Professional Documents

Culture Documents

Sail Brochure New-2023

Sail Brochure New-2023

Uploaded by

NAQIB METKAR0 ratings0% found this document useful (0 votes)

20 views20 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

20 views20 pagesSail Brochure New-2023

Sail Brochure New-2023

Uploaded by

NAQIB METKARCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 20

Structurals from SAIL

Structurally Ahead

baad Structurals from SAIL

SAILis one of the largest and leading steel manufacturer of India and

possesses a robust knowhow and expertise to produce a wide variety of

prime steel products such as Plates, Sheets, Coils, Rebars, Structural, Rails,

Pipes etc. for various applications.

SAIL has set up State-of-the-art Universal Section Mill (USM) at IISCO Steel

Plant, Burnpur and Medium Structural Mill (MSM) at Durgapur Steel Plant.

SAIL is in a position to supply a wide variety of Parallel Flange Sections

(PFS) and Conventional Structurals with high quality and consistent

dimensional accuracy to meet the requirement of construction and

infrastructure segments in the country.

SAIL has been endeavoring superior quality of high performing end

products through investment in technological upgradations, continuous

R&D (Research & Development) & Services.

: ) Structurals from SAIL

aaa

© 1S 2062 E250BR, 300BR, 350BR, 410BR, 450BR.

© EN 10025 2.5275 JR, $355 JR (for exports / IPEs)

{Structurals in IS specifications can be supplied in Grade BO & Grade C with mutual agreement.)

{Structurals with Copper addition (0.20 - 0.60%) can also be supplied).

In addition to above IS 11587 WR 480A & 480B (WEATHER RESISTANT) grades can also be supplied.

Sections from MSM & USM are normally supplied in 12 meter length. However specific lengths can be

supplied with mutual agreement

Testing fai available - Tensile, bend, impact testing (including sub zero temp testing) and inspection of

finished products. Bundling - Automatic strapping & bundling facility with tagging. Mill Certifications available

with MSM of DSP

© CE Certificate # Certificate from CSIR and CBRI, Roorkee for Fire Resistant Steel

Abbreviations used:

MSM - Medium Structural Mill USM - Universal Section Mil

DSP - Durgapur Stee! Plant ISP -lISCO Stee! Plant, Burnpur

‘SM. Section Mill, Durgapur EPA External Processing Agency

BSP - Bhilai Steel Plant. MM- Merchant Mill, Bhilai

Basa Structurals from SAIL

Universal Rolling Stand

Cooling Bed

Dividing Shear

‘Saw Cutting Suche and Bundling

3

9

INEX

PRODUCT RANGE —T

Parallel Flange Sections (PFS) Seen!

‘Narrow Parallel Flange Beams

Fn Wea) TP wt | Ratnam |

NPB 100%55 81 sP | MsM IPE 100

NPB 200. 100 2236/2509 sp | sa IPE 200/ PE 2000

NPB 250. 125 3011 sp _| MSM 1PE250

**NPB 270% 135 30,73/3607/42.26 1se_| usm IPE 270 A/IPE 270/ PE 2700

NPB 300. 150 3653/42.24/4932 1se_| usm IPE 300 A/IPE 300/ PE 300.0

NPB 350x170 50.22/5710/6605 1se_| usm IPE 350 A/IPE 350/ PE 35000

NPB 400. 180 57,38/66.31/7567/84.00 1se_| usm IPE 400 APE 40/ PE 400 0 PE 400

NPB450x190 | _67.16/77:58/9237/95.20/104 | 1SP_| USM | IPE450 A/PE 450/ PE 450 0/1PE 450 R/ PE 450V

NPB 500 x200 79.36/9069/107:32 1se_| usm IPE 500 A IPE 500/ PE 500.0

**NPB 550x210 92.08/105.52/12252 1sp_| usm IPE 550 A/IPE 550/ PE 55000

1NP600x220 | _1o7s7/2245/15447/18400 | 1sP_| USM IPE 600/PE 600 0/ PE 600V

NPB 750x270 | 173.00/17454/185.00/196.00/202.49 | Isp | USM | IPE750A/IPE750/ IPE7S0 0/ PE 750 /IPE 750

Wide Parallel Flange Beams

Scion Cnn (Cd

‘WB 150% 150, 235/30.11/3597 sp | MSM HE 150 AA/HE 150 A/HE 1508

WPS 1603 160 22,75/30.44/4259/76.19 sp | MSM | HE 160 ANE 160 A/HE 160 8/ HE 160.

WB 2003200 3734 1se_| USM

WPB 200.200 34.65/42.26/61.30 /50.92" 15?_| usm | __HE200 AA/HE 200 A/HE 200 B /HE 200M

WPB 240240 47 40/60.32/83 20715668 15e_| USM | __ HE2#0 AA/HE 240 A/HE 240 B/HE 240 M

WB 300x300 100.85 /69380"/ 8834" 15? _| USM HE300 AA/HE 300 A

WPB 3003x300 117.03/237.92 1se_| USM 300 B/ HE 300M

“=WPB340x300 | 78:90/104,78/134.16/290.64 15? | USM | __ HE340 AA/HE 340 A/HE340 B/HE 340M

**wB-450x300 | __13976/171.12/26833 /9975 ise | UsM | __HE450 AA/HE 450 A/HE 450 8/HE 450M

** New Section: Under Development

*New Variant: Under Development

Orne

6861 : 62221 S| BujUoJU09 aq jm Sa>ues9|0) |euOIsUaWIC

wae wor 6

ome oT 6

on rh 0 6

er 0 6

0

Fee oH 6

vo ow 6

‘oF 6

Pie os ve

c

c 6

ae? 6 er | seerostterean

wrt 6 [ sere xoncea

ri 69 6

a Tak 6

vr arr 6 TTA

re wt 6 eos TLEAN

9 re

7 va | es 6

00 oman | any mony 2)

W ay My a a 4 | a | (miadonsaboey

saquadoug

(adN) suieag aBuely paifered MoueN “(1Z07:808 S| 03 BuyULI0JU0>) sa}jsedoug [eUoN|>25

(GdN-Sdd) STVUNLONULS XIN TIVS

pessooy: es | mia]

ssouyaia gam

ssauypiy] aBuely

upim a6uely

uided =

aaaae

(5661) 6861 : 62221 S| 8ulWojUO> aq jym saruesa|0] JeuoIsuaWIG

Coa

RASA

008

006

08

a any | ewan | wa [ww [jo oy sabe af

fi a ES (pdosebuny [a | + @ ¥

‘onda ‘esa ey

(gdN) sweeg e6ue]y

SESLEWOT OOS aN

=| £/8/ 8/3

an

ageing

Je4ed MoUeN “(1Z0Z:808 S| 03 BulWU0JUO>) safzedorg |eUO!IIaS

(GdN-Sdd) STVUNLONULS XIN TIVS

snipes yoy :

SSBUDINN GEN #

ssawpiip a6uely :

apm abuely :

wydag

(5661) 6861: 62221 s1 SuIMLoJU0> aq jm saduEsaIO] jeuoIsuaLIG

we

ow

ont

SOVEXCOCHONCAM

19 | 6USLXOOLEOHL BAM

6 | SSTTUOLTOL EAM

wot

oe

wan uo aon wu | wa wy

w m [ele] tivtele, [ew aan

soda soI0 en [sy | waneuisag

(adm) sweag a6ue}4 [9112424 BPIM “(LZOZ:808 SI 03 Buyu40;UOD) sayiadog jeuoNraS

(ddM-Sdd) STVUN.LONULS XIN T1IVS

y youn>rS |

poal snipes yooy :

ay SOUPINGEM |

- ssauyriuy aBuely

YSN) uppim abuely =

uidag :

Aeree

aaaas

erst

(5661) 6861 $6221 51 Buiwuojuo> aq jim sa>ues9jo) jeuoIsuaWiG

ereoexoocnosr aan

cra

ce xoacnOsr gam

S66 OOE OSH AAR

irsexoorxone aan

ove xoacxone aan

vor xeocnonc aan

OFAC OOEOFEGGR

Tececoocxone wan

a

7

ft

‘aan | aw avy | 2m any wu | ifop [ww [ww | ae

Re ao [ermpiew a fay fatal vw | w an

sound ‘sag ear [sey | wneating

(gdm) sweag aBuey, jay/esed @piM (LZ0Z:808 S| 0} Burw40ju05) sarradog jeuolas

(ddM-Sid) STVUNLONULS XIN TIVS

poagy Aoam>reas angers: ya oe

ls SsoupIun gam: 3

ssowpiyy aBuely:

YEN wpm abuely sg

udea: a

aaaae

&

Scoot

PRODUCT RANGE

Conventional Structurals

Section Weight(Kg/m) fas co

rah et

MB 100 x50 8.95 DsP MSM

MB 150 x75 1496 DSP. MSM

MB 200 x 100 2417 DSP. SM

MB 250 x 125 3730 DSP. MSM

MB 300 x 140 46.02 DSP MSM

M75 x40 744, asp. MM.

MC 100% 50 956 Dsp/BsP_| MSM

_MC 125 x65, “13.10 DSP MSM

"MC 150x75 “16:80 DsP MSM/SM

MC 200% 75 230 sp | MSM/SM

MC 250x82 34.20 ISP USM

MC 300% 90 3630 IsP/DSP_| USM/MSM

MC 400 x 100 50.10 ISP usM

“Angle 50x 50x 5/6 3.79 /4.49 BSP MM

‘Angle 60 x 60 x 5/6/8 450/5.40/7.00 BSP MM

Angle 65 x 65 x 5/6/8/10 498/5 9177. 7319.49 BSP MM

‘Angle 70x 70x 5/6 530/630 BSP MM

“Angle 75 x 75x5/6/8/10 "5.77/6.86/9.00/11.07 BSP. MM.

‘Angle 80 x 80 x 6/8/10 7,36/9.65/11.88/14.05 BSP MM

‘Angle 90 x 90 x 6/8/10/12 8.32/10.92/13.47/15.95 DSP/BSP_ | MSM/MIM

‘Angle 100 x 100 x 6/8/10/12 9.26/12.18/15.04/17.83 DsP MSM

Angle 150x 150x 10/12 22.93/27.29 ISP USM

‘Angle 200 x 200x 12/16/18/20/25 | 36.85/48,53/54.3/59.96/73.90 | ISP/DSP_ |USM/MSM™*

‘** New Section: Under Development

Besides our plant rolled sections, we can also supply the following range through our EPAs.

‘Angle 45 mm to 150 mm

MC 75 x.40 mm to MC 400 x 100 mm

MB 100 mm to MB 600 mm

H Beams: 150 mm, 152mm & 200 mm

Rail: 15 kg, 30 kg

Flats : 50 x 6 to 150x 12mm

Mild Stee! Rounds

sa

861 : 7581 S| BuIUUojUOD aq |}! sa>ueIa/0) JeUO|SUBWIG

corer wm [co | vs | wenn

wis woe [ew | et | emma

owe ox | va | em | easton

wi c ea | soem

ar «

ow es a

us 80 ora 00194

waoory | awyouny wa opy wu | wu,

a m a[ yf | own

aio wo [en | vam

(OWS) sjuueyD wnypaw psepueys UeIpUl (LZ07:808 SI 40ju09) saniadoig jeuonr2as

5861: ZS81 S| BulWUOJUOD aq IIIM sodURIaIOJ [eUoISuoWIQ,

wre |e was [ew] | ome wm] ow [ra ve [wm

wes | a8 ey [sxe | eo | one [oa| ow [se su otee

wert | 98 Tit eo | om sv[ ee ow [ov oi

se | ae 198 ve | sum [sf oe) ew lef fa

maou | anny tony | us [wus] a oy | yumyoury | wu | wan | saaiop | | wh

on u m [alu aw a | ww | (opdosebuey [a [a | a |e w awst

saauadong suosuaaig seq | wogeubag

(aws}) sweag wnpay psepuess ueIpul ‘(LZ07:808 S| 03 Busw40JUO>) sansadodg [eUoN>2S

TIVS WOU (SAL) SNOILOIS JONVIY GTUIdVL

STVUNLONULS TVS

awsi

10

erst

$861: Z$81 S| BuILWOJUO> ag jI!m sarues9|04 jeUO!suaULIG

wu | axORAOD

we

sm

‘996

7

z

.

a mm [it ¢ a

a =a [ao mae pe [me = [os

Ea x ‘ost [sh | aw 7

ta

(WSI) s2i6uy 607 enby paepuers uerpul (1Z07:808 S| 03 BujUU0JU0D) so}yiedoud euoNr95

(VS WOU (SAL) SNOILOIS JONVIY ATWIdVL

STVUN.LONULS TIVS

yn

INEX

from SAIL

Structurally Ahead

Parallel Flange Sections (PFS) from SAIL’s state-of-the-art mills at

DSP (MSM) & ISP (USM) are branded as SAIL NEX

PFS are hot rolled steel structural sections, with parallel flanges

having square toes and curves at the root of flange and web

PFS meet international standards of quality and stringent

requirements of the infrastructure and construction industries

PFS and other structurals from New Mills of SAIL (DSP - MSM, & ISP - USM) are

preferred by today’s structural engineers, architects and construction companies

Parallel Flange Sections have

multiple advantages over conventional sections

Higher product flexibility - Wide range of width, flange thickness and web thickness

combinations for any nominal depth

D_ : Depth

B_: Flange Width

T _ : Flange thickness

t —: Web thickness

Ri: Root radius

yy

Mechanically more efficient - Higher bending strength for beams and higher axial load

carrying capacity for columns

Structurally more stable - Greater radius of gyration lowers slendermess ration and allows

withstanding of buckling to a greater extent

Lighter structures - Higher strength to-weight ratio leads to lighter structures and

foundations

o

aarsatt

Easier fabrication - Easier connection of joints by direct bolting on flanges without using

tapered washes and easier butt welding of plate at edge of flange

Only small thickness weld possible

Bent bolt-shank

Economical - Substantial saving in material weight when used as compression member

(columns) or flexural member (beams)

Dr Weight | Area | Radius of Couns

cei ar Gyration (cm. Com PCEt nest

ISMB | 600x210 | 121.00 4.08 (cy)

NPB | 600x210 | 122.45 re 4.66 ISMB 400 61.55 1020

wes | 400x300 | 124.80 | 158 7.33 NPB 400x180x57.38 | 57.38 1020

Parallel Flange Sections (PFS) are more efficient and provide more economic designs

then Tapered Flange Sections (TFS) e.g. UTILISATION RATIO of sections.

Conventional (TFS) ‘SAIL NEX (PFS)

4,000m

4,000m

Y

x

4,000m,

Z

of the

Paralel Flange section used:

‘Top Beams: ‘B250-0.328 Top Beams: NPB250x30.11- 0.371

Mid Beams: MB350 -0.894 Mid Beams: NPB300x49,32 -0.821

Lower Beams: MB450-0.892 LowerBeams: NPB400x66.31-0.81

Columns: MB600 -0.916 Columns: WPB240x83.2 - 0.874

The ratio of calculated design load on any structural member to its load-carrying capacity is known

as UTILISATION RATIO which should normally be less than one

ro

LOADING CONDITIONS

© Dead Load of 400 kg/m on floor beams & 100 kg/m on roof beams.

© Live Load of 1000 kg/m? on lower level floor beams & 600 kng/m? on mid level floor and 200 kg/m on

roof beams.

\d Load of 300 kg/m on each column in both X &Z direction.

© Comp:

\n of the weight of structure, for the above example, is given below:

Circe erie eee Carine

MB 600 x 123.0 5.79 WPB 240 x 83.20 3.985

MB 450x72.4 1.735 WPB 400 x66.31 1.588

MB 350x52.4 1.254 WPB 300 x 49.32 1.181

MB 250x37.3 1.125 NPB 250x30.11 0.906

Total 9.904 Total 7.661

723% saving in weight is realised by using NEX Parallel Flange Sections insted of

Conventional sections for the example shown

© Greater efficiency of the Parallel Flange Sections is primarily due to better distribution of material across

the section. This leads to greater moment of inertia, section modulus and radius of gyration. Consequently

PFS has more load carrying capacity.

ADVANTAGES OF USING HIGH TENSILE SECTIONS

b> Lighter super structure

»» Upfront savings in cost due to lesser weight of steel

>> Reduced depth of beams

»

»

Greater load carrying capacity for same depth of columns used in mild steel

Lower transportation, handling and erection costs due to lower weight of structure

SAIL NEX AS ELECTRIC POLE (WPB 160)

Section | Mass all D B t T | Flange | Rr Ra

(kg/m) (Depth) | (Width) | (Web | (Flange | Slope, | (Root

(cm?) thick) | thick) | adeg | Radius)

wes16o | 3044 | 38.78 | 152 | 160 6 9 : 15 :

Prine

‘Moment of Section Plastic Sectior

Inertia Modulus Modulus

Section Mass_| be (em*) [ly (em*) Zx (em?) | Zy (em) |Zpx em?) [Zpx (em?)

(kg/m)

WPB 160x160 | 30.44 | 1670 | 615 220 | 769 | 245 17

Advantages of using SAIL NEX (WPB 160) as electric pole

Comparatively lighter steel member with higher section modulus,

Saving in cost due to lower weight of steel member

Easier connection due to parallel flanges

Lower transportation, handling and erection cost owing to lighter members

Superior finish from state-of the-art mills,

Supply in specific lengths as per requirement

auVaene

44

Structurals from SAIL

sa

SAIL NEX WPB 160 as ELECTRIC POLE

Installation by Tata Power Ltd. Odisha & WBSEDCL West Bengal

Infrastructure support: WPB 200 & WPB 240 (SAIL NEX)

SAIL Steel Products have been an integral part of Infrastructure segment for decades. in its quest for

producing efficient steel, SAIL developed Parallel Flange Sections which offer better sectional properties

along with savings in weight and faster construction, thus improving the entire process cycle. These are

branded as SAIL NEX and these sections are being used widely as an alternate to Conventional sections,

which have tapered flanges.

SAIL, in its endeavour to support Indian Railways in reducing the nation’s dependence on petroleum-based

energy by rapid electrification of railway tracks, developed WPB 240 (47.4 kg/m) for use as OHE Mast in

place of RSJ (8'x6") (52.1 kg/m) currently being used for Electrification, Northern railway has started using

this for OHE Mast.

SAIL NEX sections are being supplied to various projects of Metros, DFCC, RVNL, IRCON ete. and can find

application for masts too depending on the suitability of design as per RDSO.

Wide Flange Parallel! Beam (WP8) 200 being supplied by SAIL has the approval of RDSO for making Stee!

Sleepers. Steel Sleepers impart higher strength in bearing the load of the rolling stock and thus improve

the maintenance cycle, safety and overall operational efficiency.

RDSO has approved for adoption of SAIL NEX (Parallel Flange Sections - NPB/WP8) in designs for bridges

where it fulfils the requirement of strength and serviceability.

WPB 200 & 240 can be utilized for many different areas depending on design and usage.

Some of the examples are:

Railways:

» Electric poles, Steel Sleepers for Railway Bridges.

» Railway Station development works & passenger shelters in stations.

Transport:

» Walkways/ Cross overs for urban roads and highways.

» Multilevel car parking in Airports, Railway & Bus Terminals, Business centers etc.

Construction Sector

»» Multi storied high rise residential & Commercial buildings.

»» Buildings for commercial usage, Mini sports complex, Stadiums.

» Industrial sheds.

Applications of SAIL Structurals

Flyovers, Stadiums, Foot Over Bridges, Multi-level Car Parks

Metro Rails, Indian Re

Industrial Buildings, Residential Complexes, Commercial Complexes

Raw Material Handling Plants

Power Plants, Ports, Offshore Structures

Oil Refineries, Petrochemical Plants

Electric Poles (Masts)

Trailer and Truck Bed Frames

veyereee

16

Sarat

unisva qa

T

ES

“ONINOBUVO NIV

Nivea

“pr |9a3s mst

Mst

Sar

os

199d#9

ASLERE

=

"aon om

ni s1OH via

TXEXEE]

Muoweatoodeys

we

Viv.

A

Ut ha pe}

sjeanjonayg 1]VS Buisn saawioysnd panjer ano yo awos

yy Aounsonns

wu

=

X4NI

ana us

(.

}'vonavavn

saianis'

©

CONTACT DETAILS

Regional Manager, Eastern Region : e-mail : rmer.cmo@sail.in

Regional Manager, Northern Region : e-mail : rmnr.cmo@sail.in

Regional Manager, Western Reg il : mwr.cmo@sail.in

Regional Manager, Southern Region : e-mail : rmsr.cmo@sailin

BAC Tra Ce RIC

STEEL AUTHORITY OF INDIA LIMITED

See te Yt A a ot at Noy ALD

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

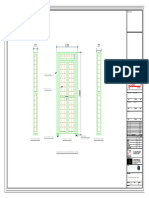

- Cage Drawing 1 of 2Document1 pageCage Drawing 1 of 2NAQIB METKARNo ratings yet

- Aws Romp03 1142 Aarkfab EngDocument1 pageAws Romp03 1142 Aarkfab EngNAQIB METKARNo ratings yet

- Aws Romp04 1141 Aarkfab EngDocument1 pageAws Romp04 1141 Aarkfab EngNAQIB METKARNo ratings yet

- Sterling: Space For Lms PanelDocument1 pageSterling: Space For Lms PanelNAQIB METKARNo ratings yet

- Rmu Stand: Base Plate 180 350 12mmDocument1 pageRmu Stand: Base Plate 180 350 12mmNAQIB METKARNo ratings yet