Professional Documents

Culture Documents

NSK Ball Rail Guide Wall Chart LH Series

NSK Ball Rail Guide Wall Chart LH Series

Uploaded by

HenryCopyright:

Available Formats

You might also like

- Electric Drawing-FR2000Document19 pagesElectric Drawing-FR2000MuMoMa100% (1)

- Iec 63132 3 2020Document15 pagesIec 63132 3 2020Gastón MelgrattiNo ratings yet

- HG Series TOPDocument22 pagesHG Series TOPJhon SyalfiandyNo ratings yet

- Ball Splines BSPDocument20 pagesBall Splines BSPTravis DavisNo ratings yet

- EG-Series-HIWIN CatalogDocument17 pagesEG-Series-HIWIN CatalogLoc HuynhNo ratings yet

- Taillift Types Slider Lifts: Pos Code DescriptionDocument9 pagesTaillift Types Slider Lifts: Pos Code DescriptiontecnicomanelNo ratings yet

- QW-Series Patines HiwinDocument13 pagesQW-Series Patines HiwinWANKEL25No ratings yet

- ES B TrenchDrainGratingsDocument1 pageES B TrenchDrainGratingsBLUCHERNo ratings yet

- GMB CATALOGUE Universal Joint 2016 PDFDocument49 pagesGMB CATALOGUE Universal Joint 2016 PDFHalim Bessouf100% (1)

- M81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationDocument1 pageM81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationFlavio Abreu100% (1)

- Level Indicator Vertical Float TypeDocument4 pagesLevel Indicator Vertical Float Typeanon_83594873No ratings yet

- HIWIN Compact Catalogue (English)Document80 pagesHIWIN Compact Catalogue (English)Dobrica PetrovicNo ratings yet

- Drawing by: Job number: Id: Project:: Pitch (Θ) =0° Roll (Φ) =0° TopDocument2 pagesDrawing by: Job number: Id: Project:: Pitch (Θ) =0° Roll (Φ) =0° TopDylanLiNo ratings yet

- BS4190 Grade 4: Anchor Bolt Type A Anchor Bolt Type BDocument1 pageBS4190 Grade 4: Anchor Bolt Type A Anchor Bolt Type BmodarthNo ratings yet

- DR Nomenclature Poster 9TRP0700Document1 pageDR Nomenclature Poster 9TRP0700hatem.ahmedNo ratings yet

- Bucket Elevator Outage Inspection & Service Form-1Document1 pageBucket Elevator Outage Inspection & Service Form-1Ermiyas MistreNo ratings yet

- LM 10 03Document7 pagesLM 10 03ashraf elsayedNo ratings yet

- Door Courtesy Switch Circuit: Circuit Description Wiring DiagramDocument3 pagesDoor Courtesy Switch Circuit: Circuit Description Wiring DiagramPhang KumwingNo ratings yet

- 2017092016131920170516140747KLS7 KW10Document5 pages2017092016131920170516140747KLS7 KW10Eazhil PreethiNo ratings yet

- CKQG32 br2023Document22 pagesCKQG32 br2023AlexandreNo ratings yet

- Burndy PDFDocument36 pagesBurndy PDFDiego ChavezNo ratings yet

- FUJI Flow MeterDocument12 pagesFUJI Flow MeterKareem RMGNo ratings yet

- Lube Linear Way MH - Lube Linear: Identifi Cation Number and Specifi CationDocument22 pagesLube Linear Way MH - Lube Linear: Identifi Cation Number and Specifi CationAndre CorreiaNo ratings yet

- Miniature Linear Guideway: MSC Stainless Steel SeriesDocument10 pagesMiniature Linear Guideway: MSC Stainless Steel SeriesVikaas JainNo ratings yet

- En d2hwDocument11 pagesEn d2hwOchitt DoankNo ratings yet

- NSK - TS30AN New Type of Rolling ElementDocument4 pagesNSK - TS30AN New Type of Rolling ElementeliscarlosNo ratings yet

- MC Gill Cam Follower BearingsDocument2 pagesMC Gill Cam Follower BearingsRaphael RezendeNo ratings yet

- Wiring Diagram Elevator: PT - Industri Lift Indo NusantaraDocument28 pagesWiring Diagram Elevator: PT - Industri Lift Indo NusantaraGogik AntoNo ratings yet

- 11Document1 page11Saragh BhandaryNo ratings yet

- Chaín AgriculturalDocument3 pagesChaín AgriculturalWilheam Mamani CasillaNo ratings yet

- LR and LR-Z LRADocument2 pagesLR and LR-Z LRAPerfil DE Aluminio T-slotNo ratings yet

- Level Switches Series UNS 2000-S With Shipbuilding ApprovalsDocument2 pagesLevel Switches Series UNS 2000-S With Shipbuilding ApprovalsStefanitaNo ratings yet

- Yamaha Mio Lubrication PointsDocument1 pageYamaha Mio Lubrication Pointsmotley crewzNo ratings yet

- Sumitomo Catalogue 2020-2021 enDocument652 pagesSumitomo Catalogue 2020-2021 enDuc HoangNo ratings yet

- 03 01 02 PDFDocument1 page03 01 02 PDFAnonymous lswzqloNo ratings yet

- Encoder E58 10mm AutonicDocument2 pagesEncoder E58 10mm Autonicedwin_54No ratings yet

- ES-W-W1911 Datasheet Sep20 PDFDocument2 pagesES-W-W1911 Datasheet Sep20 PDFEslam ElsayedNo ratings yet

- JSD Engineering Products: Vane PumpDocument3 pagesJSD Engineering Products: Vane PumptanveerNo ratings yet

- 81 1 Catalogo Cilindri ENGDocument14 pages81 1 Catalogo Cilindri ENGsundyaNo ratings yet

- Ic RegulatorDocument19 pagesIc RegulatorDavit OmegaNo ratings yet

- High-Pressure Centrifugal Pumps: Application Branch Positions/flangesDocument16 pagesHigh-Pressure Centrifugal Pumps: Application Branch Positions/flangesJhonNo ratings yet

- ME Catalog Epoxy 2Document4 pagesME Catalog Epoxy 2wqeNo ratings yet

- Classifier - Separator Inspection FormDocument1 pageClassifier - Separator Inspection FormErmiyas Mistre100% (1)

- 2.2 Identification of Model Number: 11 System OverviewDocument1 page2.2 Identification of Model Number: 11 System Overviewwoki hojNo ratings yet

- Models Bif, BNFN, MDK, MBF and BNF: Standard-Stock Precision Ball Screw Unfinished Shaft EndsDocument12 pagesModels Bif, BNFN, MDK, MBF and BNF: Standard-Stock Precision Ball Screw Unfinished Shaft EndsSueli ZaniNo ratings yet

- Kh-Din Flange Ball Valve With DIN Connection Steel: Available Sizes ConnectionsDocument2 pagesKh-Din Flange Ball Valve With DIN Connection Steel: Available Sizes ConnectionsTrong Hung NguyenNo ratings yet

- Al - Majal (Red Sea Pro) - PDFDocument4 pagesAl - Majal (Red Sea Pro) - PDFzubair.zubairbaigNo ratings yet

- Sony SS-K90ED Speaker ManualDocument2 pagesSony SS-K90ED Speaker ManualPaul PaciniNo ratings yet

- CJ Series: Ordering Information CJ HPFP NL V 20 1N 1A 010Document2 pagesCJ Series: Ordering Information CJ HPFP NL V 20 1N 1A 010johanes kharismaNo ratings yet

- Low Noise Solenoid Controlled Relief ValvesDocument7 pagesLow Noise Solenoid Controlled Relief ValveshectorNo ratings yet

- PRPQ 410 GK SeriesDocument36 pagesPRPQ 410 GK SeriesJaime Albarrán FaríasNo ratings yet

- 26052017021532page No. 129Document1 page26052017021532page No. 129beemasundarNo ratings yet

- Installation Guide: Clamp-On Flow MeterDocument4 pagesInstallation Guide: Clamp-On Flow MeterOthoniel KanoNo ratings yet

- Router: (Plunge Type)Document2 pagesRouter: (Plunge Type)AljonDo-ongCastidadesNo ratings yet

- Cyclo 6000 Gearmotor Complete Catalog-páginas-8,16,70-ComprimidoDocument3 pagesCyclo 6000 Gearmotor Complete Catalog-páginas-8,16,70-ComprimidoFernando Chunga AtalayaNo ratings yet

- (BAT) (IG) : Air ConditionerDocument2 pages(BAT) (IG) : Air ConditionerLinh Pham HoangNo ratings yet

- Plano Fuji Yida NuevoDocument18 pagesPlano Fuji Yida Nuevooro plata100% (1)

- At C Combined ManualDocument42 pagesAt C Combined ManualHenryNo ratings yet

- M075 E1 03 2BH8PS 2BDatasheet 1Document32 pagesM075 E1 03 2BH8PS 2BDatasheet 1HenryNo ratings yet

- Takamaz X20 Hi Server - enDocument4 pagesTakamaz X20 Hi Server - enHenryNo ratings yet

- Instruction Manual: Standard ChuckDocument40 pagesInstruction Manual: Standard ChuckHenryNo ratings yet

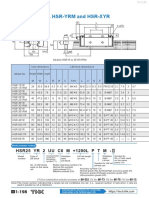

- Models HSR-YR, HSR-YRM and HSR-XYR: Hsr25 Yr 2 Uu C0 M +1200L P T MDocument2 pagesModels HSR-YR, HSR-YRM and HSR-XYR: Hsr25 Yr 2 Uu C0 M +1200L P T MHenryNo ratings yet

- GE Fanuc Automation: C Series LaserDocument87 pagesGE Fanuc Automation: C Series LaserHenryNo ratings yet

- CS20 Instruction Manual: Inverted Vertical Turning CellDocument83 pagesCS20 Instruction Manual: Inverted Vertical Turning CellHenryNo ratings yet

- Porta Herramientas MORI SEIKIDocument23 pagesPorta Herramientas MORI SEIKIHenryNo ratings yet

- Rim Clamp Tire Changer Maintenance TipsDocument7 pagesRim Clamp Tire Changer Maintenance Tipsdionisio emilio reyes jimenezNo ratings yet

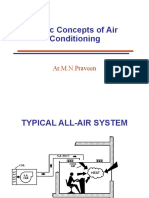

- Typical All Air System Explanation With SketchesDocument19 pagesTypical All Air System Explanation With SketchesMADHU MITHANo ratings yet

- Astm e 330Document7 pagesAstm e 330Zahoor Ahmed MohsanNo ratings yet

- Dynamic MeshDocument152 pagesDynamic Meshdeniscik100% (2)

- HKL Ope Manual EngDocument25 pagesHKL Ope Manual Engmjl47No ratings yet

- 12mmTMX-UNBS. March23Document3 pages12mmTMX-UNBS. March23Okello StevenNo ratings yet

- Note Chapter2 SF017Document79 pagesNote Chapter2 SF017api-3699866100% (3)

- Airtech-Brosura TehnicaDocument4 pagesAirtech-Brosura TehnicaImed RebaiNo ratings yet

- Boiler SafetyDocument12 pagesBoiler Safetyrize1159100% (1)

- Libro de Oro KOMATSU PDFDocument154 pagesLibro de Oro KOMATSU PDFErwinParis100% (6)

- Tutorial 2 - Failure Theories ReliabilityDocument10 pagesTutorial 2 - Failure Theories ReliabilitysharleenNo ratings yet

- Design Philosophy PDFDocument12 pagesDesign Philosophy PDFRufus ChengNo ratings yet

- 6 Worksheet (AS) MomentumDocument4 pages6 Worksheet (AS) MomentumMahad AsimNo ratings yet

- SE MMT ARAF D 24002XX 10003 DWG 10003Document1 pageSE MMT ARAF D 24002XX 10003 DWG 10003Tanveer PatilNo ratings yet

- Principles of Flight - 081 POFDocument476 pagesPrinciples of Flight - 081 POFobrajiorNo ratings yet

- Doosan Gas TurbinesDocument20 pagesDoosan Gas TurbinesUhrin Imre100% (1)

- Dynamic Design and Analysis of Car Wheel Rim Using FEA MethodDocument14 pagesDynamic Design and Analysis of Car Wheel Rim Using FEA MethodIJRASETPublicationsNo ratings yet

- P020E-Fuel Injector 5 Performance: Theory of OperationDocument2 pagesP020E-Fuel Injector 5 Performance: Theory of OperationWillie AustineNo ratings yet

- Ans. C C P 60 + 0.8 P 0.005 P P P 100 Parts Ans.: X X X e X e e X X X X e e Ans X XDocument10 pagesAns. C C P 60 + 0.8 P 0.005 P P P 100 Parts Ans.: X X X e X e e X X X X e e Ans X XR RameshNo ratings yet

- Bombas BerkeleyDocument136 pagesBombas BerkeleyDaniel Alejandro GuerreroNo ratings yet

- Operation Manual For Model SP 305Document104 pagesOperation Manual For Model SP 305alexnobinarie04No ratings yet

- D1 Hyd Hose 2016 MJ Hydraulics LRDocument34 pagesD1 Hyd Hose 2016 MJ Hydraulics LRtestNo ratings yet

- Flexural Strengthening of Reinforced Concrete Beam-Column Joints Using Innovative Anchorage SystemDocument12 pagesFlexural Strengthening of Reinforced Concrete Beam-Column Joints Using Innovative Anchorage SystemmekidesNo ratings yet

- Asme B31.3 Process Piping: Case Study 4: Hydro and Pneumatic Testing (Question)Document2 pagesAsme B31.3 Process Piping: Case Study 4: Hydro and Pneumatic Testing (Question)Michael AlbuquerqueNo ratings yet

- Rotor Hub AnalysisDocument21 pagesRotor Hub AnalysisJoshua Simon TelagalapudiNo ratings yet

- A Project Report RaviDocument25 pagesA Project Report RaviKunal Kumar YaadavNo ratings yet

- Pro Dec PlateDocument9 pagesPro Dec PlateAbe VoigNo ratings yet

- Subcooling Exam DanfossDocument8 pagesSubcooling Exam Danfossmarjan 01No ratings yet

- Course Title: Thermal System DesignDocument27 pagesCourse Title: Thermal System DesignhailemebrahtuNo ratings yet

NSK Ball Rail Guide Wall Chart LH Series

NSK Ball Rail Guide Wall Chart LH Series

Uploaded by

HenryOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NSK Ball Rail Guide Wall Chart LH Series

NSK Ball Rail Guide Wall Chart LH Series

Uploaded by

HenryCopyright:

Available Formats

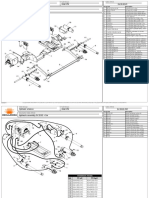

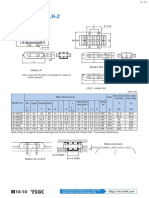

LH Series LH Series LH Series Accessories

Identification Number Ball Slide Rail Dimension Table

Ball Slide (Stocked item) Separately Sold Rail for NSK Linear Guide Protector and Double Seal

LAH 25 AN Z-K LH series Standard Rail Travel length is reduced by the thickness of the end

L1H-Z : Preloaded Interchangeable Type seal on the ball slide. Consider the value of V in the

table below when calculating the travel length.

Ball Slide Type LH series Butting Rail

No code: No special accessories and fluoride black chrome plating

L1H-01Z : Preloaded Interchangeable Type Protector Seal Unit : mm Double Seal Unit : mm

K: One K1 Lubrication Unit each side

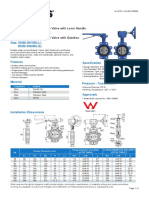

Size No. K2: Two K1 Lubrication Units each side LH series butting rail features higher precision tolerances for L0 and G dimensions. Linear Guide Protector No. Protector No. Increased Linear Guide Double Seal No. Double Seal No. Increased

AN: Square - Standard D: Double Seals each side Model No. Plug End Grease Fitting End Thickness V1 Model No. Plug End Grease Fitting End Thickness V2

AL: Square - Short height standard P: Protector Plate each side

LH15 LH15PT-01 LH15PTC-01 2.7 LH15 LH15WS-01 LH15WSC-01 2.5

BN: Square - Long

BL: Square - Short height long

No code: Clearance Type

Z: Preloaded Type

L1H 25 1200 - 01 Z LH20 LH20PT-01 LH20PTC-01 2.9 LH20 LH20WS-01 LH20WSC-01 2.5

EM: Flanged (Tapped & Thru hole) Standard LH25 LH25PT-01 LH25PTC-01 3.2 LH25 LH25WS-01 LH25WSC-01 2.8

GM: Flanged (Tapped & Thru hole) Long No Code: Clearance Type

Rail Type Z: Preloaded Type LH30 LH30PT-01 LH30PTC-01 4.2 LH30 LH30WS-01 LH30WSC-01 3.6

Style Material Code LH35 LH35PT-01 LH35PTC-01 4.2 LH35 LH35WS-01 LH35WSC-01 3.6

Size No.

Material Code No Code: Standard Carbon Steel LH45 LH45PT-01 LH45PTC-01 4.9 LH45 LH45WS-01 LH45WSC-01 4.3

Rail Length (mm) S: Stainless Steel (standard for LU and LE series) LH55 LH55PT-01 LH55PTC-01 4.9 LH55 LH55WS-01 LH55WSC-01 4.3

No Code: Standard Carbon Steel (may also be C)

S: Stainless Steel (standard for LU and LE Series) D: Carbon Steel + Fluoride Coating

LH65 LH65PT-01 LH65PTC-01 5.5 LH65 LH65WS-01 LH65WSC-01 4.9

D: Carbon Steel + Fluoride Coating No Code: Standard H: Stainless Steel + Fluoride Coating

A: Carbon Steel + Armoloy Coating One of each PT and PTC is required to do one linear bearing. One of each WS and WSC is required to do one linear bearing.

H: Stainless Steel + Fluoride Coating 01: Butting Rail

A: Carbon Steel + Armoloy Coating B: Stainless Steel + Armoloy Coating

B: Stainless Steel + Armoloy Coating F: Fluoride Black Chrome Plating Fig.-8 Protector and Double Seal

Protector (made of steel) Double Seal Fig.-13

(2 end seals)

End Seal

EM (High Load)

Flanged Type Low Height Type with Tapped & Thru Holes

GM (Ultra High Load)

Square Type High Type LH-AN (High Load), LH-BN (Ultra High Load)

Fig.-1 LH-AN, LH-BN TYPE Fig.-2 LH-EM, LH-GM TYPE NOTE: V1 includes the thickness of the screw head.

1 mm = .0394 inch *NOTE: - The protector (steel) is always ahead of the side seal or

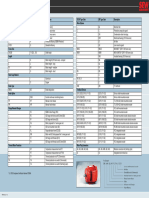

Rail Dimensions Table Unit: mm 1kgf/m = .67 Ft/Lb

Adapters double seal.

These parts connect piping to the tapped hole when the

Model No. Max. rail length Rail Rail Weight grease fitting is removed.

L 0 max. W1 H1 F dxDxh Plastic Cap for Rail Mounting Hole

Standard Butting ( ) indicates Stainless Steel Butting G-0.5

0

(kg/m)

Fig.-6 LF Type Linear Guide Rail Mounting Cap. No. for Rail

L1H15 L1H15-01 1440

L1H15-Z L1H15-01Z (1260) 15 15 60 4.5 x 7.5 x 5.3 30 1.6 For LH20, 25 Model No. Bolt Size Mounting Hole

For LH30, 35

LH15 M4 L45800004-003

L1H20 L1H20-01 3960 LH20 M5 L45800005-003

L1H20-Z L1H20-01Z (3460) 20 18 60 6 x 9.5 x 8.5 30 2.6

LH25 M6 L45800006-003

Internal Clearance and Preload L1H25 L1H25-01 3960 LH30

L1H25-Z L1H25-01Z (3460) 23 22 60 7 x 11 x 9 30 3.6 M8 L45800008-003

The internal clearance refers to the amount of movement of the ball slide, when moved up and down with the rail fixed. LH35

The amount of preload is specified by size as follows. L1H30 L1H30-01 4000 LH45 M12 L45800012-003

L1H30-Z L1H30-01Z (3480) 28 26 80 9 x 14 x 12 40 5.2 LH55 M14 L45800014-003

Table 1 Unit: µm LH65 M16 L45800016-003

L1H35 L1H35-01

Size #15 #20 #25 #30 #35 #45 #55 #65 L1H35-Z L1H35-01Z 4000 34 29 80 9 x 14 x 12 40 7.2 Fig.-7 SF Type

For LH20, 25 Brass Cap for Rail Mounting Hole

Clearance 15~–4 15~–5 L1H45 L1H45-01 For LH30, 35

3990 45 38 105 14 x 20 x 17 52.5 12.3 Linear Guide Rail Mounting Cap. No. for Rail

L1H45-Z L1H45-01Z Model No. Bolt Size Mounting Hole

Preloaded 0~–4 0~–5 0~–7 0~–9

L1H55 L1H55-01 LH20 M5 L45800005-004

L1H55-Z L1H55-01Z 3960 53 44 120 16 x 23 x 20 60 16.9

LH25 M6 L45800006-004

L1H65 L1H65-01 LH30

3900 63 53 150 18 x 26 x 22 75 24.3 M8 L45800008-004

L1H65-Z L1H65-01Z LH35

LH45 M12 L45800012-004

Rail butting can be used for longer lengths. Please contact NSK for details

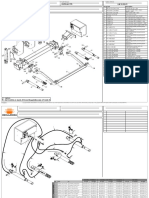

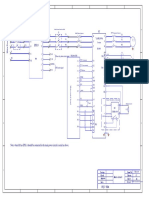

K1 Maintenance Slide Dimensions with K1 Assembly Instructions

-Free Lubrication System Interchangeable Linear Guide Dimensions – LH Series

Interchangeable

Unit: mm

Standard Ball slide length Thickness Thickness of Grease fitting K1 Lubricating Unit for Linear Guides

Ball Slide Ball slide Ball Slide with two NSK K1 of NSK K1 protective cover projection

size code form length L V1 V2 N (mm) 1. Slide linear bearing on to the linear rail, using the plastic provisional rail supplied.

The NSK K1’s distinctive capabilities as a compact and

efficient oil-impregnated lubrication unit as well as a seal, AN EM 55 65.6

LAH15 GM 74 84.6 4.5 0.8 5 2. Remove the grease fitting from the end of the bearing.

greatly increases the performance of the Linear Guide.

AN EM 69.8 80.4 3. Remove the Phillips screws (2 pieces).

The K1 Lubrication Unit is available in two types, one for LAH20 BN GM 91.8 102.4 4.5 0.8 14

industrial applications and one for food and medical AN/AL EM 79 90.6 4. Remove the end seal from end of bearing.

devices where cleanliness and safety are paramount. 5.0 0.8 14

LAH25 BN/BL GM 107 118.6

5. For maintenance free operation, install threaded plug; for re-greasing option, see points 10 & 11 below.

AN/AL 85.6 97.6

Features: LAH30 EM 98.6 110.6 5.0 1.0 14 6. Install the cover plate from the K1™ kit to the end of bearing, against the end cap.

BN/BL GM 124.6 136.6

1. Long-term, maintenance-free usage. 7. Install K1™ lubricating unit without fixing rings, so it can be expanded over the rail.

AN/AL EM 109 122

LAH35 5.5 1.0 14

BN/BL GM 143 156 8. Put the three (3) fixing rings in position on the K1™ lubricating unit.

In mechanical environments where lubrication

AN EM 139 154

is difficult to apply, long-term running efficiency LAH45 6.5 1.0 15 9. Replace the end seal, in front of the K1™ lubricating unit.

BN GM 171 186

is maintained by using the NSK K1 in combination

AN EM 163 178 10. Install connector screw for grease fitting.

with grease. LAH55 BN GM 201 216 6.5 1.0 15

AN EM 193 211

11. Replace the grease fitting in connector screw.

2. Prevention of oil-related environmental pollution. LAH65

BN GM 253 271

8.0 1.0 16

12. Install the extension Phillips screws (2 pieces, supplied with the K1™ seal kit).

In locations where oil greatly affects the environment, or in mechanisms with severe hygiene restrictions,

LH Series Note Ball slide

sufficient lubrication is provided using the NSK K1 in combination with grease.

The K1™ lubricating unit has a shelf life.

They should be installed immediately upon receipt.

3. Effective in environments where the lubricant is washed away. It is important to avoid direct sunlight and

In facilities where mechanisms are washed down with water, or subject to severe weather conditions, extreme heat conditions. Spring ring

long service life is ensured by using the NSK K1 in combination with grease. Especially effective under NSK K1

hygienic conditions where oil must not be dispersed.

4. Maintains efficiency in dusty environments.

End seal

In environments where oil and grease-absorbing dust is produced, long-term efficiency is maintained

by using the NSK K1 in combination with grease.

End cap

Protector plate

Rail

1-800-387-9362 • www.ca.nsk.com

You might also like

- Electric Drawing-FR2000Document19 pagesElectric Drawing-FR2000MuMoMa100% (1)

- Iec 63132 3 2020Document15 pagesIec 63132 3 2020Gastón MelgrattiNo ratings yet

- HG Series TOPDocument22 pagesHG Series TOPJhon SyalfiandyNo ratings yet

- Ball Splines BSPDocument20 pagesBall Splines BSPTravis DavisNo ratings yet

- EG-Series-HIWIN CatalogDocument17 pagesEG-Series-HIWIN CatalogLoc HuynhNo ratings yet

- Taillift Types Slider Lifts: Pos Code DescriptionDocument9 pagesTaillift Types Slider Lifts: Pos Code DescriptiontecnicomanelNo ratings yet

- QW-Series Patines HiwinDocument13 pagesQW-Series Patines HiwinWANKEL25No ratings yet

- ES B TrenchDrainGratingsDocument1 pageES B TrenchDrainGratingsBLUCHERNo ratings yet

- GMB CATALOGUE Universal Joint 2016 PDFDocument49 pagesGMB CATALOGUE Universal Joint 2016 PDFHalim Bessouf100% (1)

- M81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationDocument1 pageM81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationFlavio Abreu100% (1)

- Level Indicator Vertical Float TypeDocument4 pagesLevel Indicator Vertical Float Typeanon_83594873No ratings yet

- HIWIN Compact Catalogue (English)Document80 pagesHIWIN Compact Catalogue (English)Dobrica PetrovicNo ratings yet

- Drawing by: Job number: Id: Project:: Pitch (Θ) =0° Roll (Φ) =0° TopDocument2 pagesDrawing by: Job number: Id: Project:: Pitch (Θ) =0° Roll (Φ) =0° TopDylanLiNo ratings yet

- BS4190 Grade 4: Anchor Bolt Type A Anchor Bolt Type BDocument1 pageBS4190 Grade 4: Anchor Bolt Type A Anchor Bolt Type BmodarthNo ratings yet

- DR Nomenclature Poster 9TRP0700Document1 pageDR Nomenclature Poster 9TRP0700hatem.ahmedNo ratings yet

- Bucket Elevator Outage Inspection & Service Form-1Document1 pageBucket Elevator Outage Inspection & Service Form-1Ermiyas MistreNo ratings yet

- LM 10 03Document7 pagesLM 10 03ashraf elsayedNo ratings yet

- Door Courtesy Switch Circuit: Circuit Description Wiring DiagramDocument3 pagesDoor Courtesy Switch Circuit: Circuit Description Wiring DiagramPhang KumwingNo ratings yet

- 2017092016131920170516140747KLS7 KW10Document5 pages2017092016131920170516140747KLS7 KW10Eazhil PreethiNo ratings yet

- CKQG32 br2023Document22 pagesCKQG32 br2023AlexandreNo ratings yet

- Burndy PDFDocument36 pagesBurndy PDFDiego ChavezNo ratings yet

- FUJI Flow MeterDocument12 pagesFUJI Flow MeterKareem RMGNo ratings yet

- Lube Linear Way MH - Lube Linear: Identifi Cation Number and Specifi CationDocument22 pagesLube Linear Way MH - Lube Linear: Identifi Cation Number and Specifi CationAndre CorreiaNo ratings yet

- Miniature Linear Guideway: MSC Stainless Steel SeriesDocument10 pagesMiniature Linear Guideway: MSC Stainless Steel SeriesVikaas JainNo ratings yet

- En d2hwDocument11 pagesEn d2hwOchitt DoankNo ratings yet

- NSK - TS30AN New Type of Rolling ElementDocument4 pagesNSK - TS30AN New Type of Rolling ElementeliscarlosNo ratings yet

- MC Gill Cam Follower BearingsDocument2 pagesMC Gill Cam Follower BearingsRaphael RezendeNo ratings yet

- Wiring Diagram Elevator: PT - Industri Lift Indo NusantaraDocument28 pagesWiring Diagram Elevator: PT - Industri Lift Indo NusantaraGogik AntoNo ratings yet

- 11Document1 page11Saragh BhandaryNo ratings yet

- Chaín AgriculturalDocument3 pagesChaín AgriculturalWilheam Mamani CasillaNo ratings yet

- LR and LR-Z LRADocument2 pagesLR and LR-Z LRAPerfil DE Aluminio T-slotNo ratings yet

- Level Switches Series UNS 2000-S With Shipbuilding ApprovalsDocument2 pagesLevel Switches Series UNS 2000-S With Shipbuilding ApprovalsStefanitaNo ratings yet

- Yamaha Mio Lubrication PointsDocument1 pageYamaha Mio Lubrication Pointsmotley crewzNo ratings yet

- Sumitomo Catalogue 2020-2021 enDocument652 pagesSumitomo Catalogue 2020-2021 enDuc HoangNo ratings yet

- 03 01 02 PDFDocument1 page03 01 02 PDFAnonymous lswzqloNo ratings yet

- Encoder E58 10mm AutonicDocument2 pagesEncoder E58 10mm Autonicedwin_54No ratings yet

- ES-W-W1911 Datasheet Sep20 PDFDocument2 pagesES-W-W1911 Datasheet Sep20 PDFEslam ElsayedNo ratings yet

- JSD Engineering Products: Vane PumpDocument3 pagesJSD Engineering Products: Vane PumptanveerNo ratings yet

- 81 1 Catalogo Cilindri ENGDocument14 pages81 1 Catalogo Cilindri ENGsundyaNo ratings yet

- Ic RegulatorDocument19 pagesIc RegulatorDavit OmegaNo ratings yet

- High-Pressure Centrifugal Pumps: Application Branch Positions/flangesDocument16 pagesHigh-Pressure Centrifugal Pumps: Application Branch Positions/flangesJhonNo ratings yet

- ME Catalog Epoxy 2Document4 pagesME Catalog Epoxy 2wqeNo ratings yet

- Classifier - Separator Inspection FormDocument1 pageClassifier - Separator Inspection FormErmiyas Mistre100% (1)

- 2.2 Identification of Model Number: 11 System OverviewDocument1 page2.2 Identification of Model Number: 11 System Overviewwoki hojNo ratings yet

- Models Bif, BNFN, MDK, MBF and BNF: Standard-Stock Precision Ball Screw Unfinished Shaft EndsDocument12 pagesModels Bif, BNFN, MDK, MBF and BNF: Standard-Stock Precision Ball Screw Unfinished Shaft EndsSueli ZaniNo ratings yet

- Kh-Din Flange Ball Valve With DIN Connection Steel: Available Sizes ConnectionsDocument2 pagesKh-Din Flange Ball Valve With DIN Connection Steel: Available Sizes ConnectionsTrong Hung NguyenNo ratings yet

- Al - Majal (Red Sea Pro) - PDFDocument4 pagesAl - Majal (Red Sea Pro) - PDFzubair.zubairbaigNo ratings yet

- Sony SS-K90ED Speaker ManualDocument2 pagesSony SS-K90ED Speaker ManualPaul PaciniNo ratings yet

- CJ Series: Ordering Information CJ HPFP NL V 20 1N 1A 010Document2 pagesCJ Series: Ordering Information CJ HPFP NL V 20 1N 1A 010johanes kharismaNo ratings yet

- Low Noise Solenoid Controlled Relief ValvesDocument7 pagesLow Noise Solenoid Controlled Relief ValveshectorNo ratings yet

- PRPQ 410 GK SeriesDocument36 pagesPRPQ 410 GK SeriesJaime Albarrán FaríasNo ratings yet

- 26052017021532page No. 129Document1 page26052017021532page No. 129beemasundarNo ratings yet

- Installation Guide: Clamp-On Flow MeterDocument4 pagesInstallation Guide: Clamp-On Flow MeterOthoniel KanoNo ratings yet

- Router: (Plunge Type)Document2 pagesRouter: (Plunge Type)AljonDo-ongCastidadesNo ratings yet

- Cyclo 6000 Gearmotor Complete Catalog-páginas-8,16,70-ComprimidoDocument3 pagesCyclo 6000 Gearmotor Complete Catalog-páginas-8,16,70-ComprimidoFernando Chunga AtalayaNo ratings yet

- (BAT) (IG) : Air ConditionerDocument2 pages(BAT) (IG) : Air ConditionerLinh Pham HoangNo ratings yet

- Plano Fuji Yida NuevoDocument18 pagesPlano Fuji Yida Nuevooro plata100% (1)

- At C Combined ManualDocument42 pagesAt C Combined ManualHenryNo ratings yet

- M075 E1 03 2BH8PS 2BDatasheet 1Document32 pagesM075 E1 03 2BH8PS 2BDatasheet 1HenryNo ratings yet

- Takamaz X20 Hi Server - enDocument4 pagesTakamaz X20 Hi Server - enHenryNo ratings yet

- Instruction Manual: Standard ChuckDocument40 pagesInstruction Manual: Standard ChuckHenryNo ratings yet

- Models HSR-YR, HSR-YRM and HSR-XYR: Hsr25 Yr 2 Uu C0 M +1200L P T MDocument2 pagesModels HSR-YR, HSR-YRM and HSR-XYR: Hsr25 Yr 2 Uu C0 M +1200L P T MHenryNo ratings yet

- GE Fanuc Automation: C Series LaserDocument87 pagesGE Fanuc Automation: C Series LaserHenryNo ratings yet

- CS20 Instruction Manual: Inverted Vertical Turning CellDocument83 pagesCS20 Instruction Manual: Inverted Vertical Turning CellHenryNo ratings yet

- Porta Herramientas MORI SEIKIDocument23 pagesPorta Herramientas MORI SEIKIHenryNo ratings yet

- Rim Clamp Tire Changer Maintenance TipsDocument7 pagesRim Clamp Tire Changer Maintenance Tipsdionisio emilio reyes jimenezNo ratings yet

- Typical All Air System Explanation With SketchesDocument19 pagesTypical All Air System Explanation With SketchesMADHU MITHANo ratings yet

- Astm e 330Document7 pagesAstm e 330Zahoor Ahmed MohsanNo ratings yet

- Dynamic MeshDocument152 pagesDynamic Meshdeniscik100% (2)

- HKL Ope Manual EngDocument25 pagesHKL Ope Manual Engmjl47No ratings yet

- 12mmTMX-UNBS. March23Document3 pages12mmTMX-UNBS. March23Okello StevenNo ratings yet

- Note Chapter2 SF017Document79 pagesNote Chapter2 SF017api-3699866100% (3)

- Airtech-Brosura TehnicaDocument4 pagesAirtech-Brosura TehnicaImed RebaiNo ratings yet

- Boiler SafetyDocument12 pagesBoiler Safetyrize1159100% (1)

- Libro de Oro KOMATSU PDFDocument154 pagesLibro de Oro KOMATSU PDFErwinParis100% (6)

- Tutorial 2 - Failure Theories ReliabilityDocument10 pagesTutorial 2 - Failure Theories ReliabilitysharleenNo ratings yet

- Design Philosophy PDFDocument12 pagesDesign Philosophy PDFRufus ChengNo ratings yet

- 6 Worksheet (AS) MomentumDocument4 pages6 Worksheet (AS) MomentumMahad AsimNo ratings yet

- SE MMT ARAF D 24002XX 10003 DWG 10003Document1 pageSE MMT ARAF D 24002XX 10003 DWG 10003Tanveer PatilNo ratings yet

- Principles of Flight - 081 POFDocument476 pagesPrinciples of Flight - 081 POFobrajiorNo ratings yet

- Doosan Gas TurbinesDocument20 pagesDoosan Gas TurbinesUhrin Imre100% (1)

- Dynamic Design and Analysis of Car Wheel Rim Using FEA MethodDocument14 pagesDynamic Design and Analysis of Car Wheel Rim Using FEA MethodIJRASETPublicationsNo ratings yet

- P020E-Fuel Injector 5 Performance: Theory of OperationDocument2 pagesP020E-Fuel Injector 5 Performance: Theory of OperationWillie AustineNo ratings yet

- Ans. C C P 60 + 0.8 P 0.005 P P P 100 Parts Ans.: X X X e X e e X X X X e e Ans X XDocument10 pagesAns. C C P 60 + 0.8 P 0.005 P P P 100 Parts Ans.: X X X e X e e X X X X e e Ans X XR RameshNo ratings yet

- Bombas BerkeleyDocument136 pagesBombas BerkeleyDaniel Alejandro GuerreroNo ratings yet

- Operation Manual For Model SP 305Document104 pagesOperation Manual For Model SP 305alexnobinarie04No ratings yet

- D1 Hyd Hose 2016 MJ Hydraulics LRDocument34 pagesD1 Hyd Hose 2016 MJ Hydraulics LRtestNo ratings yet

- Flexural Strengthening of Reinforced Concrete Beam-Column Joints Using Innovative Anchorage SystemDocument12 pagesFlexural Strengthening of Reinforced Concrete Beam-Column Joints Using Innovative Anchorage SystemmekidesNo ratings yet

- Asme B31.3 Process Piping: Case Study 4: Hydro and Pneumatic Testing (Question)Document2 pagesAsme B31.3 Process Piping: Case Study 4: Hydro and Pneumatic Testing (Question)Michael AlbuquerqueNo ratings yet

- Rotor Hub AnalysisDocument21 pagesRotor Hub AnalysisJoshua Simon TelagalapudiNo ratings yet

- A Project Report RaviDocument25 pagesA Project Report RaviKunal Kumar YaadavNo ratings yet

- Pro Dec PlateDocument9 pagesPro Dec PlateAbe VoigNo ratings yet

- Subcooling Exam DanfossDocument8 pagesSubcooling Exam Danfossmarjan 01No ratings yet

- Course Title: Thermal System DesignDocument27 pagesCourse Title: Thermal System DesignhailemebrahtuNo ratings yet