Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

14 viewsFsis09cxswyl004c006sa (FR LSH)

Fsis09cxswyl004c006sa (FR LSH)

Uploaded by

pkThis document provides the technical specifications for a 4 core, 6 sqmm LT XLPE cable manufactured by Polycab India Ltd. It includes details on the conductor material and dimensions, insulation material and thickness, inner and outer sheath materials and thicknesses, armouring, electrical parameters, temperature ratings, printing and embossing. The cable meets standards for fire survival cables including IEC 60331 for the circuit integrity test and FR-LSH properties test standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Shoulder: Theory & Practice: Jeremy LewisDocument3 pagesThe Shoulder: Theory & Practice: Jeremy Lewisparakram0% (1)

- Polycab 16mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 16mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- LVIS09CXSFYL004C010SA001SDocument1 pageLVIS09CXSFYL004C010SA001Ssuvir VigneshNo ratings yet

- Polycab 10mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 10mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- 2c x1.5 FAS CableDocument1 page2c x1.5 FAS CableSanjay KumarNo ratings yet

- Cable GTPDocument1 pageCable GTPtukaram.pawarNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.JayagurunathanNo ratings yet

- Lvis09axsfy23 5c300sa002sDocument1 pageLvis09axsfy23 5c300sa002sVishal SharmaNo ratings yet

- 2 5px3cywystrfrlsDocument2 pages2 5px3cywystrfrlsKrish0% (1)

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.rajesh1200No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.rajesh1200100% (1)

- Polycab 300mm 3 Core Aluminium Armoured Cable Specification SheetDocument2 pagesPolycab 300mm 3 Core Aluminium Armoured Cable Specification SheetZIRWA ENTERPRISESNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.rajesh1200No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.rajesh1200No ratings yet

- 400PX3 5caywyxlpeDocument2 pages400PX3 5caywyxlpeAnonymous SDeSP1No ratings yet

- Sr. No. 3B Datasheet 1.5PX6CYWY 100Document2 pagesSr. No. 3B Datasheet 1.5PX6CYWY 100hemantmech099200No ratings yet

- Sr. No. 3A Datasheet 4PX3CYWY 100Document2 pagesSr. No. 3A Datasheet 4PX3CYWY 100hemantmech099200No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSFY2012C2.5SA004S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSFY2012C2.5SA004S Date: Rev No.Anonymous SDeSP1No ratings yet

- Data Sheet For LT XLPE Cable: S.No Particulars 3.5 X 50Document2 pagesData Sheet For LT XLPE Cable: S.No Particulars 3.5 X 50AteebNo ratings yet

- 2 5px12cywyfrlsstrDocument2 pages2 5px12cywyfrlsstramzad aliNo ratings yet

- 10X4 A2xfy (FRLS) Alum ArmdDocument2 pages10X4 A2xfy (FRLS) Alum ArmdParth DhobiNo ratings yet

- 10X4 A2xfy Alum - ArmdDocument2 pages10X4 A2xfy Alum - ArmdParth DhobiNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.maharia_22No ratings yet

- LT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02Document2 pagesLT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02y8jkfz98m9No ratings yet

- FSBS07CXSWLS002C2 5saDocument1 pageFSBS07CXSWLS002C2 5sapradeepyellurNo ratings yet

- 400PX3CHT33UEFLATDocument2 pages400PX3CHT33UEFLATjayesh95395No ratings yet

- Lvbs09cxswy2004c1 5sa002sDocument1 pageLvbs09cxswy2004c1 5sa002sKrishNo ratings yet

- Cable GTPDocument1 pageCable GTPAnwar HussainNo ratings yet

- GTP - 12PX0.5,6PX0.75,2PX0.5,10PX0.5Document3 pagesGTP - 12PX0.5,6PX0.75,2PX0.5,10PX0.5santhoshNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVBS09CXSWY2003C004SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVBS09CXSWY2003C004SA002S Date: Rev No.bharathNo ratings yet

- 3SFL 2core Power Cable SpecsDocument1 page3SFL 2core Power Cable Specssandeep bagulNo ratings yet

- 1.5sqmm X 3C Arm DatasheetDocument2 pages1.5sqmm X 3C Arm DatasheetAshwin SupeNo ratings yet

- Instrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- Polycab Multicore CablesDocument2 pagesPolycab Multicore CablesAkhil SasidharanNo ratings yet

- GEN GP 208 5143 SRNo A1 141010 PDFDocument4 pagesGEN GP 208 5143 SRNo A1 141010 PDFdamlanNo ratings yet

- Electrical Cable - GTPDocument3 pagesElectrical Cable - GTPNawfel ArafathNo ratings yet

- 0 75px1tscnarmdDocument2 pages0 75px1tscnarmdnmpkumarNo ratings yet

- Document ID: TE/QMS/F/02 Rev. No.: 00 - Issued Date: 02/04/2018Document1 pageDocument ID: TE/QMS/F/02 Rev. No.: 00 - Issued Date: 02/04/2018dhanishlNo ratings yet

- 33 KV 3 Core Aluminium XLPE CableDocument3 pages33 KV 3 Core Aluminium XLPE CableSai KumarNo ratings yet

- Technical Specifications of The 2 Core, 1.5 Sq. MM, Un-Armoured Cable: Sr. No Description DataDocument4 pagesTechnical Specifications of The 2 Core, 1.5 Sq. MM, Un-Armoured Cable: Sr. No Description DataNikhil KarkeraNo ratings yet

- Instrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- FRLS 1.5 X 2 CoreDocument1 pageFRLS 1.5 X 2 CorerhladiNo ratings yet

- 2 5PX3CBLKFRLS100 PDFDocument1 page2 5PX3CBLKFRLS100 PDFSushil Kumar ShuklaNo ratings yet

- GTP - 1.1kv 1c Copper Xlpe Armd CableDocument1 pageGTP - 1.1kv 1c Copper Xlpe Armd CableShivam DwivediNo ratings yet

- 1.93.3KV 3Cx 35 SQMM Cable GTPDocument1 page1.93.3KV 3Cx 35 SQMM Cable GTPDarshit VyasNo ratings yet

- 1PX12PSCNARMDDocument1 page1PX12PSCNARMDJainam ShahNo ratings yet

- Hmnjopl PDFDocument1 pageHmnjopl PDFAjay PrajapatiNo ratings yet

- SR - No. Description Unit Technical Datasheet of Flexible Cables LDIS09CYUAY1003C006S 3CX6 Sq. MMDocument1 pageSR - No. Description Unit Technical Datasheet of Flexible Cables LDIS09CYUAY1003C006S 3CX6 Sq. MMSushil Kumar ShuklaNo ratings yet

- 33 KV Single Core Copper XLPE CableDocument3 pages33 KV Single Core Copper XLPE CableSai KumarNo ratings yet

- Solar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Document1 pageSolar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Koushik KarmakarNo ratings yet

- 6 RR FR LSHDocument1 page6 RR FR LSHGaurav MittalNo ratings yet

- Technical Data Sheets & Cross Sectional Details of 33kV XLPE CablesDocument4 pagesTechnical Data Sheets & Cross Sectional Details of 33kV XLPE CablesRamaKrishna ANo ratings yet

- GTP HavellsDocument24 pagesGTP HavellsPradeep GoelNo ratings yet

- DS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstDocument3 pagesDS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstAppzNo ratings yet

- 1C X 2.50 SQMM PTFE Single Core CableDocument1 page1C X 2.50 SQMM PTFE Single Core CablerijoNo ratings yet

- GTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding CableDocument1 pageGTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding Cableshivam dwivedi100% (1)

- SR - No. Description Unit Technical Datasheet of Flexible Cables LDIS09CYUAY1004C006S 4CX6 Sq. MMDocument1 pageSR - No. Description Unit Technical Datasheet of Flexible Cables LDIS09CYUAY1004C006S 4CX6 Sq. MMkiranNo ratings yet

- Polycab 2C X 4 SQMMDocument1 pagePolycab 2C X 4 SQMMHiteshChauhanNo ratings yet

- Site Order BookDocument3 pagesSite Order BookpkNo ratings yet

- Tds-Mot Fsd-Airtech Engg-Rajkot AirportDocument1 pageTds-Mot Fsd-Airtech Engg-Rajkot AirportpkNo ratings yet

- Tds-Man Vcd-Airtech Engg-Rajkot AirportDocument1 pageTds-Man Vcd-Airtech Engg-Rajkot AirportpkNo ratings yet

- TDS-SQ Diff-Airtech Engg-Rajkot AirportDocument1 pageTDS-SQ Diff-Airtech Engg-Rajkot AirportpkNo ratings yet

- Cu StripDocument4 pagesCu StrippkNo ratings yet

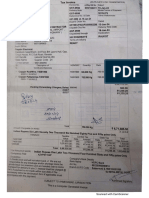

- SalesBill GT 1020Document1 pageSalesBill GT 1020pkNo ratings yet

- SalesBill GT 93Document1 pageSalesBill GT 93pkNo ratings yet

- 3351 e Way BillDocument2 pages3351 e Way BillpkNo ratings yet

- SalesBill GT 930Document4 pagesSalesBill GT 930pkNo ratings yet

- SalesBill GT 1002Document1 pageSalesBill GT 1002pkNo ratings yet

- SalesBill GT 983Document1 pageSalesBill GT 983pkNo ratings yet

- 2ADocument2 pages2ApkNo ratings yet

- Check ListDocument2 pagesCheck ListpkNo ratings yet

- SalesBill GT 930Document1 pageSalesBill GT 930pkNo ratings yet

- CamScanner 11-03-2023 10.37.11 - 4Document1 pageCamScanner 11-03-2023 10.37.11 - 4pkNo ratings yet

- SalesBill GT 957Document1 pageSalesBill GT 957pkNo ratings yet

- 3351 e Way BillDocument2 pages3351 e Way BillpkNo ratings yet

- 3ADocument2 pages3ApkNo ratings yet

- Ca1 JPGDocument1 pageCa1 JPGpkNo ratings yet

- 5AADocument2 pages5AApkNo ratings yet

- DPR FormatDocument1 pageDPR FormatpkNo ratings yet

- List of SignagesDocument5 pagesList of SignagespkNo ratings yet

- PCB Layout Thermal Design Guide An-EDocument18 pagesPCB Layout Thermal Design Guide An-EpkNo ratings yet

- Advanced Steel DesignDocument2 pagesAdvanced Steel DesignVaneeta SainiNo ratings yet

- Internships: Internships Often Bring To Mind TV and Movie Characters Who Fetch CoffeeDocument52 pagesInternships: Internships Often Bring To Mind TV and Movie Characters Who Fetch CoffeeShiva ShivaNo ratings yet

- BOARD EXAM QUESTIONS ON ArraysDocument6 pagesBOARD EXAM QUESTIONS ON ArraysAD SOLUTIONSNo ratings yet

- ACTIVITY Got Energy Food WebsDocument6 pagesACTIVITY Got Energy Food WebsShivangi SharmaNo ratings yet

- 2foundation Moments Hydraulics and CM Self Study QuestionsDocument40 pages2foundation Moments Hydraulics and CM Self Study QuestionsAngel TeyNo ratings yet

- Understanding The Principles of Ethics in Health CDocument8 pagesUnderstanding The Principles of Ethics in Health CAfina Zahrah MNo ratings yet

- Policy Brief 16 - Internal Migration in China-Integrating Migration With Urbanization Policies and Hukou Reform-Nov 21Document9 pagesPolicy Brief 16 - Internal Migration in China-Integrating Migration With Urbanization Policies and Hukou Reform-Nov 21oreoolepNo ratings yet

- Shiva Alloys Mandi Gobindgarh - Met. Lab Eqpts.Document3 pagesShiva Alloys Mandi Gobindgarh - Met. Lab Eqpts.Mandeep SodhiNo ratings yet

- Uc Boyutlu Baglanma Stilleri Olcegi ToadDocument21 pagesUc Boyutlu Baglanma Stilleri Olcegi Toad4sq8vnbsv2No ratings yet

- Electrical Engnieering 2K16.xls 7th SemesterDocument5 pagesElectrical Engnieering 2K16.xls 7th SemesterSyed Waqar Ul HaqNo ratings yet

- Clincher DiesDocument4 pagesClincher DiestibismtxNo ratings yet

- Cambridge International AS & A Level: Information Technology 9626/04 February/March 2022Document10 pagesCambridge International AS & A Level: Information Technology 9626/04 February/March 2022jesuNo ratings yet

- Solutions Acids and Bases Test Review AnswersDocument2 pagesSolutions Acids and Bases Test Review Answersapi-305204604No ratings yet

- Year 5 Math PDFDocument24 pagesYear 5 Math PDFRashida Nagarseth100% (1)

- Home Tuitions 870Document68 pagesHome Tuitions 870maxisinc.inNo ratings yet

- Determining Reaction Order Initial Rates and The Method of IsolationDocument4 pagesDetermining Reaction Order Initial Rates and The Method of IsolationDeepak PandeyNo ratings yet

- CG-107-F Bulk EarthworksDocument1 pageCG-107-F Bulk EarthworksJose AmorimNo ratings yet

- A Territorial Approach To The SDGs in Viken, NorwayDocument83 pagesA Territorial Approach To The SDGs in Viken, NorwayAna NichitusNo ratings yet

- LAB - REPORT - Che233Document8 pagesLAB - REPORT - Che2332022627312No ratings yet

- Corazón de Agua, Parque Ecológico en SacatepéquezDocument2 pagesCorazón de Agua, Parque Ecológico en SacatepéquezAna PaNjojNo ratings yet

- Schaffer HouseDocument39 pagesSchaffer HouseFrancisca CerdaNo ratings yet

- ppt3 Descriptive2 (23-24)Document74 pagesppt3 Descriptive2 (23-24)alexzandrei.rara937No ratings yet

- Cape Mock Exam 2023Document2 pagesCape Mock Exam 2023Tahj ThomasNo ratings yet

- Usa Architecture ProjectDocument4 pagesUsa Architecture ProjectnullifyNo ratings yet

- (Uttar Pradesh Public Service Commission, Prayagraj) : Print Application FormDocument5 pages(Uttar Pradesh Public Service Commission, Prayagraj) : Print Application FormmanishNo ratings yet

- Physics:: JEE-ADVANCED-2012-P1-Model IDocument1 pagePhysics:: JEE-ADVANCED-2012-P1-Model IJohn CarterNo ratings yet

- Isaac Thomas - Introduction - Advocate (INFJ) Personality - 16personalities - B4Document6 pagesIsaac Thomas - Introduction - Advocate (INFJ) Personality - 16personalities - B4isaacNo ratings yet

- Palomaria - Module 3Document9 pagesPalomaria - Module 3ALMIRA LOUISE PALOMARIANo ratings yet

- Useful Expressions To Express Your OpinionDocument2 pagesUseful Expressions To Express Your OpinionbttNo ratings yet

Fsis09cxswyl004c006sa (FR LSH)

Fsis09cxswyl004c006sa (FR LSH)

Uploaded by

pk0 ratings0% found this document useful (0 votes)

14 views1 pageThis document provides the technical specifications for a 4 core, 6 sqmm LT XLPE cable manufactured by Polycab India Ltd. It includes details on the conductor material and dimensions, insulation material and thickness, inner and outer sheath materials and thicknesses, armouring, electrical parameters, temperature ratings, printing and embossing. The cable meets standards for fire survival cables including IEC 60331 for the circuit integrity test and FR-LSH properties test standards.

Original Description:

Original Title

FSIS09CXSWYL004C006SA(FR-LSH) (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides the technical specifications for a 4 core, 6 sqmm LT XLPE cable manufactured by Polycab India Ltd. It includes details on the conductor material and dimensions, insulation material and thickness, inner and outer sheath materials and thicknesses, armouring, electrical parameters, temperature ratings, printing and embossing. The cable meets standards for fire survival cables including IEC 60331 for the circuit integrity test and FR-LSH properties test standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

14 views1 pageFsis09cxswyl004c006sa (FR LSH)

Fsis09cxswyl004c006sa (FR LSH)

Uploaded by

pkThis document provides the technical specifications for a 4 core, 6 sqmm LT XLPE cable manufactured by Polycab India Ltd. It includes details on the conductor material and dimensions, insulation material and thickness, inner and outer sheath materials and thicknesses, armouring, electrical parameters, temperature ratings, printing and embossing. The cable meets standards for fire survival cables including IEC 60331 for the circuit integrity test and FR-LSH properties test standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

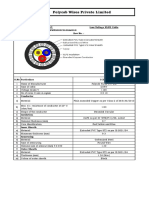

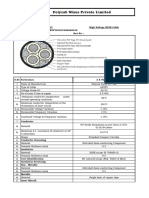

Document ID: TE/QMS/F/02

Rev. No. : 01 | Issued Date : 10/06/2021

Technical Data of LT XLPE Cables

S.No Particulars 4 Core X 6 Sq.mm

1 Name of Manufacturer Polycab India Ltd.

2 Type of cable Fire Survival

3 Voltage Grade (V) 1100

4 No of cores X size in sqmm 4 Core X 6 Sq.mm

5 Conductor

a) Material Plain annealed Copper as per Class 2 of IS:8130/2013

b) Max. d.c. resistance of conductor at 20° C (ohm/km) 3.08

c) Shape of the conductor Stranded Circular

d) Heat barrier tape over conductor Two Layer of Glass mica Tape

e) Fire Performance Circuit integrity test 950 Deg C for 3 Hours

6 Insulation

a) Material XLPE as per IS 7098(Pt-1)/88, Latest

b) Nominal thickness (mm) 0.7

c) Core identification Red,Yellow, Blue & Black

7 Inner Sheath

a) Material Extruded FR-LSH PVC Type ST2 as per IS:5831/84

b) Minimum thickness (mm) 0.3

c) Colour of Inner sheath. Black

8 Armouring

a) Material Galvanised Steel

b) Type of armouring Round Wire

c) Nominal size of armour (mm) 1.40

d) Tolerance on armour dimensions +/- 0.040

9 Outer Sheath

a) Material Extruded FR-LSH PVC Type ST2 as per IS:5831/84

b) Thickness (mm) 1.24 (Min.)

c) Colour of outer sheath. Black

10 Electrical Parameters

a) Max. a.c. resistance of conductor at 90° C (ohm/km) 3.93

b) Calculated Cable reactance (ohm/km) 0.0888

c) Impedance of cable (ohm/km) 3.93

d) Approx. Cable Capacitance (mfd/km) 0.29

Maximum conductor temperature under normal operating

11 90°C

conditions

Maximum conductor temperature at the termination of short

12 250°C

circuit

13 Short Circuit rating of conductor for the duration of 1 sec (kA) 0.86

Continuous Current carrying capacities for standard

14

conditions :-

(a) In Ground at 30°C (A) 56

(b) In Air at 40°C (A) 52

IS 8130/2013,Generally as per IS 7098 Part I/88, IS

15 Applicable Standard 5831/84, IS 3975/1999 etc. with latest up to date

amendments

16 Approx. overall diameter of the cable in (mm) 19.5 +/- 2.0

17 Minimum bending radius 12 times Overall diameter

18 Max. Tensile strength

(i) for Cables pulled with stocking (Newtons) 9 x D², D is the cable OD in mm

ii) for Cables pulled with pulling eyes (N) 1200

19 Embossing POLYCAB ELECTRIC 1100 VOLTS GRADE XLPE FR-LSH

YEAR POLYCAB ELECTRIC 1100 VOLTS GRADE XLPE FR-

20 Printing LSH CABLE SIZE FIRE SURVIVAL WITH SEQUENTIAL

MARKING at every one meter interval.

21 Standard Drum Length (Mtr.) 1000 ± 5%

Maximum 5% of order quantity and Individual Non-

22 Non- Standard Drum Length (Mtr.)

standard drum length minimum 200m.

23 FR-LSH PROPERTIES

a) Oxygen Index Min. 29% as per ASTM D- 2863

b) Temperature Index Min. 250 Deg.C as per ASTM D- 2863

c) Smoke Density Rating Max. 60% as per ASTM D- 2843

d) Acid Gas Generation Max. 20% as per IEC- 754- 1

e) Flammability Test As per IEC:332-I

Note 1 :-The values given above are subject to tolerances as per the

relevant standards.

Note 2 :-Incase of any Typographical error /Discrepancy, relevant

standards shall be prevailed.

Note 3 :-ISI Marking not applicable.

You might also like

- The Shoulder: Theory & Practice: Jeremy LewisDocument3 pagesThe Shoulder: Theory & Practice: Jeremy Lewisparakram0% (1)

- Polycab 16mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 16mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- LVIS09CXSFYL004C010SA001SDocument1 pageLVIS09CXSFYL004C010SA001Ssuvir VigneshNo ratings yet

- Polycab 10mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 10mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- 2c x1.5 FAS CableDocument1 page2c x1.5 FAS CableSanjay KumarNo ratings yet

- Cable GTPDocument1 pageCable GTPtukaram.pawarNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.JayagurunathanNo ratings yet

- Lvis09axsfy23 5c300sa002sDocument1 pageLvis09axsfy23 5c300sa002sVishal SharmaNo ratings yet

- 2 5px3cywystrfrlsDocument2 pages2 5px3cywystrfrlsKrish0% (1)

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.rajesh1200No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.rajesh1200100% (1)

- Polycab 300mm 3 Core Aluminium Armoured Cable Specification SheetDocument2 pagesPolycab 300mm 3 Core Aluminium Armoured Cable Specification SheetZIRWA ENTERPRISESNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.rajesh1200No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.rajesh1200No ratings yet

- 400PX3 5caywyxlpeDocument2 pages400PX3 5caywyxlpeAnonymous SDeSP1No ratings yet

- Sr. No. 3B Datasheet 1.5PX6CYWY 100Document2 pagesSr. No. 3B Datasheet 1.5PX6CYWY 100hemantmech099200No ratings yet

- Sr. No. 3A Datasheet 4PX3CYWY 100Document2 pagesSr. No. 3A Datasheet 4PX3CYWY 100hemantmech099200No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSFY2012C2.5SA004S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSFY2012C2.5SA004S Date: Rev No.Anonymous SDeSP1No ratings yet

- Data Sheet For LT XLPE Cable: S.No Particulars 3.5 X 50Document2 pagesData Sheet For LT XLPE Cable: S.No Particulars 3.5 X 50AteebNo ratings yet

- 2 5px12cywyfrlsstrDocument2 pages2 5px12cywyfrlsstramzad aliNo ratings yet

- 10X4 A2xfy (FRLS) Alum ArmdDocument2 pages10X4 A2xfy (FRLS) Alum ArmdParth DhobiNo ratings yet

- 10X4 A2xfy Alum - ArmdDocument2 pages10X4 A2xfy Alum - ArmdParth DhobiNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.maharia_22No ratings yet

- LT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02Document2 pagesLT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02y8jkfz98m9No ratings yet

- FSBS07CXSWLS002C2 5saDocument1 pageFSBS07CXSWLS002C2 5sapradeepyellurNo ratings yet

- 400PX3CHT33UEFLATDocument2 pages400PX3CHT33UEFLATjayesh95395No ratings yet

- Lvbs09cxswy2004c1 5sa002sDocument1 pageLvbs09cxswy2004c1 5sa002sKrishNo ratings yet

- Cable GTPDocument1 pageCable GTPAnwar HussainNo ratings yet

- GTP - 12PX0.5,6PX0.75,2PX0.5,10PX0.5Document3 pagesGTP - 12PX0.5,6PX0.75,2PX0.5,10PX0.5santhoshNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVBS09CXSWY2003C004SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVBS09CXSWY2003C004SA002S Date: Rev No.bharathNo ratings yet

- 3SFL 2core Power Cable SpecsDocument1 page3SFL 2core Power Cable Specssandeep bagulNo ratings yet

- 1.5sqmm X 3C Arm DatasheetDocument2 pages1.5sqmm X 3C Arm DatasheetAshwin SupeNo ratings yet

- Instrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- Polycab Multicore CablesDocument2 pagesPolycab Multicore CablesAkhil SasidharanNo ratings yet

- GEN GP 208 5143 SRNo A1 141010 PDFDocument4 pagesGEN GP 208 5143 SRNo A1 141010 PDFdamlanNo ratings yet

- Electrical Cable - GTPDocument3 pagesElectrical Cable - GTPNawfel ArafathNo ratings yet

- 0 75px1tscnarmdDocument2 pages0 75px1tscnarmdnmpkumarNo ratings yet

- Document ID: TE/QMS/F/02 Rev. No.: 00 - Issued Date: 02/04/2018Document1 pageDocument ID: TE/QMS/F/02 Rev. No.: 00 - Issued Date: 02/04/2018dhanishlNo ratings yet

- 33 KV 3 Core Aluminium XLPE CableDocument3 pages33 KV 3 Core Aluminium XLPE CableSai KumarNo ratings yet

- Technical Specifications of The 2 Core, 1.5 Sq. MM, Un-Armoured Cable: Sr. No Description DataDocument4 pagesTechnical Specifications of The 2 Core, 1.5 Sq. MM, Un-Armoured Cable: Sr. No Description DataNikhil KarkeraNo ratings yet

- Instrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- FRLS 1.5 X 2 CoreDocument1 pageFRLS 1.5 X 2 CorerhladiNo ratings yet

- 2 5PX3CBLKFRLS100 PDFDocument1 page2 5PX3CBLKFRLS100 PDFSushil Kumar ShuklaNo ratings yet

- GTP - 1.1kv 1c Copper Xlpe Armd CableDocument1 pageGTP - 1.1kv 1c Copper Xlpe Armd CableShivam DwivediNo ratings yet

- 1.93.3KV 3Cx 35 SQMM Cable GTPDocument1 page1.93.3KV 3Cx 35 SQMM Cable GTPDarshit VyasNo ratings yet

- 1PX12PSCNARMDDocument1 page1PX12PSCNARMDJainam ShahNo ratings yet

- Hmnjopl PDFDocument1 pageHmnjopl PDFAjay PrajapatiNo ratings yet

- SR - No. Description Unit Technical Datasheet of Flexible Cables LDIS09CYUAY1003C006S 3CX6 Sq. MMDocument1 pageSR - No. Description Unit Technical Datasheet of Flexible Cables LDIS09CYUAY1003C006S 3CX6 Sq. MMSushil Kumar ShuklaNo ratings yet

- 33 KV Single Core Copper XLPE CableDocument3 pages33 KV Single Core Copper XLPE CableSai KumarNo ratings yet

- Solar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Document1 pageSolar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Koushik KarmakarNo ratings yet

- 6 RR FR LSHDocument1 page6 RR FR LSHGaurav MittalNo ratings yet

- Technical Data Sheets & Cross Sectional Details of 33kV XLPE CablesDocument4 pagesTechnical Data Sheets & Cross Sectional Details of 33kV XLPE CablesRamaKrishna ANo ratings yet

- GTP HavellsDocument24 pagesGTP HavellsPradeep GoelNo ratings yet

- DS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstDocument3 pagesDS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstAppzNo ratings yet

- 1C X 2.50 SQMM PTFE Single Core CableDocument1 page1C X 2.50 SQMM PTFE Single Core CablerijoNo ratings yet

- GTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding CableDocument1 pageGTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding Cableshivam dwivedi100% (1)

- SR - No. Description Unit Technical Datasheet of Flexible Cables LDIS09CYUAY1004C006S 4CX6 Sq. MMDocument1 pageSR - No. Description Unit Technical Datasheet of Flexible Cables LDIS09CYUAY1004C006S 4CX6 Sq. MMkiranNo ratings yet

- Polycab 2C X 4 SQMMDocument1 pagePolycab 2C X 4 SQMMHiteshChauhanNo ratings yet

- Site Order BookDocument3 pagesSite Order BookpkNo ratings yet

- Tds-Mot Fsd-Airtech Engg-Rajkot AirportDocument1 pageTds-Mot Fsd-Airtech Engg-Rajkot AirportpkNo ratings yet

- Tds-Man Vcd-Airtech Engg-Rajkot AirportDocument1 pageTds-Man Vcd-Airtech Engg-Rajkot AirportpkNo ratings yet

- TDS-SQ Diff-Airtech Engg-Rajkot AirportDocument1 pageTDS-SQ Diff-Airtech Engg-Rajkot AirportpkNo ratings yet

- Cu StripDocument4 pagesCu StrippkNo ratings yet

- SalesBill GT 1020Document1 pageSalesBill GT 1020pkNo ratings yet

- SalesBill GT 93Document1 pageSalesBill GT 93pkNo ratings yet

- 3351 e Way BillDocument2 pages3351 e Way BillpkNo ratings yet

- SalesBill GT 930Document4 pagesSalesBill GT 930pkNo ratings yet

- SalesBill GT 1002Document1 pageSalesBill GT 1002pkNo ratings yet

- SalesBill GT 983Document1 pageSalesBill GT 983pkNo ratings yet

- 2ADocument2 pages2ApkNo ratings yet

- Check ListDocument2 pagesCheck ListpkNo ratings yet

- SalesBill GT 930Document1 pageSalesBill GT 930pkNo ratings yet

- CamScanner 11-03-2023 10.37.11 - 4Document1 pageCamScanner 11-03-2023 10.37.11 - 4pkNo ratings yet

- SalesBill GT 957Document1 pageSalesBill GT 957pkNo ratings yet

- 3351 e Way BillDocument2 pages3351 e Way BillpkNo ratings yet

- 3ADocument2 pages3ApkNo ratings yet

- Ca1 JPGDocument1 pageCa1 JPGpkNo ratings yet

- 5AADocument2 pages5AApkNo ratings yet

- DPR FormatDocument1 pageDPR FormatpkNo ratings yet

- List of SignagesDocument5 pagesList of SignagespkNo ratings yet

- PCB Layout Thermal Design Guide An-EDocument18 pagesPCB Layout Thermal Design Guide An-EpkNo ratings yet

- Advanced Steel DesignDocument2 pagesAdvanced Steel DesignVaneeta SainiNo ratings yet

- Internships: Internships Often Bring To Mind TV and Movie Characters Who Fetch CoffeeDocument52 pagesInternships: Internships Often Bring To Mind TV and Movie Characters Who Fetch CoffeeShiva ShivaNo ratings yet

- BOARD EXAM QUESTIONS ON ArraysDocument6 pagesBOARD EXAM QUESTIONS ON ArraysAD SOLUTIONSNo ratings yet

- ACTIVITY Got Energy Food WebsDocument6 pagesACTIVITY Got Energy Food WebsShivangi SharmaNo ratings yet

- 2foundation Moments Hydraulics and CM Self Study QuestionsDocument40 pages2foundation Moments Hydraulics and CM Self Study QuestionsAngel TeyNo ratings yet

- Understanding The Principles of Ethics in Health CDocument8 pagesUnderstanding The Principles of Ethics in Health CAfina Zahrah MNo ratings yet

- Policy Brief 16 - Internal Migration in China-Integrating Migration With Urbanization Policies and Hukou Reform-Nov 21Document9 pagesPolicy Brief 16 - Internal Migration in China-Integrating Migration With Urbanization Policies and Hukou Reform-Nov 21oreoolepNo ratings yet

- Shiva Alloys Mandi Gobindgarh - Met. Lab Eqpts.Document3 pagesShiva Alloys Mandi Gobindgarh - Met. Lab Eqpts.Mandeep SodhiNo ratings yet

- Uc Boyutlu Baglanma Stilleri Olcegi ToadDocument21 pagesUc Boyutlu Baglanma Stilleri Olcegi Toad4sq8vnbsv2No ratings yet

- Electrical Engnieering 2K16.xls 7th SemesterDocument5 pagesElectrical Engnieering 2K16.xls 7th SemesterSyed Waqar Ul HaqNo ratings yet

- Clincher DiesDocument4 pagesClincher DiestibismtxNo ratings yet

- Cambridge International AS & A Level: Information Technology 9626/04 February/March 2022Document10 pagesCambridge International AS & A Level: Information Technology 9626/04 February/March 2022jesuNo ratings yet

- Solutions Acids and Bases Test Review AnswersDocument2 pagesSolutions Acids and Bases Test Review Answersapi-305204604No ratings yet

- Year 5 Math PDFDocument24 pagesYear 5 Math PDFRashida Nagarseth100% (1)

- Home Tuitions 870Document68 pagesHome Tuitions 870maxisinc.inNo ratings yet

- Determining Reaction Order Initial Rates and The Method of IsolationDocument4 pagesDetermining Reaction Order Initial Rates and The Method of IsolationDeepak PandeyNo ratings yet

- CG-107-F Bulk EarthworksDocument1 pageCG-107-F Bulk EarthworksJose AmorimNo ratings yet

- A Territorial Approach To The SDGs in Viken, NorwayDocument83 pagesA Territorial Approach To The SDGs in Viken, NorwayAna NichitusNo ratings yet

- LAB - REPORT - Che233Document8 pagesLAB - REPORT - Che2332022627312No ratings yet

- Corazón de Agua, Parque Ecológico en SacatepéquezDocument2 pagesCorazón de Agua, Parque Ecológico en SacatepéquezAna PaNjojNo ratings yet

- Schaffer HouseDocument39 pagesSchaffer HouseFrancisca CerdaNo ratings yet

- ppt3 Descriptive2 (23-24)Document74 pagesppt3 Descriptive2 (23-24)alexzandrei.rara937No ratings yet

- Cape Mock Exam 2023Document2 pagesCape Mock Exam 2023Tahj ThomasNo ratings yet

- Usa Architecture ProjectDocument4 pagesUsa Architecture ProjectnullifyNo ratings yet

- (Uttar Pradesh Public Service Commission, Prayagraj) : Print Application FormDocument5 pages(Uttar Pradesh Public Service Commission, Prayagraj) : Print Application FormmanishNo ratings yet

- Physics:: JEE-ADVANCED-2012-P1-Model IDocument1 pagePhysics:: JEE-ADVANCED-2012-P1-Model IJohn CarterNo ratings yet

- Isaac Thomas - Introduction - Advocate (INFJ) Personality - 16personalities - B4Document6 pagesIsaac Thomas - Introduction - Advocate (INFJ) Personality - 16personalities - B4isaacNo ratings yet

- Palomaria - Module 3Document9 pagesPalomaria - Module 3ALMIRA LOUISE PALOMARIANo ratings yet

- Useful Expressions To Express Your OpinionDocument2 pagesUseful Expressions To Express Your OpinionbttNo ratings yet