Professional Documents

Culture Documents

SACIC-S-4098 Rev - Fit Layer Laminate of RTRGRE, GRV, and GRP Piping

SACIC-S-4098 Rev - Fit Layer Laminate of RTRGRE, GRV, and GRP Piping

Uploaded by

Shohrab JiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SACIC-S-4098 Rev - Fit Layer Laminate of RTRGRE, GRV, and GRP Piping

SACIC-S-4098 Rev - Fit Layer Laminate of RTRGRE, GRV, and GRP Piping

Uploaded by

Shohrab JiCopyright:

Available Formats

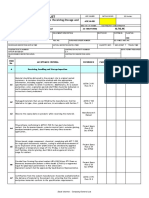

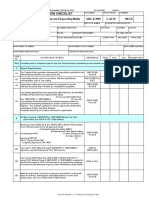

#

Standards Cutoff - May 31 2016 Rev 04

SACIC NUMBER DATE APPROVED QR NUMBER

SAC INSPECTION CHECKLIST

Fit Layer laminate of RTR/GRE, GRV, and GRP piping SACIC-S-4098 PLUMB

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

25-00053,0004, CONSORTIUM of BRANCH OF SINO

KING SALMAN INTERNATIONAL COMPLEX FOR MARITIME INDUSTRIES

0005, 0006, 0007/ HYDRO CORPORATION COMPANY

AND SERVICES (MYP)

6600042823 (IK) LTD. and SEPCO ARABIA COMPANY

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAC TIP NUMBER SAC ACTIVITY NUMBER WORK PERMIT REQUIRED?

SACTIP-S-070-03 2/Jan/00

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

W H

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Check whether the sections to be joined together are dry, clean and at the Manufacturer

A1

right temperature. recommendation

Fill any existing gap between two pipe segments using putty, made of resin Manufacturer

A2

and CAB-O-SIL mixture. recommendation

Once the putty is cured, grind it and laminate the required number of

Manufacturer

A3 continuous fit layers around the joint as per recipe given by the pipe

recommendation

manufacturer.

Prepare the adhesive/resin mixture according to given instructions. The two

Manufacturer

A4 components must be stirred (e.g. 1 minute) until there is

recommendation

a uniform color.

Start the lamination of the fitted sections within two hours after sanding or

Manufacturer

A5 grinding; re-sanding of lamination area shall be required

recommendation

if the waiting period exceeds two hours.

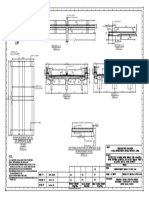

The fit laminate shall be applied over the minimum fit

length (LF). The fit laminate is reinforced with several layers of woven

Manufacturer

A6 roving,using a minimum overlap of 50% and having a woven roving width

recommendation

depending on the ID. Folding, cutting or deforming of the woven roving

shall be minimized in this stage.

Manufacturer

A7 The maximum fit length (LF) shall not exceed the laminate length (LV).

recommendation

Close the ends of the pipe during curing to avoid cooling by airflow through Manufacturer

A8

the pipe. recommendation

After gelling, the fit laminate is cured at a curing temperature of 125°C for

45 minutes (30minutes heating up and 15 minutes curing) Heating up to the Manufacturer

A10

curing temperature shall proceed gradually. The fit laminate shall be cured recommendation

in a controlled way with the aid of heating blankets.

Saudi Aramco: Company General Use

# Page 1 of 2

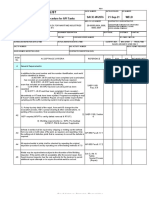

#

Standards Cutoff - May 31 2016 Rev 04

SACIC NUMBER DATE APPROVED QR NUMBER

SAC INSPECTION CHECKLIST

Fit Layer laminate of RTR/GRE, GRV, and GRP piping SACIC-S-4098 PLUMB

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

25-00053,0004, CONSORTIUM of BRANCH OF SINO

KING SALMAN INTERNATIONAL COMPLEX FOR MARITIME INDUSTRIES

0005, 0006, 0007/ HYDRO CORPORATION COMPANY

AND SERVICES (MYP)

6600042823 (IK) LTD. and SEPCO ARABIA COMPANY

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAC TIP NUMBER SAC ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

W H

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

The curing temperature is the average temperature of the laminate surface

during the curing. The curing time starts after the laminate has reached the

curing temperature. The required heating-up time of the laminate joint

Manufacturer

A11 depends on the diameter (ID), pipe wall thickness (TW), heat source and

recommendation

the local circumstances. The curing temperature shall be monitored and

controlled over the complete circumference of the laminate during the

curing.

During the gelling and curing, the pipe parts shall not be moved and/or

dislocated until the fit laminate has cured sufficiently. Use stable Manufacturer

A12

supporting! After curing and cooling the adjusted pipe part may eventually recommendation

be moved carefully.

REMARKS:

REFERENCE DOCUMENTS:

1-SAES-S-070 -- Installation of Utility Piping Systems, 1 March 2017

2-SAES-L-610 -- Nonmetallic Piping -- 22 July, 2014

3- 01-SAMSS-029 -- RTR Sewer Pipes & Fittings for Gravity Flow -- 4 July 2014

4- 01-SAMSS-034 -- RTR Pressure Pipes & Fittings -- 19 March 2013

5-RTR Pipe Manufacturer recommendation

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection:BASSAM T&I

QC Record Reviewed Work Verified

Witnessed

Name, Initials and Date: Name, Initials and Date:

MR. FASHEEH

QC Inspector PID Representative

T&I

Performed Inspection Work / Rework May Proceed QC Record Reviewed Work Verified

Witnessed

Name, Initials and Date: Name, Initials and Date:

D. ANSARI MR. MOIN HUDED

QC Supervisor Proponent and Others

Quality Record Approved: SYED ARSHAD T&I

QC Record Reviewed Work Verified

Name, Organization, Witnessed

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

# Page 2 of 2

You might also like

- Inspection and Test Plan For Fire Proofing Sealer ApplicationDocument6 pagesInspection and Test Plan For Fire Proofing Sealer Applicationmoytabura96100% (7)

- Saic H 2082Document8 pagesSaic H 2082jerin100% (1)

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Lanko Grout 280 Eco BrochureDocument2 pagesLanko Grout 280 Eco BrochureMrgsrzNo ratings yet

- Cube Failure ReportDocument15 pagesCube Failure ReportVenu PrasadNo ratings yet

- Vessel Cleaning ProcedureDocument6 pagesVessel Cleaning ProcedureUmair Awan80% (5)

- SACIC-Q-1022 Rev.01 Precast Concrete Sampling, Testing & Placement InspectionDocument4 pagesSACIC-Q-1022 Rev.01 Precast Concrete Sampling, Testing & Placement InspectionMuhammad AbrarNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19Document3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19harisNo ratings yet

- SACIC-T-5709 OSP Ductbank-Duct Bank Fabrication, Installation and Mandrel TestDocument3 pagesSACIC-T-5709 OSP Ductbank-Duct Bank Fabrication, Installation and Mandrel TestArshad ImamNo ratings yet

- Afic M 001Document2 pagesAfic M 001Basir AhmadNo ratings yet

- NPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709Document3 pagesNPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709afareenkhanNo ratings yet

- Saic A 1016Document2 pagesSaic A 1016Nickath BanuNo ratings yet

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- Saic-H-2029Document12 pagesSaic-H-2029mominNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistaamirapi100% (2)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saic-H-2027Document3 pagesSaic-H-2027momin0% (1)

- Saic A 1016Document2 pagesSaic A 1016Ansar Ali VemmullyNo ratings yet

- Saic W 2035Document2 pagesSaic W 2035ABDUL RAHMAN ALI MIRNo ratings yet

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistSardar Muhamad RashidNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- SACIC-CV-0003 Rev.04 Electronic Friction Cone and Piezocone Penetration TestDocument3 pagesSACIC-CV-0003 Rev.04 Electronic Friction Cone and Piezocone Penetration TestEr Nizamuddin AliNo ratings yet

- Saic A 1016Document2 pagesSaic A 1016karthi51289No ratings yet

- SAIC-W-2031 In-Process Welding Inspection of Hot TapDocument2 pagesSAIC-W-2031 In-Process Welding Inspection of Hot TapAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Document3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNo ratings yet

- Saic H 2014Document2 pagesSaic H 2014Ansar Ali VemmullyNo ratings yet

- Saic D 2023Document2 pagesSaic D 2023razzak.me.enggNo ratings yet

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- Ayc Ic & Itp SealerDocument6 pagesAyc Ic & Itp Sealermoytabura96No ratings yet

- SAIC-D-2005 Rev 8Document6 pagesSAIC-D-2005 Rev 8Syed ImranNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistMainuddin AliNo ratings yet

- SAIC-H-2032 Rev 7Document4 pagesSAIC-H-2032 Rev 7Satheesh Rama SamyNo ratings yet

- SAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewDocument8 pagesSAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewAbdul HannanNo ratings yet

- Saic H 2002Document3 pagesSaic H 2002NASIR SYEDNo ratings yet

- Sac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API TanksDocument14 pagesSac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API Tankshusnain aliNo ratings yet

- Saic N 2026Document3 pagesSaic N 2026jerinNo ratings yet

- SAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewDocument7 pagesSAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewAbdul HannanNo ratings yet

- Saic P 3314Document2 pagesSaic P 3314Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistAnantha PadmanabhanNo ratings yet

- SAIC-W-C013-Inprocess Welding Inspection - Offshore StructuresDocument4 pagesSAIC-W-C013-Inprocess Welding Inspection - Offshore StructuresVinu MadhavanNo ratings yet

- SAIC-H-1002 Rev 7 (Final)Document2 pagesSAIC-H-1002 Rev 7 (Final)ryann mananquilNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic-M-1012 Rev 7 (Final)Document3 pagesSaic-M-1012 Rev 7 (Final)Satheesh Rama SamyNo ratings yet

- CLT 5Document1 pageCLT 5MAXWELL ERIPONNo ratings yet

- Saic N 2029Document6 pagesSaic N 2029aamirapi100% (1)

- Saic M 1034Document3 pagesSaic M 1034Hussain Nasser Al- NowiesserNo ratings yet

- SACIC-CV-0005 Rev.04 Packer TestsDocument2 pagesSACIC-CV-0005 Rev.04 Packer TestsEr Nizamuddin AliNo ratings yet

- Saic H 1002Document4 pagesSaic H 1002NASIR SYEDNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saic B 1002Document2 pagesSaic B 1002Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document2 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- Saic H 1003Document4 pagesSaic H 1003NASIR SYEDNo ratings yet

- Saic W 2006Document1 pageSaic W 2006Abdelaziz MohamedNo ratings yet

- Saic e 2005Document13 pagesSaic e 2005jerinNo ratings yet

- Saic W 2036Document2 pagesSaic W 2036Basheer VadakkethilNo ratings yet

- Saic L 2115Document4 pagesSaic L 2115khuram shahzadNo ratings yet

- 6 SACIC-W-2012 Rev 2Document5 pages6 SACIC-W-2012 Rev 2husnain aliNo ratings yet

- Prevention of Corrotion in RCCDocument1 pagePrevention of Corrotion in RCCRakib HossainNo ratings yet

- ES-1652 Shell and Tube Heat Exchangers r0Document14 pagesES-1652 Shell and Tube Heat Exchangers r0Raul García (INNTELLIA)No ratings yet

- Handover Notes: Sl. NoDocument4 pagesHandover Notes: Sl. NoAnonymous 3akQhQFJSLNo ratings yet

- Paper Astm StandardsDocument10 pagesPaper Astm StandardsjklelvisNo ratings yet

- Chemical Resistance Guide For Elastomers and ThermoplasticsDocument35 pagesChemical Resistance Guide For Elastomers and ThermoplasticsTomás MercadoNo ratings yet

- تصنيع ومعالجة المواد المركبةDocument32 pagesتصنيع ومعالجة المواد المركبةadel1hammiaNo ratings yet

- Stainless Steel Pipes - Allowable Pressure RatingDocument7 pagesStainless Steel Pipes - Allowable Pressure RatingBahim BahimanNo ratings yet

- Complete Report Progress - PDFDocument50 pagesComplete Report Progress - PDFNik Izzati Nik RazaliNo ratings yet

- Checklist For Civil Works: Engr. Jerome V. KatigbakDocument35 pagesChecklist For Civil Works: Engr. Jerome V. KatigbakKian InductivoNo ratings yet

- Fundamentals of ExplosivesDocument41 pagesFundamentals of ExplosivesLinet MwikaliNo ratings yet

- Preparation of Concrete Using Gold Mine Waste - Civil Engineering Project TopicsDocument7 pagesPreparation of Concrete Using Gold Mine Waste - Civil Engineering Project Topicsmynameisguna100% (1)

- How To Calculate Cutting Length in Bar Bending Schedule - CivilologyDocument5 pagesHow To Calculate Cutting Length in Bar Bending Schedule - CivilologyNaveen BansalNo ratings yet

- Flyer The Adixen 2000 Series Vacuum GaugesDocument2 pagesFlyer The Adixen 2000 Series Vacuum GaugespradungNo ratings yet

- CH 18 Solutions ManualDocument67 pagesCH 18 Solutions ManualAhmad FauzanNo ratings yet

- Dupont Material Compatibility General - Chemical - ResistanceDocument39 pagesDupont Material Compatibility General - Chemical - ResistanceCecep AtmegaNo ratings yet

- Section Q-Q Section Z-Z: of Approach Slab Reinforcement Detail (PLAN)Document1 pageSection Q-Q Section Z-Z: of Approach Slab Reinforcement Detail (PLAN)praloy dasNo ratings yet

- TTT Curves 1Document101 pagesTTT Curves 1ibrahimNo ratings yet

- Saic A 2010Document13 pagesSaic A 2010jerinNo ratings yet

- Mass Production of High Quality Graphene An Analysis of Worldwide PatentsDocument12 pagesMass Production of High Quality Graphene An Analysis of Worldwide PatentsSrramNo ratings yet

- ASTM A 395 - A 395M - 99 DI CastingsDocument8 pagesASTM A 395 - A 395M - 99 DI CastingsSaravanan VaradarajanNo ratings yet

- Appendix A - DATASHEET - DPDocument11 pagesAppendix A - DATASHEET - DPChakravarthy Bharath0% (1)

- Vulcanization Rubber With Diepoxy Compound: - Chlorobutadiene-ButadieneDocument7 pagesVulcanization Rubber With Diepoxy Compound: - Chlorobutadiene-ButadieneDaikinllcNo ratings yet

- B.inggris Tugas LKS Ayu Khofizah 2320142Document7 pagesB.inggris Tugas LKS Ayu Khofizah 2320142Adinda AmaliaNo ratings yet

- Oxygen GeneratorDocument100 pagesOxygen GeneratorCliver Chumacero100% (4)

- Reverse Osmosis PlantsDocument3 pagesReverse Osmosis Plantsvishal kashyapNo ratings yet

- Dhaka Epz Factory List & List of Inspected Factories by EIMS For AllianceDocument12 pagesDhaka Epz Factory List & List of Inspected Factories by EIMS For Alliancearman chowdhury100% (4)

- Mix Design As Per Is 10262Document5 pagesMix Design As Per Is 10262Sonia MohapatraNo ratings yet