calculations

299 KM-01-KT08 Types and function of locking devices and fasteners

301 KT0801 Fasteners and locking devices (machine screws, set screws, cap screws, grub screw, studs, loc

302 KT0802 Application of fasteners and locking devices

303 KT0803 Drawings of fasteners and locking devices

317 KM-01-KT09 Principles, equipment and methods of arc welding, gas cutting, brazing and silver soldering

319 KT0901 Arc welding and gas cutting equipment and consumables

320 KT0902 Arc welding and gas cutting techniques and principles

321 KT0903 Material selection

322 KT0904 Cutting and welding defects

323 KT0905 Safe handling of gas cylinders

324 KT0906 Health and safety risks and protective equipment and measures

368 2652302000-KM-02 Fitting theory, NQF Level 4 (38)

388 KM-02-KT01 Static and dynamic seals and gaskets

390 KT010601 Seals and gaskets

391 KT010602 The stuffing box and gland (packings)

392 KT010603 Lagging pipelines

393 KT010604 O-rings

408 KM-02-KT02 Types, and application of bearings

410 KS0201 Bearings (anti-friction and friction bearings)

411 KS0202 Application of bearing

412 KS0203 Maintenance of bearing

413 KS0204 Causes of failures in bearings

414 KS0205 Removal and installation of bearings

431 KM-02-KT03 Types and application of valves

433 KT0301 Classification and types of valves (Classification includes linear motion, rotary motion and q

434 KT0302 Terminology of valves

435 KT0303 Function and working principle of valves

436 KT0304 Removal and installation of valves

452 KM-02-KT04 Perform routine maintenance of a range mechanical machines and sub-assemblies autonomo

454 KT0401 Drives (direct and indirect)

455 KT0402 Terminology of drives

456 KT0403 Functions and working principle of drives

472 KM-02-KT05 Perform routine maintenance of mechanical machines and sub-assemblies autonomously under

474 KT0501 Classification of pumps

475 KT0502 Terminology of pumps

476 KT0503 Functions and working principles of pumps

492 KM-02-KT06 Drill material to specifications using a fixed drilling machine

494 KT0601 Gearboxes (single reduction, double reduction, variable speed)

495 KT0602 Terminology of gearboxes

496 KT0603 Functions and working principles of gearboxes

497 KT0604 Removal and installation procedures for gearboxes

511 KM-02-KT07 Arc weld metal to specification

513 KT0701 Types of clutches

514 KT0702 Terminology of clutches

515 KT0703 Functions and working principles of clutches

516 KT0704 Removal and installation procedure for clutches

530 KM-02-KT08 Mechanical working principles, types and applications of brakes

532 KT0801 Types of brakes

533 KT0802 Terminology of brakes

534 KT0803 Functions and working principles of brakes

535 KT0804 Removal and installation procedures for brakes

550 KM-02-KT09 Mechanical working principles, types and applications of lubrication systems

552 KT0901 Lubrication systems and devices

553 KT0902 Properties of lubricants

554 KT0903 Terminology of lubrication systems and devices

555 KT0904 Working principles of lubrication systems and devices

569 KM-02-KT10 Mechanical working principles, types and applications of hydraulic systems

571 KT1001 Hydraulic systems

572 KT1002 Units of measurement in hydraulic systems (pressure, flow rate, area)

573 KT1003 Hydraulic symbols and circuits

585 KM-02-KT11 Mechanical working principles, types and applications of pneumatic systems

587 KT1101 Pneumatic systems

588 KT1102 Units of measurement in pneumatic systems (pressure, flow rate, area)

589 KT1103 Pneumatic symbols and circuits

601 KM-02-KT12 Types and functions of conveyors

603 KT1201 Conveyors

604 KT1202 Functions of conveyors

614 KM-02-KT13 Diagnostic techniques

616 KT1301 Diagnostic equipment

617 KT1302 Diagnostic techniques

618 KT1303 Diagnostic testing

661 3652302000-KM-03 Machining theory, NQF Level 4 (36)

673 KM-03-KT01 Principles, methods and techniques of fabrication

675 KT0101 Machine lubrication and cutting fluids

676 KT0102 Speeds, feeds and cutting tools

677 KT0103 Taper systems and their applications

678 KT0104 Limit and fits

698 KM-03-KT02 Principles, methods and techniques of machining work pieces with a centre lathe

700 KT0201 Working principles of a centre lathe

701 KT0202 Terminology and components of a centre lathe

702 KT0203 Internal and external turning procedures

703 KT0204 Thread cutting

704 KT0205 Taper cutting

705 KT0206 Speeds and feeds

706 KT0207 Tools and tool selection

726 KM-03-KT03 Principles, methods and techniques of machining work pieces with a milling machine

728 KT0301 Working principles of a milling machine

729 KT0302 Terminology and components of a milling machine

730 KT0303 Milling machine cutting procedures including drilling and boring, straddle, gang and form mil

731 KT0304 Speeds and feeds

732 KT0305 Tool selection

733 KT0306 Indexing (dividing head and differential)

754 KM-03-KT04 Types and working principles of pedestal grinding machine

756 KT0401 Working principles of a pedestal-grinding machine

757 KT0402 Grinding machine types, parts and attachments

758 KT0403 Terminology and components

759 KT0404 Wheel selection

760 KT0405 Balancing, mounting and dressing

774 KM-03-KT05 Principles, methods and techniques of machining work pieces with surface and cylindrical

776 KT0501 Working principles of surface and cylindrical grinding machines

777 KT0502 Terminology and components of surface and cylindrical grinding machines

778 KT0503 Off-hand and precision grinding cutting procedures for cylindrical and surface grinding mac

779 KT0504 Speeds and feeds

780 KT0505 Grinding wheel selection, classification, bonding types and wheel markings, profiles

781 KT0506 Grinding faults

1652302000-KM-01 Basic engineering, NQF Level 3 (32) (Module 1)

KM-01-KT01

KT0101 IAC-01

KT0102 IAC-02

KT0103 IAC-03

KM-01-KT02

KT0201 IAC-01

KT0202 IAC-02

KT0204 IAC-04

KT0205 IAC-05

KT0206

KT0207

KT0208

KM-01-KT03

KT0301 IAC-01

KT0302 IAC-02

KT0303 IAC-03

KT0304 IAC-04

KT0305 IAC-05

KT0306

KM-01-KT04

KT0401 IAC-01

KT0402 IAC-02

KT0403 IAC-03

KT0404 IAC-04

KM-01-KT05

KT0501 IAC-01

KT0502 IAC-02

KT0503 IAC-03

KT0504 IAC-04

KT0505 IAC-05

KM-01-KT06

KT0601 IAC-01

KT0602 IAC-02

KT0603 IAC-03

KT0604 IAC-04

KM-01-KT07

KT0701 IAC-01

KT0702 IAC-02

KT0703 IAC-03

KT0704 IAC-04

KM-01-KT08

KT0801 IAC-01

KT0802 IAC-02

KT0803 IAC-03

KM-01-KT09

KT0901 IAC-01

KT0902 IAC-02

KT0903 IAC-03

KT0904 IAC-04

KT0905 IAC-05

KT0906

2652302000-KM-02 Fitting theory, NQF Level 4 (38)

KM-02-KT01

KT010601 IAC-01

KT010602 IAC-02

KT010603 IAC-03

KT010604 IAC-04

KM-02-KT02

KS0201 IAC-01

KS0202 IAC-02

KS0203 IAC-03

KS0204 IAC-04

KS0205 IAC-05

KM-02-KT03

KT0301 IAC-01

KT0302 IAC-02

KT0303 IAC-03

KT0304 IAC-04

KM-02-KT04

KT0401

KT0402 IAC-02

KT0403 IAC-03

KM-02-KT05

KT0501 IAC-01

KT0502 IAC-02

KT0503 IAC-03

KM-02-KT06

KT0601 IAC-01

KT0602 IAC-02

KT0603 IAC-03

KT0604 IAC-04

KM-02-KT07

KT0701 IAC-01

KT0702 IAC-02

KT0703 IAC-03

KT0704 IAC-04

KM-02-KT08

KT0801 IAC-01

KT0802 IAC-02

KT0803 IAC-03

KT0804 IAC-04

KM-02-KT09

KT0901 IAC-01

KT0902 IAC-02

KT0903 IAC-03

KT0904 IAC-04

KM-02-KT10

KT1001 IAC-01

KT1002 IAC-02

KT1003 IAC-03

KM-02-KT11

KT1101 IAC-01

KT1102 IAC-02

KT1103 IAC-03

KM-02-KT12

KT1201 IAC-01

KT1202 IAC-02

KM-02-KT13

KT1301 IAC-01

KT1302 IAC-02

KT1303 IAC-03

3652302000-KM-03 Machining theory, NQF Level 4 (36)

KM-03-KT01

KT0101 IAC-01

KT0102 IAC-02

KT0103 IAC-03

KT0104 IAC-04

KM-03-KT02

KT0201 IAC-01

KT0202 IAC-02

KT0203 IAC-03

KT0204 IAC-04

KT0205 IAC-05

KT0206 IAC-06

KT0207 IAC-07

KM-03-KT03

KT0301 IAC-01

KT0302 IAC-02

KT0303 IAC-03

KT0304 IAC-04

KT0305 IAC-05

KT0306 IAC-06

KM-03-KT04

KT0401 IAC-01

KT0402 IAC-02

KT0403 IAC-03

KT0404 IAC-04

KT0405

KM-03-KT05

KT0501 IAC-01

KT0502 IAC-02

KT0503 IAC-03

KT0504 IAC-04

KT0505 IAC-05

KT0506 IAC-06

1652302000-KM-01 Basic engineering, NQF Level 3 (32) (Module 1)

KM-01-KT01

KT0101 IAC-01

KT0102 IAC-02

KT0103 IAC-03

KM-01-KT02

KT0201 IAC-01

KT0202 IAC-02

KT0204 IAC-04

KT0205 IAC-05

KT0206

KT0207

KT0208

KM-01-KT03

KT0301 IAC-01

KT0302 IAC-02

KT0303 IAC-03

KT0304 IAC-04

KT0305 IAC-05

KT0306

KM-01-KT04

KT0401 IAC-01

KT0402 IAC-02

KT0403 IAC-03

KT0404 IAC-04

KM-01-KT05

KT0501 IAC-01

KT0502 IAC-02

KT0503 IAC-03

KT0504 IAC-04

KT0505 IAC-05

KM-01-KT06

KT0601 IAC-01

KT0602 IAC-02

KT0603 IAC-03

KT0604 IAC-04

KM-01-KT07

KT0701 IAC-01

KT0702 IAC-02

KT0703 IAC-03

KT0704 IAC-04

KM-01-KT08

KT0801 IAC-01

KT0802 IAC-02

KT0803 IAC-03

KM-01-KT09

KT0901 IAC-01

KT0902 IAC-02

KT0903 IAC-03

KT0904 IAC-04

KT0905 IAC-05

KT0906

2652302000-KM-02 Fitting theory, NQF Level 4 (38)

KM-02-KT01

KT010601 IAC-01

KT010602 IAC-02

KT010603 IAC-03

KT010604 IAC-04

KM-02-KT02

KS0201 IAC-01

KS0202 IAC-02

KS0203 IAC-03

KS0204 IAC-04

KS0205 IAC-05

KM-02-KT03

KT0301 IAC-01

KT0302 IAC-02

KT0303 IAC-03

KT0304 IAC-04

KM-02-KT04

KT0401

KT0402 IAC-02

KT0403 IAC-03

KM-02-KT05

KT0501 IAC-01

KT0502 IAC-02

KT0503 IAC-03

KM-02-KT06

KT0601 IAC-01

KT0602 IAC-02

KT0603 IAC-03

KT0604 IAC-04

KM-02-KT07

KT0701 IAC-01

KT0702 IAC-02

KT0703 IAC-03

KT0704 IAC-04

KM-02-KT08

KT0801 IAC-01

KT0802 IAC-02

KT0803 IAC-03

KT0804 IAC-04

KM-02-KT09

KT0901 IAC-01

KT0902 IAC-02

KT0903 IAC-03

KT0904 IAC-04

KM-02-KT10

KT1001 IAC-01

KT1002 IAC-02

KT1003 IAC-03

KM-02-KT11

KT1101 IAC-01

KT1102 IAC-02

KT1103 IAC-03

KM-02-KT12

KT1201 IAC-01

KT1202 IAC-02

KM-02-KT13

KT1301 IAC-01

KT1302 IAC-02

KT1303 IAC-03

3652302000-KM-03 Machining theory, NQF Level 4 (36)

KM-03-KT01

KT0101 IAC-01

KT0102 IAC-02

KT0103 IAC-03

KT0104 IAC-04

KM-03-KT02

KT0201 IAC-01

KT0202 IAC-02

KT0203 IAC-03

KT0204 IAC-04

KT0205 IAC-05

KT0206 IAC-06

KT0207 IAC-07

KM-03-KT03

KT0301 IAC-01

KT0302 IAC-02

KT0303 IAC-03

KT0304 IAC-04

KT0305 IAC-05

KT0306 IAC-06

KM-03-KT04

KT0401 IAC-01

KT0402 IAC-02

KT0403 IAC-03

KT0404 IAC-04

KT0405

KM-03-KT05

KT0501 IAC-01

KT0502 IAC-02

KT0503 IAC-03

KT0504 IAC-04

KT0505 IAC-05

KT0506 IAC-06

You might also like

- CASE 440, 440CT Series 3 Skid Steer Loader Service Repair Manual PDFDocument29 pagesCASE 440, 440CT Series 3 Skid Steer Loader Service Repair Manual PDFjkmmmm20% (5)

- Cat Forklift t40d t50d Service ManualDocument27 pagesCat Forklift t40d t50d Service Manualalexhughes210188sxi96% (52)

- Cat Forklift V40e V50e Schematic Service ManualDocument15 pagesCat Forklift V40e V50e Schematic Service Manualethanmann190786ikm98% (94)

- Cat Forklift v50d Schematic Service ManualDocument27 pagesCat Forklift v50d Schematic Service Manualashleymcneil190382yko99% (125)

- Cat Forklift Dp70 Service ManualDocument27 pagesCat Forklift Dp70 Service Manualsamanthamoyer170885csp100% (84)

- Reuse and Salvage GuidelinesDocument89 pagesReuse and Salvage Guidelinesmeceng86% (7)

- Cat Forklift Gp30 Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift Gp30 Schematic Service Operation Maintenance Manualfrankstewart270488qny99% (84)

- Case 430 Series 3 Skid Steer PDFDocument1,724 pagesCase 430 Series 3 Skid Steer PDFAny Rayli100% (3)

- SM PC300-350 LC 8Document1,025 pagesSM PC300-350 LC 8Cesar Ego-Aguirre Calderon93% (45)

- Case 440 440ct Series 3 Skid Steer Loader Service Repair ManualpdfDocument58 pagesCase 440 440ct Series 3 Skid Steer Loader Service Repair Manualpdfsebastian velasquezNo ratings yet

- Supersack Winch LC2A030DDocument79 pagesSupersack Winch LC2A030DMohamed AliNo ratings yet

- Catalogo Case 420Document1,840 pagesCatalogo Case 420Fabio100% (2)

- Crude Pump Installation Manual - SULZER PDFDocument992 pagesCrude Pump Installation Manual - SULZER PDFnobelr100% (4)

- Yanmar Diesel EngineDocument240 pagesYanmar Diesel Engineaveselov8887% (23)

- Catalogo Mcbee Cummins KT, QSK 2019Document64 pagesCatalogo Mcbee Cummins KT, QSK 2019Alexis Sanchez100% (1)

- CAT Excavator 330L 9ML ManualsDocument9 pagesCAT Excavator 330L 9ML ManualsCristhian Cardenas88% (8)

- Reading: Healthy Lifestyle Role For All Society'Document4 pagesReading: Healthy Lifestyle Role For All Society'Tore CusimanoNo ratings yet

- HV Turbo Aeration Compressor Service: EngineeringDocument3 pagesHV Turbo Aeration Compressor Service: EngineeringCornel NasturasNo ratings yet

- Impact of Porn On Youth 9Document4 pagesImpact of Porn On Youth 9terminolohiyaNo ratings yet

- 966H Wheel LoadersDocument54 pages966H Wheel Loadersjorge.quiquijana14No ratings yet

- Standard Bills of Materials: MetersDocument48 pagesStandard Bills of Materials: MetersgusmilexaNo ratings yet

- BFL Spinning ScheduleDocument3 pagesBFL Spinning ScheduleBADRI VENKATESHNo ratings yet

- Cat Forklift Gp40 Service Operation Maintenance ManualDocument25 pagesCat Forklift Gp40 Service Operation Maintenance Manualfrankstewart270488qny100% (87)

- 3000 Series Class Literature ListDocument5 pages3000 Series Class Literature ListNova KurniawanNo ratings yet

- Structural Fabrication SpecificationDocument18 pagesStructural Fabrication Specificationravirawat15No ratings yet

- List of Gear StandardDocument7 pagesList of Gear StandardManoj SinghNo ratings yet

- Gears Standards-1Document10 pagesGears Standards-1maheshmbelgavi100% (1)

- Final Year Project - (Mechanical) IEEE 2016-17 Project ListDocument10 pagesFinal Year Project - (Mechanical) IEEE 2016-17 Project ListSPECTRUM SOLUTIONSNo ratings yet

- S-000-1134-004 B 0020 20140625Document12 pagesS-000-1134-004 B 0020 20140625Faris Rosi100% (1)

- Helical Coil SpringDocument36 pagesHelical Coil SpringmailbkraoNo ratings yet

- Cat Forklift Vc60d Service ManualDocument27 pagesCat Forklift Vc60d Service Manualethanmann190786ikm99% (92)

- Cat Forklift Tc60d Schematic Service ManualDocument27 pagesCat Forklift Tc60d Schematic Service Manualchristineferguson190889rtw100% (125)

- H360 LaDocument3 pagesH360 LaAnderson SantosNo ratings yet

- 2013-m100k Int'l SparesDocument3 pages2013-m100k Int'l SparesabdulNo ratings yet

- Treadmill 93T-04 - THH100000 - PARTS LISTDocument19 pagesTreadmill 93T-04 - THH100000 - PARTS LISTpowerliftermiloNo ratings yet

- OPSS 2414 Nov08Document13 pagesOPSS 2414 Nov08Muhammad UmarNo ratings yet

- Engineer's Training Manual-2023Document16 pagesEngineer's Training Manual-2023Jagannath EpeeliNo ratings yet

- Lista Normas EngranajesDocument5 pagesLista Normas EngranajesCarlosQuelartNo ratings yet

- 4065 MDR Phase I - 191001-PaaDocument70 pages4065 MDR Phase I - 191001-PaaPrima AdhiyasaNo ratings yet

- Canalis KTA en Catalogue BD 27 03 2007Document214 pagesCanalis KTA en Catalogue BD 27 03 2007Gabriel Alexis Malagon CarvajalNo ratings yet

- 1U-5482 Pressure Adapter GroupDocument3 pages1U-5482 Pressure Adapter Groupvictor.cipriani0% (1)

- OEM Manuals Service Related Product LogDocument657 pagesOEM Manuals Service Related Product Logmatthew.polenNo ratings yet

- Normas Da AGMA - AtualizadaDocument2 pagesNormas Da AGMA - Atualizadaprofjohnalencar100% (1)

- Turbine Blade MachiningDocument36 pagesTurbine Blade Machiningyh1.yuNo ratings yet

- Shop PC300 8Document989 pagesShop PC300 8MaiChiVu100% (7)

- KoneMontgomery - 47-54 RefacionDocument8 pagesKoneMontgomery - 47-54 RefacionAlex GonzalezNo ratings yet

- Scule HidrauliceDocument34 pagesScule HidraulicelucianbordeutNo ratings yet

- Knuth Milling Machine VHF 3Document5 pagesKnuth Milling Machine VHF 3martin_jaitmanNo ratings yet

- Laurus As Built BOP Part Numbers - UnlockedDocument166 pagesLaurus As Built BOP Part Numbers - UnlockedEstuardo OlanNo ratings yet

- CATDocument21 pagesCATCendit thomas BarusNo ratings yet

- Normas Da AGMA AtualizadaDocument2 pagesNormas Da AGMA AtualizadaSERGIO ALMEIDA BOCCHINo ratings yet

- Ccs Prop ThicknessDocument21 pagesCcs Prop ThicknessAndreas ArapakopoulosNo ratings yet

- APT Special Offers WebDocument8 pagesAPT Special Offers Webjim_m_smithNo ratings yet

- NewDocument47 pagesNewPrufenAmin100% (1)

- LG933Document297 pagesLG933Li Eric0% (1)

- ISM-IsX Wiring Repair KitDocument1 pageISM-IsX Wiring Repair KitHolly ThompsonNo ratings yet

- Xl4000 Series AlkDocument19 pagesXl4000 Series AlkJesant17No ratings yet

- Parts Manual: Customer Support ServicesDocument21 pagesParts Manual: Customer Support ServicespowerliftermiloNo ratings yet

- TBA 3 POMPA - 4-04-13 Rev.1Document14 pagesTBA 3 POMPA - 4-04-13 Rev.1Pratama Trendy LeoNo ratings yet

- Specification For Manufacture Erection and Acceptance of Gate Hoists in Hydraulic and Hydroelectric ProjectsDocument40 pagesSpecification For Manufacture Erection and Acceptance of Gate Hoists in Hydraulic and Hydroelectric Projectssaliyarumesh2292No ratings yet

- Parts Catalog Cummins (500KVA), KTA19 G4 - ESN 41289367 - CPL 4153Document144 pagesParts Catalog Cummins (500KVA), KTA19 G4 - ESN 41289367 - CPL 4153Ari100% (2)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Engineering Graphics & Design P1 Nov 2022 AfrDocument8 pagesEngineering Graphics & Design P1 Nov 2022 AfrMarico River Conservation AssociationNo ratings yet

- Engineering Graphics & Design P1 Nov 2022 MG EngDocument8 pagesEngineering Graphics & Design P1 Nov 2022 MG EngMarico River Conservation AssociationNo ratings yet

- Distance Learning PolicyDocument8 pagesDistance Learning PolicyMarico River Conservation AssociationNo ratings yet

- ED610619Document9 pagesED610619Marico River Conservation AssociationNo ratings yet

- Electricity GridsDocument130 pagesElectricity GridsMarico River Conservation AssociationNo ratings yet

- Engineering Fabrication - Boiler MakingDocument10 pagesEngineering Fabrication - Boiler MakingMarico River Conservation AssociationNo ratings yet

- New Repair and Expansion of Existing HWLC Systems Programe RulesDocument12 pagesNew Repair and Expansion of Existing HWLC Systems Programe RulesMarico River Conservation AssociationNo ratings yet

- Handbook For Teaching and LearningDocument65 pagesHandbook For Teaching and LearningMarico River Conservation AssociationNo ratings yet

- MEMO 04 OF 2015 - CONDUCT OF THE 2015 NC (V) L2-4 SUPPLEMENTARY EXAMINATIONS (All Documents)Document53 pagesMEMO 04 OF 2015 - CONDUCT OF THE 2015 NC (V) L2-4 SUPPLEMENTARY EXAMINATIONS (All Documents)Marico River Conservation AssociationNo ratings yet

- First Principle Thinking - Psychology and The Philosophy of Creativity 2023.V21Document37 pagesFirst Principle Thinking - Psychology and The Philosophy of Creativity 2023.V21Marico River Conservation AssociationNo ratings yet

- Automotive Repair and MaintenanceDocument19 pagesAutomotive Repair and MaintenanceMarico River Conservation AssociationNo ratings yet

- Communication SkillsDocument44 pagesCommunication SkillsMarico River Conservation AssociationNo ratings yet

- Formative Assessment For Students With Disabilities PDFDocument34 pagesFormative Assessment For Students With Disabilities PDFMarico River Conservation AssociationNo ratings yet

- Remedial Teaching StrategiesDocument12 pagesRemedial Teaching StrategiesMarico River Conservation AssociationNo ratings yet

- Learners With Learning DisabilitiesDocument3 pagesLearners With Learning DisabilitiesMarico River Conservation AssociationNo ratings yet

- BilcoDocument16 pagesBilcoruloNo ratings yet

- Exercise 1. You Have Been Given A Form Which Shows The Details of Technical Jobs Carried OutDocument2 pagesExercise 1. You Have Been Given A Form Which Shows The Details of Technical Jobs Carried OutNgo Gia Huy (K15 HCM)No ratings yet

- Basic Facts About ESOPs2Document20 pagesBasic Facts About ESOPs2Quant TradingNo ratings yet

- Annex 3 - 5-Revised EMFDocument3 pagesAnnex 3 - 5-Revised EMFVholts Villa VitugNo ratings yet

- Code of Sports EthicsDocument4 pagesCode of Sports EthicsRadu MiclausNo ratings yet

- Ctu (Zuuu) PDFDocument45 pagesCtu (Zuuu) PDFchang woo yunNo ratings yet

- Roach PreviewDocument14 pagesRoach PreviewDomênico GayNo ratings yet

- Last Six Months Current AffairsDocument102 pagesLast Six Months Current Affairschoudharysiya8580409398No ratings yet

- Pathfit 2Document18 pagesPathfit 2Pam LlanetaNo ratings yet

- 2-BP-3.5K-5K 220v ManualDocument42 pages2-BP-3.5K-5K 220v ManualEcosenseTechnologies GreenenergyNo ratings yet

- Evelyn Glennie (Responses) PDFDocument8 pagesEvelyn Glennie (Responses) PDFRohit JhambNo ratings yet

- Master Circular 16 Compassionate GroundDocument13 pagesMaster Circular 16 Compassionate GroundSHANMUGA VADIVEL SUNDARARAJANNo ratings yet

- Activity 1: Measuring The Volume of Irregularly Shaped ObjectsDocument4 pagesActivity 1: Measuring The Volume of Irregularly Shaped ObjectsBamPanggatNo ratings yet

- Chapter 2 Lesson 21 Animals That Live On LandDocument17 pagesChapter 2 Lesson 21 Animals That Live On LandRoxan S. Pumphrey0% (1)

- 1A Innledning - EPS - Flyer - 2 - Jan - VaslestadDocument4 pages1A Innledning - EPS - Flyer - 2 - Jan - VaslestadNCS40 Trương Quốc BảoNo ratings yet

- 7B ReportDocument12 pages7B ReportRowena A. TomalabcadNo ratings yet

- Essay C DraftDocument7 pagesEssay C Draftapi-242837115No ratings yet

- Activated Carbon From BambooDocument19 pagesActivated Carbon From BambooErik WeeksNo ratings yet

- PC3SH21YFZBFDocument15 pagesPC3SH21YFZBFkrimoNo ratings yet

- The Nest Is Empty - The Hindu Folio On AgingDocument6 pagesThe Nest Is Empty - The Hindu Folio On AgingebooksufiNo ratings yet

- Zoology Mammals (Rabbit)Document3 pagesZoology Mammals (Rabbit)PerrieNo ratings yet

- Copper (RJ-45) SFP: Technical SpecificationsDocument1 pageCopper (RJ-45) SFP: Technical SpecificationsDanielLopezNo ratings yet

- 2022 Tucson Plug in Hybrid Emergency Response Quick Reference GuideDocument2 pages2022 Tucson Plug in Hybrid Emergency Response Quick Reference GuideForum PompieriiNo ratings yet

- Women EmpowermentDocument7 pagesWomen EmpowermentJessica Glenn100% (1)

- D154-85 (2009) Standard Guide For Testing VarnishesDocument4 pagesD154-85 (2009) Standard Guide For Testing VarnishesRonny100% (1)

- Prospect Dispersion Protocol PDFDocument10 pagesProspect Dispersion Protocol PDFsasikala38No ratings yet

- Beyond The Five Stages of Grief - Class 6 DocumentDocument2 pagesBeyond The Five Stages of Grief - Class 6 DocumentoksanaNo ratings yet