Professional Documents

Culture Documents

NPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709

NPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709

Uploaded by

afareenkhanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709

NPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709

Uploaded by

afareenkhanCopyright:

Available Formats

SAUDI ARAMCO ID/PIEU-30-Jun-2021 - REV.2021.06.

00 (Standards Cutoff - June 30,2021) Rev 68 30-Jun-21

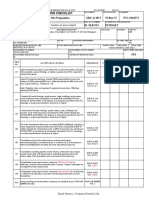

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

OSP Ductbank - Ductbank Fabrication, Installation and EPM# 0014055074402

SAIC -T-5709 30-Jun-21 NPCL-YBP-RFI-TEL-0005

Mandrel Test

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

Upgrade Fire Protection & Industrial Drainage System-II-WRDD Nesma Projects Company Limited

BI-10-01547-0002

Contract # 6601000224 (NPCL-YBP-06)_

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

NA Four 4" PVC Conduit Installation & Initial Mandrel test NA X06

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

T-XA-033066-002 00 NA NA

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SATIP-T-911-01 3.2

SAUDI ARAMCO INSPECTION LEVEL

H

CONTRACTOR INSPECTION LEVEL

H

YES

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A. Conduit Fabrication and Installation

Verify and ensure that conduits are free of ultra violet damage. Conduits

that became discolored because of prolonged exposure to SAES-T-911,

A1

sunlight/ultraviolet rays (UV), shall not be used in telecommunication para. 5.1.5 (1)

conduit system.

Verify conduit spacers with a minimum of 38 mm separation between

SAES-T-911,

A2 conduits are used in all concrete encased conduit sections. Typically,

para. 5.1.4 (9)

spacers are placed 1.5 to 2.4 meters (5-8 feet) apart.

Ensure that, when joining conduits (Bell ends, joints, couplings etc), the

ends are dry and free of all foreign matter, joined while the cement is wet SAES-T-911,

A3 and cured undisturbed for 30 min. Also, verify that conduit ends are fully para. 5.1.3.3 (a-

and properly seated and aligned in the conduit end bell socket of the e)

conduit section to which it is being joined or in the joint coupling.

Verify and ensure that proper solvents, cements and primers are being

used for joining the conduit sections and it is not placed in excess to avoid

SAES-T-911,

A4 having it forced to the interior conduit wall. Ensure that solvents, cements

para. 5.1.3.2

and primers shall comply to all precautions of the manufacturer when

these products are in used.

Verify and ensure that the color orange is used to identify the

telecommunication facilities. Orange colored marker/identification tape

shall be placed in the trench above the cable and the

specification shall be in accordance with SD: AA-036748, “Buried

Telephone Cable/Distribution Wire - Installation Details”. While for conduit

SAES-T-911,

A5 systems, this may be accomplished by placing orange marker tape above

para. 5.1.3.7 (7)

the conduit concrete encasement. Additional marker tape is to be located

300 mm minimum above the conduit system upper surface to provide an

early warning. This is considered the preferred method. The specifications

of the marker tape materials shall conform to SAMS Stock No. 18-070-

890 (SAP No. 1000-078-516) or equivalent.

Verify all trenches or other excavations that are 1.2 meters or more in

SAEST-911, para.

A6 depth are safeguarded by shoring or sloping the trench walls as per

4.9.3

SAES-A-114 paragraph 5.5.2.3.

Verify that corresponding conduits of conduit entrances in opposite ends

SAEST-911, para.

A7 of manholes shall be at the same level and in the same position with

5.1.3.1

respect to the side walls.

Verify that if the trench walls are used as a form for the concrete, the

SAEST-911, para.

A8 minimum thickness of 75 mm. (3 inches) of concrete is provided on each

5.1.3.6 (5)

side of the conduit bank.

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-30-Jun-2021 - REV.2021.06.00 (Standards Cutoff - June 30,2021) Rev 68 30-Jun-21

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

OSP Ductbank - Ductbank Fabrication, Installation and EPM# 0014055074402

SAIC -T-5709 30-Jun-21 NPCL-YBP-RFI-TEL-0005

Mandrel Test

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

Upgrade Fire Protection & Industrial Drainage System-II-WRDD Nesma Projects Company Limited

BI-10-01547-0002

Contract # 6601000224 (NPCL-YBP-06)_

Verify that Main Conduits stubbed out in the trench for future use is using

full 6 m. (20 feet) conduit sections for a minimum distance of 12 m. (40

SAEST-911, para.

A9 feet) from the central office or manhole wall and shall be sealed with

5.1.1

plastic caps cemented onto the end of each conduit before backfilling the

trench.

Except for the minor curves involved when splaying main conduits at MH

entrances, curves in conduit runs should be avoided whenever possible.

But, if necessary, verify that the constructed curves in a main conduit

section shall not:

SAEST-911, para.

A10 a) Transverse more than 90 degrees,

5.1.3.5 (1)

b) Have a radius of less than 6 m,

Main conduit sections shall not have more than the equivalent of two 90

degree turns.

Verify main conduit section lengths for various degrees of curve and radii

of curve should not exceed those indicated in SAES-T-911, TABLE 4.

SAEST-911, para.

A11 But, main conduit section lengths which exceed those shown in TABLE 4,

5.1.3.5 (2)

must be proven with cable pulling tension calculations and side wall

pressure calculations.

Verify the minimum amount of concrete encasement used shall be 75 SAEST-911, para.

A12

mm. (3 in.) along the top, sides and bottom of the conduit formation 5.1.3.6 (4)

Verify main conduit sections, placed in roadways and other traffic areas, SAEST-911, para.

A13

shall provide a minimum ground cover of 760 mm. 5.1.3.7 (4)

Verify that temporary plugs is placed at the end of each installed conduit

SAEST-911, para.

A14 in the trench when conduit installation is stopped for any length of time

4.8

(overnight, etc.).

B. Mandrel Test

Verify that each new conduit is cleaned and tested (in both directions) with

the appropriate size test mandrel. (Nominal Four inch inside diameter

SAES-T-911,

B1 conduits must pass a 3-5/8 inch diameter x 12 inch length mandrel and

para. 7.3.1 (a-b)

the wooden mandrel used have a round, 3 5/8 in.dia., square edge steel

plate or cap on each end of the mandrel.

Ensure that the mandrel test is performed before concrete encasement

SAES-T-911,

B2 and again after concrete encasement, and before doing any paving work

para. 7.3.1

over the conduits.

SAES-T-911,

Ensure that for Mandrel Test, Pass or Fail requirements; corresponding

B3 para. 7.3.5 and

commentary notes shall be followed as required.

para. 7.3.6

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-30-Jun-2021 - REV.2021.06.00 (Standards Cutoff - June 30,2021) Rev 68 30-Jun-21

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

OSP Ductbank - Ductbank Fabrication, Installation and EPM# 0014055074402

SAIC -T-5709 30-Jun-21 NPCL-YBP-RFI-TEL-0005

Mandrel Test

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

Upgrade Fire Protection & Industrial Drainage System-II-WRDD Nesma Projects Company Limited

BI-10-01547-0002

Contract # 6601000224 (NPCL-YBP-06)_

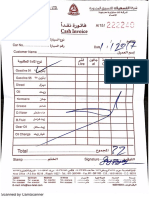

REMARKS:

Visual Inspection for IT Duct Bank installation and initial mandrel test North side STA.00+449 to STA.00+300 (149 m) along Existing Camera

Pole at Yanbu Bulk Plant X06

Drawing: T-XA-033066-002/003-00

REFERENCE DOCUMENTS:

1. SAES-T-911 - Telecommunication Conduit Design System, Issue 25 August, 2020

2. Standard Drawing AA-036748 - Buried Telephone Cable/Distribution Wire - Installation Details.

NOTES:

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

Mr.Omar Sagar

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

Afareen Khan-8390052 Mr.Rashid Arshad

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

You might also like

- E-EAN-BBHB-0349-AGR-15 Rev 001Document19 pagesE-EAN-BBHB-0349-AGR-15 Rev 001Jonicus-DextoreNo ratings yet

- AGPT06-09 Guide To Pavement Technology Part 6 Unsealed Pavements PDFDocument87 pagesAGPT06-09 Guide To Pavement Technology Part 6 Unsealed Pavements PDFThomasJohnnoStevensonNo ratings yet

- Saic H 2082Document8 pagesSaic H 2082jerin100% (1)

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistZia ur RehmanNo ratings yet

- Analytical Modeling of Carbon Transport Rocesses in Heat Treatment Technology of SteelsDocument14 pagesAnalytical Modeling of Carbon Transport Rocesses in Heat Treatment Technology of SteelsdeimosXNo ratings yet

- Botaniesoap Soap Making Instructions PDFDocument8 pagesBotaniesoap Soap Making Instructions PDFFreddy SalinasNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19Document3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19harisNo ratings yet

- SACIC-T-5709 OSP Ductbank-Duct Bank Fabrication, Installation and Mandrel TestDocument3 pagesSACIC-T-5709 OSP Ductbank-Duct Bank Fabrication, Installation and Mandrel TestArshad ImamNo ratings yet

- Satr-P-3206 LV Cable TerminationDocument5 pagesSatr-P-3206 LV Cable TerminationSurendren RNo ratings yet

- SAIC-T-5916 Rev 8building Premises Distribution System - Installation of Backbone Cable Tray SystemDocument3 pagesSAIC-T-5916 Rev 8building Premises Distribution System - Installation of Backbone Cable Tray Systemhomsalwaled88No ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Document3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNo ratings yet

- Saic-H-2029Document12 pagesSaic-H-2029mominNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistMAZHARULNo ratings yet

- Saic Q 1011Document2 pagesSaic Q 1011Shazab NawazNo ratings yet

- SAIC-X-3104 Rev 3Document4 pagesSAIC-X-3104 Rev 3Imran khanNo ratings yet

- SAIC W 1312 Pre WeldingDocument3 pagesSAIC W 1312 Pre Weldingmohamed mubinNo ratings yet

- Saudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 ElectDocument6 pagesSaudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Test Report: SATR-P-3205 30-Apr-13 Elect-Low Voltage Power and Control Cable, Termination Torque TestingDocument7 pagesSaudi Aramco Test Report: SATR-P-3205 30-Apr-13 Elect-Low Voltage Power and Control Cable, Termination Torque TestingzhangNo ratings yet

- Saudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 ElectDocument5 pagesSaudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 Electkarthi51289No ratings yet

- Saic S 4057Document5 pagesSaic S 4057Engr IrfanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument22 pagesSaudi Aramco Inspection ChecklistAhdal NoushadNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- SAIC-W-C013-Inprocess Welding Inspection - Offshore StructuresDocument4 pagesSAIC-W-C013-Inprocess Welding Inspection - Offshore StructuresVinu MadhavanNo ratings yet

- Saudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ElectDocument8 pagesSaudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 Electkarthi51289No ratings yet

- Saic-N - 2008Document2 pagesSaic-N - 2008SUNIL RAJPUTNo ratings yet

- SAICbDocument2 pagesSAICbAfzal HussainNo ratings yet

- Satr-P-3912 Transformer InsulationDocument8 pagesSatr-P-3912 Transformer InsulationSurendren R100% (1)

- Satip M 100 02 Rev 7 (Final)Document3 pagesSatip M 100 02 Rev 7 (Final)Satheesh Rama SamyNo ratings yet

- Saes T 911Document60 pagesSaes T 911RijoNo ratings yet

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- Saic Co 3008Document12 pagesSaic Co 3008zhangNo ratings yet

- Saic-N - 2019Document3 pagesSaic-N - 2019SUNIL RAJPUTNo ratings yet

- SACIC-S-4098 Rev - Fit Layer Laminate of RTRGRE, GRV, and GRP PipingDocument2 pagesSACIC-S-4098 Rev - Fit Layer Laminate of RTRGRE, GRV, and GRP PipingShohrab JiNo ratings yet

- Saudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 ElectDocument6 pagesSaudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistaamirapi100% (2)

- Saic S 4058Document6 pagesSaic S 4058Engr IrfanNo ratings yet

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- Saic M 1044Document2 pagesSaic M 1044Hussain Nasser Al- Nowiesser100% (1)

- Satr-P-3216 Rev 3Document4 pagesSatr-P-3216 Rev 3Parag WadekarNo ratings yet

- Saudi Aramco Test Report Re-Instatement Checklist (Form) : Fadhili Gas Sulfur Recovery Unit (Package 3)Document4 pagesSaudi Aramco Test Report Re-Instatement Checklist (Form) : Fadhili Gas Sulfur Recovery Unit (Package 3)Nivash KrishnabalaNo ratings yet

- SACIC-CV-0003 Rev.04 Electronic Friction Cone and Piezocone Penetration TestDocument3 pagesSACIC-CV-0003 Rev.04 Electronic Friction Cone and Piezocone Penetration TestEr Nizamuddin AliNo ratings yet

- Saudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 30-Nov-17 CivilDocument4 pagesSaudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 30-Nov-17 CivilMD SHARIQUENo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistMainuddin AliNo ratings yet

- SACIC-T-5705 OSP Ductbank-Maintenance & Service Hole Hardware - Material ReceivingDocument3 pagesSACIC-T-5705 OSP Ductbank-Maintenance & Service Hole Hardware - Material ReceivingArshad ImamNo ratings yet

- Saic L 2115Document4 pagesSaic L 2115khuram shahzadNo ratings yet

- Saic-M-1012 Rev 7 (Final)Document3 pagesSaic-M-1012 Rev 7 (Final)Satheesh Rama SamyNo ratings yet

- Saic A 1005.Document3 pagesSaic A 1005.Shazab NawazNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistAnantha PadmanabhanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistmkalidas2006No ratings yet

- Saudi Aramco Inspection Checklist: Galvanic CP Anode Installation and Pre-Commissioning SAIC-X-3103 15-Dec-19 CPDocument3 pagesSaudi Aramco Inspection Checklist: Galvanic CP Anode Installation and Pre-Commissioning SAIC-X-3103 15-Dec-19 CPAwais NaeemNo ratings yet

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- SAIC-P-3008 Rev 3Document9 pagesSAIC-P-3008 Rev 3YaserNo ratings yet

- SAIC-W-2015 Rev 7 (NDE Selection)Document17 pagesSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduNo ratings yet

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- Chip Detector Task CardDocument13 pagesChip Detector Task CardPablo BalderramaNo ratings yet

- SAIC-A-1005 Rev 7 (Final) Compaction TestingDocument2 pagesSAIC-A-1005 Rev 7 (Final) Compaction Testingryann mananquilNo ratings yet

- SAIC-P-3004 Rev 7 FinalDocument3 pagesSAIC-P-3004 Rev 7 Finalmustafa abdelshafiNo ratings yet

- Saic M 1012Document2 pagesSaic M 1012Hussain Nasser Al- NowiesserNo ratings yet

- Splicing Optical Fiber CableDocument25 pagesSplicing Optical Fiber Cableafareenkhan100% (1)

- Rfi Log ShareDocument51 pagesRfi Log ShareafareenkhanNo ratings yet

- 399 Closure of Saipem NCR (Ref. Sp-khcpf-ncr-113)Document5 pages399 Closure of Saipem NCR (Ref. Sp-khcpf-ncr-113)afareenkhanNo ratings yet

- Control & InstrumentationDocument119 pagesControl & Instrumentationafareenkhan50% (2)

- QC Supervisor Telecommunication PDFDocument2 pagesQC Supervisor Telecommunication PDFafareenkhanNo ratings yet

- 1.01.17 222240Document1 page1.01.17 222240afareenkhanNo ratings yet

- HSE-002 Environmental Management Program - Ver.0 - 150402 Signed by MR - JangDocument55 pagesHSE-002 Environmental Management Program - Ver.0 - 150402 Signed by MR - JangafareenkhanNo ratings yet

- Malak Sher Khan Daily Vehicle Inspection (04-02-17)Document1 pageMalak Sher Khan Daily Vehicle Inspection (04-02-17)Afareen KhanNo ratings yet

- Apm-4 5TDocument6 pagesApm-4 5TelsadwihermiatiNo ratings yet

- Inventarizasiya 22.09.2018 Material Batch Material Description Stock Sap Unit Storage Bin Anbarda SayılanDocument100 pagesInventarizasiya 22.09.2018 Material Batch Material Description Stock Sap Unit Storage Bin Anbarda SayılanTuralNo ratings yet

- Chapter 16-Macro-Etching-ExaminationDocument10 pagesChapter 16-Macro-Etching-ExaminationBARCELON, CHRISTOPHER JAMESNo ratings yet

- Carbon FoamDocument25 pagesCarbon FoamSahil KumarNo ratings yet

- FRP Above Ground Installation ManualDocument32 pagesFRP Above Ground Installation ManualCarlos GutierrezNo ratings yet

- Experimental Investigation of Self Compacting Concrete by Partially Replacing Fine Aggregate With Quartz Sand With Use of Recron FibreDocument6 pagesExperimental Investigation of Self Compacting Concrete by Partially Replacing Fine Aggregate With Quartz Sand With Use of Recron Fibreshivanand hippargaNo ratings yet

- SD - Cupric Tartrate TS, Alkaline (Fehling's Solution) (B) (USP204) (EU)Document7 pagesSD - Cupric Tartrate TS, Alkaline (Fehling's Solution) (B) (USP204) (EU)atikah razakNo ratings yet

- Jis G3312 2012 JisfDocument27 pagesJis G3312 2012 JisfTUAN NGUYEN VANNo ratings yet

- 2015-TransNonferrousMetSocChina-Formation Mechanism of Ni-Al Intermetallics During Heat Treatment of Ni Coating On Al SusbtrateDocument8 pages2015-TransNonferrousMetSocChina-Formation Mechanism of Ni-Al Intermetallics During Heat Treatment of Ni Coating On Al SusbtrateSIVAJI TADISETTYNo ratings yet

- Mist Entrainment Separation For Sugar Mill Evaporators and Vacuum PansDocument13 pagesMist Entrainment Separation For Sugar Mill Evaporators and Vacuum PansLong Bui ThanhNo ratings yet

- 18033TEI Prod Broch Endumax - LRDocument9 pages18033TEI Prod Broch Endumax - LRmeterabNo ratings yet

- Concrete Design ProkonDocument206 pagesConcrete Design ProkonBoon Fui100% (2)

- Catalogo WfiDocument36 pagesCatalogo WfiJack DominikNo ratings yet

- E448-82 (2008) Standard Practice For Scleroscope Hardness Testing of Metallic MaterialsDocument5 pagesE448-82 (2008) Standard Practice For Scleroscope Hardness Testing of Metallic MaterialsislamakthamNo ratings yet

- TCVN 9888-3 - 2013 - IEC 62305-3 - 2010 - 1049711 EN VerDocument137 pagesTCVN 9888-3 - 2013 - IEC 62305-3 - 2010 - 1049711 EN VerNam NguyenNo ratings yet

- 4 Concrete Repair GuideDocument42 pages4 Concrete Repair GuideBenharzallah KrobbaNo ratings yet

- Group-2 Value Based Questions Subject: Chemistry Class XIIDocument6 pagesGroup-2 Value Based Questions Subject: Chemistry Class XIISsNo ratings yet

- Medical Device Standards and Implant StandardsDocument13 pagesMedical Device Standards and Implant StandardsAnil Kumar50% (4)

- N2 Reference SheetDocument2 pagesN2 Reference SheetsthrzrNo ratings yet

- Chemistry BookletDocument835 pagesChemistry BookletNiharika ShahNo ratings yet

- Chair Analysis in ANSYSDocument5 pagesChair Analysis in ANSYSAditya DaveNo ratings yet

- Presentation - Frame Construction in Concrete SteelDocument23 pagesPresentation - Frame Construction in Concrete SteelOlay KwongNo ratings yet

- Crevice Corrosion: How To Reduce The Risk of Crevice CorrosionDocument2 pagesCrevice Corrosion: How To Reduce The Risk of Crevice CorrosionMohamedNo ratings yet

- Fluting Vs Non-Fluting Steel Technical BulletinDocument2 pagesFluting Vs Non-Fluting Steel Technical BulletinĐinh Nho KhiêmNo ratings yet

- Buderus G125BE High Efficiency Oil Fired BoilerDocument4 pagesBuderus G125BE High Efficiency Oil Fired Boilere-ComfortUSANo ratings yet

- CH 15 PDFDocument64 pagesCH 15 PDFkrishnaNo ratings yet