Professional Documents

Culture Documents

Validation of A Reversed-Phase HPLC Method For Qua

Validation of A Reversed-Phase HPLC Method For Qua

Uploaded by

elsyCopyright:

Available Formats

You might also like

- OCR Chemistry A: 4 Acids and Redox Exam-Style Mark SchemeDocument3 pagesOCR Chemistry A: 4 Acids and Redox Exam-Style Mark Schemenoreen doraniNo ratings yet

- 10 1002@sici1097-001019981278@4461@@aid-Jsfa1383 0 Co2-KDocument5 pages10 1002@sici1097-001019981278@4461@@aid-Jsfa1383 0 Co2-KMd. Sohanur RahmanNo ratings yet

- Valporate 3Document7 pagesValporate 3sisnaingaungNo ratings yet

- Heliyon: Amira F. El-Yazbi, Karin M. Guirguis, Mona M. Bedair, Tarek S. BelalDocument10 pagesHeliyon: Amira F. El-Yazbi, Karin M. Guirguis, Mona M. Bedair, Tarek S. BelalWentySafitriNo ratings yet

- Anal Methods 2011Document9 pagesAnal Methods 2011artemNo ratings yet

- Vydac Reference Handbook Proteins PeptidesDocument88 pagesVydac Reference Handbook Proteins PeptidesChintan VaywalaNo ratings yet

- Microchemical Journal: Geetika Wadhwa, Kowthavarapu Venkata Krishna, Sunil Kumar Dubey, Rajeev TaliyanDocument10 pagesMicrochemical Journal: Geetika Wadhwa, Kowthavarapu Venkata Krishna, Sunil Kumar Dubey, Rajeev TaliyanAriana NoeliaNo ratings yet

- Biogenic Amine-1Document7 pagesBiogenic Amine-1hariharan rNo ratings yet

- A Method For The Qualitative and Quantitative Determination of The Amino Acid Composition of Pharmaceutical Products - SGSDocument6 pagesA Method For The Qualitative and Quantitative Determination of The Amino Acid Composition of Pharmaceutical Products - SGSiirffannnNo ratings yet

- AN789 Fast Extraction of VMA 5-HIAA and HVA From Synthetic UrineDocument4 pagesAN789 Fast Extraction of VMA 5-HIAA and HVA From Synthetic UrineDarshana JuvekarNo ratings yet

- The Handbook of Analysis and Purification of Peptides and Proteins by Reversed-Phase HPLCDocument36 pagesThe Handbook of Analysis and Purification of Peptides and Proteins by Reversed-Phase HPLCdanny3001_1999No ratings yet

- Development and Validation of Liquid Chromatography Method For Simultaneous Estimation of Miconazole and Clobetasol andDocument13 pagesDevelopment and Validation of Liquid Chromatography Method For Simultaneous Estimation of Miconazole and Clobetasol andvinayNo ratings yet

- Alexandre Et Al-2016-Brazilian Journal of Pharmaceutical SciencesDocument8 pagesAlexandre Et Al-2016-Brazilian Journal of Pharmaceutical Sciencesvsvsuresh2099No ratings yet

- Articulo 1 SalchichasDocument5 pagesArticulo 1 SalchichasLALILA ORTIZ DIAZNo ratings yet

- A Novel and Rapid LC-MS:MS Assay For The Determination of Mycophenolate and Mycophenolic Acid in Human PlasmaDocument8 pagesA Novel and Rapid LC-MS:MS Assay For The Determination of Mycophenolate and Mycophenolic Acid in Human PlasmaFKUPN 2002No ratings yet

- Metodo Isocratico Por HPLC de Besifloxacino HCLDocument5 pagesMetodo Isocratico Por HPLC de Besifloxacino HCLJuan SNo ratings yet

- Chatzimichalakis 2004Document8 pagesChatzimichalakis 2004Pamela Agredo SaninNo ratings yet

- HPLC AcidosDocument5 pagesHPLC AcidosAlejandra Calderón RodríguezNo ratings yet

- Optimization of Phenol-Chloroform RNA ExtractionDocument10 pagesOptimization of Phenol-Chloroform RNA Extractionunggarapunja12No ratings yet

- High-Performance Liquid Chromatography Determination of Zn-Bacitracin in Animal Feed by Post-Column Derivatization and Fluorescence DetectionDocument8 pagesHigh-Performance Liquid Chromatography Determination of Zn-Bacitracin in Animal Feed by Post-Column Derivatization and Fluorescence DetectionngobaochanNo ratings yet

- Namratha FinalDocument56 pagesNamratha FinalAkhil KattamuriNo ratings yet

- Lab Report 2 HPLCDocument9 pagesLab Report 2 HPLCGissela BTNo ratings yet

- Nok-Sorbic-And-BenzoicDocument9 pagesNok-Sorbic-And-BenzoicKaewta DanchanaNo ratings yet

- Preparative HPLC Separation and Isolation of Bacitracin Components and Their Relationship To Microbiological ActivityDocument6 pagesPreparative HPLC Separation and Isolation of Bacitracin Components and Their Relationship To Microbiological ActivityngobaochanNo ratings yet

- Articulo 06Document7 pagesArticulo 06iria.gonzalez.micoNo ratings yet

- M2P11 Anal ChemDocument8 pagesM2P11 Anal ChempedroNo ratings yet

- Quetiapine FumarateDocument9 pagesQuetiapine FumarateVinaya SnehalathaNo ratings yet

- Validation of A Capillary Electrophoresis Method For The Analysis of Ibandronate Related ImpuritiesDocument4 pagesValidation of A Capillary Electrophoresis Method For The Analysis of Ibandronate Related ImpuritiescesarNo ratings yet

- Detection ListeriaDocument5 pagesDetection ListeriaDiego ValenteNo ratings yet

- Automated Analysis For Free and Short-Chain Acylcarnitine in Plasma With A Centrifugal AnalyzerDocument6 pagesAutomated Analysis For Free and Short-Chain Acylcarnitine in Plasma With A Centrifugal AnalyzerHarry YucraNo ratings yet

- Development and Validation of An Extraction Method Using Liquid Chromatography-Tandem Mass Spectrometry To Determine Patulin in Apple JuiceDocument7 pagesDevelopment and Validation of An Extraction Method Using Liquid Chromatography-Tandem Mass Spectrometry To Determine Patulin in Apple JuiceMai NhựtNo ratings yet

- Determination of Niacin in Food Materials by Liquid Chromatography Using Isotope Dilution Mass SpectrometryDocument6 pagesDetermination of Niacin in Food Materials by Liquid Chromatography Using Isotope Dilution Mass SpectrometryMonica chavez escamNo ratings yet

- Lopez Cervantes (Quitina)Document5 pagesLopez Cervantes (Quitina)Sandra MuñozNo ratings yet

- Research Paper - IJPBSDocument10 pagesResearch Paper - IJPBSFarahat AliNo ratings yet

- Vydac Protein and Peptide HandbookDocument92 pagesVydac Protein and Peptide HandbookyonkaniNo ratings yet

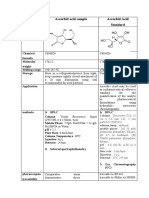

- Parameters Ascorbid Acid Sample Ascorbid Acid Standard: Column: Discovery C18, 15Document2 pagesParameters Ascorbid Acid Sample Ascorbid Acid Standard: Column: Discovery C18, 15anisaNo ratings yet

- LCGC NAmerica September2012ANDocument68 pagesLCGC NAmerica September2012ANSalman AbuzuhairaNo ratings yet

- Ocratoxina en CafeDocument4 pagesOcratoxina en Cafenabucodonossor24No ratings yet

- 1 s2.0 S2352340915003777 MainDocument6 pages1 s2.0 S2352340915003777 MainBouguetaia YacineNo ratings yet

- Bai Bao EC-1998Document5 pagesBai Bao EC-1998Bình GiangNo ratings yet

- HPLC Tech ReportDocument5 pagesHPLC Tech Reportclou3d.1No ratings yet

- 1 s2.0 S2095177912000834 Main PDFDocument4 pages1 s2.0 S2095177912000834 Main PDFelvinaNo ratings yet

- Theory of HPLC Reverse Phase ChromatographyDocument93 pagesTheory of HPLC Reverse Phase ChromatographyBenjaminHrustićNo ratings yet

- Application Pahs Salmon Beef 5994 0553en AgilentDocument12 pagesApplication Pahs Salmon Beef 5994 0553en AgilentYEMERSON MEYER BARTOLO CHARRINo ratings yet

- LC-MS/MS For The Determination of Four Water Soluble Vitamins: Method Development, Validation and Comparison To EC MethodDocument6 pagesLC-MS/MS For The Determination of Four Water Soluble Vitamins: Method Development, Validation and Comparison To EC MethoddewiNo ratings yet

- Chisvert 2002Document5 pagesChisvert 2002nambiarnedumchalNo ratings yet

- Automated In-Tube Solid Phase Microextraction Coupled With HPLC-ES-MS For The Determination of Catechins and Caffeine in TeaDocument7 pagesAutomated In-Tube Solid Phase Microextraction Coupled With HPLC-ES-MS For The Determination of Catechins and Caffeine in TeaSeema YadavNo ratings yet

- Experiment 7Document6 pagesExperiment 7Rodney SalazarNo ratings yet

- Metode Vit CDocument6 pagesMetode Vit CRuang BazaarNo ratings yet

- Development and Validation of A Precise Method ForDocument11 pagesDevelopment and Validation of A Precise Method Forantyka kawaNo ratings yet

- Exp 5 HPLCDocument2 pagesExp 5 HPLCAnonymous XbbVyRNo ratings yet

- AN122 IC Carbohydrates Alcohol Glycol Fermentation Broth - AN70494 - EDocument9 pagesAN122 IC Carbohydrates Alcohol Glycol Fermentation Broth - AN70494 - EfabiowalligatorNo ratings yet

- 1052 USP Amino Acid AnalysisDocument11 pages1052 USP Amino Acid Analysissuhas.lavhekarNo ratings yet

- Application Note: A Cleaning Validation Swab Recovery Study Using A UV/Persulfate AnalyzerDocument4 pagesApplication Note: A Cleaning Validation Swab Recovery Study Using A UV/Persulfate AnalyzerPrianurraufikachmadNo ratings yet

- Single Determination of A-Ketoglutaric Acid and Pyruvic Acid in Beer by HPLC With UV DetectionDocument6 pagesSingle Determination of A-Ketoglutaric Acid and Pyruvic Acid in Beer by HPLC With UV DetectionPatrícia MontenegroNo ratings yet

- Proteomics Lab ReportDocument4 pagesProteomics Lab Reportnursah.aslanNo ratings yet

- HPLCC KDocument6 pagesHPLCC Kfreskim.gashiNo ratings yet

- An 122 Ic Carbs Alcohol Glycol Fermentation Broth An70494 enDocument12 pagesAn 122 Ic Carbs Alcohol Glycol Fermentation Broth An70494 enSantiago Rivera AlbaNo ratings yet

- HPLC Method For The Analysis of Paracetamol Caffeine and Dipyron-1Document9 pagesHPLC Method For The Analysis of Paracetamol Caffeine and Dipyron-1Đoàn Lê Thuý HiềnNo ratings yet

- 2011 Schumann Alp-Reference-Method CCLMDocument8 pages2011 Schumann Alp-Reference-Method CCLMأم الجودNo ratings yet

- Coupled Bioluminescent Assays: Methods, Evaluations, and ApplicationsFrom EverandCoupled Bioluminescent Assays: Methods, Evaluations, and ApplicationsNo ratings yet

- List of Ingredients - OrganicDocument13 pagesList of Ingredients - OrganicedmondjoshiNo ratings yet

- Support Compatibility SheetDocument1 pageSupport Compatibility SheetJxyz QwNo ratings yet

- Lovely Professional UniversityDocument11 pagesLovely Professional UniversityAnkush KaithNo ratings yet

- Noncanonical Transnitrosylation Network Contributes To Synapse Loss in Alzheimer's DiseaseDocument18 pagesNoncanonical Transnitrosylation Network Contributes To Synapse Loss in Alzheimer's DiseasedmitworNo ratings yet

- Lecture - 7-8Document19 pagesLecture - 7-8Amierson TilendoNo ratings yet

- Redox ReactionDocument40 pagesRedox Reactionjakegrayzon13No ratings yet

- Progression Test 2024 Paper 2 Marking SchemeDocument12 pagesProgression Test 2024 Paper 2 Marking SchemeAkshat ArchitNo ratings yet

- Chemistry ProjectDocument16 pagesChemistry ProjectvalanrkNo ratings yet

- PPSC Junior Auditor Question Papers 1Document5 pagesPPSC Junior Auditor Question Papers 1preet103411No ratings yet

- AFBC Boiler O&MDocument134 pagesAFBC Boiler O&MVijay Raj87% (15)

- Gaseous Exchange in Humans ANSWERDocument23 pagesGaseous Exchange in Humans ANSWERKeertana SubramaniamNo ratings yet

- Periodic Table, Group 2 and The Halogens 1 QPDocument13 pagesPeriodic Table, Group 2 and The Halogens 1 QPmalakNo ratings yet

- Opposites Attract and Like Repel.: Inductive Effect Resonance EffectDocument12 pagesOpposites Attract and Like Repel.: Inductive Effect Resonance EffectAwais Arshad0% (1)

- Work Sheet-9 PDFDocument3 pagesWork Sheet-9 PDFKesanam Sp100% (1)

- Water Heater Catalogue 2019 PDFDocument32 pagesWater Heater Catalogue 2019 PDFHarshit SharmaNo ratings yet

- M.Sc. - Mathematics - 2022 9 28 15 40 8Document111 pagesM.Sc. - Mathematics - 2022 9 28 15 40 8Dontha Udaykumar2527No ratings yet

- Concrete Repair & Restoration (Sika)Document37 pagesConcrete Repair & Restoration (Sika)Dinn Ns100% (2)

- Lab Manual Exp 12-Blast FreezerDocument7 pagesLab Manual Exp 12-Blast FreezerChong EkNo ratings yet

- Syllabus Bs ChemistryDocument6 pagesSyllabus Bs ChemistryWaqas LuckyNo ratings yet

- Evaluation of Chromium Carbide Coatings On AISI 52100 Steel Obtained by Thermo-Reactive Diffusion TechniqueDocument6 pagesEvaluation of Chromium Carbide Coatings On AISI 52100 Steel Obtained by Thermo-Reactive Diffusion Techniquedaniel leonNo ratings yet

- 6compiled PDFDocument42 pages6compiled PDFMiracleNo ratings yet

- Influence of Ambient Air and Different Surface Treatments On The Bonding Performance of A CAD CAM Composite Block. Alghamdi Ali. 2018. J Adhes DentDocument8 pagesInfluence of Ambient Air and Different Surface Treatments On The Bonding Performance of A CAD CAM Composite Block. Alghamdi Ali. 2018. J Adhes DentValeria CrespoNo ratings yet

- Alcohal, Phenol MCQDocument6 pagesAlcohal, Phenol MCQAryan SharmaNo ratings yet

- Inorganic and Organic Chemistry Experiment No. 4: Preparation of ColloidsDocument4 pagesInorganic and Organic Chemistry Experiment No. 4: Preparation of ColloidsDanzel MalicNo ratings yet

- Cambridge IGCSE: Combined Science 0653/23Document16 pagesCambridge IGCSE: Combined Science 0653/23annwong85No ratings yet

- Physicochemical Changes During 4 Weeks Ripening of Camembert Cheeses Salted With Four Types of SaltsDocument12 pagesPhysicochemical Changes During 4 Weeks Ripening of Camembert Cheeses Salted With Four Types of SaltsGina FelyaNo ratings yet

- Daftar Obat Zenith: Gol - AntibiotikaDocument3 pagesDaftar Obat Zenith: Gol - AntibiotikaNetriNo ratings yet

- Design Steam Consumption DataDocument5 pagesDesign Steam Consumption DataKishore KumarNo ratings yet

- Dow™ Ldpe 352E: Low Density Polyethylene ResinDocument1 pageDow™ Ldpe 352E: Low Density Polyethylene Resinvantuan17792No ratings yet

Validation of A Reversed-Phase HPLC Method For Qua

Validation of A Reversed-Phase HPLC Method For Qua

Uploaded by

elsyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Validation of A Reversed-Phase HPLC Method For Qua

Validation of A Reversed-Phase HPLC Method For Qua

Uploaded by

elsyCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/7042205

Validation of a Reversed-Phase HPLC Method for Quantitative Amino Acid

Analysis

Article in Journal of biomolecular techniques: JBT · May 2006

Source: PubMed

CITATIONS READS

149 2,471

2 authors:

Maria paola Bartolomeo Federico Maisano

Bracco Group Bracco Group

5 PUBLICATIONS 250 CITATIONS 26 PUBLICATIONS 892 CITATIONS

SEE PROFILE SEE PROFILE

All content following this page was uploaded by Federico Maisano on 31 May 2014.

The user has requested enhancement of the downloaded file.

Journal of Biomolecular Techniques

17:131–137 © 2006 ABRF

AB

RF

Validation of a Reversed-Phase HPLC Method for Quantitative Amino Acid Analysis

Maria Paola Bartolomeo and Federico Maisano

Milano Research Centre, Bracco Imaging SpA, Milan, Italy

A semi-automated method for amino acid derivatization and analysis has been validated for use in analy-

sis of protein biopharmaceuticals. The method includes protein hydrolysis, o‑phthalaldehyde derivatization,

and reversed-phase high-performance liquid chromatography analysis in a general-purpose UV‑visible high-

performance liquid chromatography system. Amino-acid derivatization is performed automatically by the

high-performance liquid chromatography autosampler right before injection. The required validation param-

eters, i.e., specificity, linearity, accuracy, precision, limit of detection, and limit of quantification, were studied

for bovine serum albumin and for a recombinant human Fab fragment. The method can be employed as an

absolute quantification method for determination of extinction coefficients of recombinant proteins.

Key Words : Amino acid analysis, OPA-derivatization, reverse-phase HPLC, validation.

A mino-acid analysis has a long history in the char-

acterization of protein-based products, since it

provides information on the product concentra-

tion without referring to an external protein standard

and it is independent from the shape and the charge

reversed-phase high-performance liquid chromatography

(RP-HPLC), because the latter techniques imply extensive

sample manipulation before analysis and are affected by

the limited stability of the preformed derivatives. 2 How-

ever, such RP-HPLC-based methods have the advantage

of the protein. In addition, the determined amino-acid of being accessible to most analytical laboratories, since

composition can confirm sample identity and gives a they do not require expensive dedicated instruments. In

measure of sample purity. Furthermore, when combined addition, manufacturing of dedicated instruments is being

with absorbance measurements, it allows the determina- halted, making the availability of validated pre-column

tion of extinction coefficients under various conditions.1 methods even more important.

For protein conjugates, where the synthetic counterpart In this paper, we describe the validation of a method

modifies the protein absorption properties, amino-acid that takes advantage of robotic sample derivatization,

analysis may be required as the only reliable quantifica- thereby limiting considerably the manual manipulation

tion method. of samples. Another advantage of automation is that

However, in spite of these features, few laboratories derivatization is performed just before the injection;

can perform such analysis in a reliable and quantitative therefore, the time from reaction to injection is kept abso-

way, due to the need for specialized equipment and skills. lutely constant for all samples, thus avoiding differential

Usually, techniques based on ion-exchange separation degradation of labile derivatives. We have studied the

coupled with post-column derivatization (e.g., with nin- performance characteristics in terms of specificity, lin-

hydrin, the “classical” method) are considered more pre- earity, accuracy, precision, limit of detection, and limit of

cise1 than those based on pre-column derivatization and quantification for bovine serum albumin (BSA) and for a

recombinant human Fab (rFab) fragment, whose extinc-

tion coefficient needs to be determined.

Protein samples were hydrolyzed, then automati-

Address correspondence and reprint requests to : Dr. Federico

cally derivatized with o-phthalaldehyde (OPA) and in-line

Maisano, CRM/Pharmatox, Bracco Imaging SpA, Via Folli, analyzed by RP-HPLC with ultraviolet-visible (UV-Vis)

50, 20134 Milan, Italy (phone +39 02 21772369; fax +39 02 detection, according to a method published in an Agilent

21772794; email: federico.maisano@bracco.com). application note.3

Journal of Biomolecular Techniques, Volume 17, issue 2, April 2006 131

M.P. Bartolomeo and F. Maisano

Materials and methods and dried again in the lyophilizer to remove any liquid

Reagents, Solvents, and Materials traces (condensed vapors). The dried residues were dis-

Sodium phosphate monobasic monohydrate, sodium solved in 100 µL of 0.1 N HCl and transferred into the

hydroxide, boric acid, acetonitrile (LC grade), and metha- HPLC glass insert vials.

nol (LC grade) were obtained from Merck KGaA (Darm-

Instrumentation

stadt, Germany). OPA reagent was prepared as described

(Agilent art. 5061-3335, Palo Alto, CA). Borate buffer was Analyses were performed using an Agilent 1100 Liquid

prepared by adjusting 0.4 N boric acid to pH 10.2 with Chromatograph, equipped with a binary pump delivery

NaOH. Constant-boiling HCl was obtained from Sigma- system (G1312A), robotic autosampler (G1313A), col-

Aldrich (St. Louis, MO). Chromatographic-grade water umn thermostat (G1316A) and multi-wavelength detector

was produced by a Milli-Q system (Millipore, Billerica, (G1365A).

MA)

Analytical Procedure

Disposable glass test tubes (50 × 6 mm) and hydrolysis

reaction vials (25 × 120 mm) with Mininert valves were Chromatography conditions were in accordance with the

from Kimble Glass, Inc., and Kontes Glass Co. (Vineland, Agilent method. 2 Briefly, the hydrolyzed samples and

NJ). Amber wide-opening vials, glass conical inserts with the norvaline-spiked amino acid standard solutions were

polymer feet, and screw caps were from Agilent. automatically derivatized with OPA by programming the

Albumin standard solution (2 mg/mL) was supplied robotic autosampler (Table 1). After derivatization, an

by Pierce Biotechnology (Rockford, IL), while amino acid amount equivalent to 2.5 µL of each sample was injected

standard mixtures at the concentration of 1 nmol/µL and on a Zorbax Eclipse-AAA column, 5 µm, 150 × 4.6 mm

250 pmol/µL were from Agilent. The internal standard (Agilent), at 40°C, with detection at λ = 338 nm. Mobile

l-norvaline was obtained from Sigma-Aldrich. A recombi- phase A was 40 mM NaH 2PO4, adjusted to pH 7.8 with

nant Fab fragment (rFab) was obtained from the research NaOH, while mobile phase B was acetonitrile/methanol/

laboratories of Bracco Imaging (Milan, Italy). water (45/45/10 v/v/v). The separation was obtained at

a flow rate of 2 mL/min with a gradient program that

allowed for 1.9 min at 0% B followed by a 16.3-min step

Amino Acid Standard Solutions

that raised eluent B to 53%. Then washing at 100% B and

Amino acid standard samples were prepared by mixing equilibration at 0% B was performed in a total analysis

95 µL of the 250 pmol/µL amino acid standard mixture time of 26 min.

with 5 µL of 10 mM norvaline and analyzed directly by

RP-HPLC, within 24 h from preparation. Solutions for Results and Discussion

linearity study were prepared in duplicate by diluting the

Acid hydrolysis is a crucial step that considerably influ-

1 nmol/µL amino acid standard solution, and contained

ences amino-acid recovery. In fact, during acid hydroly-

20, 50, 130, 250, or 500 pmol/µL of amino acid standard

sis, tryptophan and cysteine are destroyed and serine and

mixture together with 0.5 mM norvaline.

threonine are also partially lost, while methionine can

undergo oxidation. Moreover, some amino acids such as

Protein Samples glycine and serine are common contaminants; therefore,

Glass test tubes (50 × 6 mm) were marked with incisions their quantification needs careful subtraction of average

and soaked in a detergent solution for at least 12 h. They responses in blank runs, which, in the case of glycine, is

were rinsed thoroughly in Milli-Q water and dried in also complicated by the fact that this residue is known

an oven at 80°C. Protein samples (7–75 µg) were trans- to give rise to multiple derivatives after OPA reaction.2

ferred into the glass test tubes and spiked with 0.5 mM Therefore, the validation parameters were estimated

norvaline. They were quickly spun in a low-velocity cen- using the following seven best-recovered amino acids:

trifuge, then frozen and dried in a lyophilizer. Samples Asx (Asn+Asp), Glx (Glu+Gln), Arg, Ala, Phe, Leu, and

were then transferred into the reaction vial containing Lys.4

0.5 mL of constant-boiling HCl on the bottom. Up to In order to fully assess the method’s performance,

12 test tubes could be accommodated in a reaction vial. both a standard amino acid mixture and a reference pro-

The reaction vial was tightly closed and transferred into tein (e.g., BSA) should be assayed along with the product.

a pre-heated oven at 110°C for 18 h. The reaction vial The standard amino acid mixture (Figure 1) enables the

was cooled at room temperature, then carefully opened verification of the HPLC method’s performance, includ-

under an aspirated hood. The test tubes were centrifuged ing derivatization, while the reference protein samples

132 Journal of Biomolecular Techniques, Volume 17, issue 2, April 2006

Validation of RP-HPLC amino acid analysis

Table 1

Autosampler Programming Instructions

Position of vials

Position 1: borate buffer

Position 2: water for needle wash (open vial)

Position 3: OPA reagent

Position 4: water

Position X: sample (amino acids standard, BSA, test article)

X is any other position of the autosampler tray.

Derivatization/injection routine:

1 Draw 2.5 µL from vial 1 (borate buffer)

2 Draw 2.5 µL from sample vial (e.g., position #11)

3 Mix 3 µL in air, max speed, 2X

4 Wait 0.5 min

5 Draw 0 µL from vial 2 (needle wash)

6 Draw 0.5 µL from vial 3 (OPA reagent)

7 Mix 3.5 µL in air, max speed, 6X

8 Draw 0 µL from vial 2 (needle wash)

9 Draw 32 µL from vial 4 (water)

10 Mix 18 µL in air, max speed, 2X

11 Inject

Auxiliary instructions: draw speed, 200 µL/min; eject speed,

600 µL/min; draw position, 0.0 mm.

(Figure 2) assess the completeness of the hydrolysis step. Linearity and Range

In addition, L‑norvaline, which is added as the inter- Linearity was studied in the range from 20 to 500 pmol/μL

nal standard, provides a control for sample-to-sample of standard amino acids and from 1.5 to 15 pmol/μL of

variability. rFab, corresponding approximately to 20–200% of the

test concentration. Five concentration points were assayed

Specificity

in duplicate. Both the standard amino acid mixture and

Specificity was documented by comparing retention times the test product showed good linearity in the tested range.

obtained in the standard amino acid mixture (five samples) The area response obeyed the equation y = mx + C, where

with those obtained from the reference protein samples the intercept C was zero within 95% confidence limits and

(three samples). Results are reported in Table 2. The mini- the square correlation coefficient (R 2) was always greater

mal difference between retention times (<0.1%) allows then 0.985 (Table 3).

confident, highly specific, peak identification. Usually, a

difference within ±3% is considered acceptable between Accuracy

retention times of the same amino acids present in the Accuracy is defined as the agreement between the found

standard mixture and in the hydrolyzed sample.5 value and the true, independently determined, concentra-

Figure 1

Example of a standard amino acid

mixture analysis at a concentration of

250 pmol/µL.

Journal of Biomolecular Techniques, Volume 17, issue 2, April 2006 133

M.P. Bartolomeo and F. Maisano

Figure 2

Example of a protein hydrolysate

analysis for one of the 35-µg BSA

samples.

tion value. It was studied on BSA samples prepared from Repeatability was studied on six injections (and

a calibrated standard, which is normally used in protein derivatization) of the same BSA sample. The mean accu-

determination assays. The accuracy of the method was racy of each well-recovered amino acid was calculated.

evaluated considering two different parameters: the abso- The percentage coefficient of variation (%CV) for each

lute percent error and the recovery. The absolute percent well-recovered amino acid was less than 2.5% (Table 6),

error (%ABS) was calculated for each well-recovered compared with an acceptance range of 5%.

amino acid. It was always less then 7%, and the average Intermediate precision was studied by running the

percent error was less then 2.5% (Table 4). Based on the whole method on three different days. Each day, three

found amino acid concentrations and the known com- equivalent BSA samples were prepared, hydrolyzed, deriva-

position of BSA, the percent recovery of BSA was calcu- tized, and injected. The %CV for each well-recovered

lated. Considering each single amino acid, the recovery amino acid was generally not greater than 2.5%, with only

was found within the range 97–108%, while the aver- one exception for arginine at 8%, as reported in Table 7.

age recovery, considering all the amino acids, was 102%

(Table 5), which is largely within the 90–110% range that Quantification and Detection Limits

is considered acceptable.5 The limit of quantification (LOQ) and the limit of detec-

tion (LOD) were calculated on the basis of the standard

Precision deviation of the response and the slope obtained from

Precision was measured as repeatability and intermediate the linearity plot of each well-recovered amino acid of

precision. Reproducibility, which refers to the use of the the standard mixture, as described in the relevant ICH

analytical procedure in different laboratories, was beyond guideline.6 LOQ and LOD were calculated as 3.3α/S and

the scope of the present study. 10α/S, respectively, where α is the standard deviation of

the y-intercept and S is the slope of regression line. The

Table 2

Specificity Evaluation Comparing Retention Times

AA Std. Sol. (n = 5) BSA (n = 3)

Tr SD Tr SD Difference

(min) (min) (min) (min) (%)

Asx 1.895 0.0018 1.897 0.0020 0.08

Glx 4.019 0.0045 4.018 0.0000 –0.03

Arg 8.469 0.0025 8.467 0.0010 –0.02

Ala 9.030 0.0050 9.028 0.0015 –0.02

Phe 13.305 0.0065 13.304 0.0026 –0.01

Leu 14.099 0.0061 14.097 0.0015 –0.02

Lys 14.494 0.0055 14.492 0.0015 –0.01

134 Journal of Biomolecular Techniques, Volume 17, issue 2, April 2006

Validation of RP-HPLC amino acid analysis

Table 3

Linearity Data for Amino Acid Standard Mixture and rFab

Amino acid standard mixture rFab

Slope Intercept R2 Slope Intercept R2

Asx 0.0019 –0.0119 0.9986 0.0112 + 0.0034 0.9921

Glx 0.0017 –0.0113 0.9984 0.0181 – 0.0261 0.9933

Arg 0.0020 –0.0084 0.9972 0.0277 – 0.0079 0.9856

Ala 0.0021 –0.0132 0 9976 0.0127 – 0.0186 0.9904

Phe 0.0021 –0.0137 0 9982 0.0054 + 0.0062 0.9900

Leu 0.0020 –0.0158 0 9980 0.0150 – 0.0184 0.9933

Lys 0.0035 –0.0199 0 9956 0.0180 + 0.0136 0.9980

calculated values of LOQ and LOD for each considered BSA known composition. The average absolute error was

residue are reported in Table 8. 2.33%. In addition, BSA recovery was determined both

from single amino acids (range 97–108%) and as an aver-

Conclusions age value (102%).

Method specificity was demonstrated by comparing the Repeatability was measured by carrying out analyses

retention times for the considered amino acids in hydro- on six injections (including derivatization) of the same

lyzed BSA samples and amino acid standard solutions. hydrolyzed BSA sample. The %CV for each considered

Given the excellent reproducibility of retention times amino acid was less than 5%.

between amino acid standard solution and protein sam- Intermediate precision was determined on three dif-

ples, the method proved highly specific. ferent days, by processing three equivalent BSA samples

Linearity was demonstrated for single amino acid each day. For single amino acid recovery, the %CV for

response both in recombinant Fab and in standard each considered amino acid was less than 8%, with only

amino acid samples in a range of 25–150% of the usu- one case (arginine) above 2.5%.

ally analyzed amount. The square correlation coeffi- The determined validation parameters are in the com-

cient was above 0.985, with only one case (arginine) monly acceptable ranges for this kind of analysis, and

below 0.99. allow the use of the method with various recombinant

The LOQ and the LOD were in the range 33– proteins (e.g., antibody fragments) both as an identity test

60 pmol/µL and 11–20 pmol/µL, respectively, depending and for extinction coefficient determination when the

on the amino acid under consideration. sequence in known.

Accuracy was determined by comparison of found An important contribution to these results came from

amino acid residue numbers with those obtained from the automation adopted for amino acid derivatization,

Table 4

Absolute Percent Error (%ABS) of Found to Theoretical (Nt) Residue Numbers for the

BSA Molecule

Nt Inj. #1 Inj. #2 Inj. #3 Mean ± SD %ABS

Asx 54 54.2 53.7 54.7 54 ± 0.45 0.34

Glx 79 82.0 81.7 76.8 80 ± 2.93 1.49

Arg 23 20.9 27.0 25.8 25 ± 3.19 6.99

Ala 47 45.0 44.5 45.0 45 ± 0.29 4.60

Phe 27 26.7 26.9 28.0 27 ± 0.67 0.77

Leu 61 61.0 59.9 61.6 61 ± 0.85 0.30

Lys 59 59.9 56.1 57.9 58 ± 1.93 4.78

Avg. %ABS 2.33

Journal of Biomolecular Techniques, Volume 17, issue 2, April 2006 135

M.P. Bartolomeo and F. Maisano

Table 5

BSA Recovery, as Calculated from Single Amino Acids

Inj. #1 (µg) Inj. #2 (µg) Inj. #3 (µg) Mean ± SD (µg) Recovery %

Asx 34.7 36.1 35.9 35 .6 ± 0.8 102

Glx 35.9 37.5 34.5 36.0 ± 1.5 103

Arg 31.5 42.6 39.7 37.9 ± 5.7 108

Ala 33.1 34.3 34.0 33.8 ± 0.6 97

Phe 34.3 36.1 36.8 35.7 ± 1.3 102

Leu 34.6 35.6 35.8 35.3 ± 0.6 101

Lys 35.1 34.5 34.8 34.8 ± 0.3 99

Average Recovery % 102

Table 6

Repeatability (Numbers of Residues)

Nt Inj. #1 Inj. #2 Inj. #3 Inj. #4 Inj. #5 Inj. #6 Mean ± SD %CV

Asx 54 54.9 55.2 53.7 54.6 54.5 53.9 54.5 ± 0.54 1.00

Glx 79 83.6 83.0 82.0 83.9 83.7 83.7 83.3 ± 0.69 0.83

Arg 23 20.7 21.3 21.5 21.6 20.5 21.4 21.2 ± 0.47 2.21

Ala 47 44.8 44.7 46.6 44.7 44.3 44.7 45.0 ± 0.80 1.78

Phe 27 27.2 28.0 27.7 26.7 28.3 27.5 27.6 ± 0.54 1.97

Leu 61 62.3 62.0 61.3 61.2 61.5 61.5 61.6 ± 0.44 0.72

Lys 59 56.2 55.8 57.0 57.1 57.1 57.0 56.7 ± 0.55 0.97

Table 7

Intermediate Precision of Well-Recovered Amino Acid Residues (Numbers of Residues)

Intermediate Precision

Nt Day 1 Day 2 Day 3 Mean ± SD Percentage

Asx 54 55.2 54.2 55.1 54.8 ± 0.56 101.5 ± 1.03

Glx 79 84.2 80.2 81.7 82.1 ± 2.05 103.9 ± 2.50

Arg 23 21.1 24.6 23.9 23.2 ± 1.85 100.1 ± 7.97

Ala 47 44.4 44.8 45.5 44.9 ± 0.53 95.5 ± 1.17

Phe 27 26.2 27.2 27.3 26.9 ± 0.62 99.6 ± 2.30

Leu 61 60.3 60.8 60.3 60.5 ± 0.30 99.2 ± 0.49

Lys 59 58.5 57.9 55.9 57.4 ± 1.39 97.3 ± 2.42

Table 8

LOQ and LOD Values (pmol/µL)

Asx Glx Arg Ala Phe Leu Lys

LOQ 34 37 48 44 39 41 61

LOD 11 12 16 15 13 14 20

136 Journal of Biomolecular Techniques, Volume 17, issue 2, April 2006

Validation of RP-HPLC amino acid analysis

which guarantees highly reproducible reaction times and dialdehyde/3-mercaptopropionic acid and o-phthaldialdehyde/N-

lack of degradation. In addition, the short reaction times acetyl-l-cysteine reagents: High-performance liquid chromatogra-

phy-mass spectrometry study. J Chromatogr A 2002;949:99–124.

seem not to give rise to multiple derivatives, as previously 3. Henderson JW, Ricker RD, Bidlingmeyer BA, Woodward C. Agi-

observed.2 Also the use of absorbance instead of fluores- lent Technical Note 1999;5980–1193E.

cence detection did not negatively influence the perfor- 4. Anders JC, Parten BF, Petrie GE, Marlowe RL, McEntire JE.

Using amino acid analysis to determine absorptivity constants:

mance characteristics of the method. A validation case study using bovine serum albumin. BioPharm

Int 2003;2:30–37.

References 5. Reason AJ. Validation of amino acid analysis methods. In Smith

1. Anders JC. Advances in amino acid analysis. BioPharm Int BJ (ed), Protein Sequencing Protocols, 2nd Edition: Methods in Molecular

2002;4:32–39. Biolog y, Vol. 211. Totowa, NJ: Humana Press, 2003:181–194.

2. Mengerink Y, Kutlán D, Tóth F, Csámpai A, Molnár-Perl I. 6. International Conference of Harmonisation (ICH) Harmon-

Advances in the evaluation of the stability and characteristics of ised Tripartite Guideline—Validation of Analytical Procedures:

the amino acid and amine derivatives obtained with the o-phthal- Methodology Q2B. November 1996.

Journal of Biomolecular Techniques, Volume 17, issue 2, April 2006 137

View publication stats

You might also like

- OCR Chemistry A: 4 Acids and Redox Exam-Style Mark SchemeDocument3 pagesOCR Chemistry A: 4 Acids and Redox Exam-Style Mark Schemenoreen doraniNo ratings yet

- 10 1002@sici1097-001019981278@4461@@aid-Jsfa1383 0 Co2-KDocument5 pages10 1002@sici1097-001019981278@4461@@aid-Jsfa1383 0 Co2-KMd. Sohanur RahmanNo ratings yet

- Valporate 3Document7 pagesValporate 3sisnaingaungNo ratings yet

- Heliyon: Amira F. El-Yazbi, Karin M. Guirguis, Mona M. Bedair, Tarek S. BelalDocument10 pagesHeliyon: Amira F. El-Yazbi, Karin M. Guirguis, Mona M. Bedair, Tarek S. BelalWentySafitriNo ratings yet

- Anal Methods 2011Document9 pagesAnal Methods 2011artemNo ratings yet

- Vydac Reference Handbook Proteins PeptidesDocument88 pagesVydac Reference Handbook Proteins PeptidesChintan VaywalaNo ratings yet

- Microchemical Journal: Geetika Wadhwa, Kowthavarapu Venkata Krishna, Sunil Kumar Dubey, Rajeev TaliyanDocument10 pagesMicrochemical Journal: Geetika Wadhwa, Kowthavarapu Venkata Krishna, Sunil Kumar Dubey, Rajeev TaliyanAriana NoeliaNo ratings yet

- Biogenic Amine-1Document7 pagesBiogenic Amine-1hariharan rNo ratings yet

- A Method For The Qualitative and Quantitative Determination of The Amino Acid Composition of Pharmaceutical Products - SGSDocument6 pagesA Method For The Qualitative and Quantitative Determination of The Amino Acid Composition of Pharmaceutical Products - SGSiirffannnNo ratings yet

- AN789 Fast Extraction of VMA 5-HIAA and HVA From Synthetic UrineDocument4 pagesAN789 Fast Extraction of VMA 5-HIAA and HVA From Synthetic UrineDarshana JuvekarNo ratings yet

- The Handbook of Analysis and Purification of Peptides and Proteins by Reversed-Phase HPLCDocument36 pagesThe Handbook of Analysis and Purification of Peptides and Proteins by Reversed-Phase HPLCdanny3001_1999No ratings yet

- Development and Validation of Liquid Chromatography Method For Simultaneous Estimation of Miconazole and Clobetasol andDocument13 pagesDevelopment and Validation of Liquid Chromatography Method For Simultaneous Estimation of Miconazole and Clobetasol andvinayNo ratings yet

- Alexandre Et Al-2016-Brazilian Journal of Pharmaceutical SciencesDocument8 pagesAlexandre Et Al-2016-Brazilian Journal of Pharmaceutical Sciencesvsvsuresh2099No ratings yet

- Articulo 1 SalchichasDocument5 pagesArticulo 1 SalchichasLALILA ORTIZ DIAZNo ratings yet

- A Novel and Rapid LC-MS:MS Assay For The Determination of Mycophenolate and Mycophenolic Acid in Human PlasmaDocument8 pagesA Novel and Rapid LC-MS:MS Assay For The Determination of Mycophenolate and Mycophenolic Acid in Human PlasmaFKUPN 2002No ratings yet

- Metodo Isocratico Por HPLC de Besifloxacino HCLDocument5 pagesMetodo Isocratico Por HPLC de Besifloxacino HCLJuan SNo ratings yet

- Chatzimichalakis 2004Document8 pagesChatzimichalakis 2004Pamela Agredo SaninNo ratings yet

- HPLC AcidosDocument5 pagesHPLC AcidosAlejandra Calderón RodríguezNo ratings yet

- Optimization of Phenol-Chloroform RNA ExtractionDocument10 pagesOptimization of Phenol-Chloroform RNA Extractionunggarapunja12No ratings yet

- High-Performance Liquid Chromatography Determination of Zn-Bacitracin in Animal Feed by Post-Column Derivatization and Fluorescence DetectionDocument8 pagesHigh-Performance Liquid Chromatography Determination of Zn-Bacitracin in Animal Feed by Post-Column Derivatization and Fluorescence DetectionngobaochanNo ratings yet

- Namratha FinalDocument56 pagesNamratha FinalAkhil KattamuriNo ratings yet

- Lab Report 2 HPLCDocument9 pagesLab Report 2 HPLCGissela BTNo ratings yet

- Nok-Sorbic-And-BenzoicDocument9 pagesNok-Sorbic-And-BenzoicKaewta DanchanaNo ratings yet

- Preparative HPLC Separation and Isolation of Bacitracin Components and Their Relationship To Microbiological ActivityDocument6 pagesPreparative HPLC Separation and Isolation of Bacitracin Components and Their Relationship To Microbiological ActivityngobaochanNo ratings yet

- Articulo 06Document7 pagesArticulo 06iria.gonzalez.micoNo ratings yet

- M2P11 Anal ChemDocument8 pagesM2P11 Anal ChempedroNo ratings yet

- Quetiapine FumarateDocument9 pagesQuetiapine FumarateVinaya SnehalathaNo ratings yet

- Validation of A Capillary Electrophoresis Method For The Analysis of Ibandronate Related ImpuritiesDocument4 pagesValidation of A Capillary Electrophoresis Method For The Analysis of Ibandronate Related ImpuritiescesarNo ratings yet

- Detection ListeriaDocument5 pagesDetection ListeriaDiego ValenteNo ratings yet

- Automated Analysis For Free and Short-Chain Acylcarnitine in Plasma With A Centrifugal AnalyzerDocument6 pagesAutomated Analysis For Free and Short-Chain Acylcarnitine in Plasma With A Centrifugal AnalyzerHarry YucraNo ratings yet

- Development and Validation of An Extraction Method Using Liquid Chromatography-Tandem Mass Spectrometry To Determine Patulin in Apple JuiceDocument7 pagesDevelopment and Validation of An Extraction Method Using Liquid Chromatography-Tandem Mass Spectrometry To Determine Patulin in Apple JuiceMai NhựtNo ratings yet

- Determination of Niacin in Food Materials by Liquid Chromatography Using Isotope Dilution Mass SpectrometryDocument6 pagesDetermination of Niacin in Food Materials by Liquid Chromatography Using Isotope Dilution Mass SpectrometryMonica chavez escamNo ratings yet

- Lopez Cervantes (Quitina)Document5 pagesLopez Cervantes (Quitina)Sandra MuñozNo ratings yet

- Research Paper - IJPBSDocument10 pagesResearch Paper - IJPBSFarahat AliNo ratings yet

- Vydac Protein and Peptide HandbookDocument92 pagesVydac Protein and Peptide HandbookyonkaniNo ratings yet

- Parameters Ascorbid Acid Sample Ascorbid Acid Standard: Column: Discovery C18, 15Document2 pagesParameters Ascorbid Acid Sample Ascorbid Acid Standard: Column: Discovery C18, 15anisaNo ratings yet

- LCGC NAmerica September2012ANDocument68 pagesLCGC NAmerica September2012ANSalman AbuzuhairaNo ratings yet

- Ocratoxina en CafeDocument4 pagesOcratoxina en Cafenabucodonossor24No ratings yet

- 1 s2.0 S2352340915003777 MainDocument6 pages1 s2.0 S2352340915003777 MainBouguetaia YacineNo ratings yet

- Bai Bao EC-1998Document5 pagesBai Bao EC-1998Bình GiangNo ratings yet

- HPLC Tech ReportDocument5 pagesHPLC Tech Reportclou3d.1No ratings yet

- 1 s2.0 S2095177912000834 Main PDFDocument4 pages1 s2.0 S2095177912000834 Main PDFelvinaNo ratings yet

- Theory of HPLC Reverse Phase ChromatographyDocument93 pagesTheory of HPLC Reverse Phase ChromatographyBenjaminHrustićNo ratings yet

- Application Pahs Salmon Beef 5994 0553en AgilentDocument12 pagesApplication Pahs Salmon Beef 5994 0553en AgilentYEMERSON MEYER BARTOLO CHARRINo ratings yet

- LC-MS/MS For The Determination of Four Water Soluble Vitamins: Method Development, Validation and Comparison To EC MethodDocument6 pagesLC-MS/MS For The Determination of Four Water Soluble Vitamins: Method Development, Validation and Comparison To EC MethoddewiNo ratings yet

- Chisvert 2002Document5 pagesChisvert 2002nambiarnedumchalNo ratings yet

- Automated In-Tube Solid Phase Microextraction Coupled With HPLC-ES-MS For The Determination of Catechins and Caffeine in TeaDocument7 pagesAutomated In-Tube Solid Phase Microextraction Coupled With HPLC-ES-MS For The Determination of Catechins and Caffeine in TeaSeema YadavNo ratings yet

- Experiment 7Document6 pagesExperiment 7Rodney SalazarNo ratings yet

- Metode Vit CDocument6 pagesMetode Vit CRuang BazaarNo ratings yet

- Development and Validation of A Precise Method ForDocument11 pagesDevelopment and Validation of A Precise Method Forantyka kawaNo ratings yet

- Exp 5 HPLCDocument2 pagesExp 5 HPLCAnonymous XbbVyRNo ratings yet

- AN122 IC Carbohydrates Alcohol Glycol Fermentation Broth - AN70494 - EDocument9 pagesAN122 IC Carbohydrates Alcohol Glycol Fermentation Broth - AN70494 - EfabiowalligatorNo ratings yet

- 1052 USP Amino Acid AnalysisDocument11 pages1052 USP Amino Acid Analysissuhas.lavhekarNo ratings yet

- Application Note: A Cleaning Validation Swab Recovery Study Using A UV/Persulfate AnalyzerDocument4 pagesApplication Note: A Cleaning Validation Swab Recovery Study Using A UV/Persulfate AnalyzerPrianurraufikachmadNo ratings yet

- Single Determination of A-Ketoglutaric Acid and Pyruvic Acid in Beer by HPLC With UV DetectionDocument6 pagesSingle Determination of A-Ketoglutaric Acid and Pyruvic Acid in Beer by HPLC With UV DetectionPatrícia MontenegroNo ratings yet

- Proteomics Lab ReportDocument4 pagesProteomics Lab Reportnursah.aslanNo ratings yet

- HPLCC KDocument6 pagesHPLCC Kfreskim.gashiNo ratings yet

- An 122 Ic Carbs Alcohol Glycol Fermentation Broth An70494 enDocument12 pagesAn 122 Ic Carbs Alcohol Glycol Fermentation Broth An70494 enSantiago Rivera AlbaNo ratings yet

- HPLC Method For The Analysis of Paracetamol Caffeine and Dipyron-1Document9 pagesHPLC Method For The Analysis of Paracetamol Caffeine and Dipyron-1Đoàn Lê Thuý HiềnNo ratings yet

- 2011 Schumann Alp-Reference-Method CCLMDocument8 pages2011 Schumann Alp-Reference-Method CCLMأم الجودNo ratings yet

- Coupled Bioluminescent Assays: Methods, Evaluations, and ApplicationsFrom EverandCoupled Bioluminescent Assays: Methods, Evaluations, and ApplicationsNo ratings yet

- List of Ingredients - OrganicDocument13 pagesList of Ingredients - OrganicedmondjoshiNo ratings yet

- Support Compatibility SheetDocument1 pageSupport Compatibility SheetJxyz QwNo ratings yet

- Lovely Professional UniversityDocument11 pagesLovely Professional UniversityAnkush KaithNo ratings yet

- Noncanonical Transnitrosylation Network Contributes To Synapse Loss in Alzheimer's DiseaseDocument18 pagesNoncanonical Transnitrosylation Network Contributes To Synapse Loss in Alzheimer's DiseasedmitworNo ratings yet

- Lecture - 7-8Document19 pagesLecture - 7-8Amierson TilendoNo ratings yet

- Redox ReactionDocument40 pagesRedox Reactionjakegrayzon13No ratings yet

- Progression Test 2024 Paper 2 Marking SchemeDocument12 pagesProgression Test 2024 Paper 2 Marking SchemeAkshat ArchitNo ratings yet

- Chemistry ProjectDocument16 pagesChemistry ProjectvalanrkNo ratings yet

- PPSC Junior Auditor Question Papers 1Document5 pagesPPSC Junior Auditor Question Papers 1preet103411No ratings yet

- AFBC Boiler O&MDocument134 pagesAFBC Boiler O&MVijay Raj87% (15)

- Gaseous Exchange in Humans ANSWERDocument23 pagesGaseous Exchange in Humans ANSWERKeertana SubramaniamNo ratings yet

- Periodic Table, Group 2 and The Halogens 1 QPDocument13 pagesPeriodic Table, Group 2 and The Halogens 1 QPmalakNo ratings yet

- Opposites Attract and Like Repel.: Inductive Effect Resonance EffectDocument12 pagesOpposites Attract and Like Repel.: Inductive Effect Resonance EffectAwais Arshad0% (1)

- Work Sheet-9 PDFDocument3 pagesWork Sheet-9 PDFKesanam Sp100% (1)

- Water Heater Catalogue 2019 PDFDocument32 pagesWater Heater Catalogue 2019 PDFHarshit SharmaNo ratings yet

- M.Sc. - Mathematics - 2022 9 28 15 40 8Document111 pagesM.Sc. - Mathematics - 2022 9 28 15 40 8Dontha Udaykumar2527No ratings yet

- Concrete Repair & Restoration (Sika)Document37 pagesConcrete Repair & Restoration (Sika)Dinn Ns100% (2)

- Lab Manual Exp 12-Blast FreezerDocument7 pagesLab Manual Exp 12-Blast FreezerChong EkNo ratings yet

- Syllabus Bs ChemistryDocument6 pagesSyllabus Bs ChemistryWaqas LuckyNo ratings yet

- Evaluation of Chromium Carbide Coatings On AISI 52100 Steel Obtained by Thermo-Reactive Diffusion TechniqueDocument6 pagesEvaluation of Chromium Carbide Coatings On AISI 52100 Steel Obtained by Thermo-Reactive Diffusion Techniquedaniel leonNo ratings yet

- 6compiled PDFDocument42 pages6compiled PDFMiracleNo ratings yet

- Influence of Ambient Air and Different Surface Treatments On The Bonding Performance of A CAD CAM Composite Block. Alghamdi Ali. 2018. J Adhes DentDocument8 pagesInfluence of Ambient Air and Different Surface Treatments On The Bonding Performance of A CAD CAM Composite Block. Alghamdi Ali. 2018. J Adhes DentValeria CrespoNo ratings yet

- Alcohal, Phenol MCQDocument6 pagesAlcohal, Phenol MCQAryan SharmaNo ratings yet

- Inorganic and Organic Chemistry Experiment No. 4: Preparation of ColloidsDocument4 pagesInorganic and Organic Chemistry Experiment No. 4: Preparation of ColloidsDanzel MalicNo ratings yet

- Cambridge IGCSE: Combined Science 0653/23Document16 pagesCambridge IGCSE: Combined Science 0653/23annwong85No ratings yet

- Physicochemical Changes During 4 Weeks Ripening of Camembert Cheeses Salted With Four Types of SaltsDocument12 pagesPhysicochemical Changes During 4 Weeks Ripening of Camembert Cheeses Salted With Four Types of SaltsGina FelyaNo ratings yet

- Daftar Obat Zenith: Gol - AntibiotikaDocument3 pagesDaftar Obat Zenith: Gol - AntibiotikaNetriNo ratings yet

- Design Steam Consumption DataDocument5 pagesDesign Steam Consumption DataKishore KumarNo ratings yet

- Dow™ Ldpe 352E: Low Density Polyethylene ResinDocument1 pageDow™ Ldpe 352E: Low Density Polyethylene Resinvantuan17792No ratings yet