Professional Documents

Culture Documents

TET-SS-5003 Carbon Steel Pipes and Fittings v1 2 PDF

TET-SS-5003 Carbon Steel Pipes and Fittings v1 2 PDF

Uploaded by

rod allinasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TET-SS-5003 Carbon Steel Pipes and Fittings v1 2 PDF

TET-SS-5003 Carbon Steel Pipes and Fittings v1 2 PDF

Uploaded by

rod allinasCopyright:

Available Formats

Standard Specification TET/SS/5003

Date: 03/01/2016

CARBON STEEL PIPES AND FITTINGS Issue: 1.2

Electronic Document, only the original archived in Quality Department is signed / Printed copies uncontrolled

Contents

1. SCOPE....................................................................................................................................................... 2

2. APPLICABLE STANDARDS AND CODES .......................................................................................... 2

3. CLIMATIC DATA .................................................................................................................................... 3

4. DESIGN CONSIDERATIONS ................................................................................................................. 3

4.1 Pipes ...................................................................................................................................................... 4

4.2 Fittings .................................................................................................................................................. 4

4.3 Flanges .................................................................................................................................................. 4

4.4 Gaskets and Bolting .............................................................................................................................. 5

5. PIPE DIMENSIONS ................................................................................................................................. 5

6. INTERNAL AND EXTERNAL COATING ............................................................................................. 6

6.1 Internal coating ..................................................................................................................................... 6

6.2 External coating .................................................................................................................................... 6

7. INSPECTION AND TESTING ................................................................................................................. 6

7.1 Test results and frequencies .................................................................................................................. 6

7.2 Inspection requirements ........................................................................................................................ 7

7.3 Acceptance criteria ................................................................................................................................ 7

8. QUALITY ASSURANCE AND QUALITY CONTROL ......................................................................... 7

9. MARKING ................................................................................................................................................ 7

10. PACKING AND DELIVERY .............................................................................................................. 8

10.1 Delivery................................................................................................................................................. 8

11. DOCUMENTATION ............................................................................................................................ 8

Attached to: TET/PRO/5002 1/8

Sultanate of Oman, Public Authority for Electricity and Water

Standard Specification TET/SS/5003

Date: 03/01/2016

CARBON STEEL PIPES AND FITTINGS Issue: 1.2

1. SCOPE

This specification sets the minimum acceptable requirements for supply of carbon steel pipes and fittings.

In case of difference between this specification and the specified international standards then the most

stringent requirements shall prevail.

2. APPLICABLE STANDARDS AND CODES

Steel pipes, fittings and shall comply with the latest issue of the following standards and other

relevant standards noted elsewhere in this specification:

API 5L Specification for line pipe

API 1104 Welding of pipelines and related facilities

ASME B 31.4 Pipeline Transportation Systems for Liquids and Slurries.

ASME B 36.10 Dimensions and weights of seamless and welded steel pipes.

ASTM A 105/A Standard Specification for Forgings, carbon steel for Piping

105M Components.

ASTM A 106 Seamless carbon Steel Pipe for high temperature service.

ASTM A 193 Alloy Steel and Stainless Steel Bolting Materials for high

temperature service.

ASTM A 194 Carbon and Alloy Steel Nuts for Bolts for high pressure or high

temperature service.

AWWA C 200 Steel water pipe 6 inch (150 mm) and larger for transmission and

distribution of water

AWWA C 203 Protective coatings and linings for steel water pipelines

AWWA C 210 Liquid Epoxy Coating systems for the interior and exterior of steel

water pipelines

AWWA C 215 Polyolefin coatings for the interior and exterior of steel water

pipelines

AWWA C 222 Polyurethane coatings for the interior and exterior of steel water

pipelines

ISO 7005 Steel flanges

BS EN 10288 Steel tubes and fittings for onshore and offshore pipelines –

External extruded polyethylene based coatings

BS EN ISO Hot dip galvanized coatings on fabricated iron and steel articles –

1461 Specifications and test methods

DIN 30678 Polypropylene coatings for steel pipes

Attached to: TET/PRO/5002 2/8

Sultanate of Oman, Public Authority for Electricity and Water

Standard Specification TET/SS/5003

Date: 03/01/2016

CARBON STEEL PIPES AND FITTINGS Issue: 1.2

ISO 4633 Rubber seals – Joint rings for water supply pipelines –

Specifications for materials

ISO 10474 Steel and Steel products inspection documents

ISO 8501-1 Preparation of steel substrates before application of paints and

related products – Surface roughness.

ISO 9001 Quality Management System

AWWA C604 Installation of steel water pipe – 4 inch and larger

AWWA C206 Field welding of steel water pipe

AWWA C 207 Steel pipe flanges for waterworks service 100mm (4”) and larger

AWWA C208 Dimensions of fabricated steel pipe fittings

AWWA C 606 Grooved and shouldered joints

AWWA M11 Steel pipe – Guide for design and installation

3. CLIMATIC DATA

The climatic conditions of the Sultanate of Oman shall be taken into account. Following data provided is

for guidance only.

Maximum ambient temperature: 55 ºC

Maximum humidity: can reach 100 %

Maximum metal temperature in the sun: 80 ºC

Maximum temperature of supply water: 40 ºC

Rainfall: 100 mm per year approx.

The pipes and fittings shall be capable of handling water of potable quality from Desalination plants,

wells and a combination of such sources unless specifically mentioned otherwise.

4. DESIGN CONSIDERATIONS

Steel pipes and fittings shall be manufactured in either seamless or welded construction complying with

Specification API 5L.

The wall thickness of piping components shall be determined by the PAEW (or their Consultant) to meet

the design conditions (pressure, loading requirements and local soil conditions etc.,) accordance with

ASME B 31.4 / API 5L.

The grade of pipe, internal and external coatings shall be determined by PAEW (or their Consultant) as

per project requirement.

The pipes and fittings shall be hydrostatically tested to 75% of their Minimum Yield Strength in

accordance with Clause 9.4.3 of API 5L.

All material in contact with potable water shall not affect in anyway the water quality requirement

mentioned in the Regulations of WHO.

Attached to: TET/PRO/5002 3/8

Sultanate of Oman, Public Authority for Electricity and Water

Standard Specification TET/SS/5003

Date: 03/01/2016

CARBON STEEL PIPES AND FITTINGS Issue: 1.2

4.1 Pipes

Pipes shall be manufactured in either seamless or welded construction complying with Specification API

5L.

Pipes shall be seamless for DN ≤ 400. Above DN 400, they shall be Electrically Resistance Welded or

Submerged Arc Welded, unless specified otherwise.

Pipes intended for fabrication by welding and for cutting into closing lengths shall be truly circular and

sized uniformly throughout their lengths, the tolerances applicable to their entire outside diameter shall be

those given in API 5L table 8. All other pipes shall be fabricated to the tolerances given in the tables 7

and 8 of API 5L.

Steel pipes shall have the same strength and shall be compatible with the pipes with which they are to be

used.

The wall thickness and the steel grade (Grade A, Grade B, X- 42 etc.) shall be determined by PAEW as

per the project requirement.

4.2 Fittings

The sizes of fittings DN≤ 600 shall be conform to ASME B16.9 and shall be seamless. Elbows with butt

welded ends shall be long radius type (radius = 1.5 x nominal pipe size).

If miter elbows are economically justified in accordance with the ASME B31.4 requirements, they may

be substituted for bends as follows:

Three weld (90 degree) and two weld (45 degree) miter elbows may be used in sizes larger than

DN 600,

Bends may be substituted for welded elbows provided they are made of seamless pipe. Cold

bends shall be limited to DN≤ 150 subject to satisfying code requirements.

Elbowlets shall not be used for branch connections, instrument taps or vent and drain connections unless

space considerations dictate. Drain and vent connections shall not be installed in elbows.

Reducing tees and reducers shall be supplied with butt weld end schedules to match the pipe, the

allowable size combinations are as shown in ASME B 16.9.

Branch connections shall be made from equal tees or reducing tees, integral reinforced branch fittings as

approved by PAEW. In case reducing tee of required combinations is not available a combination of

reducing tee and reducer shall be used.

4.3 Flanges

Flange dimension shall be conforming to ISO 7005 Part 1 and the rating of the flanges shall be as per the

project requirement.

All the flanges shall be welding neck raised face type. Slip or raised face flanges shall be accepted in

place of welding neck flanges to suit the project requirements and as approved by PAEW.

For the gasket contact surface of DN≤ 600 flanges, the surface roughness shall be made between Ra 6.3

and 12.5 µm. For sizes DN ≥ 600, the surface roughness shall be between Ra 12.5 and 25 µm.

Serrations may be either spiral or concentric.

Attached to: TET/PRO/5002 4/8

Sultanate of Oman, Public Authority for Electricity and Water

Standard Specification TET/SS/5003

Date: 03/01/2016

CARBON STEEL PIPES AND FITTINGS Issue: 1.2

4.4 Gaskets and Bolting

Gaskets shall be manufactured from EPDM rubber conforming to ISO 4633/ EN 681 and shall be a

minimum of 3 mm thick.

The gasket shall extend from the inside diameter of the flange to at least the inside edge of the bolt holes

or may laid beyond the bolt circle to the outside diameter of the flange.

Unless or otherwise specified, bolts and nuts shall be alloy steel conforming to ASTMA A 193 Gr B7/A

and have regular square and hexagonal dimensions. . All nuts, bolts and washers shall be galvanised or

cadmium plated. The galvanization shall be in accordance with BS EN ISO1461.

Screw threads shall be in accordance with ASME B.1.1.

Machine bolts shall only be used for jackscrews. Jackscrews shall be threaded full length. The length

shall be measured from the bearing surface of the head and shall include the end point.

5. PIPE DIMENSIONS

The following range of nominal pipe sizes shall be used. Outside diameter of the pipe shall meet the

requirements of ASME B 36.10 or API 5L as applicable. The required thickness shall be calculated by the

design consultant considering all functional requirements in consultation with PAEW.

Nominal Diameter Equivalent Nominal Outside

(mm) Diameter (inch) Diameter (mm)

DN 200 8 219.1

DN 250 10 273.1

DN 300 12 323.9

DN 350 14 355.6

DN 400 16 406.4

DN 450 18 457.2

DN 500 20 508

DN 600 24 609.6

DN 900 36 914.4

DN 1000 40 1016

DN 1200 48 1219.2

DN 1400 56 1422.4

DN 1500 60 1524

DN 1600 64 1625.6

DN 1800 72 1828.8

Attached to: TET/PRO/5002 5/8

Sultanate of Oman, Public Authority for Electricity and Water

Standard Specification TET/SS/5003

Date: 03/01/2016

CARBON STEEL PIPES AND FITTINGS Issue: 1.2

6. INTERNAL AND EXTERNAL COATING

6.1 Internal coating

Internal surface of the pipes and fittings shall be blast cleaned to SA 2.5 in accordance with ISO 8501-1

standard and lined as per project requirements.

All the internal coatings shall be certified as suitable for use with potable water according to BS 6920 and

by an internationally accepted organization such as NSF–WRc or ACS.

The following types of coatings could be used in accordance with project requirements:

Liquid epoxy coating according to API 5L RP2/ AWWA C 200

Cement Mortar Lining according to EN 10289

Polyurethane coating according to AWWA C-222 / EN 10290

Solvent Free Epoxy according to AWWA C-210 / EN 10289

6.2 External coating

EXTERNAL surface of the pipes and fittings shall be blast cleaned to SA 2.5 in accordance with ISO

8501-1 standard and lined as per project requirements.

The following types of coatings could be used in accordance with project requirements:

Fusion Bonded Epoxy coating according to AWWA C-203

3 Layer Polyethylene coating according to DIN 30670/ AWWA C-215 / BS EN 10288

3 layer Polypropylene coating according to DIN 30678

For each coating and as per requirement PAEW (or their consultant) shall specify the coating

requirements (preparation, thickness, coating application, physical and performance requirement etc.) as

per the above mentioned standards.

7. INSPECTION AND TESTING

7.1 Test results and frequencies

The MANUFACTURER shall establish and maintain a current record of test results according to the

requirements of the applicable standards and this specification. The MANUFACTURER shall perform

all the tests required ( chemical composition, mechanical properties, hydrostatic tests, dimensional

testing, tensile test, etc.) to demonstrate the characteristics and quality of the material and the

dimensional tolerances of the pipe according to API 5L.

The MANUFACTURER shall submit a detailed Inspection and test Plan for approval showing

manufacturing, inspection and testing activities and its acceptance criteria prior to commencement of

manufacturing. All certification shall be 3.1 B as per ISO 10474. The radiography test and hydrotest shall

be witnessed by PAEW.

In order to prove the quality of material according to the agreement the MANUFACTURER shall produce

the certificates according to EN 10204.

The MANUFACTURER shall supply the PAEW, with copies of all material certificates and inspection and

test results obtained in the course of quality verification. When requested, the MANUFACTURER shall

also provide access to and copies of all production record, process control charts, and other records

compiled during manufacture.

Attached to: TET/PRO/5002 6/8

Sultanate of Oman, Public Authority for Electricity and Water

Standard Specification TET/SS/5003

Date: 03/01/2016

CARBON STEEL PIPES AND FITTINGS Issue: 1.2

7.2 Inspection requirements

MANUFACTURER in his capacity as a prudent operator should follow all these specifications and codes

and internationally accepted standards in the manufacturing process that he follows.

In case of bulk supplies or bulk procurements (including major Projects), to verify the compliance with this

Specifications, PAEW has the right to insist on a fresh production, factory inspection by an independent

third party auditor at the cost of the supplier or manufacturer. The third party auditor shall be of

International repute and the one opted by PAEW. The auditing and quality testing procedures would be

as per the prevailing internationally accepted codes of testing as indicated in the document.

The MANUFACTURER shall provide full assistance and co-operation for any such inspection, when

required by PAEW or CONSULTANT.

MANUFACTURER shall ensure that all the applicable codes and standards are available at their works

for PAEW or CONSULTANT's reference during their visit to manufacturer's works for shop

inspection/tests.

7.3 Acceptance criteria

The material shall meet the following criteria:

Pipe wall thickness, internal and external coatings shall be controlled according to the standards,

Successful test performance and acceptable results mentioned in this specification,

An acceptable inspection report from a third party inspection above mentioned,

All test, material certificates, witnessed test documents shall be submitted to PAEW prior to the

dispatch of the materials.

PAEW may reject any item that does not totally comply with requirements of

specification.

When a pipe / fitting is rejected, the items manufactured immediately before or after shall be carefully

examined. If further defects are found, the entire batch will be rejected.

8. QUALITY ASSURANCE AND QUALITY CONTROL

A copy of manufacturer`s Quality Assurance and Quality Control shall be submitted for review and

approval.

9. MARKING

Each pipes and fitting shall be indelibly marked over any factory applied coating with the following

information.

Diameter,

Nominal pipe thickness,

Class,

Grade of steel,

Length of pipe,

Works Test Pressure

Year of Manufacture

Reference number to enable items to be correlated to works fabrication records, work test

certificates etc.

Wherever possible, the marks shall be painted on the outside of pipes and fittings close to one end.

Attached to: TET/PRO/5002 7/8

Sultanate of Oman, Public Authority for Electricity and Water

Standard Specification TET/SS/5003

Date: 03/01/2016

CARBON STEEL PIPES AND FITTINGS Issue: 1.2

10. PACKING AND DELIVERY

The MANUFACTURER shall provide packing and shipping procedures for PAEW’s approval.

10.1 Delivery

Delivery of pipes and fittings shall be decided by PAEW as per requirement.

11. DOCUMENTATION

The MANUFACTURER shall furnish the following vendor data as a minimum:

Catalogues of the proposed manufacturer`s

Dimensional details of pipes and fittings

Complete details of testing facilities available

Local agent name and address

Detailed material specification

Manufacturer`s drawings, showing fittings dimensions

Attached to: TET/PRO/5002 8/8

Sultanate of Oman, Public Authority for Electricity and Water

You might also like

- Method Statement For Domestic Water Piping Installation UG & AGDocument14 pagesMethod Statement For Domestic Water Piping Installation UG & AGBelal AlrwadiehNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- MTC Forged Fitting ElbowDocument1 pageMTC Forged Fitting Elbowfreeman11072000100% (1)

- Awwa C200 PDFDocument6 pagesAwwa C200 PDFangel darioNo ratings yet

- Ontario Water Main StandardsDocument15 pagesOntario Water Main Standardsrhunter2010No ratings yet

- List of Awwa StanderdsDocument6 pagesList of Awwa StanderdstadagidsNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- TET-SS-5004 Stainless Steel Pipes and Fittings v1.1 PDFDocument5 pagesTET-SS-5004 Stainless Steel Pipes and Fittings v1.1 PDFrod allinasNo ratings yet

- Specification For Steel PipingDocument28 pagesSpecification For Steel Pipingfelixrich100% (2)

- 11/20/2018 /conversion/tmp/scratch/402494814Document13 pages11/20/2018 /conversion/tmp/scratch/402494814Anonymous NR3qZ30No ratings yet

- WSP CML X Tape W CMO Guide SpecificationDocument13 pagesWSP CML X Tape W CMO Guide SpecificationskzubsNo ratings yet

- Annex 14 - Piping SpecDocument18 pagesAnnex 14 - Piping SpecbisworupmNo ratings yet

- Ductile Iron Pipe For Sewers 012221Document9 pagesDuctile Iron Pipe For Sewers 012221สุภรัตน์ จันทร์คุณาภาสNo ratings yet

- Pipe and Pipe FittingsDocument21 pagesPipe and Pipe FittingsAdamNo ratings yet

- Section 02420 - Fabricated Steel Pipe and Specials Part 1 - GeneralDocument8 pagesSection 02420 - Fabricated Steel Pipe and Specials Part 1 - GeneralpdiconpNo ratings yet

- PipingDocument7 pagesPipingAshar HassanNo ratings yet

- Specification For Fabrication, Construction & Testing of Steel Pipe SystemDocument43 pagesSpecification For Fabrication, Construction & Testing of Steel Pipe SystemALINo ratings yet

- 15-1-6 - Chilled Water Piping SystemDocument10 pages15-1-6 - Chilled Water Piping Systemfarshan296015No ratings yet

- Pghu Eh Lspds 002004 Rev 0Document43 pagesPghu Eh Lspds 002004 Rev 0BhoyPachoNo ratings yet

- Csi 2018 Mechanical Division 15Document303 pagesCsi 2018 Mechanical Division 15Taner Demirezen100% (1)

- Welded Austenitic Stainless Steel Feedwater Heater Tubes: Standard Specification ForDocument6 pagesWelded Austenitic Stainless Steel Feedwater Heater Tubes: Standard Specification ForsanthakumarNo ratings yet

- 1/27/2019 /conversion/tmp/scratch/407716113Document10 pages1/27/2019 /conversion/tmp/scratch/407716113Maki DizonNo ratings yet

- PROJECT STANDARDS and Specifications Offshore Skid Packages Piping Design Rev01Document7 pagesPROJECT STANDARDS and Specifications Offshore Skid Packages Piping Design Rev01mihahudeaNo ratings yet

- Revised 4/2008Document10 pagesRevised 4/2008Richabson OsmanNo ratings yet

- DR Engp I 1.1 R.11Document1,093 pagesDR Engp I 1.1 R.11HEFTOS P-55100% (1)

- Add02 1060.1Document14 pagesAdd02 1060.1Diego Calderón AlvaradoNo ratings yet

- Asme Sa961-2015Document12 pagesAsme Sa961-2015Geraldo GasparottoNo ratings yet

- Domestic Water SystemsDocument20 pagesDomestic Water Systemsabdullah sahibNo ratings yet

- 903-10004-SPC-M-001 Piping Material SpecificationDocument15 pages903-10004-SPC-M-001 Piping Material SpecificationChitradeep FalguniyaNo ratings yet

- 33 11 13.13 Ductile Iron Pipe Fittings and Special Items PDFDocument17 pages33 11 13.13 Ductile Iron Pipe Fittings and Special Items PDFAhmed El-NahasNo ratings yet

- A 688 - A 688M - 03 Qty4oc9bnjg4tqDocument7 pagesA 688 - A 688M - 03 Qty4oc9bnjg4tqalucard375No ratings yet

- Codes and Standards DocumentDocument4 pagesCodes and Standards DocumentOvaisNo ratings yet

- Corrugated Steel Pipe, Metallic-Coated For Sewers and DrainsDocument15 pagesCorrugated Steel Pipe, Metallic-Coated For Sewers and Drainsjavier martinezNo ratings yet

- Section 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesDocument23 pagesSection 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesMohammed HarrisNo ratings yet

- Common Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsDocument8 pagesCommon Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsOvelhaNo ratings yet

- A961 PDFDocument7 pagesA961 PDFAkash Singh TomarNo ratings yet

- Section 221116 - Domestic Water Piping-PexDocument16 pagesSection 221116 - Domestic Water Piping-PexChase GietterNo ratings yet

- DR Engp 1.1 R13Document2,070 pagesDR Engp 1.1 R13Revair CostaNo ratings yet

- SECTION 15120 Piping Specialties Rev 0Document35 pagesSECTION 15120 Piping Specialties Rev 0Azhar Ali50% (2)

- SECTION 15140 Domestic Water Piping General 1.1Document20 pagesSECTION 15140 Domestic Water Piping General 1.1Munir RasheedNo ratings yet

- Specification For Carbon Steel Pipes & FittingsDocument27 pagesSpecification For Carbon Steel Pipes & FittingsNoor Anter100% (1)

- w-p-ss-001 R4Document23 pagesw-p-ss-001 R4Unni CyriacNo ratings yet

- ASTM A790-2001 Standard Specification For Seamless & Welded Ferritic Austentic SS PipeDocument6 pagesASTM A790-2001 Standard Specification For Seamless & Welded Ferritic Austentic SS PipeHyundianto AgNo ratings yet

- Section - 15100 Valves PDFDocument40 pagesSection - 15100 Valves PDFNana Delgado100% (1)

- 1113 DWSDWSDDocument53 pages1113 DWSDWSDenjoygurujiNo ratings yet

- UTL G GS-8 Rev10 Piping MaterialsDocument253 pagesUTL G GS-8 Rev10 Piping Materialsmasoud132No ratings yet

- A135 PDFDocument9 pagesA135 PDFIng. Adolfo GarciaNo ratings yet

- 36 - Compressed Air InstallationDocument28 pages36 - Compressed Air InstallationTemur LomidzeNo ratings yet

- 15510Document13 pages15510mahaboobptmNo ratings yet

- Common Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsDocument8 pagesCommon Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsKipper KimNo ratings yet

- Water Distribution For Fire Protection ServiceDocument21 pagesWater Distribution For Fire Protection ServiceAmritraj CharlesNo ratings yet

- General Requirements For Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel TubesDocument10 pagesGeneral Requirements For Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel TubesMartuaHaojahanSaragihSidabutarNo ratings yet

- Astm A961Document8 pagesAstm A961Eduardo PNo ratings yet

- Bart Facilities StandardDocument8 pagesBart Facilities StandardBehnam AshouriNo ratings yet

- Specification For Hot Water BoilersDocument6 pagesSpecification For Hot Water BoilersKarthik AnandanNo ratings yet

- Water and ArregationDocument9 pagesWater and ArregationYasser FathiNo ratings yet

- Guide Spec PlumbingDocument18 pagesGuide Spec PlumbingEric ToroNo ratings yet

- Water Agencies' StandardsDocument16 pagesWater Agencies' StandardsYakdhan YaseenNo ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- CCI Notes: Silver - Care and Tarnish RemovalDocument5 pagesCCI Notes: Silver - Care and Tarnish RemovalVitor RodriguesNo ratings yet

- Specification Ig and Packing MaterialDocument8 pagesSpecification Ig and Packing MaterialVåïbhäv ÇhåühåñNo ratings yet

- FAB Enq-BRU-1-3073H-2xHE80LSDocument9 pagesFAB Enq-BRU-1-3073H-2xHE80LSMohammad Adil100% (1)

- Welded PipeDocument2 pagesWelded PipeНемања КараклајићNo ratings yet

- Vk-20 Louvre Shutter: Item NoDocument2 pagesVk-20 Louvre Shutter: Item NoXAVIER RUBIONo ratings yet

- Farooq ChemicalsDocument2 pagesFarooq ChemicalsAbdulNo ratings yet

- Chapter 1Document61 pagesChapter 1ቀዳሚሃ ለጥበብ ፈሪሃ እግዚያብሔርNo ratings yet

- Lit5664500000 Sak PDFDocument306 pagesLit5664500000 Sak PDFIts NinaNo ratings yet

- AISI 51b60Document2 pagesAISI 51b60PABLO DIAZ ENRIQUEZNo ratings yet

- Pioneer ScopeDocument85 pagesPioneer ScopeArchana ShuklaNo ratings yet

- ASME IX Interpretation Part11 PDFDocument40 pagesASME IX Interpretation Part11 PDFrichadNo ratings yet

- ASME IX Changes 2003 PDFDocument5 pagesASME IX Changes 2003 PDFRaul Humberto Mora VillamizarNo ratings yet

- Concrete Roof Tiles Technical ManualDocument130 pagesConcrete Roof Tiles Technical ManualNicholas FeatherstonNo ratings yet

- Razon Heat Proofing - White Water ProoferDocument2 pagesRazon Heat Proofing - White Water ProoferjustinNo ratings yet

- Astm b221mDocument14 pagesAstm b221mrandi777770% (1)

- Swagelok Biopharm Fittings BrochureDocument12 pagesSwagelok Biopharm Fittings BrochureBobby LewisNo ratings yet

- Clear LiteDocument2 pagesClear LitemanojNo ratings yet

- Millstones Sheet 2Document1 pageMillstones Sheet 2samNo ratings yet

- Hangers & SupportsDocument10 pagesHangers & SupportsAnonymous NR3qZ30No ratings yet

- Mps-Hsaw Qa Awwa 001Document9 pagesMps-Hsaw Qa Awwa 001Armando BiringkanaeNo ratings yet

- Powder Metallurgy Seminar GautamDocument31 pagesPowder Metallurgy Seminar GautamSidhartha GolchhaNo ratings yet

- Electrogas Welding Process PDFDocument8 pagesElectrogas Welding Process PDFsaravananNo ratings yet

- Dawasa Offgrid-Plumbingdrawings-221121073350-8a62b55bDocument7 pagesDawasa Offgrid-Plumbingdrawings-221121073350-8a62b55bKISUJA MADUHUNo ratings yet

- PM 6 - ApplicationsDocument21 pagesPM 6 - ApplicationsShivraj ChouguleNo ratings yet

- Weld Joints and Weld Types - Part2Document1 pageWeld Joints and Weld Types - Part2joshua_tan_31No ratings yet

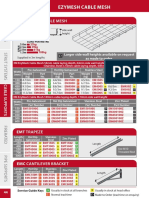

- EzyMesh and Accessories DataSheetDocument2 pagesEzyMesh and Accessories DataSheet30101985No ratings yet

- K. Bargaheiser - Corrosion PaperDocument16 pagesK. Bargaheiser - Corrosion PaperJHON WILMAR CARDENAS PULIDONo ratings yet

- 2.2.3.1 Buildex® Screw Fasteners: 2.2.3.1.1 Fastener Assembly and DesignationDocument11 pages2.2.3.1 Buildex® Screw Fasteners: 2.2.3.1.1 Fastener Assembly and DesignationJoseph BookerNo ratings yet